Views: 222 Author: Amanda Publish Time: 2026-01-19 Origin: Site

Content Menu

● Overview of On Demand 3D Printing in Japan

● Leading On Demand 3D Printing Manufacturers and Suppliers in Japan

>> SOLIZE – Long‑Established 3D Printing Service Bureau

>> 3D Printing Corporation – Localized Industrial 3D Solutions

>> Marketplaces and Directories for 3D Printing Services

>> International On‑Demand 3D Printing Services Serving Japan

>> Japanese 3D Printer Distributors Supporting the Ecosystem

● Role of Shangchen in Global On‑Demand Manufacturing

● Combining Japanese 3D Printing with Chinese OEM Production

● Typical Industries Using On Demand 3D Printing in Japan

● How to Choose On Demand 3D Printing Manufacturers and Suppliers in Japan

● Example Workflow: From Design to Mass Production

● Practical Tips for Working with On Demand 3D Printing Manufacturers and Suppliers

● Why Japan Is Attractive for On‑Demand 3D Printing

● How Shangchen Complements Japanese On‑Demand Services

● FAQ

>> 1. What are the main advantages of using On Demand 3D Printing Manufacturers and Suppliers in Japan?

>> 2. How can I work with both Japanese 3D printing suppliers and Shangchen as an OEM partner?

>> 3. Which industries in Japan rely most on on‑demand 3D printing services?

>> 4. What data should I provide to On Demand 3D Printing Manufacturers and Suppliers?

>> 5. How do Japanese on‑demand 3D printing services compare with international platforms?

As brands, wholesalers, and manufacturers worldwide seek agile partners, on demand 3D printing manufacturers and suppliers in Japan stand out for quality, precision, and fast turnaround supported by robust manufacturing ecosystems in Tokyo, Osaka, Nagoya, and beyond. Many international buyers now combine Japanese on‑demand 3D printing partners with high‑value OEM factories in China such as Shangchen for rapid prototyping, CNC machining, and batch production to optimize cost and lead time.

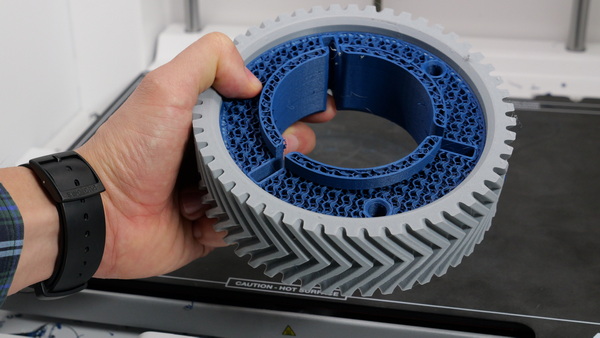

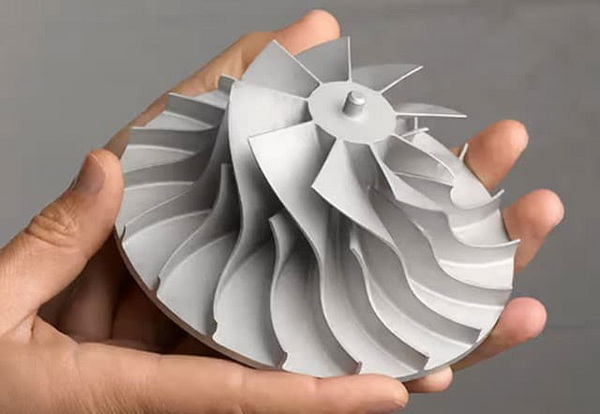

Japan has built a mature ecosystem of professional 3D printing service bureaus, industrial machine distributors, and integrators that together form a strong On Demand 3D Printing Manufacturers and Suppliers network. These providers cover technologies such as FDM/FFF, SLA, SLS, MJF, SLM, DMLS, and WAAM for metals, serving industries from automotive and aerospace to consumer goods and medical devices.

Many Japanese on‑demand 3D printing providers also offer engineering support, design for additive manufacturing (DfAM), and hybrid workflows that combine additive with CNC machining, sheet metal, casting, and molding. International buyers often place low‑volume or validation batches in Japan, then scale up with cost‑effective OEM partners in China for CNC machining, vacuum casting, sheet metal fabrication, and injection molds.

SOLIZE is recognized as one of the earliest commercial additive manufacturing bureaus in Japan, having used industrial 3D printers for over three decades to support domestic and global customers. The company owns dozens of industrial printers across multiple technologies and manufactures tens of thousands of parts per year, making it one of the largest on‑demand hubs in the country.

SOLIZE focuses strongly on optimizing quality, cost, and delivery, using high‑end equipment such as HP Multi Jet Fusion and other professional systems to support demanding sectors like automotive. In addition to 3D printing, it offers machining, sheet metal processing, casting, and mold prototyping, so buyers can manage prototyping and short‑run production through a single integrated partner.

3D Printing Corporation (3DPC) positions itself as a partner that combines industrial 3D printers, design support, and production services for Japanese and international customers. It offers printer sales and installation, but also accepts on‑demand jobs, effectively acting as both technology provider and service bureau.

Because 3DPC supports both Japanese and English communication, it is attractive to foreign companies that need local guidance on materials, technologies, and standards. This combination of consulting and on‑demand part production makes it an important participant in the wider On Demand 3D Printing Manufacturers and Suppliers ecosystem in Japan.

Online manufacturing platforms and directories simplify the process of finding On Demand 3D Printing Manufacturers and Suppliers in Japan. Dedicated directories list professional bureaus in Tokyo and other regions, often including the technologies offered, typical lead times, and the industries served.

Manufacturing marketplaces allow customers to upload CAD files, receive instant or rapid quotes, and choose among multiple Japanese and international providers. These systems let buyers compare different On Demand 3D Printing Manufacturers and Suppliers by cost, delivery, material options, and certifications, before assigning each project to the most suitable partner.

Alongside domestic providers, several overseas players deliver on‑demand 3D printing parts to Japanese customers. Some companies focus on niche technologies such as robotic WAAM metal 3D printing, offering large, complex metal components that would be expensive to produce via traditional methods in local facilities.

Other online platforms and service bureaus operate globally and ship custom 3D printed parts to Japan using processes like SLA, SLS, MJF, SLM, and FDM. These international services complement local On Demand 3D Printing Manufacturers and Suppliers by adding specialized materials, surface finishes, or backup capacity for high‑peak seasons and urgent programs.

Japan hosts several distributors that sell industrial and professional 3D printers, scanners, and associated software to manufacturers, universities, and research institutes. Companies in this segment provide hardware from multiple brands, giving factories and design offices access to a wide variety of additive technologies.

These distributors typically offer installation, training, and maintenance, helping customers integrate 3D printing into existing production lines. Many also work closely with On Demand 3D Printing Manufacturers and Suppliers, since customers may start with outsourced on‑demand services, then later bring part of the capacity in‑house while still relying on external bureaus for overflow or specialized projects.

While Japanese bureaus deliver local engineering support and just‑in‑time 3D printing, many overseas brands and trading companies rely on China‑based OEM partners like Shangchen to scale from prototypes to precision production. Shangchen specializes in rapid prototyping, CNC machining, precision batch machining, lathe turning, sheet metal manufacturing, 3D printing services, and mold fabrication for global clients.

The factory serves industries such as aerospace, automotive, medical devices, consumer electronics, architecture, and sports equipment, using metals and engineering plastics. With advanced CNC machining centers, multi‑axis milling, and inspection tools such as coordinate measuring machines and 3D scanners, Shangchen can hold tight tolerances and provide detailed inspection reports to support demanding quality requirements.

By acting as an OEM and ODM partner, Shangchen helps customers refine product designs, select suitable manufacturing processes, and transition smoothly from single prototypes to thousands of precision parts. This makes it a natural extension of On Demand 3D Printing Manufacturers and Suppliers in Japan, particularly for projects that need both rapid prototyping and cost‑effective mass production.

For many global buyers, an effective strategy is to combine Japanese On Demand 3D Printing Manufacturers and Suppliers with Chinese OEM factories like Shangchen. In the early stages, Japanese 3D printing bureaus provide fast prototypes and functional test parts close to design teams in Tokyo or other cities.

Once the design is validated, CAD models, tolerance requirements, and material specifications can be transferred to Shangchen for CNC machining, sheet metal fabrication, and injection molding. This staged approach minimizes development risk, shortens design cycles, and leverages the strengths of each region: local responsiveness and communication from Japanese on‑demand providers, together with high‑efficiency precision manufacturing in China.

Several industries rely heavily on On Demand 3D Printing Manufacturers and Suppliers in Japan, particularly during product development and pre‑production phases. Leading users include:

- Automotive and mobility

- Aerospace and defense

- Industrial machinery and robotics

- Consumer electronics and appliances

- Medical devices, dental, and healthcare products

Automotive and aerospace companies use 3D printing for aerodynamic models, fit‑check prototypes, test fixtures, and custom tooling inserts. Medical and dental professionals turn to on‑demand 3D printing for anatomical models, patient‑specific guides, and low‑volume custom devices. Start‑ups and consumer brands in Tokyo often use local bureaus to build appearance models and pilot runs before sending larger volumes to OEM partners such as Shangchen.

Choosing the right On Demand 3D Printing Manufacturers and Suppliers in Japan requires a structured evaluation process. Buyers typically start by defining their technical needs, then shortlisting suppliers according to capabilities and track record.

Key criteria include:

- Technology portfolio: Whether the supplier offers the required process (FDM, SLA, SLS, MJF, SLM, DMLS, WAAM, etc.) and can meet the necessary build envelope and resolution.

- Materials and certifications: Availability of engineering plastics, elastomers, metals, and composites, plus quality certifications and traceability documents.

- Industry experience: Proven projects in fields such as automotive, aerospace, medical, or consumer products, and familiarity with applicable standards.

- Quality control: Use of calibrated inspection equipment, documented procedures, and clear acceptance criteria for dimensional accuracy and surface finish.

- Communication and language: Ability to work in English as well as Japanese, provide clear quotations, and respond quickly to engineering questions.

For projects that must eventually scale into higher volumes, it is also important to assess how well the Japanese on‑demand bureau can coordinate with downstream manufacturers. Many buyers prefer On Demand 3D Printing Manufacturers and Suppliers that are comfortable collaborating with OEMs like Shangchen to ensure design consistency from prototype to mass production.

A typical product development workflow that combines Japanese and Chinese resources might follow these steps:

1. Concept and design

Product concept and CAD models are created by the brand owner or a Japanese design office. Initial design reviews consider both additive manufacturing and conventional machining constraints.

2. Local prototyping with Japanese On Demand 3D Printing Manufacturers and Suppliers

CAD data is sent to a Japanese 3D printing bureau for quick prototypes, allowing engineers to evaluate form, fit, and ergonomics. Several design iterations can be completed rapidly without international shipping delays.

3. Functional testing and DfAM optimization

Test parts are evaluated under real‑world load and environmental conditions. The supplier may suggest DfAM improvements such as lattice structures, weight reduction, or topology changes that make full use of additive capabilities.

4. Transfer to Shangchen for pre‑production

Once the design stabilizes, the final models, drawings, and tolerance schemes are shared with Shangchen. The engineering team selects appropriate CNC machining, turning, sheet metal, or soft tooling methods to produce pre‑production samples.

5. Validation and ramp‑up

Pre‑production parts go through dimensional inspection, functional testing, and sometimes certification processes. After approval, Shangchen ramps up to batch manufacturing and, if needed, full-scale production while Japanese 3D printing partners continue to support fixtures, jigs, or custom variants.

This workflow demonstrates how On Demand 3D Printing Manufacturers and Suppliers in Japan can act as the front‑end of a global, digitally connected manufacturing chain with Shangchen as a core precision production node.

To maximize the value of On Demand 3D Printing Manufacturers and Suppliers in Japan and OEM factories such as Shangchen, international buyers can follow several practical tips. Clear data, open communication, and realistic expectations are essential for success.

Recommended practices include:

- Prepare clean 3D CAD models (such as STEP or IGES) and avoid relying only on mesh files when precise machining will follow.

- Include 2D drawings that call out critical dimensions, tolerances, hole fits, and surface finish requirements.

- Highlight functional surfaces and interfaces that must remain consistent between 3D printed prototypes and CNC‑machined production parts.

- Ask suppliers for DfAM and DFM suggestions to reduce unnecessary complexity and optimize parts for both additive and subtractive processes.

- Confirm lead times and shipping options upfront, especially when coordinating between Japanese on‑demand bureaus and Chinese OEM plants.

For ongoing production, many companies maintain long‑term relationships with a small group of preferred On Demand 3D Printing Manufacturers and Suppliers and with a trusted OEM like Shangchen. This continuity improves communication, reduces ramp‑up time for new projects, and allows suppliers to gain deep familiarity with the buyer's standards and preferences.

Japan's manufacturing culture emphasizes precision, reliability, and continuous improvement, which translates naturally into the operation of On Demand 3D Printing Manufacturers and Suppliers. Service bureaus often adopt procedures similar to those used in traditional automotive or electronics supply chains, ensuring strong process control and documentation.

Additionally, Japan's dense industrial clusters make logistics efficient; parts can move quickly between 3D printing bureaus, machine shops, and assembly plants within major regions. For overseas brands working with Japanese distributors or sales offices, local on‑demand 3D printing enables rapid, region‑specific customization and faster customer feedback.

Shangchen's capabilities extend beyond typical rapid prototyping and into precision machining, small‑to‑medium batch runs, and mold making. This allows customers to maintain design continuity from early additive prototypes made by Japanese On Demand 3D Printing Manufacturers and Suppliers through to production‑grade components.

Because Shangchen offers CNC milling, turning, sheet metal fabrication, and mold production in parallel with its own 3D printing services, it can act as a one‑stop OEM hub after the prototyping stage. For many brands, this reduces the complexity of managing multiple vendors, shortens lead times, and creates a stable, repeatable manufacturing pipeline.

On Demand 3D Printing Manufacturers and Suppliers in Japan provide high‑quality, fast, and flexible solutions for prototyping, tooling, and low‑volume production across many industries. By leveraging advanced additive technologies, strong engineering support, and reliable logistics, they help brands accelerate product development and testing.

When these Japanese services are combined with a capable OEM partner like Shangchen in China, companies can build an end‑to‑end digital manufacturing workflow. This model uses local on‑demand 3D printing for design agility and cost‑effective CNC machining, sheet metal, and molding for scale, forming a powerful foundation for global product launches.

Japan offers a rich landscape of On Demand 3D Printing Manufacturers and Suppliers, ranging from long‑established bureaus like SOLIZE to specialized marketplaces and printer distributors. These providers support a wide variety of materials, technologies, and industries, making Japan an attractive destination for high‑quality additive manufacturing.

For global brands, wholesalers, and manufacturers, combining Japanese on‑demand 3D printing resources with high‑precision OEM partners such as Shangchen in China creates an efficient path from rapid prototyping to full‑scale production. By carefully selecting partners, aligning on processes and quality expectations, and integrating additive and subtractive manufacturing, companies can shorten development cycles and launch competitive products with confidence.

The main advantages include high part quality, strong engineering support, and reliable lead times backed by Japan's mature manufacturing culture. Buyers also benefit from access to multiple industrial technologies and materials within a single country.

A common approach is to prototype and refine designs with On Demand 3D Printing Manufacturers and Suppliers in Japan, then send the finalized CAD models and specifications to Shangchen for CNC machining, sheet metal fabrication, and mold production. Keeping drawings, tolerances, and materials consistent ensures a smooth transition from prototyping to volume manufacturing.

Industries that rely heavily on on‑demand 3D printing include automotive, aerospace, industrial machinery, consumer electronics, and medical devices. These sectors use On Demand 3D Printing Manufacturers and Suppliers for tasks such as rapid prototyping, tooling, fixtures, custom components, and small pilot runs.

You should provide 3D CAD files in common formats like STEP or IGES, along with 2D drawings that specify critical dimensions, tolerances, and surface finishes. It is also useful to share information about functional requirements, assembly context, and any regulatory standards so that both Japanese 3D printing partners and Shangchen can propose appropriate processes and materials.

Japanese On Demand 3D Printing Manufacturers and Suppliers typically offer strong local support, in‑person communication, and deep knowledge of domestic standards and industry practices. International platforms complement them by providing broader material selections and additional capacity, so many companies choose a hybrid strategy that uses both domestic Japanese providers and overseas services, together with an OEM like Shangchen for production.

1. SOLIZE 3D printed parts manufacturing – https://partners.solize.com/en/manufacturing

2. SOLIZE digital engineering and additive background – https://partners.solize.com/en

3. Article on SOLIZE and Roboze high‑speed polymer 3D printing in Japan – https://www.tctmagazine.com/solize-corporation-roboze-3d-printing-products-japan/

4. Overview of top 3D printing companies in Japan – https://www.kemalmfg.com/3d-printing/companies/japan/

5. Top 3D printing service manufacturers and suppliers in Japan – https://anebonmetal.com/top-3d-printing-services-manufacturers-and-suppliers-in-japan/

6. 3D printing service in Japan (marketplace overview) – https://seekmake.com/mfg/3d-printing/japan

7. 3D printing services in Tokyo directory – https://www.3d.directory/directory/3d-printing-services?country=Japan&state=Tokyo

8. SeekMake 3D printing services in Tokyo – https://seekmake.com/mfg/3d-printing/japan/tokyo

9. Professional 3D printing service with multiple technologies – https://www.pcbway.jp/rapid-prototyping/3d-printing/

10. JLC3DP online 3D printing service – https://jlc3dp.com

11. Reddit discussion on personal 3D printing services in Tokyo – https://www.reddit.com/r/Tokyo/comments/13xld5p/3d_printing_services_for_personal_purpose/

12. Toyota and HP 3D printing announcement involving SOLIZE – https://jp.ext.hp.com/info/newsroom/2022/20220615/english/

13. Shangchen rapid prototyping and CNC machining – https://www.sc-rapidmanufacturing.com

14. Shangchen CNC machining listing – https://shangchencnc.en.made-in-china.com

15. General rapid CNC prototyping example (industry benchmark) – https://www.jpmcnc.com/rapid-cnc-prototyping

16. CNC Rapid machining reference (industry benchmark) – https://cncrapid.com

17. Keheng rapid prototyping and 3D printing equipment scale (industry benchmark) – http://www.kehengdg.com/en/

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic