Views: 222 Author: Amanda Publish Time: 2025-08-05 Origin: Site

Content Menu

● Understanding Moulding Production

● The Role of OEM Services in Moulding Production

● Top Moulding Production Manufacturers and Suppliers in America

>> Proto Labs (Protolabs, Inc.)

>> Accurate Molded Plastics, Inc.

>> MANAR Inc.

>> PreciKam

● Key Capabilities of Leading American Moulding Suppliers

● Choosing the Right Moulding Partner

● Future Trends in American Moulding Production

● FAQs

>> 1. What types of moulding processes do American manufacturers offer?

>> 2. What certifications should reputable moulding manufacturers have?

>> 3. Can American moulding suppliers handle OEM and large-batch requirements?

>> 4. What industries do these manufacturers primarily serve?

>> 5. How do American suppliers ensure product quality and precision?

In the dynamic world of industrial manufacturing, moulding production manufacturers and suppliers in America serve as the backbone for countless sectors, from automotive and medical to aerospace, consumer electronics, and beyond. These companies leverage state-of-the-art technology, experience, and an unwavering commitment to quality to deliver innovative solutions for brands, wholesalers, and OEM clients around the globe. This article explores the leading American moulding production manufacturers and suppliers, revealing industry trends, competitive advantages, and practical tips for selecting the right partner for your project.

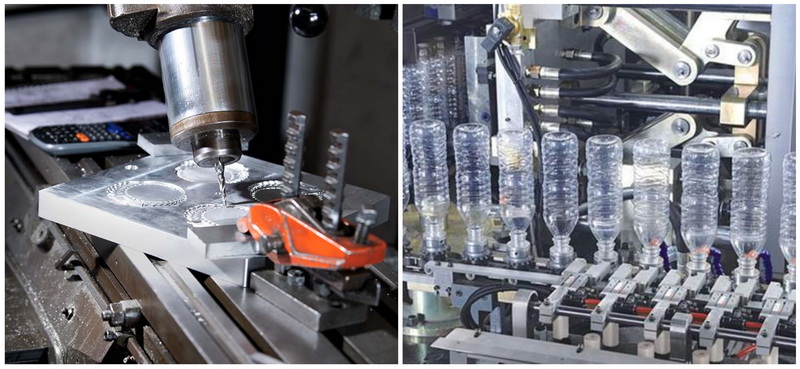

Moulding production is a foundational process in manufacturing that enables the creation of precise and complex parts in vast quantities. This method includes several primary categories such as:

- Injection Moulding: The most common industrial method, used for high-volume, precise plastic parts.

- Blow Moulding: Specializes in hollow parts like bottles.

- Compression Moulding: Often applied for thermo-set plastics and rubbers.

- Rotational Moulding: Useful for producing large, hollow products.

- Extrusion Moulding: Used for continuous profiles like pipes and tubing.

These processes are integral to the mass production of plastic, metal, and composite components used in virtually every modern product.

OEM (Original Equipment Manufacturer) services have become vital in the global supply chain. Top American moulding production manufacturers and suppliers frequently offer OEM packages, providing clients with:

- Custom design and prototyping

- Precision CNC machining for mould creation

- Small- to large-batch production

- Assembly and packaging solutions

- On-time worldwide delivery

American suppliers partner with international clients from a multitude of industries, designing bespoke production solutions to help brands realize innovative product ideas with maximum efficiency and scalability.

The Rodon Group, based in Pennsylvania, has been a major player since 1956. Specializing in high-volume, high-precision injection moulding, they operate over 125 automated presses. Their focus is on small plastic parts for industries like food, beverage, medical, and construction. With end-to-end solutions encompassing mould design, automated production, and packaging, their facility is ISO 9001:2015 certified. They are known for competitive pricing and the advantages of domestic manufacturing.

Founded in Ohio in 1986, GSH Industries is a pioneer in custom plastic injection moulding, extrusion, and prototype production. They operate 15 injection moulding machines ranging from 75 to 1,500 tons, capable of handling diverse project requirements. Clients benefit from comprehensive design assistance, advanced engineering support, and strict quality control.

Proto Labs, headquartered in Minnesota, is a global digital manufacturing leader. Founded in 1999, they combine rapid injection moulding, CNC machining, and 3D printing to accelerate product development cycles. Their expertise in rapid prototyping and low-volume production makes them a preferred choice for startups and established companies alike. Their large network of manufacturing partners adds flexibility and scale.

Located in Idaho and operating since 1980, Accurate Molded Plastics is recognized for its ability to produce technically intricate custom injection moulded parts. They emphasize customer service and offer in-house prototyping and project partnership throughout the product lifecycle. Their strong DFM (Design For Manufacturability) process ensures efficient, high-quality production for various sectors.

Based in Houston, Texas Injection Molding caters to a broad client base nationwide. They maintain 33 injection machines ranging from 55 to 1,350 tons and provide in-house tooling design, engineering consultancy, and ISO 9001:2015 certified quality control. Their customer-centric approach supports both small batch and mass production needs.

Specializing in the medical device and technical moulding sector, Springboard Manufacturing offers full-service injection moulding with cleanroom production capabilities. They apply lean manufacturing principles and conduct tight tolerance assemblies critical for the healthcare industry, making them a trusted OEM partner in demanding environments.

Established in Indiana and Tennessee since 1974, MANAR Inc. serves the automotive, aerospace, and industrial markets. Their offerings cover automotive moulding, rapid prototyping, contract manufacturing, and turnkey assembly solutions. They are praised for their versatility and expertise in handling complex, high-precision moulding projects.

Located in Illinois, D&M Plastics specializes in custom injection moulded parts for sensitive sectors such as medical, electronics, defense, and automotive. They uphold stringent quality standards backed by ISO 13485:2016 and ISO 9001:2015 certifications.

Kenmold in Kentucky provides injection moulding services across multiple industries including appliances, electronics, and consumer goods. They handle a variety of materials such as metal, ceramics, silicone, and plastics, with robust quality and process certifications like IATF 16949:2016.

Based in Florida, American Tool and Mold stands out in precision multi-cavity moulds, thin-wall and stack moulds, and technical mould engineering serving OEM contracts. Their focus on innovation and fast turnaround times makes them a critical partner in complex mould development.

PreciKam is known for precision CNC post-moulding, especially on complex industrial and technical projects requiring exacting standards. Their engineering-driven approach ensures superior quality for demanding customers.

Leading moulding manufacturers in America distinguish themselves through several key capabilities:

- Advanced engineering and design support: Utilizing CAD, simulation, and prototyping tools to optimize designs for moulding efficiency and product functionality.

- In-house tooling and mould making: This capability allows faster lead times and tighter quality control.

- Flexibility in production scale: Offering services that span from rapid prototyping and low-volume runs to high-volume precision manufacturing.

- Certified quality management: Adherence to various industry standards such as ISO 9001, ISO 13485 for medical applications, and IATF 16949 for automotive ensures consistent product quality.

- Comprehensive aftermarket services: Including assembly, packaging, inventory management, and logistics, ideal for OEM clients requiring turnkey solutions.

American moulding production manufacturers and suppliers serve a wide variety of sectors, including:

- Automotive: Interior and exterior parts, lighting, and components designed to meet rigorous performance standards.

- Medical Devices: Injection moulded housings, surgical instruments, and precision parts manufactured in cleanroom environments.

- Consumer Electronics: Housings, connectors, switches, and other plastic parts requiring exacting tolerances.

- Construction: Fittings, fixtures, and structural components fabricated for durability and ease of installation.

- Food and Beverage: Packaging solutions, dispensing components, and robust materials that meet hygiene standards.

- Aerospace and Defense: High-precision, mission-critical components made with specialized materials and manufacturing controls.

The integration of automation, robotics, and lean manufacturing techniques ensures these parts meet high standards at competitive costs while enabling scalability.

Choosing the right moulding production manufacturer or supplier in America requires careful consideration of multiple factors:

- Engineering and Design Support: Verify whether the supplier provides design for manufacturability advice and advanced simulation to optimize your part.

- Tooling and Prototype Capabilities: Access to in-house tooling and quick prototyping significantly reduces lead times.

- Quality Certifications: Look for adherence to ISO standards and industry-specific certifications appropriate for your application.

- Production Versatility: Ensure the company can support your required volume, whether for rapid prototyping or full-scale production.

- Communication and Support: Especially important for international OEMs, suppliers with strong communication channels and collaborative project management enhance success.

- Industry Experience and Reputation: Companies with proven track records in your sector often deliver better outcomes.

- Sustainability Practices: Consider suppliers adopting green manufacturing practices if sustainability is important to your brand.

The moulding industry in America is evolving rapidly with several key trends shaping its future:

- Automation and Smart Manufacturing: The integration of the Internet of Things (IoT), artificial intelligence (AI), and robotics enables real-time quality monitoring, predictive maintenance, and increased efficiency.

- Sustainable Materials and Practices: Progressive adoption of bioplastics, recycled resin materials, and energy-efficient production methods reduces environmental impact.

- Digital Transformation: Enhanced use of digital platforms for design, estimation, and rapid prototyping accelerates product development cycles.

- Globalized OEM Partnerships: American manufacturers are improving international logistics, remote monitoring, and virtual collaboration tools to better serve overseas clients.

- Customization and On-Demand Manufacturing: Shift toward small-batch customized production models enabled by modular tool design and flexible manufacturing systems.

America's moulding production manufacturers and suppliers are global leaders renowned for their quality, innovation, and comprehensive OEM services across a diverse range of industries. These companies combine cutting-edge technology, engineering expertise, and a focus on quality assurance to deliver exceptional products from rapid prototype to precision batch manufacturing. Partnering with the right American moulding supplier ensures businesses worldwide benefit from scalable production capabilities, superior product performance, and reliable supply chain support.

American suppliers offer a broad spectrum of processes including injection moulding, blow moulding, compression moulding, rotational moulding, and extrusion moulding. These processes accommodate plastics, metals, and advanced composites for an array of industrial and commercial applications.

ISO 9001:2015 is the most common quality management certification, while ISO 13485:2016 is essential for medical device manufacturers. The automotive industry often requires IATF 16949:2016 certification. These standards ensure rigorous quality control and compliance.

Yes, many American manufacturers specialize in OEM services and can handle orders ranging from rapid prototypes to large batch production runs. Their in-house tooling and engineering support provide flexibility and cost efficiency.

Top industries served include automotive, medical devices, consumer electronics, aerospace, defense, food and beverage, and construction, showcasing their diverse capabilities.

American moulding manufacturers employ advanced robotics, real-time monitoring, stringent quality management systems, and certified engineering processes. These practices ensure high precision and consistency across all products.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product