Views: 222 Author: Amanda Publish Time: 2025-08-05 Origin: Site

Content Menu

● The Landscape of Moulding Production in Europe

● Why Choose European Moulding Production Manufacturers and Suppliers?

● Leading Moulding Production Manufacturers and Suppliers in Europe

>> Robust Plastics GmbH (Austria)

>> Leading Moulding Companies in the Netherlands

● Innovative Moulding Production Processes

● Frequently Asked Questions (FAQ)

>> 1. What are the advantages of choosing European moulding production manufacturers and suppliers?

>> 2. Which sectors rely most on European moulding production?

>> 3. What technologies and materials are commonly used by these manufacturers?

>> 4. How do European suppliers address sustainability?

Europe stands at the forefront of the moulding production industry, offering world-class manufacturers and suppliers who deliver precision, innovation, and reliability. As global brands, wholesalers, and producers increasingly seek high-quality OEM solutions, European companies have continued to invest in cutting-edge technologies, sustainability, and customer-focused services. This article explores the top moulding production manufacturers and suppliers in Europe, showcases their industry impact, and provides valuable answers to common questions about this critical manufacturing sector.

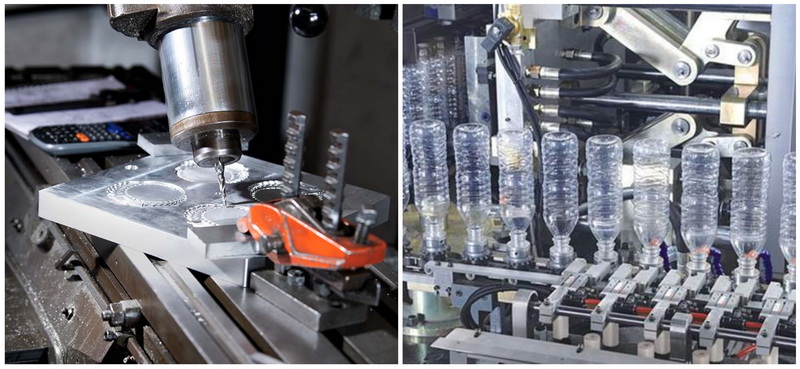

Europe's moulding industry encompasses a wide array of processes, from rapid prototyping and CNC machining to precision batch production, turning, sheet metal fabrication, 3D printing, and advanced tooling. This diversity empowers both longstanding brands and new entrants to bring innovative products to market quickly and cost-effectively. The integration of various techniques allows manufacturers to adapt to evolving market demands, enhance product customization, and improve overall efficiency.

One of the critical advantages of choosing European moulding production manufacturers and suppliers is adherence to stringent quality standards. Many European manufacturers hold certifications like ISO 9001, ISO 14001, IATF 16949, and other industry-specific accreditations that guarantee exceptional product quality, consistency, and traceability.

Moreover, European manufacturers are widely recognized for their investment in advanced technologies. Many utilize state-of-the-art machinery and incorporate sustainable practices, including the use of bioplastics, recycled materials, and digital manufacturing methods like Industry 4.0 automation and smart factory concepts. This commitment to innovation supports flexible production runs and the ability to meet complex design specifications.

Another significant benefit is the comprehensive services offered. Leading suppliers provide end-to-end solutions, covering everything from prototyping and product design to assembly, quality control, and logistics. This makes it efficient for clients to streamline their supply chains and reduce time to market.

Micro Systems specializes in precision injection moulding with a reputation for ultra-precise tool making and turnkey mass-production solutions. They operate with state-of-the-art cleanroom facilities tailored for medical and biotech sectors, ensuring the highest standards of hygiene and precision. Their certifications in ISO 9001 and ISO 13485 highlight their commitment to quality, particularly in highly regulated industries.

Famed for innovation, Stamm AG focuses on micro and multi-component moulding, harnessing hybrid and multi-material capabilities to serve specialized markets. The company's expertise in rotary, index plate, and core-back technologies enables highly customized components with complex designs, meeting the demands of automotive, electronics, and medical sectors.

With over five decades of experience, Sovrin Plastics pioneers bespoke micro-injection moulding, especially in controlled cleanroom environments. Their precision cleanroom manufacturing caters predominantly to the medical and electronic device industries, maintaining ISO Class 7 and 8 cleanroom standards supported by lean Six Sigma methodologies.

Robust Plastics excels in automotive, technical, and industrial packaging applications. Offering custom injection moulding and comprehensive toolmaking services, the company integrates just-in-time delivery and product development to optimize manufacturing timelines. They hold IATF 16949 and ISO 9001 certifications underscoring their dedication to automotive industry standards.

Camo provides integrated moulding solutions encompassing the entire product lifecycle—from development and prototyping to assembly and packaging. Their expansive, highly automated facility covers diverse sectors including automotive, electronics, construction, and medical industries, delivering high-quality molded components efficiently.

Omnia Plastica specializes in precision injection moulding and extrusion of technopolymers for civil and defense applications. Their comprehensive processing capabilities enable them to produce complex components with tight tolerances and excellent finish, backed by a strong international network that supports global OEM customers.

Rosti Group boasts a multinational presence, operating production facilities across Europe and Asia. They offer world-class engineering, automation, and OEM plastic parts manufacturing, capable of medium and high-volume production. Their flexibility and quality control make them preferred suppliers for automotive, consumer goods, and industrial sectors.

The Netherlands hosts several top manufacturers known for specialization in rubber and plastic components, rapid prototyping, and cleanroom assembly. Companies like Helvoet Rubber & Plastic Technologies BV focus on precision automotive and electronics parts, while HSV Technical Moulded Parts offers expertise in large plastic product manufacturing.

Orange Plastics BV provides rapid prototyping and cleanroom services suited for medical and high-tech applications. Rompa Group balances injection moulding with electronics packaging and assembly services, backed by certifications including ISO 9001 and IATF 16949. Bema Kunststoffen BV rounds out the list with a focus on plastic processing for technical, industrial, and medical markets.

Moulding production in Europe is driven by the latest advances in technology, including:

- Injection Moulding: The foundation of mass manufacturing, injection moulding involves injecting molten material into precision-engineered molds. This process can produce millions of identical parts with excellent surface quality and dimensional accuracy.

- Multi-Component Moulding: Allows the production of complex parts using multiple materials or colors in one cycle, reducing assembly costs and enhancing functionality.

- Micro Moulding: Specialized for tiny, high-precision components needed in electronics, medical devices, and automotive sensors.

- Rapid Prototyping: Techniques such as CNC machining and 3D printing accelerate product development, enabling fast design iterations and early testing.

- Sustainable Moulding: Adoption of bioplastics, recycled polymers, and energy-efficient machines contributes to lower environmental impacts and compliance with Europe's sustainability goals.

European moulding manufacturers cater to a wide range of industries:

- Automotive: Production of functional parts like panels, housings, connectors, and interior components using robust thermoplastic materials with precise tolerances.

- Medical Devices: Injection moulding cleanroom environments produce critical components such as syringe parts, diagnostic devices, and surgical instruments that meet stringent regulatory requirements.

- Consumer Electronics: Miniature, complex housings and connectors tailored to high-tech consumer products.

- Aerospace: Lightweight, high-strength composite plastic parts that comply with rigorous safety and performance standards.

- Industrial Equipment: Durable moulded parts for machinery, packaging, and assembly lines.

Many leading European suppliers also offer value-added services such as:

- Tool and Die Design and Manufacturing: Creating highly accurate molds is fundamental to quality moulding production. European companies possess advanced CNC and EDM capabilities to produce molds that last for millions of cycles.

- Assembly and Packaging: Post-production services include insertion, bonding, and packaging, ensuring the product is market-ready.

- Logistics and Supply Chain Management: Efficient handling of deliveries, just-in-time inventory, and tailored supply solutions reduce costs and improve client responsiveness.

Europe's moulding production manufacturers and suppliers lead the world with their commitment to unparalleled quality, innovation, and environmental responsibility. Whether you require rapid prototyping, high-volume OEM production, or highly specialized components for automotive, electronics, medical, or industrial use, European companies offer comprehensive solutions that meet and exceed all modern manufacturing demands. For global brands and wholesalers seeking trusted OEM partners, Europe's moulding industry remains the gold standard for reliability, quality, and customer service.

European manufacturers offer unmatched product quality, advanced technical know-how, certified facilities such as ISO and IATF, and strict environmental standards. Their one-stop solutions from design to batch production ensure fast turnaround, precision, and consistency.

Leading sectors include automotive, medical devices, electronics, aerospace, industrial, and consumer products. These industries demand high precision, low defect rates, and reliable supply chains that only top-tier manufacturers and suppliers can provide.

State-of-the-art manufacturers utilize multi-cavity and micro-moulding, rapid prototyping (including CNC and 3D printing), high-performance polymers, liquid silicone, and engineered thermoplastics. Many also invest in sustainable materials, such as bioplastics and recycled polymers.

By implementing closed-loop recycling, using green energy, integrating bioplastics, and constantly innovating to reduce environmental impact, European OEM suppliers are leaders in sustainable production and responsible sourcing.

Absolutely. European moulding production manufacturers are equipped for the entire product lifecycle—from concept prototype to large-scale, high-volume OEM production—offering flexibility, speed, and consistent high quality at every stage.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal