Views: 222 Author: Amanda Publish Time: 2025-12-15 Origin: Site

Content Menu

● Sweden as a CNC machining hub

● Key characteristics of Swedish suppliers

● Leading Swedish CNC machining brands

● Typical capabilities of Swedish CNC shops

● Quality, standards, and certifications

● Sustainability and Industry 4.0 initiatives

● Industries served by Swedish CNC machining

● Working with Swedish suppliers as an overseas buyer

● How Shangchen complements Swedish CNC machining

● Practical tips for selecting Metal CNC Machining Manufacturers and Suppliers

● FAQ

>> 1. What makes Swedish Metal CNC Machining Manufacturers and Suppliers unique?

>> 2. Which industries use Metal CNC Machining Manufacturers and Suppliers in Sweden the most?

>> 3. Can overseas buyers combine Swedish and Chinese CNC machining partners?

>> 4. What services does Shangchen offer in addition to CNC machining?

>> 5. How should buyers evaluate Metal CNC Machining Manufacturers and Suppliers in Sweden?

Sweden has a mature ecosystem of Metal CNC Machining Manufacturers and Suppliers serving automotive, aerospace, medical, energy, and general engineering customers across Europe and the world. For overseas buyers, working with reliable Metal CNC Machining Manufacturers and Suppliers in Sweden, combined with cost‑effective partners such as Shangchen (sc-rapidmanufacturing.com) in China, can create a robust and flexible supply chain for both prototypes and series production.

Sweden's manufacturing sector is highly advanced, with strong industrial clusters around Gothenburg, Stockholm, Jönköping, and several other engineering hubs that host many Metal CNC Machining Manufacturers and Suppliers. These regions offer access to skilled labor, research institutions, and established logistics networks, making Swedish CNC machining particularly attractive for European OEMs and Tier‑1 suppliers.

The country emphasizes precision engineering and Industry 4.0 automation, so Swedish Metal CNC Machining Manufacturers and Suppliers often run state‑of‑the‑art machining centers, robotics, and digital production systems. In addition, Swedish industrial policy places strong focus on sustainability and environmental performance, which pushes many local machining companies to optimize energy use, reduce waste, and document their environmental impact.

Metal CNC Machining Manufacturers and Suppliers in Sweden are widely recognized for combining technical competence with reliability and long‑term partnership thinking. Buyers that value predictable quality and responsive engineering support often choose Swedish CNC machining companies for high‑value, complex projects rather than purely price‑driven work.

Typical characteristics include:

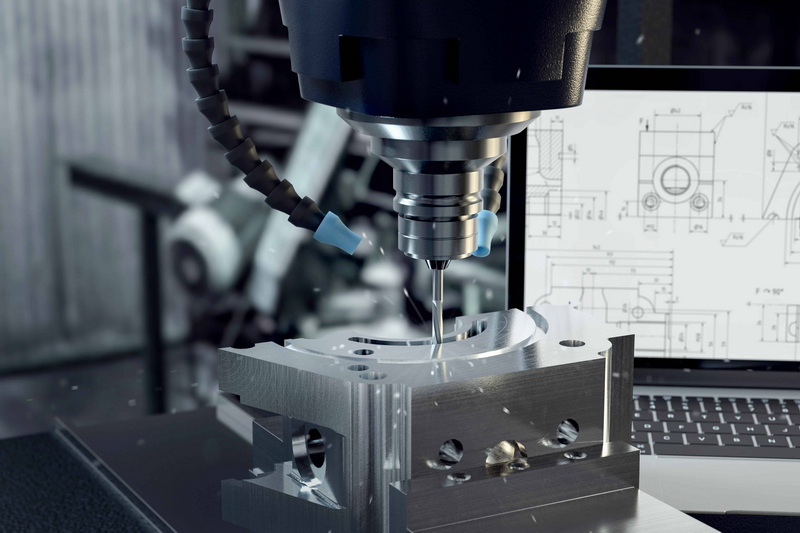

- Advanced automation and digitalization in CNC milling, turning, and drilling, with multi‑axis equipment and robotized handling.

- Strong engineering support, CAD/CAM integration, and design‑for‑manufacturing feedback right from the RFQ and prototyping phase.

- Emphasis on sustainable production, energy efficiency, and closed‑loop metal recycling in machining operations.

- Flexible small and medium‑sized enterprises capable of customized low‑ to medium‑volume runs with short lead times and high mix.

Several well‑known companies anchor the Swedish CNC machining and precision engineering landscape, ranging from global technology leaders to specialized Metal CNC Machining Manufacturers and Suppliers. These firms supply cutting tools, finished components, and turnkey machining solutions to customers in Europe, North America, and beyond.

Representative examples include global producers of cutting tools and machining solutions that support aerospace, automotive, and energy industries with high‑performance inserts and tool holders. In addition, there are Swedish CNC machining companies that focus on contract manufacturing of precision components in steel, aluminum, and non‑ferrous alloys, serving OEMs that require consistent quality and traceability. Many of these suppliers also provide value‑added services such as assembly, testing, and logistics coordination, making them strategic partners rather than simple job shops.

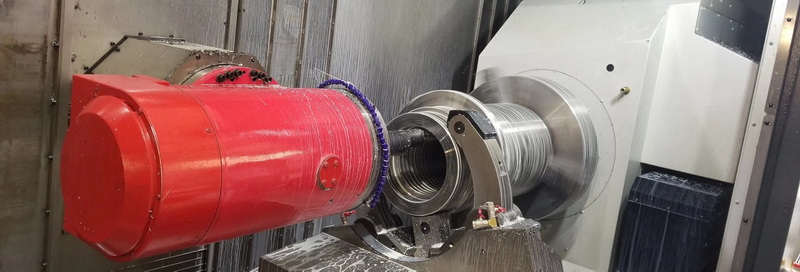

Metal CNC Machining Manufacturers and Suppliers in Sweden usually operate modern machine parks combining multi‑axis machining centers, CNC lathes, and specialized finishing equipment. This allows them to machine common metals such as steel, stainless steel, aluminum, brass, and copper, as well as more demanding alloys used in high‑temperature or corrosive environments.

Key capabilities typically include:

- CNC milling (3‑axis to 5‑axis) for complex geometries, precise surface finishes, and tight positional tolerances.

- CNC turning and turn‑mill operations for shafts, bushings, flanges, and other rotational components with both internal and external features.

- Drilling, tapping, and boring processes for deep holes, threaded features, and accurate bores in a wide variety of metals.

- Sheet metal fabrication, bending, and welding for chassis, enclosures, brackets, and structural elements that complement machined parts.

- Surface treatments, coatings, heat treatment coordination, and assembly to deliver components that are ready for direct use in customers' production lines.

Because Swedish Metal CNC Machining Manufacturers and Suppliers often target demanding applications, they tend to maintain a wide range of tooling, fixtures, and inspection equipment to cover different complexities and batch sizes. Many are used to handling prototype quantities, pilot runs, and serial production using the same process control standards.

The Swedish CNC machining sector is known for rigorous adherence to international quality standards. Metal CNC Machining Manufacturers and Suppliers in Sweden commonly operate under certified quality management systems and, for some industries, hold sector‑specific approvals related to automotive, aerospace, or medical regulations.

Quality is typically ensured through:

- Documented process control, traceability, and inspection procedures throughout the CNC machining workflow, from raw material incoming inspection to final shipment.

- Use of advanced measurement tools, such as coordinate measuring machines (CMM), optical measurement systems, and in‑process probing on machining centers.

- Structured risk assessments, control plans, and capability studies when qualifying new parts, especially for safety‑critical applications.

Beyond formal certificates, Swedish Metal CNC Machining Manufacturers and Suppliers often emphasize open communication with customers, rapid feedback on manufacturability issues, and continuous improvement programs. This culture of quality and transparency builds confidence for international OEMs that rely on stable long‑term sourcing.

Sustainability is not just a marketing phrase in Sweden; it is deeply embedded in how many Metal CNC Machining Manufacturers and Suppliers plan and run their production. Companies pay close attention to energy consumption, coolant usage, and metal scrap handling, often investing in high‑efficiency equipment and recycling systems.

At the same time, Industry 4.0 technologies are transforming the shop floor:

- Robotics and automation handle material loading and unloading, palletizing, and unattended night shifts, improving productivity and consistency.

- CAD/CAM and simulation tools optimize toolpaths, reduce machining time, and minimize tool wear, which directly improves cost and environmental performance.

- Real‑time monitoring and data analytics track machine utilization, process stability, and quality trends, supporting predictive maintenance and fast problem resolution.

These initiatives position Swedish Metal CNC Machining Manufacturers and Suppliers as forward‑looking partners for customers that prioritize both performance and sustainability in their supply chains.

Metal CNC Machining Manufacturers and Suppliers in Sweden support a diverse mix of industries, which helps them maintain technical breadth and financial stability. Automotive and heavy‑vehicle manufacturers rely on Swedish CNC shops for engine parts, drivetrain components, structural brackets, and custom fixtures used in assembly.

Aerospace and defense companies source high‑precision components in aluminum and specialty alloys, often requiring strict documentation and traceability standards. Medical technology and life‑science companies purchase housings, surgical instruments, and complex machined parts with tight cleanliness and surface requirements. Energy, electronics, and general industrial customers add further diversity, ordering everything from heat‑sink housings and power‑train parts to custom tooling and test fixtures.

Because of this broad industrial base, many Swedish Metal CNC Machining Manufacturers and Suppliers are comfortable meeting a variety of standards, tolerance ranges, and inspection requirements. This flexibility benefits international buyers who need a single supplier capable of handling different product lines and technical demands.

For international OEMs, brand owners, and wholesalers, Sweden's Metal CNC Machining Manufacturers and Suppliers offer a compelling mix of high quality, technical expertise, and reliable delivery. However, due to higher labor and overhead costs, unit prices can be higher than in some Asian markets, especially for labor‑intensive operations or very large volumes.

As a result, many global buyers adopt a balanced strategy:

- Use Swedish Metal CNC Machining Manufacturers and Suppliers for high‑complexity, safety‑critical, or design‑sensitive parts where close engineering collaboration and quick communication with European teams are essential.

- Combine Swedish partners with cost‑competitive overseas suppliers for volume production of simpler components or for projects where cost pressure is particularly intense.

- Leverage Swedish suppliers for early prototypes, testing fixtures, and pilot runs before ramping up mass production in another region.

A well‑structured RFQ process is crucial when dealing with Swedish CNC machining companies. Buyers should provide complete 3D models, 2D drawings with tolerances, material specifications, surface and heat treatment requirements, and anticipated volumes. Clear documentation enables Metal CNC Machining Manufacturers and Suppliers in Sweden to respond with accurate quotations, feasible lead times, and manufacturability feedback.

Shangchen (sc‑rapidmanufacturing.com) in China is a professional factory providing rapid prototyping, CNC machining services, precision batch production, lathe turning, sheet metal fabrication, 3D printing services, and mold manufacturing for overseas customers. As a flexible contract manufacturer, Shangchen focuses on OEM work for foreign brand owners, wholesalers, and manufacturers that need reliable partners for both small batches and mass production.

Shangchen's core strengths include:

- High‑precision CNC machining for metal and plastic components, from one‑off prototypes to tens of thousands of pieces, using a wide selection of materials and surface treatments.

- Integrated rapid manufacturing services, including 3D printing, vacuum casting, injection molding, and sheet metal processing, allowing customers to move from concept to production with a single supplier.

- Experience supporting global projects in automotive parts, consumer electronics, industrial equipment, and medical‑related products, while offering competitive pricing and flexible lead times.

For European and North American OEMs already working with Swedish Metal CNC Machining Manufacturers and Suppliers, Shangchen can act as a complementary partner. Critical components or those requiring close physical proximity to design teams can remain with Swedish suppliers, while cost‑sensitive or labor‑intensive parts move to Shangchen for CNC machining or other processes. This dual‑sourcing strategy combines the strengths of Sweden's advanced engineering with China's cost‑effective manufacturing capacity.

When evaluating Metal CNC Machining Manufacturers and Suppliers in Sweden and abroad, buyers should look beyond headline price and consider the total value offered. A structured approach makes it easier to identify the right mix of Swedish and overseas partners for each project.

Key evaluation points:

- Technical capability: Check machine types, axis counts, materials handled, and experience with similar parts. Metal CNC Machining Manufacturers and Suppliers that already serve your industry are more likely to understand your standards and expectations.

- Quality and certifications: Review certificates, inspection equipment, sample reports, and process documents. Ask how they manage traceability and handle non‑conformities.

- Engineering support: Determine whether the supplier can provide design‑for‑manufacturing suggestions, tolerance optimization, and early involvement in new product development.

- Communication and project management: Assess responsiveness, language skills, and the clarity of their documentation and reporting. Effective communication is especially critical when working across time zones.

- Cost, lead time, and logistics: Consider not only piece price but also shipping costs, customs duties, inventory needs, and the supplier's ability to handle urgent orders or design changes.

By applying these criteria consistently, buyers can build a portfolio of Metal CNC Machining Manufacturers and Suppliers that includes both Swedish and Chinese partners, optimizing for quality, cost, and risk across their entire product range.

Sweden offers a dense network of Metal CNC Machining Manufacturers and Suppliers known for precision, innovation, and sustainable production, making them reliable partners for high‑value components and demanding industries. For international OEMs, integrating Swedish CNC machining capabilities with complementary services from Chinese providers like Shangchen enables rapid prototyping, scalable production, and a resilient, cost‑effective global sourcing strategy that covers everything from custom prototypes to mass‑produced metal parts.

Swedish Metal CNC Machining Manufacturers and Suppliers stand out because they combine advanced automation, strong engineering skills, and a deep commitment to sustainability. Many operate in well‑developed industrial clusters supported by universities and research organizations, which promotes continuous innovation in machining processes and digital manufacturing.

The main industries working with Metal CNC Machining Manufacturers and Suppliers in Sweden include automotive and heavy vehicles, aerospace and defense, medical technology, energy systems, and high‑end industrial equipment. These sectors rely on Swedish CNC machining companies for safety‑critical, precision‑machined metal components that must meet strict quality and documentation requirements.

Yes, many international OEMs successfully combine Swedish Metal CNC Machining Manufacturers and Suppliers with Chinese CNC machining partners to balance quality and cost. A common strategy is to use Swedish suppliers for complex or design‑sensitive components while relying on Chinese manufacturers such as Shangchen for cost‑driven volume production and rapid prototyping support.

Besides CNC machining for metals and plastics, Shangchen offers rapid prototyping, 3D printing, vacuum casting, injection molding, sheet metal fabrication, and mold design and manufacturing. This full‑process capability allows customers to complete product development—from concept models to functional prototypes and final production tools—within one integrated manufacturing partner.

Buyers should evaluate Swedish Metal CNC Machining Manufacturers and Suppliers by reviewing their technical capabilities, certifications, and sample work, as well as by checking communication efficiency and responsiveness during the RFQ phase. It is also essential to confirm their experience in the relevant industry, their ability to work with the required materials and volumes, and their willingness to engage in long‑term partnerships that include continuous improvement and cost‑optimization discussions.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia