Views: 222 Author: Amanda Publish Time: 2025-12-14 Origin: Site

Content Menu

● Advantages of Metal CNC Machining in Vietnam

● Key Industries Served by Vietnamese CNC Suppliers

● Types of Metal CNC Machining Services Available

● Materials Processed by Vietnamese CNC Shops

● Quality Systems, Inspection, and Certifications

● Lead Times, Capacity, and Scalability

● How to Evaluate Metal CNC Machining Manufacturers and Suppliers in Vietnam

● Sourcing Strategy: Direct vs. Partner-Assisted

● Shangchen as an OEM Manufacturing Partner

● Technical Strengths of Shangchen

● OEM-Focused Services and Project Management

● Practical Tips for Working with Vietnamese CNC Suppliers

● FAQ

>> 1. How do I choose the right Metal CNC Machining Manufacturers and Suppliers in Vietnam?

>> 2. What materials can Vietnam Metal CNC Machining Manufacturers and Suppliers handle?

>> 4. How can Shangchen help if production is in Vietnam?

>> 5. What trends are shaping the future of Metal CNC Machining Manufacturers and Suppliers in Vietnam?

Metal CNC Machining Manufacturers and Suppliers in Vietnam are increasingly recognized as strategic partners for global brands, wholesalers, and OEMs that require precision components with competitive pricing and reliable quality. As global supply chains diversify, more buyers see Vietnam as an important pillar alongside traditional hubs, particularly for metal parts that require tight tolerances, stable quality systems, and scalable capacity.

Vietnam's growth as a destination for Metal CNC Machining Manufacturers and Suppliers is driven by a combination of cost advantages, improving technical capabilities, and a supportive industrial environment. The manufacturing workforce benefits from strong vocational and engineering education, creating a talent pool capable of operating modern CNC equipment and applying robust process controls. At the same time, industrial parks and export-oriented policies have encouraged foreign and local investments in machinery, automation, and quality assurance.

Another key factor is Vietnam's increasing role in “China+1” strategies. Many international companies want to reduce risk by adding additional sourcing locations while preserving the benefits of East and Southeast Asian manufacturing. Metal CNC Machining Manufacturers and Suppliers in Vietnam fit naturally into this approach, offering complementary capacity, reduced labor costs compared with some regions, and geographic proximity to existing Asian supply networks.

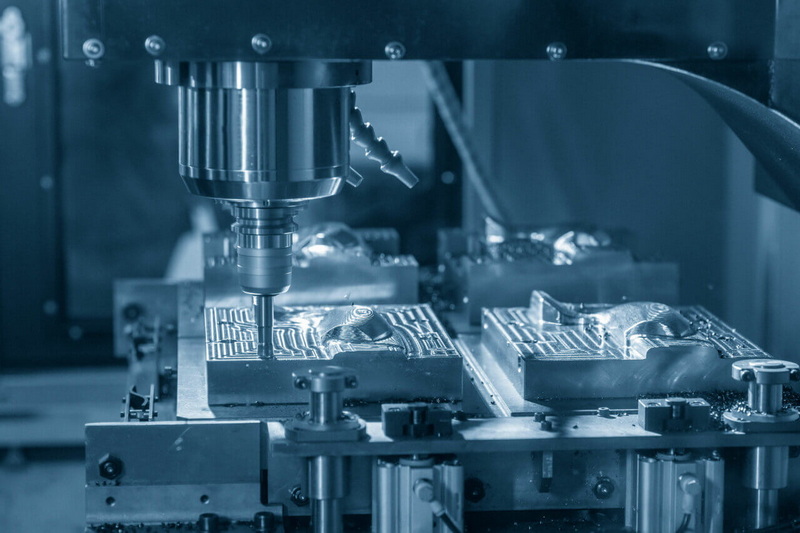

One of the main advantages of working with Metal CNC Machining Manufacturers and Suppliers in Vietnam is the combination of cost efficiency and quality. Labor costs and facility overheads tend to be lower than in many developed countries, and even compared with some more mature manufacturing hubs, which can translate into attractive unit prices and tooling costs. Yet, thanks to ongoing modernization, many factories operate 3-, 4-, and 5-axis CNC machining centers, CNC lathes, and advanced inspection equipment.

Another advantage lies in the growing ecosystem of supporting services. Vietnam's Metal CNC Machining Manufacturers and Suppliers often collaborate with local partners for casting, forging, heat treatment, surface coating, and packaging, which allows buyers to source not just individual machined parts but also more complete mechanical solutions. This integrated ecosystem supports smoother project execution, fewer logistics handoffs, and better coordination from raw material to finished, ready-to-assemble components.

Metal CNC Machining Manufacturers and Suppliers in Vietnam serve a diverse cross-section of industries, ranging from automotive and motorcycle parts to industrial machinery, electronics, home appliances, and renewable energy equipment. For the automotive and motorcycle sector, suppliers produce items such as brackets, hubs, housings, shafts, and other powertrain and chassis components that often require stable dimensional control and repeatable performance in high-volume runs.

Beyond transportation, Vietnam's CNC shops increasingly support industrial automation and robotics, providing precision parts for machinery frames, motion components, fixtures, and jigs. In consumer and industrial electronics, Metal CNC Machining Manufacturers and Suppliers deliver enclosures, heat sinks, and structural parts where thermal management and cosmetic appearance both matter. As Vietnam's role in global manufacturing expands, CNC machining capacity is also being leveraged for new energy, medical equipment, and other high-value applications.

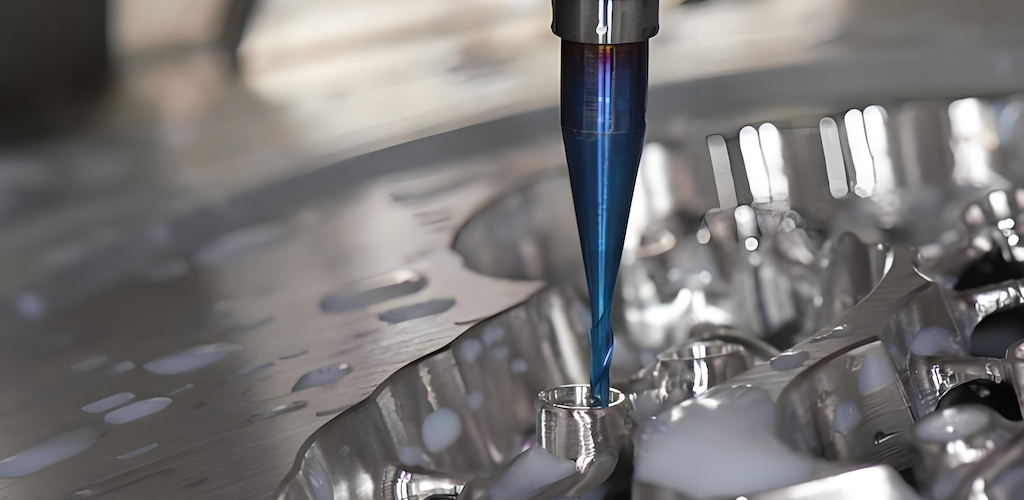

Metal CNC Machining Manufacturers and Suppliers in Vietnam typically offer a layered portfolio of services covering both simple and complex machining needs. At the core are CNC milling and CNC turning services, with 3-axis machining centers handling straightforward geometries and multi-axis machines used for complex shapes, undercuts, and demanding surface transitions. CNC turning capabilities range from simple shaft work to multi-tasking machines capable of drilling, tapping, and milling in one setup.

In addition to standard CNC milling and turning, many Vietnamese shops offer secondary and complementary processes. These may include drilling, tapping, boring, threading, broaching, grinding, and EDM for fine features and difficult materials. Some Metal CNC Machining Manufacturers and Suppliers integrate sheet metal fabrication, laser cutting, bending, and welding, enabling the production of both machined parts and fabricated assemblies under one roof. This combination is particularly attractive for buyers who want to consolidate suppliers and reduce project management complexity.

Metal CNC Machining Manufacturers and Suppliers in Vietnam work with a broad range of metals and engineering plastics. Common materials include aluminum alloys for lightweight structures, carbon steels for general mechanical applications, alloy steels for high-strength and wear-resistant parts, and stainless steels for corrosion-resistant and hygienic environments. These materials are widely used in sectors such as automotive, industrial equipment, and electronics.

For more demanding applications, some factories can machine high-performance alloys and harder metals that require advanced tooling management and careful process planning. Engineering plastics such as POM, nylon, PEEK, and ABS are also frequently machined for gears, insulators, housings, and prototypes. The ability of Vietnamese Metal CNC Machining Manufacturers and Suppliers to handle both metals and plastics lets buyers consolidate prototyping and production of mixed-material assemblies.

To compete globally, Metal CNC Machining Manufacturers and Suppliers in Vietnam have devoted significant resources to formal quality systems and inspection technology. Many factories operate under ISO 9001-based quality management, ensuring structured documentation, process control, and continuous improvement. For automotive and related sectors, some suppliers also hold additional certifications that align with industry-specific requirements.

On the inspection side, Vietnamese CNC shops increasingly deploy coordinate measuring machines (CMMs), optical measuring devices, height gauges, and specialized gauges to verify critical dimensions. Statistical process control, documented control plans, and incoming material inspection are often woven into standard operations for export-oriented suppliers. These practices help Metal CNC Machining Manufacturers and Suppliers maintain consistent quality across batches and over the full lifecycle of a project.

Lead times for Metal CNC Machining Manufacturers and Suppliers in Vietnam depend on part complexity, order quantity, and the maturity of the production process. Simple prototypes can sometimes be turned around within days or a few weeks, whereas complex assemblies and large batch orders require more planning. Many suppliers flex capacity by adding shifts, cross-training workers, and employing quick-change fixture systems to minimize setup times between jobs.

As Vietnam's manufacturing sector expands, more factories invest in additional CNC machines and partial automation, such as robotic loading, pallet systems, and tool management solutions. These investments enable Metal CNC Machining Manufacturers and Suppliers to scale from small runs to tens of thousands of units while maintaining stable lead times and quality performance. Buyers that share long-term forecasts and collaborate on capacity planning often benefit from more secure production slots and smoother delivery schedules.

Choosing the right Metal CNC Machining Manufacturers and Suppliers in Vietnam requires a structured evaluation process. Price is important, but should be considered alongside capabilities, quality systems, engineering support, communication, and export experience. Buyers should assess the supplier's machine list, process specialties, and experience with similar parts, especially when tight tolerances, complex geometries, or demanding materials are involved.

It is advisable to request detailed quotations that specify process routes, lead times, and quality control methods, as well as to analyze sample parts and inspection reports. For long-term programs, factory audits—either in person or virtually—help buyers understand the supplier's production organization, workforce stability, equipment maintenance practices, and future investment plans. By evaluating Metal CNC Machining Manufacturers and Suppliers in this comprehensive way, buyers can align expectations and reduce risk before launching mass production.

Overseas buyers typically choose between working directly with Vietnamese Metal CNC Machining Manufacturers and Suppliers or collaborating through an experienced manufacturing partner. Direct sourcing can be effective for buyers with strong engineering teams, localized support, and the capacity to manage multiple suppliers simultaneously. In such cases, buyers may build a small network of Vietnamese suppliers, each focused on specific families of parts.

However, many buyers prefer to partner with an OEM manufacturing specialist that already manages relationships with Metal CNC Machining Manufacturers and Suppliers across Asia. This approach reduces communication barriers, centralizes quality oversight, and offers a single point of contact for complex projects. A strong partner can coordinate prototyping, pilot runs, and serial production while providing guidance on manufacturability, cost optimization, and risk management.

Shangchen (SC-RapidManufacturing) is an example of a comprehensive OEM manufacturing provider that integrates rapid prototyping, metal CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold production. As a China-based factory with broad in-house capabilities, Shangchen serves overseas brand owners, wholesalers, and manufacturers that require end-to-end engineering and production support. By offering both prototype services and stable OEM production, Shangchen helps customers move smoothly from design to market.

For buyers interested in Vietnam's potential, a partner like Shangchen can act as a bridge to Metal CNC Machining Manufacturers and Suppliers in emerging hubs, while maintaining consistent quality standards and centralized project management. This allows customers to leverage cost and capacity advantages in Vietnam without needing to build and manage a large local supplier base. Shangchen coordinates cross-border production, integrates inspection data, and ensures that delivered parts meet agreed specifications and documentation requirements.

Shangchen's technical foundation lies in its advanced CNC machining centers and CNC turning equipment capable of handling a wide variety of metals and engineering plastics. Multi-axis machining enables the production of complex geometries, precision surfaces, and tight positional tolerances, which are essential in industries such as automotive components, industrial automation, and high-end consumer products. Coupled with in-house toolmaking and fixture design, Shangchen can efficiently support both one-off prototypes and stable recurring batches.

Beyond machining, Shangchen's scope includes sheet metal fabrication, welding, surface finishing coordination, and mold manufacturing for plastic and die-cast components. This breadth allows customers to combine machined parts with stamped, bent, or molded components in a single project. The result is a streamlined process where customers can receive complete mechanical assemblies or subassemblies, not just individual machined components from different Metal CNC Machining Manufacturers and Suppliers.

Shangchen positions itself as a solution-oriented OEM partner, emphasizing collaboration, transparency, and engineering support throughout the product lifecycle. Early in a project, the company can review 3D models and technical drawings to propose design-for-manufacturing improvements that lower cost, reduce machining time, or improve functional performance. This proactive engineering input is especially valuable when parts are complex or when they are intended for production with different Metal CNC Machining Manufacturers and Suppliers across regions.

During production, Shangchen manages scheduling, in-process quality checks, final inspection, and logistics, providing customers with clear communication and traceable documentation. Overseas buyers benefit from having a single point of contact that understands their quality expectations, technical language, and market timelines. This centralized project management supports smoother coordination between in-house manufacturing and external Metal CNC Machining Manufacturers and Suppliers, including those based in Vietnam.

To achieve the best outcomes when working with Metal CNC Machining Manufacturers and Suppliers in Vietnam, buyers should prepare clear and complete documentation. This includes 2D drawings with fully defined dimensions and tolerances, 3D models where relevant, material specifications, surface finish requirements, and any functional notes or standards that apply. The more precise the documentation, the more accurately suppliers can estimate costs, recommend process routes, and control quality.

It is also wise to start with smaller pilot orders to validate communication, production capability, and quality consistency before committing to large volumes. During this phase, feedback from both sides should be frequent and structured, covering technical points, packaging, labeling, and logistics. Over time, building long-term relationships with chosen Metal CNC Machining Manufacturers and Suppliers in Vietnam or through a partner like Shangchen helps stabilize supply, improve forecasting, and enable joint process optimization.

Metal CNC Machining Manufacturers and Suppliers in Vietnam have evolved into valuable partners for global buyers seeking high-quality, cost-effective precision parts and assemblies. The combination of competitive labor costs, growing technical capabilities, improving quality systems, and an expanding industrial ecosystem makes Vietnam a compelling destination for both prototypes and large-scale production. When combined with the support of an experienced OEM partner such as Shangchen, overseas brands and manufacturers can unlock the advantages of Vietnam's CNC industry while maintaining consistent quality, streamlined communication, and flexible, scalable supply.

Start by defining your technical requirements, expected volumes, quality standards, and target prices, then shortlist Metal CNC Machining Manufacturers and Suppliers that can demonstrate matching capabilities, appropriate machinery, and export experience. Request sample parts, inspection reports, and references, and consider factory audits or pilot orders to verify real performance before committing to long-term cooperation.

Most Metal CNC Machining Manufacturers and Suppliers in Vietnam are experienced with aluminum alloys, carbon steels, alloy steels, stainless steels, copper alloys, and engineering plastics such as POM, nylon, and ABS. Higher-end shops can also process more demanding materials and specialized alloys, provided that tooling, cutting parameters, and quality controls are carefully selected for the specific application.

Yes, many Metal CNC Machining Manufacturers and Suppliers operate sizeable fleets of CNC machines and can support high-volume production for automotive, motorcycle, and industrial components. By combining standardized fixtures, robust process controls, and, in some cases, automation, these suppliers are capable of delivering consistent quality and stable lead times for large and recurring orders.

Shangchen can act as an integrated OEM partner that coordinates both its own in-house manufacturing and selected Metal CNC Machining Manufacturers and Suppliers in Vietnam and other regions. Buyers benefit from a single project management and quality interface while still taking advantage of the cost and capacity benefits of Vietnamese production, making it easier to manage complex projects and long supply chains.

Key trends include increasing investment in automation and digitalization, expansion into high-value sectors such as medical devices and renewable energy equipment, and deeper integration into global supply chains as part of broader China+1 strategies. As technology adoption and quality systems continue to improve, Metal CNC Machining Manufacturers and Suppliers in Vietnam are expected to move further up the value chain and take on more complex, higher-precision work.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia