Views: 222 Author: Amanda Publish Time: 2025-08-06 Origin: Site

Content Menu

● The Italian Moulding Industry Landscape

>> Why Italy Leads in Moulding Production

● Leading Moulding Production Manufacturers and Suppliers in Italy

>> BMB S.p.A.

● Technology Driving Moulding Production in Italy

>> The Rise of Additive Manufacturing (3D Printing)

>> Quality Assurance and Inspection

>> Sustainable Practices in Moulding

● Applications Across Diverse Industries

● What Sets Italian Moulding Suppliers Apart?

● How to Select the Right Moulding Production Manufacturer or Supplier

● FAQ

>> 1. What are the main types of moulding production technologies used by Italian manufacturers?

>> 2. Which industries benefit the most from Italian moulding suppliers?

>> 3. How do Italian companies ensure the quality of their moulded products?

>> 4. Can Italian moulding manufacturers handle both custom and mass production orders?

>> 5. Are sustainable materials and processes available from Italian moulding suppliers?

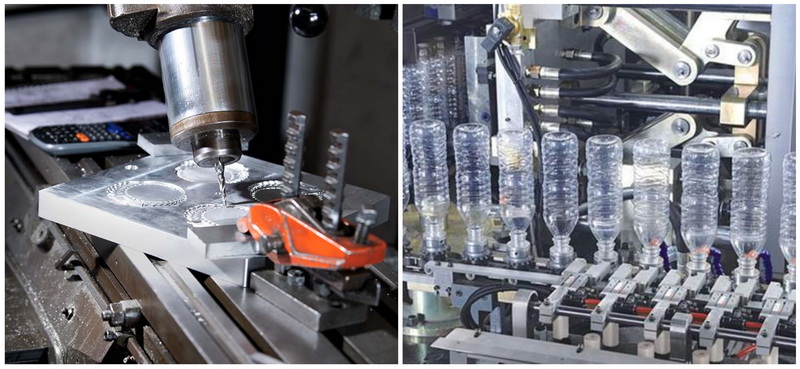

Italy has been a major hub for moulding production manufacturers and suppliers, leading advancements with innovation, precision, and quality. Italian moulding companies offer a wide array of services including rapid prototyping, CNC machining, precision bulk manufacturing, lathe turning, sheet metal fabrication, 3D printing, and mold production. These capabilities allow them to serve a broad spectrum of industries—from automotive and aerospace to healthcare and consumer goods. This comprehensive guide explores the top moulding production manufacturers and suppliers in Italy, delves into their core competencies, and provides a detailed overview of the industry's pivotal technologies, trends, and applications.

Italy's reputation in the moulding industry is rooted in its longstanding engineering excellence, creative design traditions, and tech-forward manufacturing processes. Regions such as Lombardy, Emilia-Romagna, Veneto, and Piedmont have evolved into vibrant industrial clusters, housing hundreds of moulding production manufacturers and suppliers. These companies are crucial for the Italian economy and are recognized as prominent international players supplying OEM and custom solutions worldwide.

- Focus on Precision and Quality: Italian companies invest heavily in modern machinery, apply strict quality control processes, and utilize top-grade materials to deliver unmatched product reliability.

- Integration of Innovation: The early adoption and integration of 3D printing, CAD/CAM technologies, and rapid prototyping allow Italian suppliers to offer flexible, fast production cycles tailored to client demands.

- Strong Automotive Connection: Collaboration with Italy's world-famous automotive brands such as Ferrari, Lamborghini, and Fiat drives continuous innovation in mould materials and production methods, particularly for lightweight and high-performance parts.

Italian moulding production manufacturers and suppliers consistently pursue improvements in efficiency, sustainability, and customizability, positioning the country as a strategic destination for high-quality mould production.

BMB S.p.A. stands out globally for its expertise in manufacturing high-precision, durable, and versatile injection molds. Their clientele spans automotive, food packaging, medical devices, and consumer product sectors. BMB's mold configurations span hydraulic and electric systems, each optimized for specific client needs. The company invests heavily in the continuous training of technical staff and the modernization of their production lines, ensuring molds not only meet but exceed OEM specifications. Their extensive design and manufacturing capabilities enable seamless integration of advanced cooling channels, multi-cavity mold setups, and complex insert molding processes.

CO.STAMP S.r.l. distinguishes itself by combining skilled research and development with advanced CNC machining and Electrical Discharge Machining (EDM) technology. Serving the automotive industry since 1994, the company focuses on engine housings, fuel system components, and steering parts that require high durability and thermal resistance. CO.STAMP works in partnership with some of Europe's leading car manufacturers to produce molds that underpin millions of vehicles on the road. Their ability to develop molds with long service lives ensures a steady and reliable molding process tailored to high-volume production.

Stampotecnica S.r.l. excels in the rapid prototyping and production of complex injection molds, utilizing the latest CAD-CAM software and 3D printing technologies. Their focus on innovation enables the creation of multi-cavity molds, two-color injection molds, and gas-assisted molding solutions designed to optimize cycle times and part quality. Stampotecnica provides end-to-end service, from conceptual design and prototyping to full-scale mass production. Their flexible approach makes them a popular choice for industries requiring quick product development turnaround without compromising on quality.

Founded in 1961, Brunelli Dino boasts deep experience in plastic injection moulding and comprehensive mold design and manufacturing. The company adopts Just in Time and Kanban logistics strategies to ensure punctual delivery and efficient inventory management. Their customer-centric approach meets the needs of European markets and global partners, delivering tailored molds that enhance production efficiency and product durability. Brunelli Dino's technological upgrades include in-house CNC machining centers and precision polishing capabilities that optimize mold performance.

Meccanica R.C. S.r.l. caters to the demanding requirements of aerospace, automotive, medical, and electronic applications. They specialize in customized molds built through cutting-edge 2D and 3D design software, combined with additive manufacturing techniques to prototype and produce parts with complex geometries. Their production process is aligned with strict quality and safety standards, making them reliable suppliers to industries where precision and reliability are vital.

Operating a 10,000-square-meter advanced production facility, All Thermoplast S.r.l. produces approximately 200 molds annually. Their expertise spans automotive components, household appliances, and medical devices. All Thermoplast employs an integrated suite of CAD, CAE, and 3D printing technologies to meet complex order demands with speed and accuracy. The company's high export rate is a testament to their global reputation and ability to provide fast, precise mold manufacturing tailored to diverse client needs.

CNC machining is fundamental to producing high-precision molds and components, allowing Italian manufacturers to create complex geometries with tight tolerances. Modern CNC centers operate in multiple shifts to deliver high throughput, with some plants logging over 120,000 machining hours annually. This technology enables rapid customization and consistent replication for both prototype and mass production molds. Sophisticated CNC machines equipped with multi-axis capabilities allow fine detailing, critical for molds used in high-performance automotive and aerospace parts.

Additive manufacturing has revolutionized the prototyping phase of mold production. Italian suppliers leverage 3D printing for creating highly detailed prototypes, master patterns, and even functional molds suitable for limited production. Technologies like Polyjet, Selective Laser Sintering (SLS), and Stereolithography (SLA) are widely applied, offering unmatched speed and flexibility. Firms such as DWS Systems and CRP Technology lead this space, developing solutions that speed innovation cycles, reduce costs, and expand the complexity of mold designs feasible for traditional manufacturing.

Automation is increasingly embedded into Italian mold production lines to boost productivity and improve repeatability. Robotic arms assist in tool handling, injection molding, and post-processing tasks, minimizing manual intervention and errors. Automated metrology ensures continuous inspection and real-time quality feedback, while integrated digital workflow management enables efficient tracking of production stages. These advancements reduce lead times, enhance product consistency, and help maintain competitive pricing despite rising labor costs.

Quality assurance remains a cornerstone of Italian mold manufacturing. Companies employ intense inspection regimes involving in-line metrology equipment such as coordinate measuring machines (CMM), laser scanners, and vision systems to verify dimensional accuracy during every production phase. Finite element analysis (FEA) and mold flow simulation software predict potential faults and optimize mold design, mitigating costly downstream issues. Adherence to international certifications, including ISO 9001, assures clients that manufacturing processes meet or exceed stringent global standards.

The environmental impact of manufacturing is an increasing concern within Italy's moulding sector. Leading manufacturers have adopted sustainable practices such as the integration of recyclable raw materials, reducing waste through refined cutting and machining techniques, and implementing energy-efficient production systems. Water-based cooling, solar-assisted energy inputs, and closed-loop recycling of plastics are examples of eco-friendly initiatives. These sustainable approaches not only meet regulatory demands but also align with the growing market preference for green manufacturing.

Italy's mold production manufacturers and suppliers serve a wide variety of industries by tailoring their solutions to meet specific sector needs:

- Automotive Industry: Italy's automotive sector demands molds for engine housings, body panels, dashboards, fuel system components, and safety devices. The strong heritage of Italian carmakers propels innovation in lightweight and high-strength mold components.

- Aerospace: Molds designed for aerospace applications require extreme precision, lightweight materials, and adherence to strict safety standards. Italian moulding suppliers deliver parts for aircraft interiors, structural supports, and complex fluid systems.

- Healthcare: The healthcare sector requires customized molds for medical devices, diagnostic housings, surgical instruments, and disposable products. Italian manufacturers are known for creating sterile, biocompatible molds that ensure patient safety.

- Consumer Electronics: The rapid innovation cycle in electronics requires molds capable of producing intricate enclosures, connectors, and internal components swiftly and economically.

- Industrial Equipment: High-durability molds for control panels, machine covers, and functional components ensure reliability in harsh environments, catering to industrial machinery manufacturers.

These sector-specific capabilities underscore the flexibility and broad technological expertise available among Italian moulding production companies.

Italian moulding production manufacturers and suppliers differentiate themselves through several notable characteristics:

- Tailored Solutions: Customized mold designs are core to the Italian mold industry. Companies take pride in collaborating closely with clients to develop molds precisely tailored to product requirements.

- Global Logistics Support: Many Italian companies provide end-to-end logistics and dedicated customer service, enabling smooth international shipping and timely delivery for global customers.

- Sustainability Commitment: Top suppliers actively pursue eco-friendly practices, helping clients meet environmental goals and regulatory standards without compromising quality or efficiency.

- Innovation-Driven Culture: Constant R&D investment ensures Italian manufacturers remain at the forefront of technological trends, adopting cutting-edge software and hardware solutions.

These strengths have established Italy as a prime sourcing destination for OEM molds and custom manufacturing solutions worldwide.

Choosing the right Italian moulding production manufacturer or supplier requires a strategic approach:

1. Assess Experience and Track Record: Select companies with extensive experience and a proven history of delivering quality molds within your industry. Certifications such as ISO 9001 can serve as reliability indicators.

2. Evaluate Technical Capabilities: Confirm that the supplier operates up-to-date machinery, advanced CAD/CAM tools, and employs skilled engineers familiar with your product complexity.

3. Verify Quality Control Processes: Ensure the company has robust inspection, validation, and metrology systems to maintain consistent mold performance.

4. Seek Comprehensive Project Support: Favor suppliers offering support from initial design and prototyping through to full production and post-sales maintenance, ensuring seamless project execution.

5. Consider Sustainability Initiatives: If environmental impact matters to your business, inquire about the supplier's sustainable materials, production methods, and compliance with environmental regulations.

A well-matched supplier partnership can greatly influence product quality, time-to-market, and overall manufacturing costs.

Italian moulding production manufacturers and suppliers continue to establish themselves as global leaders by combining tradition with innovation, precision, and customer orientation. Their comprehensive service offerings—from rapid prototyping with advanced 3D printing to high-throughput CNC machining and custom mold manufacturing—support some of the world's most demanding industries. Collaborating with Italian manufacturers ensures access to high-quality, durable, and customized molds that meet exacting specifications while benefiting from sustainable practices and efficient global logistics. As the industry embraces digital automation and sustainable innovations, Italy remains a strategic and reliable partner for all moulding production needs worldwide.

Italian moulding production manufacturers and suppliers utilize a combination of CNC machining, injection moulding, additive manufacturing (3D printing), electric and hydraulic molding machines, and automated robotic systems. This blend ensures precision, flexibility, consistency, and fast turnaround for a wide variety of materials and complex designs.

Key beneficiary industries include automotive, aerospace, healthcare, consumer electronics, and industrial manufacturing. Italian suppliers excel at meeting stringent quality standards and producing tailored molding solutions that address diverse technical and regulatory demands.

Quality is maintained through rigorous protocols including in-line metrology, computerized inspection systems, finite element analysis, and mold flow simulations. Compliance with international ISO 9001 and other certifications support consistent quality assurance across every production batch.

Yes, Italy's leading moulding production companies have the infrastructure and expertise to manage both customized prototyping projects and high-volume mass production efficiently. Their automated processes and flexible workflows allow for rapid transitions between order types and scales.

Absolutely. Sustainability initiatives are integral, with many Italian companies adopting recyclable plastics, minimizing waste through efficient production techniques, using energy-saving machinery, and pursuing closed-loop recycling programs—all aimed at reducing environmental impact while maintaining superior product quality.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal