Views: 222 Author: Amanda Publish Time: 2025-07-12 Origin: Site

Content Menu

● Overview of Sheet Metal Fabrication in France

● Key Services Offered by French Sheet Metal Fabrication Manufacturers and Suppliers

● Leading Sheet Metal Fabrication Manufacturers and Suppliers in France

>> FranceMetal

>> SFCMM

>> ATPA

>> Morel

>> E.S.P.A.C.E.

>> Richel Group

>> SAS Ferrier

● Industry Applications and Innovations

● Advantages of Choosing French Sheet Metal Fabrication Partners

● How to Select the Right Sheet Metal Fabrication Supplier

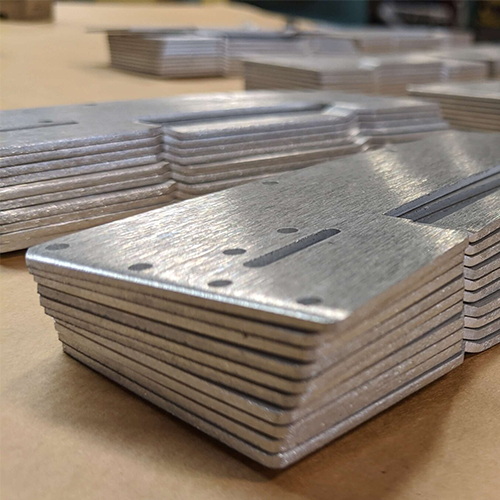

● Visual Insights: Sheet Metal Fabrication in Action

● FAQ

>> 2. How do I choose the right sheet metal fabrication supplier in France?

>> 3. What industries benefit most from French sheet metal fabrication services?

>> 4. Are French sheet metal fabrication companies equipped for rapid prototyping?

France stands as a powerhouse in the European manufacturing sector, with its sheet metal fabricationindustry renowned for innovation, precision, and quality. From aerospace to automotive, electronics to energy, French sheet metal fabrication manufacturers and suppliers are at the heart of countless global supply chains. This article explores the leading companies, their capabilities, and the reasons France has become a hub for sheet metal fabrication. Whether you are a brand owner, wholesaler, or manufacturer seeking OEM services, understanding the French sheet metal landscape is essential for sourcing, partnership, and business growth.

Sheet metal fabrication involves transforming flat metal sheets into finished products through processes such as cutting, bending, stamping, welding, and assembly. France's sheet metal fabrication manufacturers and suppliers are recognized for their technical expertise, state-of-the-art facilities, and commitment to quality. The sector is supported by a highly skilled workforce and a culture of continuous innovation.

France's sheet metal fabrication industry serves a broad spectrum of markets, including:

- Aerospace and aviation

- Automotive and transportation

- Electronics and telecommunications

- Energy and renewables

- Furniture and architectural design

- Food processing and packaging

The French industry's ability to adapt to evolving market demands and integrate cutting-edge technologies has solidified its position as a leading player in Europe and globally.

French sheet metal fabrication manufacturers and suppliers provide a comprehensive range of services, including:

- Laser cutting: High-precision cutting for intricate designs and complex geometries. Laser technology allows for minimal material waste and exceptional edge quality, making it ideal for both prototype and mass production.

- CNC machining: Automated, computer-controlled processes ensure consistent, repeatable quality. CNC machines can handle complex shapes and tight tolerances, supporting both small batch and large-scale manufacturing.

- Bending and folding: Accurate shaping of metal sheets for custom and standard parts. Advanced press brakes and folding machines enable the production of precise angles and curves.

- Stamping and punching: Mass production of components with tight tolerances. Stamping presses can produce thousands of identical parts quickly, reducing costs and lead times.

- Welding and assembly: Joining and assembling parts for finished products. Skilled welders use various techniques such as TIG, MIG, and spot welding to ensure structural integrity.

- Surface treatment: Powder coating, painting, anodizing, and other surface finishes that enhance durability and aesthetics.

- Rapid prototyping: Quick turnaround for design validation and functional testing. Rapid prototyping services help clients reduce time-to-market by enabling early-stage adjustments.

- Batch and mass production: Scalable manufacturing for small, medium, and large volumes, with flexibility to accommodate custom orders.

These services are supported by advanced software integration, including CAD/CAM systems, which streamline the design-to-production workflow and enable precise control over every fabrication step.

FranceMetal is a global leader in sheet metal fabrication, specializing in cutting, bending, and assembling steel and other metals. With over 40 years of experience, FranceMetal operates multiple production units and processes more than 10,000 metric tons of metal annually. Their expertise includes handling very long lengths—up to 14 meters in a single piece—making them a preferred partner for large-scale and custom projects. FranceMetal's commitment to innovation and quality has earned them a reputation for reliability and excellence across various industries.

Eiffage Métal is a major player in the French and European sheet metal fabrication market, offering a full suite of services from design to installation. Their capabilities include complex metal structures, precision components, and turnkey solutions for sectors such as construction, energy, and industry. Eiffage Métal integrates sustainable practices into their manufacturing processes, emphasizing eco-friendly materials and energy-efficient production.

SFCMM is known for its comprehensive range of sheet metal fabrication services, including laser cutting, bending, and rolling. Their focus on precision and quality makes them a top choice for clients seeking reliable manufacturing partners. SFCMM also invests heavily in automation and robotics, which enhances their production speed and consistency.

ATPA specializes in custom sheet metal processing, serving both domestic and international clients. Their services include laser cutting, stamping, bending, and assembly, with a strong emphasis on meeting unique customer requirements. ATPA's flexible manufacturing lines allow them to handle both prototype and high-volume production efficiently.

With over 30 years of experience, Façonnage Métallique is a specialist in precision sheet metal fabrication, developing prototypes and small batch productions for demanding industries. Their craftsmanship and attention to detail make them a preferred supplier for sectors requiring high-quality, reliable components.

Morel is a sheet metal fabrication company based in Belley, Ain, France, specializing in laser cutting, CNC folding, and mechanical welding. Their expertise in high-precision fabrication supports a wide range of industrial applications, from automotive parts to architectural elements. Morel's commitment to continuous improvement and customer satisfaction positions them well in competitive markets.

E.S.P.A.C.E. provides sheet metal fabrication services from their facility in Loire-Atlantique, offering cutting-edge solutions for clients across France. Their capabilities include complex welding, surface finishing, and assembly, supported by a team of experienced engineers and technicians.

KEP Technologies operates in Sophia Antipolis, delivering both manufacturing and service solutions in sheet metal fabrication, with a focus on advanced technology and innovation. They specialize in integrating sheet metal components into larger systems, particularly for the electronics and telecommunications sectors.

Richel Group is recognized for its high-quality sheet metal stamping and fabrication, serving industries such as agriculture, construction, and infrastructure. Their robust production capacity and quality control systems enable them to meet demanding delivery schedules without compromising standards.

SAS Ferrier harmonizes precision and industrialization in fine sheet metal subcontracting, offering services from design to final assembly. Their ability to manage complex projects and provide turnkey solutions makes them a valuable partner for OEMs and brand owners.

French sheet metal fabrication manufacturers and suppliers are at the forefront of technological advancement. Their services are integral to:

- Aerospace: Fabrication of lightweight, high-strength components for aircraft and satellites. The use of advanced alloys and precision machining ensures compliance with stringent safety and performance standards.

- Automotive: Production of body panels, chassis parts, and structural reinforcements. Innovations in lightweight materials and automated assembly lines contribute to improved vehicle efficiency.

- Electronics: Enclosures, brackets, and heat sinks for electronic devices. Precision fabrication ensures optimal thermal management and electromagnetic shielding.

- Energy: Components for wind turbines, solar panels, and power generation equipment. The industry's focus on renewable energy drives demand for durable, corrosion-resistant sheet metal products.

- Architecture: Custom facades, decorative panels, and structural elements. French manufacturers combine aesthetic design with functional performance, often collaborating closely with architects.

- Food Processing and Packaging: Hygienic and corrosion-resistant metal components that meet strict health and safety regulations.

- Automation and robotics are increasingly used for precision and efficiency, reducing human error and increasing production speed.

- 3D printing complements traditional fabrication for rapid prototyping and complex geometries, enabling faster design iterations.

- Sustainable manufacturing practices, including recycling, energy-efficient machinery, and the use of eco-friendly materials, are widely adopted to reduce environmental impact.

- Digital integration through CAD/CAM and Industry 4.0 technologies enables seamless design-to-production workflows, real-time monitoring, and predictive maintenance.

- Advanced materials such as high-strength steel, aluminum alloys, and composites are increasingly used to meet performance and weight requirements.

- Technical expertise: Highly skilled engineers and technicians ensure superior quality and innovative solutions.

- Innovation: Continuous investment in technology and process improvement keeps French manufacturers at the cutting edge.

- Customization: Flexible solutions tailored to specific client needs, whether for prototypes or large-scale production.

- Quality assurance: Rigorous testing and certification for international standards such as ISO 9001 and ISO 14001.

- Strategic location: Proximity to major European markets facilitates efficient logistics and supply chain management.

- Sustainability: Commitment to environmentally friendly practices aligns with global trends and client expectations.

- Comprehensive services: From design support to final assembly, many French suppliers offer turnkey solutions, simplifying project management.

Choosing the right sheet metal fabrication manufacturer or supplier is critical for project success. Consider the following factors:

- Experience and reputation: Look for companies with a proven track record in your industry and positive client testimonials.

- Capabilities: Ensure the supplier offers the services, technologies, and materials you require.

- Quality control: Ask about certifications, testing procedures, and quality management systems.

- Capacity: Confirm the supplier can handle your production volume and timelines without delays.

- Communication: Effective collaboration and clear communication ensure your specifications are understood and met.

- Cost-effectiveness: Balance price with quality, reliability, and service to maximize value.

- After-sales support: Consider suppliers who offer technical support, maintenance, and warranty services.

Although this article does not include images or videos directly, it is helpful to imagine the dynamic processes involved in sheet metal fabrication:

- Sheet Metal Laser Cutting: A high-powered laser beam precisely cuts metal sheets, creating intricate shapes with smooth edges and minimal waste.

- CNC Bending Process: Automated machines bend metal sheets into complex angles and curves with exact repeatability.

- Welding and Assembly: Skilled technicians use TIG, MIG, or spot welding to join components, forming strong, durable assemblies.

- Automated Production Line: Robotic arms and conveyors move parts through cutting, bending, welding, and finishing stations, boosting efficiency.

- Finished Sheet Metal Products: The end products range from automotive body panels and aerospace components to architectural facades and electronic enclosures.

France's sheet metal fabrication manufacturers and suppliers are recognized globally for their quality, innovation, and reliability. Whether you require rapid prototyping, precision components, or mass production, French companies offer comprehensive solutions tailored to diverse industry needs. Their commitment to excellence, sustainability, and customer satisfaction makes them ideal partners for international brands, wholesalers, and manufacturers seeking OEM services. By leveraging the expertise and capabilities of French sheet metal fabrication suppliers, businesses can achieve superior results and gain a competitive edge in the global marketplace.

French sheet metal fabrication manufacturers and suppliers offer a broad range of services including laser cutting, CNC machining, bending, stamping, welding, surface treatment, rapid prototyping, and batch production. These services cater to various industries and project requirements.

Key factors include the supplier's experience, technical capabilities, quality control measures, production capacity, communication effectiveness, and cost competitiveness. Evaluating these aspects helps ensure a reliable and efficient partnership.

Industries such as aerospace, automotive, electronics, energy, architecture, and food processing heavily rely on French sheet metal fabrication manufacturers and suppliers for both high-volume production and specialized custom projects.

Yes, many French manufacturers offer rapid prototyping services using advanced CNC machining and 3D printing technologies, enabling fast design validation and iteration.

Advantages include technical expertise, innovative manufacturing solutions, customization options, stringent quality assurance, strategic geographic location in Europe, and a strong commitment to sustainable practices.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product