Views: 222 Author: Amanda Publish Time: 2025-07-06 Origin: Site

Content Menu

● Leading Rapid Prototyping Manufacturers in America

>> 1. 3E Rapid Prototyping (3ERP) – Boston, MA

>> 2. Rapid Axis – Temecula, CA

>> 3. Xcentric Mold & Engineering – Clinton Township, MI

>> 4. RPS Tool and Engineering – Roseville, CA

>> 5. Prismier LLC – Bolingbrook, IL

● Technologies and Processes in Rapid Prototyping

>> CNC Machining for Prototyping

>> Injection Molding and Urethane Casting

● Materials Used in Rapid Prototyping

● Advantages of Rapid Prototyping for OEMs and Brands

● How to Choose the Right Rapid Prototyping Manufacturer

● The Future of Rapid Prototyping in America

>> 1. What industries benefit most from rapid prototyping manufacturers?

>> 2. How does CNC machining compare to 3D printing in rapid prototyping?

>> 3. Can rapid prototyping manufacturers handle low-volume production?

>> 4. What materials are commonly used in rapid prototyping?

>> 5. How fast can I expect to receive a prototype?

Rapid prototyping has become a cornerstone in modern manufacturing, enabling companies to transform ideas into tangible products quickly and efficiently. In the United States, a robust ecosystem of rapid prototyping manufacturers offers a variety of services including CNC machining, 3D printing, injection molding, and more. This article explores the top rapid prototyping manufacturers and suppliers in America, highlighting their capabilities, technologies, and how they support product development for OEMs, brands, and wholesalers worldwide.

Rapid prototyping is a group of techniques used to quickly fabricate a scale model or functional prototype of a physical part or assembly using three-dimensional computer-aided design (CAD) data. These prototypes allow designers and engineers to test and refine their ideas before moving into full-scale production, saving time and reducing costs.

Technologies used in rapid prototyping include:

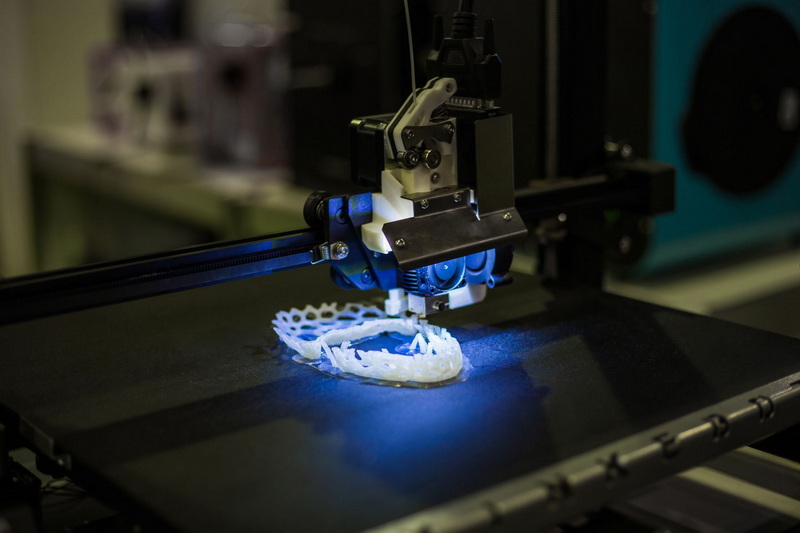

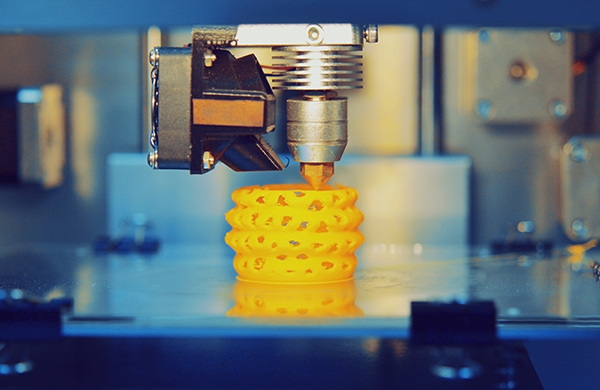

- 3D Printing (Additive Manufacturing): Methods such as stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), and binder jetting.

- CNC Machining: Subtractive manufacturing where material is precisely removed from a solid block.

- Injection Molding and Urethane Casting: For creating functional prototypes and low-volume production parts.

The choice of technology depends on the prototype's purpose—whether for visual models, functional testing, or pre-production validation.

3ERP specializes in high-quality rapid prototyping services, combining CNC machining, 3D printing, and rapid tooling. Their focus is on delivering quick, cost-effective solutions that enable clients to test and refine designs efficiently before mass production. They serve a global clientele with a strong emphasis on precision and speed.

Rapid Axis offers rapid prototyping with quick turnaround times for small quantity prototype jobs and production runs. Their in-house capabilities and strategic partnerships allow them to provide timely pricing and manufacturability feedback, ensuring quality parts at competitive prices. They excel in CNC machining and 3D printing services.

Xcentric provides comprehensive rapid prototyping services including 3D printing, CNC machining, cast urethane, and injection molding. Their integration of multiple technologies allows them to deliver fast, scalable solutions for both prototype and production projects, making them a versatile partner for OEMs.

RPS is a leader in prototype and low-volume plastic production, offering advanced 3D printing and prototype tooling solutions. Their emphasis on innovation and high-quality components supports rapid product development and manufacturing support for clients across industries.

Prismier focuses on fast and efficient manufacturing processes, offering rapid prototyping services using SLA, SLS, FDM, and urethane casting technologies. Their ability to deliver high-quality custom parts quickly makes them a trusted partner for moving parts from prototype to production.

- SLA (Stereolithography): Uses a laser to cure liquid resin into solid parts with high detail and smooth surfaces.

- SLS (Selective Laser Sintering): Fuses powdered materials like nylon into durable parts.

- FDM (Fused Deposition Modeling): Extrudes thermoplastic filaments layer-by-layer.

- Binder Jetting and Material Jetting: For full-color and multi-material prototypes.

These technologies allow rapid iteration of designs, enabling multiple revisions within days and accelerating product development cycles.

CNC machining is widely used for rapid prototyping when functional, high-precision parts are required. It involves computer-controlled cutting tools that shape parts from metal or plastic blocks. CNC prototypes often use the same materials as the final product, providing accurate mechanical properties for testing. This process is fast, cost-effective for small batches, and supports complex geometries.

Injection molding is traditionally used for mass production, but rapid prototyping manufacturers have adapted it for low-volume runs and prototype tooling. This process produces parts with excellent surface finish and mechanical properties. Urethane casting, on the other hand, is a flexible and cost-effective method to create small batches of parts that closely mimic production materials. Both techniques are invaluable for functional testing and market validation before committing to full-scale manufacturing.

The choice of materials is critical in rapid prototyping to simulate the final product's look, feel, and function. Common materials include:

- Plastics: ABS, polycarbonate, nylon, resin, and TPU for flexible parts.

- Metals: Aluminum, stainless steel, titanium, and tool steels for strength and durability.

- Composites: Carbon fiber and glass-filled polymers for lightweight and high-strength applications.

Manufacturers often offer a wide range of materials to fit the specific needs of different industries, whether for aesthetic models or functional prototypes.

Rapid prototyping manufacturers provide OEMs and brands with several key benefits:

- Accelerated Product Development: Fast turnaround times allow multiple design iterations, reducing time to market.

- Cost Savings: Early detection of design flaws prevents costly mistakes in mass production.

- Improved Communication: Physical prototypes facilitate better collaboration among design, engineering, and marketing teams.

- Customization and Flexibility: Ability to produce complex geometries and customized parts without expensive tooling.

- Risk Reduction: Functional testing of prototypes ensures product reliability and performance before large-scale manufacturing.

These advantages empower companies to innovate confidently and maintain competitiveness in fast-paced markets.

Selecting the right rapid prototyping partner is crucial for project success. Consider the following factors:

- Technological Capabilities: Ensure the manufacturer offers the technologies suited to your prototype's requirements.

- Material Options: Verify availability of materials that match your product's functional and aesthetic needs.

- Turnaround Time: Check their ability to meet your project deadlines.

- Quality Standards: Look for certifications and quality control processes.

- Experience and Industry Expertise: Choose manufacturers familiar with your industry to leverage specialized knowledge.

- Communication and Support: Strong customer service and technical support are essential for smooth collaboration.

By carefully evaluating these aspects, companies can find a rapid prototyping manufacturer that aligns with their goals and budget.

The rapid prototyping industry continues to evolve with advancements in additive manufacturing, automation, and materials science. Emerging trends include:

- Multi-Material and Full-Color Printing: Enabling more realistic and functional prototypes.

- Hybrid Manufacturing: Combining additive and subtractive processes for optimized parts.

- Sustainable Materials: Development of biodegradable and recyclable materials for eco-friendly prototyping.

- AI and Machine Learning: Enhancing design optimization and manufacturing efficiency.

- Digital Twins: Using virtual prototypes alongside physical ones to accelerate testing and validation.

These innovations promise to further enhance the speed, quality, and versatility of rapid prototyping services, reinforcing America's leadership in advanced manufacturing.

The landscape of rapid prototyping manufacturers in America is rich with companies offering diverse, cutting-edge technologies such as 3D printing and CNC machining. These manufacturers play a critical role in helping OEMs, brands, and wholesalers bring innovative products to market faster and more cost-effectively. By leveraging rapid prototyping services, companies can iterate designs quickly, validate functionality, and streamline production planning. Whether the need is for a quick visual model or a fully functional prototype, America's top rapid prototyping manufacturers provide the expertise and technology to meet these demands efficiently.

Rapid prototyping is widely used in automotive, aerospace, consumer electronics, medical devices, and industrial machinery sectors, where fast iteration and precision are critical.

CNC machining offers superior material properties and surface finish for functional prototypes, while 3D printing excels at quick, complex shapes and visual models. Often, both are used complementarily.

Yes, many rapid prototyping companies also provide low-volume manufacturing, bridging the gap between prototyping and full-scale production.

Materials include various plastics (ABS, nylon, resin), metals (aluminum, steel, titanium), and composites, selected based on prototype requirements.

Turnaround times vary by technology and complexity but can range from a few hours for simple 3D prints to a few weeks for complex CNC-machined parts.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes