Views: 222 Author: Amanda Publish Time: 2025-07-06 Origin: Site

Content Menu

● Leading Rapid Prototyping Manufacturers in the UK

● Technologies Behind Rapid Prototyping

>> 3D Printing

>> Vacuum Casting and Injection Molding

● Industry Applications of Rapid Prototyping

● Benefits of Partnering with UK Rapid Prototyping Manufacturers

● How to Choose the Right Rapid Prototyping Manufacturer

>> 1. What are the most common rapid prototyping technologies used in the UK?

>> 2. How fast can I get a prototype made?

>> 3. Can rapid prototyping be used for low volume production?

>> 4. What materials are available for rapid prototyping?

>> 5. How does rapid prototyping reduce product development risks?

Rapid prototyping has become a cornerstone of modern product development, enabling businesses to accelerate design validation, reduce costs, and bring innovative products to market faster. The UK boasts a vibrant ecosystem of Rapid Prototyping Manufacturers and suppliers, offering a wide range of advanced technologies including 3D printing, CNC machining, vacuum casting, and injection molding. This article explores the leading rapid prototyping companies in the UK, their capabilities, and how they empower brands, wholesalers, and manufacturers globally.

Rapid prototyping is the process of quickly fabricating a physical model or prototype of a part or product using digital design data. It allows designers and engineers to test form, fit, and function early in the development cycle, enabling faster decision-making and reducing risks before mass production. Common rapid prototyping technologies include:

- 3D Printing (Additive Manufacturing): Building parts layer by layer using materials such as plastics, resins, and metals.

- CNC Machining: Subtractive manufacturing that precisely carves parts from metal or plastic blocks.

- Vacuum Casting: Producing small batches of parts using silicone molds.

- Injection Molding: Creating prototypes or low-volume production parts with high repeatability.

These technologies support a wide range of industries, from automotive and aerospace to consumer electronics and medical devices.

With over 50 years of experience, Malcolm Nicholls Ltd is one of the UK's most prestigious rapid prototyping and 3D printing companies. They operate two of the largest 3D printers in the UK, offering fast turnaround on high-quality prototypes directly from CAD data. Their expertise spans 3D scanning, reverse engineering, and low-volume production, making them a trusted partner for bridging the gap from concept to mass production.

Capabilities:

- Large-scale 3D printing

- SLS, SLA, and FDM technologies

- Low volume manufacturing

- 3D scanning and reverse engineering

Based in Hertfordshire, Prototype Projects specializes in SLA, SLS, DLP 3D printing, CNC machining, and model making. Since 1980, they have provided rapid prototyping and low-volume production services with an integrated approach. Their services include finishing options like surface smoothing, painting, and dye coloring to deliver prototypes that closely match final products.

Capabilities:

- SLA, SLS, DLP 3D printing

- CNC machining

- Vacuum casting

- Model making and finishing

Located in Oxford, Rapid Prototypes Ltd offers a comprehensive range of rapid prototyping and professional 3D printing services. Their fleet of 18 production systems provides over 150,000 hours of annual 3D printing capacity, including large build volumes up to 1500 x 750 x 550 mm. They offer more than 30 material options, supporting everything from prototype to low volume production.

Capabilities:

- Large build 3D printing

- Stereolithography (SLA), Selective Laser Sintering (SLS), MultiJet Printing (MJP), Fused Deposition Modelling (FDM)

- Low volume manufacturing

- Bespoke 3D printing services

Xometry UK provides a broad portfolio of rapid prototyping technologies including 3D printing, CNC machining, sheet metal fabrication, and injection molding. They offer over 16 manufacturing technologies and 110 materials, enabling customers to select the best process for their prototype needs. Their rapid turnaround and competitive pricing make them a popular choice for engineers seeking precision and speed.

Capabilities:

- 3D printing (various methods)

- CNC machining in metals and plastics

- Sheet metal fabrication

- Injection molding for prototypes and low volume production

Complete Fabrication combines traditional skills with advanced rapid prototyping technologies to deliver high-quality working prototypes. Their collaborative design approach and expertise in various manufacturing methods enable them to meet diverse client requirements efficiently.

Capabilities:

- Rapid prototyping and 3D printing

- Low volume production

- Metal and plastic fabrication

Star Rapid offers a comprehensive suite of services from CNC machining, 3D printing, injection molding to sheet metal fabrication. Their focus on quality and design assistance ensures that prototypes are manufactured to exact specifications using plastics, metals, and elastomers.

Capabilities:

- CNC machining

- 3D printing

- Injection molding

- Sheet metal fabrication

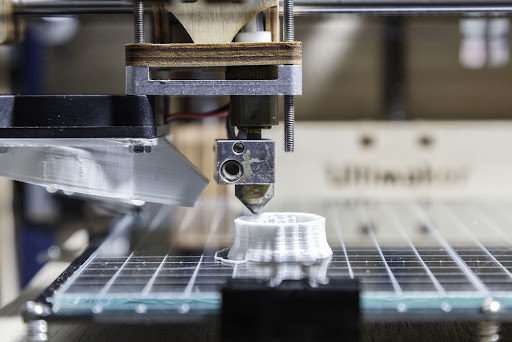

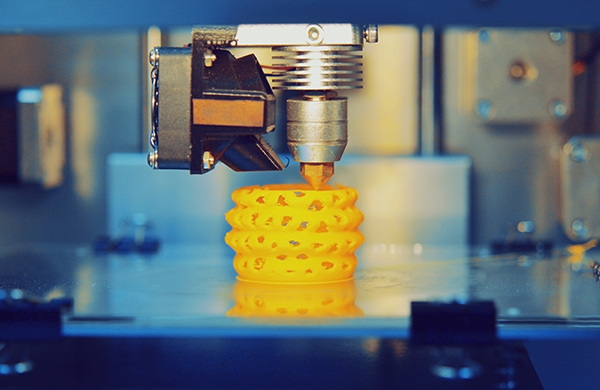

3D printing is the most popular rapid prototyping method due to its speed, flexibility, and cost-effectiveness. Common 3D printing processes include:

- Stereolithography (SLA): Uses a laser to cure resin layer by layer, producing high-resolution prototypes.

- Selective Laser Sintering (SLS): Fuses powdered materials like nylon with a laser, ideal for durable functional parts.

- Fused Deposition Modeling (FDM): Melts and extrudes thermoplastic filament, perfect for quick and affordable prototypes.

- Multi Jet Fusion (MJF): Uses inkjet arrays to fuse powder, offering fine details and excellent mechanical properties.

These methods enable the production of prototypes with varying degrees of strength, flexibility, and surface finish, catering to different stages of product development.

CNC machining provides high precision and allows prototypes to be made from production-grade metals and plastics. It is ideal for functional testing and design iterations where dimensional accuracy is critical. CNC machining is especially valuable when prototypes require mechanical properties close to final products or when tight tolerances are necessary.

Vacuum casting produces small batches of parts with excellent surface finish and material properties similar to injection molding. It is a cost-effective method for producing functional prototypes and short production runs without the expense of tooling. Injection molding, on the other hand, is used for prototypes requiring high repeatability and production-like quality. It is particularly suited for testing assembly, fit, and function in real-world conditions.

Rapid prototyping is widely used across many industries in the UK, including:

- Automotive: For designing and testing new components such as engine parts, interior fittings, and aerodynamic models.

- Aerospace: To develop lightweight, strong parts with complex geometries that meet stringent safety standards.

- Consumer Electronics: For fast iteration of device housings, buttons, and internal components.

- Medical Devices: To create patient-specific implants, surgical guides, and prototype medical instruments.

- Industrial Equipment: For functional prototypes of machinery parts and tooling.

The ability to rapidly produce and test prototypes reduces development cycles and improves product innovation across these sectors.

Choosing a UK-based rapid prototyping manufacturer offers several advantages:

- Proximity and Communication: Closer geographic location facilitates easier communication, faster shipping, and better project management.

- High Standards: UK manufacturers often adhere to strict quality and environmental standards, ensuring reliable and sustainable production.

- Expertise: Many UK companies have decades of experience and deep technical knowledge, providing valuable design feedback and manufacturing insights.

- Customization: UK suppliers typically offer flexible services tailored to unique project requirements, including bespoke finishing and assembly.

- Integration with Supply Chains: Being part of the UK's advanced manufacturing ecosystem allows seamless integration with downstream production and logistics.

When selecting a rapid prototyping partner in the UK, consider the following factors:

- Technology Range: Ensure the supplier offers the prototyping technologies that best match your product needs.

- Material Options: Check if the manufacturer provides materials that simulate your final product's mechanical and aesthetic properties.

- Turnaround Time: Confirm delivery times align with your project schedule.

- Quality Assurance: Look for certifications and quality control processes to guarantee prototype accuracy.

- Customer Support: Evaluate the level of design assistance, communication, and after-sales service.

- Cost: Balance pricing with quality and service to find the best value.

The UK is home to some of the most advanced and reliable Rapid Prototyping Manufacturers and suppliers in the world. From Malcolm Nicholls' large-scale 3D printing expertise to Prototype Projects' comprehensive finishing services, and Rapid Prototypes Ltd's vast production capacity, companies here offer cutting-edge solutions tailored to diverse industry needs. Leveraging technologies such as 3D printing, CNC machining, and vacuum casting, these manufacturers help brands, wholesalers, and producers rapidly transform ideas into tangible, testable products. For businesses aiming to reduce time to market, improve design accuracy, and optimize production costs, partnering with a top UK rapid prototyping supplier is a strategic advantage.

The UK rapid prototyping industry primarily uses 3D printing technologies like SLA, SLS, FDM, and MJF, alongside CNC machining, vacuum casting, and injection molding to create prototypes quickly and accurately.

Turnaround times vary by technology and complexity but many UK manufacturers can deliver prototypes within a few days to two weeks, enabling rapid iteration and testing.

Yes, many rapid prototyping manufacturers also offer low volume production services, bridging the gap between prototyping and full-scale manufacturing.

Materials range from various plastics and resins to metals such as aluminum, stainless steel, and titanium. Some suppliers offer over 30 material options to suit different functional and aesthetic requirements.

By allowing early physical testing of prototypes, rapid prototyping identifies design flaws and functionality issues before mass production, reducing costly errors and improving product quality.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product