Views: 222 Author: Amanda Publish Time: 2026-01-20 Origin: Site

Content Menu

● Understanding On Demand 3D Printing Manufacturers and Suppliers

● Turkey's Growing On Demand 3D Printing Ecosystem

● Key Types of On Demand 3D Printing Providers in Turkey

>> Digital Manufacturing Platforms

>> Industrial 3D Printing and Engineering Firms

>> 3D Technology Integrators and Solution Providers

>> Specialized 3D Printing Bureaus and Startups

● Typical Capabilities of Turkish On Demand 3D Printing Manufacturers and Suppliers

● Why Foreign OEMs Choose Turkey for On Demand 3D Printing

● Shangchen: A Chinese Partner for Global OEM Projects

● Bridging Turkish On Demand 3D Printing with Shangchen's Precision Manufacturing

● How to Select On Demand 3D Printing Manufacturers and Suppliers in Turkey

● Strategic Benefits for Global OEMs

● FAQ

>> 1. How do on demand 3D printing manufacturers and suppliers in Turkey support rapid prototyping?

>> 2. Can Turkish on demand 3D printing suppliers produce functional and end‑use parts?

>> 3. Why should foreign OEMs combine Turkish 3D printing with Shangchen's OEM services in China?

>> 5. How do quality levels compare between Turkish 3D printing suppliers and a factory like Shangchen?

Turkey has become one of the most dynamic markets in Europe for on demand 3D printing manufacturers and suppliers serving both local and international brands. The country's strategic location, engineering talent, and growing digital manufacturing infrastructure make it an attractive partner for OEM buyers who want to shorten development cycles, reduce risk, and stay closer to end markets.

At the same time, many foreign companies are combining Turkish On Demand 3D Printing manufacturers and suppliers with high‑precision Chinese factories like Shangchen to create hybrid global supply chains that are both fast and cost‑effective. This integrated approach connects rapid prototyping, on‑demand production, and precision batch manufacturing under one coordinated strategy.

On demand 3D printing manufacturers and suppliers are service providers that produce custom parts only when orders are placed, rather than holding large inventories. In practice, this means parts are printed immediately after receiving and reviewing product files, then shipped to the customer with minimal lead time.

From an OEM perspective, on demand 3D printing manufacturers and suppliers offer several clear advantages:

- They eliminate the need for tooling in early development, which reduces upfront investment and risk.

- They allow engineers to test multiple design iterations quickly, improving product performance and reliability before mass production.

- They support short runs, bridge production, and spare parts without the cost burden of traditional manufacturing.

In many cases, on demand 3D printing services exist alongside CNC machining, injection molding, sheet metal, and other processes, forming a complete digital manufacturing ecosystem. This is the model increasingly used in Turkey and by integrated factories such as Shangchen.

Turkey's manufacturing base covers automotive, aerospace, defense, energy, medical devices, consumer electronics, architecture, and general industrial equipment, all of which now rely heavily on rapid prototyping and agile production. Over the last decade, the country has seen strong investment in additive manufacturing, 3D modeling, and digital production systems, positioning Turkish companies as serious players in regional and global supply chains.

Clusters of 3D printing companies can be found in major cities like Istanbul, Ankara, Izmir, Bursa, and other industrial regions. These providers range from full‑service engineering firms and technology integrators to specialized print bureaus focusing on polymers, metals, or advanced applications. Many of them operate as on demand 3D printing manufacturers and suppliers for both domestic and foreign customers, with English‑language interfaces and online quotation tools.

Although each company is unique, most on demand 3D printing manufacturers and suppliers in Turkey fall into several broad categories. Understanding these categories helps foreign OEM buyers build balanced supplier portfolios.

These are online platforms that aggregate a network of manufacturing partners and offer instant pricing for processes like 3D printing, CNC machining, sheet metal, and molding. Engineers upload CAD models, select materials and technologies, and receive automatic quotations and lead times. Orders are then routed to qualified Turkish partners for production.

This type of platform is particularly attractive for foreign buyers who want a single interface for multiple processes and suppliers, without managing each workshop separately. It also fits OEMs needing quick access to on demand 3D printing manufacturers and suppliers in Turkey for diverse projects and fluctuating order volumes.

Another important group consists of engineering‑driven companies that provide industrial‑grade polymer and metal 3D printing alongside design, simulation, and application development. These firms typically serve demanding sectors like aerospace, automotive, defense, and machinery.

They help customers:

- Optimize part designs for additive manufacturing.

- Replace complex assemblies with consolidated printed parts.

- Develop new applications such as lightweight structures, conformal cooling channels, and customized tooling.

Because of their engineering strength, these firms are well suited for OEMs who need long‑term innovation partners rather than just simple print shops.

There are also companies in Turkey that focus on integrating 3D technologies into corporate workflows. These integrators provide 3D printers, scanners, software, and consulting services, and often operate their own print facilities to support customers' project needs.

They play a key role in:

- Building end‑to‑end digital manufacturing pipelines from CAD and PLM to printing and quality control.

- Training internal engineering teams on design for additive manufacturing.

- Supporting hybrid solutions that combine additive, subtractive, and forming processes.

For OEMs building long‑term capabilities in Turkey, such solution providers can support both in‑house adoption and external on demand 3D printing services.

Beyond large platforms and industrial players, Turkey has a vibrant ecosystem of startups and specialized bureaus focused on 3D design and printing. Many of these companies offer:

- Custom 3D modeling and product design.

- Prototyping for consumer products, wearables, architecture, and creative industries.

- Small‑batch production of customized components and accessories.

These niche providers often excel in flexibility and responsiveness, making them useful partners for early‑stage projects, small brands, and companies testing new markets.

Most serious on demand 3D printing manufacturers and suppliers in Turkey offer a broad set of processes and supporting services. While the exact portfolio differs by company, OEM buyers can generally expect:

1- Technologies:

- FDM/FFF for cost‑effective prototypes and fixtures.

- SLA/DLP for high‑detail visual and functional parts.

- SLS for durable nylon components.

- DMLS/SLM or similar metal processes for high‑performance parts.

- Sometimes binder‑jetting and hybrid systems for tools and casting patterns.

2- Materials:

- General‑purpose plastics like PLA, ABS, and PETG.

- Engineering polymers such as PA, PC, TPU, and high‑temperature materials.

- Stainless steels, tool steels, aluminum, and other metal powders for industrial applications.

3- Services:

- CAD modeling and design optimization.

- 3D scanning and reverse engineering.

- Post‑processing, painting, surface finishing, and assembly.

- Quality inspection and documentation for industrial customers.

These capabilities allow on demand 3D printing manufacturers and suppliers in Turkey to support the full spectrum from concept models and functional prototypes to small series and customized end‑use parts.

Foreign OEMs increasingly include Turkish providers in their supplier lists for several strategic reasons. First, Turkey's location between Europe and Asia translates into shorter transit times and lower logistics costs for European, Middle Eastern, and North African customers. Second, the country has strong mechanical and industrial engineering talent, especially in automotive, aerospace, and machinery sectors.

Additionally, Turkey's on demand 3D printing manufacturers and suppliers operate within a manufacturing culture that already understands international quality expectations, project management, and export procedures. Many of these companies are familiar with the demands of global automotive and industrial OEMs, making communication smoother and project execution more predictable.

For buyers, another benefit is flexibility. By using on demand 3D printing in Turkey, companies can maintain small but responsive production nodes close to key markets, while relying on high‑volume facilities in other countries for large batch manufacturing. This is where collaboration with factories like Shangchen becomes valuable.

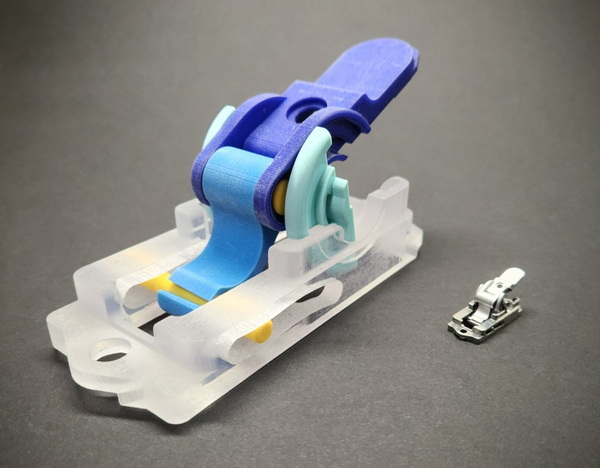

Shangchen is a Chinese rapid prototyping and manufacturing factory that supports international customers from design validation through full‑scale production. The company integrates multiple processes in‑house, including 3D printing, CNC milling, CNC turning, sheet metal fabrication, vacuum casting, and mold making.

For OEM buyers, Shangchen offers:

- Rapid prototype development using both additive and subtractive methods.

- Low‑volume and high‑volume production for metal and plastic parts.

- OEM and ODM services that cover component manufacturing and sub‑assembly.

- Engineering support to align manufacturing processes with performance and cost targets.

Because Shangchen combines rapid prototyping with precision batch production, it complements the strengths of on demand 3D printing manufacturers and suppliers in Turkey. Together, they form a practical “local‑plus‑global” strategy for OEM brands.

Many foreign OEMs now use a staged approach that connects Turkish on demand 3D printing manufacturers and suppliers with Shangchen's production capabilities. A typical lifecycle looks like this:

1. Concept and Early Prototyping in Turkey

- Designers and engineers create initial CAD models and send them to Turkish on demand 3D printing suppliers.

- Local teams iterate quickly on form, fit, and ergonomics, using polymer or resin prints.

- Stakeholders can review physical samples in person, reducing communication gaps and accelerating decisions.

2. Functional Prototyping and Pre‑Series Production

- As designs mature, Turkish suppliers produce functional parts in engineering plastics or metals for testing and validation.

- When quantities begin to rise, Shangchen can step in with CNC machining, vacuum casting, or pre‑series molding.

- This dual approach manages risk by combining local agility with stable offshore precision manufacturing.

3. Mass Production and Global Distribution with Shangchen

- Once designs are frozen and validated, Shangchen produces molds, jigs, and fixtures for full‑scale manufacturing.

- The factory delivers consistent, high‑precision parts to global warehouses or directly to OEM assembly plants.

- Meanwhile, Turkish on demand 3D printing manufacturers and suppliers remain available for engineering changes, custom variants, and spare parts close to the market.

This model allows OEMs to keep engineering and customer feedback cycles local, while leveraging Shangchen's cost‑efficient production for global volumes. It is particularly effective for products that require frequent updates, market‑specific customization, or complex supply‑chain structures.

Choosing the right on demand 3D printing manufacturers and suppliers is critical for quality, cost, and delivery performance. OEM buyers should evaluate Turkish partners across several dimensions:

1- Technical Capability

- Confirm available technologies (FDM, SLA, SLS, DMLS, etc.) and whether they match project requirements.

- Check material options and whether the supplier can source equivalents to those used in other regions.

2- Industry Experience

- Look for references or case studies in your sector, such as automotive, aerospace, consumer electronics, or medical devices.

- Evaluate their understanding of standards, documentation, and testing methods relevant to your products.

3- Quality and Certification

- Review quality control processes, inspection equipment, and any certifications (such as ISO) that support your internal quality system.

- Ask for sample reports, measurement data, and process documentation.

4- Data Handling and Communication

- Verify that the supplier can safely manage CAD files, technical drawings, and revision histories.

- Ensure that project managers and engineers can communicate smoothly in English and respond quickly to design changes.

When integrating Turkish on demand 3D printing with Shangchen's OEM services, it is also important to align:

- CAD formats and tolerancing schemes.

- Material specifications and approved alternates.

- Quality documentation, including inspection plans and reporting templates.

This alignment ensures that parts produced in Turkey and at Shangchen remain interchangeable and meet the same functional and quality targets.

By combining on demand 3D printing manufacturers and suppliers in Turkey with Shangchen's broad manufacturing capabilities in China, global OEMs can:

- Accelerate Time‑to‑Market

Local rapid prototyping and validation in Turkey shortens decision cycles, while ready‑to‑scale manufacturing at Shangchen removes bottlenecks when volumes increase.

- Optimize Total Cost

On demand 3D printing avoids early tooling expenses and reduces waste during development, and cost‑efficient CNC machining or molding in China improves unit economics once demand stabilizes.

- Increase Supply Chain Resilience

Multiple production nodes across Turkey and China reduce dependency on a single region and allow more flexible responses to demand fluctuations, disruptions, or regulatory changes.

- Enable Customization and Regionalization

Turkish providers can handle low‑volume or customized variants for local markets, while Shangchen maintains core global SKUs at scale. This setup supports product personalization without excessive complexity.

For foreign brands seeking long‑term competitiveness, this hybrid model turns the combination of Turkey and China into a powerful global manufacturing strategy built around on demand 3D printing manufacturers and suppliers.

Turkey has built a diverse and rapidly evolving ecosystem of on demand 3D printing manufacturers and suppliers that support rapid prototyping, agile production, and customized solutions for local and international customers. These providers cover everything from early‑stage concept models and functional prototypes to end‑use parts across automotive, aerospace, machinery, consumer products, and more.

At the same time, Chinese factories like Shangchen provide integrated rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production to carry OEM projects from development through precision mass production. By strategically combining Turkish on demand 3D printing manufacturers and suppliers with Shangchen's high‑precision OEM capabilities, foreign brands can build flexible, resilient supply chains that accelerate product launches, control lifecycle costs, and maintain consistent quality worldwide.

Contact us to get more information!

On demand 3D printing manufacturers and suppliers in Turkey typically accept CAD file uploads, provide quick quotations, and produce prototypes in polymers or metals within short lead times. They often combine printing with design consultation and design‑for‑manufacturing checks, helping engineers refine models before committing to tooling or high‑volume production.

Yes. Many Turkish suppliers use industrial‑grade 3D printers and engineering materials suitable for functional and end‑use applications, not just visual models. They commonly serve sectors such as automotive, aerospace, industrial machinery, and healthcare, where parts must withstand real‑world loads, temperature, and environmental conditions.

Combining Turkish on demand 3D printing with Shangchen's OEM services allows foreign OEMs to validate designs close to their markets and then scale production efficiently. Turkey offers speed, proximity, and engineering collaboration in the early stages, while Shangchen delivers integrated CNC machining, molding, and precision batch production at globally competitive cost for long‑term volumes.

Buyers should prepare 3D CAD files, approximate quantities, target lead times, preferred materials, and key functional or cosmetic requirements. Any existing drawings, tolerance schemes, surface finish expectations, and testing conditions are also valuable, as they help suppliers propose the right process, material, and pricing model from the beginning.

Many Turkish on demand 3D printing manufacturers and suppliers follow structured quality systems, including inspection routines and documentation suitable for industrial customers. Shangchen complements this by operating under formal quality management standards, using advanced metrology equipment, and providing detailed inspection reports tailored to OEM needs, ensuring that parts from different locations meet consistent performance and reliability targets.

1. https://xometry.com.tr/en/

2. https://ensun.io/search/3d-printing/turkey

3. https://www.f6s.com/companies/3d-printing/turkey/co

4. https://techbehemoths.com/companies/3d-modeling-printing/turkey

5. https://www.exone.com/en-US/Resources/News/Turkish-Foundries-invest-in-3D-printing

6. https://www.demarche.com.tr/2025/10/21/3d-printing-in-turkiye-democratized-manufacturing-revolution/

7. https://www.teameliteonline.com/on-demand-3d-printing-and-plastic-injection-molding-services/

8. https://www.3ds.com/make/solutions/on-demand-manufacturing

9. https://xometry.pro/en/articles/on-demand-manufacturing/

10. https://www.sc-rapidmanufacturing.com

11. https://www.sc-rapidmanufacturing.com/rapid-prototyping-knowledge.html

12. https://www.sc-rapidmanufacturing.com/news/Iteration-Capabilities.html

13. https://shangchencnc.en.made-in-china.com/product/eJlUizmToYrp/China-3D-Printing-Resin-Rapid-Prototype.html

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam