Views: 222 Author: Amanda Publish Time: 2025-12-13 Origin: Site

Content Menu

● Overview of Spain's CNC Machining Market

● What Metal CNC Machining Involves

● Key Spanish CNC Companies to Know

● Why Spain Is Attractive for OEMs

● Role of Global Partners Like Shangchen

● Typical Services from Spanish Metal CNC Suppliers

● Materials Used by Spanish Metal CNC Shops

● Processes and Technologies in Focus

● How to Select a Spanish CNC Partner

● Combining Spanish and Chinese Supply Chains

● Representative Companies and Focus Areas

● How Shangchen Supports Spanish‑Focused Projects

● FAQ

>> 1. How big is the CNC machining market in Spain?

>> 2. Which industries rely most on Spanish Metal CNC Machining Manufacturers and Suppliers?

>> 3. What advantages does Shangchen offer compared with local Spanish suppliers?

>> 4. How should OEMs split work between Spain and China?

>> 5. What certifications should be requested from Metal CNC Machining Manufacturers and Suppliers?

Spain has become one of the most dynamic hubs for Metal CNC Machining Manufacturers and Suppliers in Europe, driven by strong automotive, aerospace, energy, and industrial equipment sectors. For overseas brands, wholesalers, and OEM producers, working with Spanish partners while leveraging global OEM factories such as Shangchen (sc-rapidmanufacturing.com) in China creates a powerful, flexible, and cost‑effective supply chain.[1][2][3][4][5]

Spain's CNC machining and machine tool ecosystem is valued in the multi‑billion‑euro range and continues to grow with steady investment in advanced manufacturing and automation. Metal CNC Machining Manufacturers and Suppliers in Spain adopt Industry 4.0 principles such as digital monitoring, robotics, and data‑driven process optimization to stay competitive on a global scale.[2][6][7][1]

The strongest clusters of Metal CNC Machining Manufacturers and Suppliers are located in the Basque Country, Catalonia, Valencia, and the Madrid area, where industrial infrastructure and engineering universities are concentrated. These regions combine high‑end machine tools with skilled operators, making them ideal for precision, export‑oriented projects.[1][2]

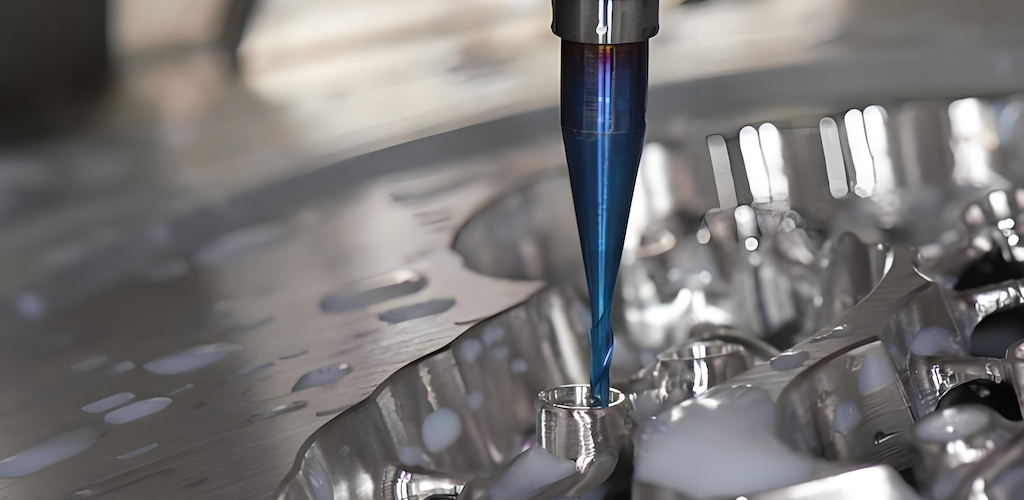

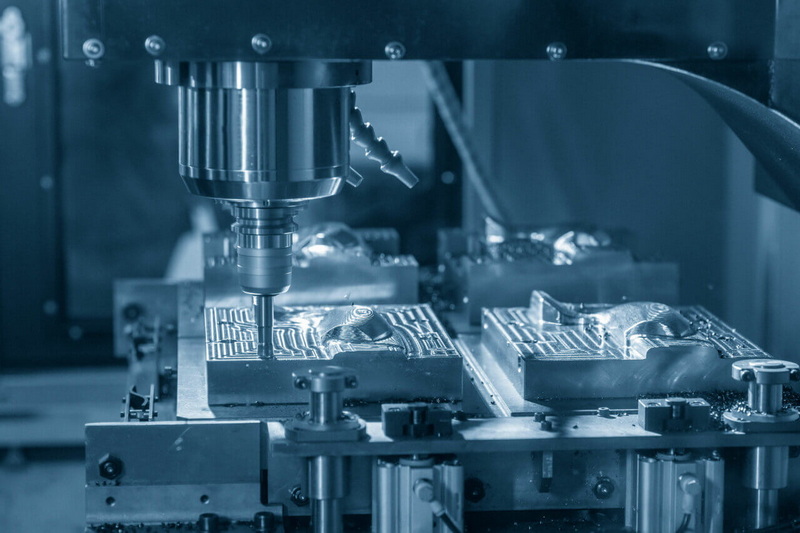

Metal CNC machining is a subtractive manufacturing method that uses computer‑controlled tools to cut, drill, mill, and turn metal workpieces into finished parts. The leading Metal CNC Machining Manufacturers and Suppliers in Spain integrate multiple processes—such as milling, turning, drilling, grinding, and finishing—to provide complete solutions from raw material to ready‑to‑assemble components.[8][9][10]

For OEM customers, the most common CNC services include:

- High‑precision CNC milling for prismatic components, molds, and complex cavities.

- CNC turning and Swiss‑type turning for shafts, bushings, pins, and precision cylindrical parts.

- Five‑axis and multi‑axis machining for aerospace, medical, and high‑value industrial components that require intricate geometry and tight tolerances.

- Secondary operations such as tapping, threading, broaching, welding, and assembly to deliver fully finished parts.

By partnering with experienced Metal CNC Machining Manufacturers and Suppliers, OEMs can move quickly from drawing to functional prototypes and serial production.

Spain is home to a wide range of Metal CNC Machining Manufacturers and Suppliers, from small specialized workshops to large industrial groups. Some of the most notable players often appearing on sourcing shortlists include:[11][1]

- Danobat Group – A leading Basque machine tool and engineering company that provides advanced CNC grinding, turning, and automated production systems for railway, aerospace, and heavy industries.[1]

- IBARMIA (Industrias Puigjaner) – Known for high‑performance machining centers and multi‑tasking milling solutions, widely used by demanding energy and industrial equipment customers.[1]

- Santander Global Metal – Focused on heavy machining of large, complex metal parts and structures, supporting energy, construction, and industrial machinery sectors.[8]

- MIPESA – Offers CNC machining services for serial manufacturing, handling small to large batches in various metals for industrial infrastructure and equipment.[9]

- Talleres Maf – Combines CNC machining with casting, stamping, and welding capabilities to deliver complete metal component solutions.[10]

- Assomec – A CNC machining center in Castellón specializing in steels, stainless steels, and aluminum components for industrial machinery and general engineering.[12]

These companies illustrate the diversity of Metal CNC Machining Manufacturers and Suppliers in Spain—ranging from high‑precision, small‑part specialists to heavy‑duty, large‑part machining experts.

There are several reasons why OEM brands and wholesalers choose Metal CNC Machining Manufacturers and Suppliers in Spain as strategic partners. The country combines technical excellence with geographic and regulatory advantages that are particularly important for European and transatlantic supply chains.[6][13][2][8]

Key benefits include:

- Compliance with European standards: Spanish suppliers operate under EU regulations and often hold certifications like ISO 9001 and sector‑specific approvals, which simplifies qualification for European projects.[2][8]

- Excellent logistics: Spain's ports, roads, and rail systems connect smoothly with the rest of Europe, North Africa, and the Americas, reducing transit times and logistics risk.[6][2]

- Industrial ecosystem: A mature network of Metal CNC Machining Manufacturers and Suppliers, surface treatment shops, foundries, and material distributors supports complex projects from prototype to series production.[11][1]

For overseas OEMs, these factors translate into shorter lead times, more predictable quality, and easier supplier management.

While Spanish suppliers are excellent for regional and high‑spec projects, many OEMs also integrate global partners, particularly in Asia, to optimize total cost and capacity. Shangchen, based in China, positions itself as a one‑stop OEM factory offering rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production for overseas customers.[3][4][5][2][6]

Shangchen's value for Metal CNC Machining Manufacturers and Suppliers and OEM buyers includes:

- Comprehensive process coverage: CNC milling, turning, 3D printing, sheet metal, plastic injection molding, and mold building under one roof help compress project timelines and reduce coordination complexity.[4][14][3]

- OEM‑oriented service: The company is structured to work directly with foreign brands, wholesalers, and manufacturers, supporting NDA projects, small batches, and continuous mass production.[5][3]

- Cost competitiveness and scalability: Labor cost advantages and a mature supply base allow Shangchen to deliver cost‑effective parts while absorbing large‑volume orders when the product enters growth or maturity stages.[14][4]

By combining Spanish Metal CNC Machining Manufacturers and Suppliers with Shangchen, OEMs can place time‑critical or EU‑regulated components in Spain and allocate cost‑sensitive or high‑volume parts to China.

Most Spanish Metal CNC Machining Manufacturers and Suppliers offer similar core services, but they differentiate themselves through part size, complexity, industry focus, and value‑added operations. Understanding these differences allows OEMs to build a portfolio of suppliers tailored to their project mix.[9][1]

Common service categories include:

- Prototype and small‑batch machining: Rapid production of prototypes and pilot series to validate design, function, and manufacturability.[15][9]

- Medium and large‑series production: Automated or semi‑automated CNC lines for recurring orders, especially for automotive, machinery, and energy components.[8][9]

- Machining of castings and forgings: Integration with foundries and forging shops to deliver machined castings and forged parts with full traceability.[10][12]

- Finishing and assembly: Some suppliers provide anodizing, painting, plating, and simple mechanical assembly to deliver ready‑to‑install units.[10][8]

These capabilities make Spanish Metal CNC Machining Manufacturers and Suppliers suitable for both stand‑alone parts and subassemblies.

Metal CNC Machining Manufacturers and Suppliers in Spain work with a broad portfolio of metals to support their diversified client base. This range also aligns well with what Chinese OEM partners like Shangchen can process, which simplifies cross‑regional standardization.[4][12][14][8]

Frequently used materials include:

- Carbon and alloy steels for structural, powertrain, and machine components where strength and durability are critical.[12][8]

- Stainless steels for food processing equipment, medical devices, and chemical plant components that require corrosion resistance.[12][8]

- Aluminum alloys for lightweight automotive, aerospace, and electronics housings that demand a good strength‑to‑weight ratio.[12][1]

- Copper, brass, and bronze for fittings, fluid handling parts, and precision mechanical elements.[10][12]

By standardizing material grades and specifications across Metal CNC Machining Manufacturers and Suppliers in Spain and China, OEMs can ensure interchangeability and smooth dual sourcing.

Spanish Metal CNC Machining Manufacturers and Suppliers increasingly invest in advanced technologies to meet modern quality and productivity requirements. These technologies enhance accuracy, reduce scrap, and shorten lead times.[11][1]

Key process and technology elements include:

- Multi‑axis CNC machining: Five‑axis and multi‑tasking machines allow complex parts to be produced in fewer setups, improving accuracy and throughput.[11][1]

- High‑speed machining and tooling: Optimized toolpaths and modern cutting tools enable faster machining of hardened steels and aluminum without compromising surface finish.[16][8]

- In‑process measurement and inspection: Probing systems, coordinate measuring machines, and statistical process control help maintain tight tolerances over long production runs.[9][8]

- Digital production management: Many shops use ERP/MES systems and real‑time monitoring dashboards to track jobs, machine utilization, and quality metrics.[7][1]

These investments position Spanish Metal CNC Machining Manufacturers and Suppliers as reliable partners for high‑value components.

Selecting the right Metal CNC Machining Manufacturers and Suppliers in Spain requires a structured approach that considers technical capability, quality systems, communication, and long‑term alignment. Overseas OEMs benefit from combining desktop audits with trial orders and occasional on‑site visits.[2][1]

A practical selection checklist:

- Certifications and quality systems: Verify ISO 9001 for general quality management and EN 9100 or similar standards for aerospace or critical sectors.[2][8]

- Technical fit: Review machine list, maximum and minimum part sizes, supported materials, and tolerance capabilities to match the specific project.[9][1]

- Inspection and documentation: Confirm that the supplier can provide inspection reports, material certificates, and traceability documents as required.[8][10]

- Communication and project management: Evaluate language skills, responsiveness, and willingness to support design for manufacturing (DFM) discussions.[7][2]

- Cost and lead time comparison: Compare offers from Spanish Metal CNC Machining Manufacturers and Suppliers and global partners like Shangchen to determine the best allocation by part family.[3][4]

By following this process, OEMs can build a robust and diversified supplier base.

Modern OEMs increasingly adopt multi‑regional sourcing strategies to balance cost, lead time, risk, and regulatory constraints. In the context of Metal CNC machining, Spain and China often play complementary roles.[6][2]

A common model involves:

- Rapid prototyping and early testing with Shangchen, using CNC machining, 3D printing, and soft tooling to validate designs before committing to expensive hard tooling.[3][4]

- Pre‑series and pilot production split between Spanish Metal CNC Machining Manufacturers and Suppliers and Shangchen to compare performance, quality, and logistics efficiency.[1][2]

- Serial production allocation based on demand patterns, tariff exposure, and service requirements, with high‑mix, low‑volume or urgent parts often produced in Spain and cost‑sensitive, high‑volume components manufactured in China.[3][2]

This dual‑sourcing strategy improves resilience and ensures that OEMs can adapt quickly to demand spikes or regional disruptions.

The following summary shows how selected Metal CNC Machining Manufacturers and Suppliers—and one key global partner—position themselves in the market.

Company / Partner | Location / Region | Main Focus in Metal CNC Machining | Typical Industries |

Danobat Group | Basque Country, Spain | Advanced CNC grinding, turning, automated lines | Railway, aerospace, heavy industry |

IBARMIA | Basque Country, Spain | Machining centers, multi tasking milling | Energy, automotive, industrial equipment |

Santander Global Metal | Spain | Heavy machining of large metal parts | Energy, construction, industrial machinery |

MIPESA | Spain | CNC machining services, serial manufacturing | Industrial infrastructure, machinery |

Talleres Maf | Spain | CNC machining, casting, stamping, welding | General mechanical, hardware, metal products |

Assomec | Castellón, Spain | CNC machining in steels, stainless, aluminum | Industrial components, machinery |

Shangchen | Dongguan, China | OEM CNC machining, sheet metal, 3D printing, molds | Automotive, aerospace, medical, electronics |

This mix helps OEM brands design sourcing strategies that exploit the specific strengths of each group of Metal CNC Machining Manufacturers and Suppliers.

For projects targeted at European customers but requiring flexible cost structures, Shangchen can serve as an extension of the Spanish supply base rather than a competitor. The factory's OEM service model and multi‑process capabilities make it extremely suitable for long‑term cooperation with international buyers.[14][4][2][3]

Key support modes include:

- Early‑stage design support: Engineers can provide DFM feedback, suggest material alternatives, and propose machining strategies to reduce unit cost without compromising function.[4][3]

- Bridge production: When local Metal CNC Machining Manufacturers and Suppliers reach capacity, Shangchen can handle overflow orders to avoid delivery delays.[5][3]

- Lifecycle coverage: From prototype and low‑volume runs to high‑volume mass production and after‑sales spare parts, Shangchen offers consistent quality and repeatability.[14][4]

Working with both Spanish and Chinese partners thus gives OEMs a flexible, long‑term framework for product development and manufacturing.

Metal CNC Machining Manufacturers and Suppliers in Spain form a technologically advanced, export‑oriented ecosystem that supports some of Europe's most demanding industries. By partnering with these Spanish companies and complementing them with global OEM factories such as Shangchen in China, overseas brands, wholesalers, and manufacturers can access rapid prototyping, precision machining, and scalable mass production within a single integrated supply network. A thoughtful supplier strategy—combining rigorous selection, dual sourcing, and clear technical standards—allows OEMs to capture the best of both worlds: the regional proximity and regulatory alignment of Spain, and the cost efficiency and capacity of China's manufacturing base.[5][4][6][2][3][1]

Spain's CNC machining and related machine tool market is estimated in the multi‑billion‑euro range, with incremental growth over the coming years. The expansion is supported by strong demand from automotive, aerospace, and general industrial customers, as well as national and EU initiatives promoting digitalized manufacturing.[13][6][2]

The largest demand comes from automotive, aerospace, machinery, energy, and medical device sectors that require precise and reliable metal components. In addition, many Metal CNC Machining Manufacturers and Suppliers in Spain also serve general engineering, construction equipment, food processing, and industrial hardware applications.[2][8][10][1]

Shangchen provides highly competitive pricing, broad process coverage, and the ability to scale quickly from prototype to high‑volume production. While Spanish Metal CNC Machining Manufacturers and Suppliers offer geographic proximity and EU compliance, Shangchen helps OEMs lower overall cost, shorten development cycles, and secure backup capacity for global demand.[4][14][3][2]

Many OEMs allocate time‑critical, service‑sensitive, or heavily regulated parts to Spanish Metal CNC Machining Manufacturers and Suppliers, especially for European end‑customers. Cost‑sensitive, high‑volume, or globally distributed products are often produced in China by partners such as Shangchen, with harmonized drawings and material specifications to ensure interchangeability.[6][3][4][2]

For most industrial projects, ISO 9001 is a minimum requirement to ensure basic quality management systems are in place. Aerospace or safety‑critical products may need EN 9100 or similar sector‑specific certifications, while environmental and sustainability‑focused OEMs increasingly request ISO 14001 and detailed traceability documentation from their Metal CNC Machining Manufacturers and Suppliers.[4][8][2]

[1](https://sinoextrud.com/cnc-machining-spain/)

[2](https://beausino.com/cnc-machining-spain/)

[3](https://www.sc-rapidmanufacturing.com/cnc-machining.html)

[4](https://shangchencnc.en.made-in-china.com/product/BFbGmPgEJNrf/China-Rapid-Plastic-Prototyping-Services-with-3D-Printing-and-CNC-Machining-China-Manufacturer.html)

[5](https://www.sc-rapidmanufacturing.com)

[6](https://www.linkedin.com/pulse/spain-cnc-machining-center-market-size-2026-cagr-vgh2c)

[7](https://www.sigmatechnik.com/cnc-factory/navigating-the-landscape-of-spains-cnc-machine-manufacturers)

[8](https://santanderglobalmetal.com/en/machining-types-spain/)

[9](https://www.mipesa.es/en/cnc-machining-services/)

[10](https://talleresmaf.com/en/home/)

[11](https://ensun.io/search/cnc-milling/spain)

[12](https://assomec.com/en/)

[13](https://www.nextmsc.com/report/spain-cnc-drilling-machine-market)

[14](https://shangchencnc.en.made-in-china.com/product/yQNYcMFxreWk/China-Rapid-CNC-Machining-Services-for-Custom-Metal-and-Plastic-Parts-China-Factory.html)

[15](http://www.metalcheck-cnc.com/en/company/)

[16](https://rierge.com/en/)

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia