Views: 222 Author: Amanda Publish Time: 2025-12-13 Origin: Site

Content Menu

● Russia's CNC Machining Landscape

● Representative Metal CNC Machining Manufacturers and Suppliers in Russia

>> JSC Sasta

>> Mehatronika LLC and CNC Control Systems

>> POLITEK Engineering Company

>> STP Perm Factory Metal Centers

>> Broader Network of Metal CNC Machining Manufacturers and Suppliers

● Capabilities Offered by Russian Metal CNC Machining Manufacturers and Suppliers

>> Core CNC Machining Processes

>> Secondary and Value‑Added Processes

● Advantages of Choosing Russian Metal CNC Machining Manufacturers and Suppliers

>> Engineering Experience and Sector Knowledge

>> Advanced Machinery and Local CNC Development

>> Cost and Logistics Considerations

● Shangchen as a Global OEM Partner

>> Complementing Russian Suppliers

● From Prototype to Mass Production

>> Scaling to Regular Production

● How to Evaluate Metal CNC Machining Manufacturers and Suppliers in Russia

>> Technical and Quality Evaluation

>> Communication and Project Management

● FAQs

>> 1. What industries do Russian Metal CNC Machining Manufacturers and Suppliers mainly serve?

>> 3. What materials can Metal CNC Machining Manufacturers and Suppliers in Russia typically process?

Russia is an important hub for precision metalworking, with a diverse base of Metal CNC Machining Manufacturers and Suppliers serving aerospace, automotive, energy, defense, and general industrial markets across Europe and Asia. Metal CNC Machiningcompanies in Russia increasingly combine advanced machine tools, domestic CNC systems, and skilled engineers to deliver complex metal parts with tight tolerances and repeatable quality.[1][2]

At the same time, many global buyers cooperate with specialized Chinese OEM partners such as Shangchen (sc-rapidmanufacturing.com) to complement Russian capacity with flexible prototyping and cost‑effective volume production. This blended sourcing model gives brands, wholesalers, and manufacturers access to a broader pool of Metal CNC Machining Manufacturers and Suppliers while optimizing cost, risk, and lead time.[3][4][5]

Russia's CNC machining landscape has developed from a strong legacy in heavy engineering, machine tools, and aerospace manufacturing. Metal CNC Machining Manufacturers and Suppliers now operate in clusters around major industrial cities, where access to engineering universities and large industrial customers supports ongoing innovation.[6][1]

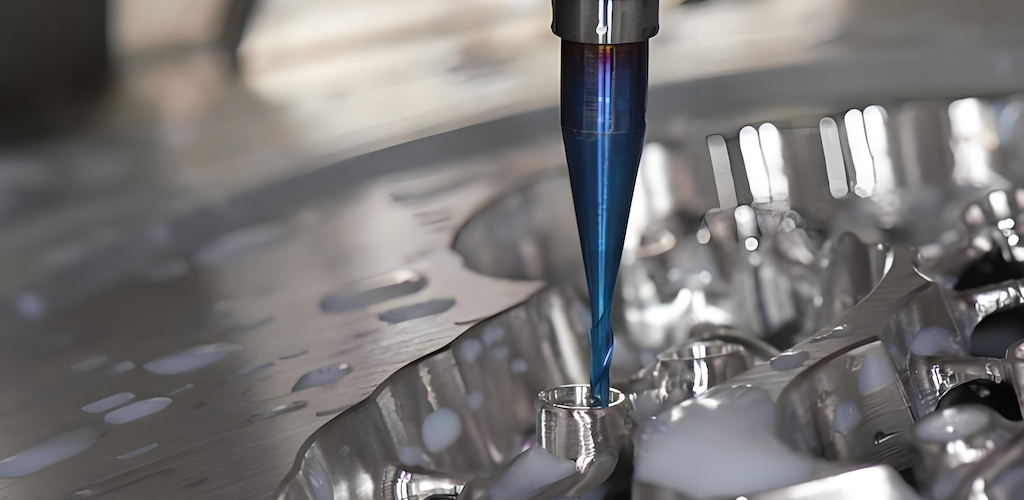

These companies run 3‑axis, 4‑axis, and 5‑axis machining centers, CNC turning lathes, and drilling machines to produce parts such as housings, shafts, flanges, manifolds, gear components, and structural brackets. Many shops integrate CAD/CAM software, automated tool changers, and in‑process measurement to ensure that Metal CNC Machining Manufacturers and Suppliers can meet international standards for dimensional accuracy and surface finish.[7][1]

Although Russia has many machining companies, several organizations stand out for their impact on the ecosystem of Metal CNC Machining Manufacturers and Suppliers.

JSC “Sasta” is a major Russian machine‑tool plant that designs and manufactures metalworking machines used by numerous Metal CNC Machining Manufacturers and Suppliers across the country. Its product range includes conventional and CNC horizontal lathes, turning and milling machining centers, and special-purpose metal cutting machines.[8]

By providing robust, high‑precision equipment, Sasta plays a strategic role in supporting Russian machining shops that produce critical metal components for heavy machinery, energy equipment, and industrial projects. Investments in modernization, casting facilities, and R&D help Sasta maintain machine accuracy and reliability in demanding production environments.[8]

Mehatronika LLC develops digital CNC control systems that power many Russian metal cutting machines and machining centers. Its controllers integrate trajectory planning, servo drive management, PLC logic, and user interfaces into a single platform suitable for multi-axis metal machining.[9]

Because high‑performance controllers directly affect accuracy, cycle times, and reliability, Mehatronika's products are important to the competitiveness of Metal CNC Machining Manufacturers and Suppliers in Russia. The company showcases its CNC systems on 4‑axis and 5‑axis machines at industrial exhibitions, supporting complex aerospace, mold, and energy components.[1][9]

POLITEK focuses on engineering and modernization projects for metalworking plants, including machining workshops that want to upgrade to advanced CNC technology. Its services range from coolant cleaning systems and thermal spray equipment to welding automation and integrated production lines.[10]

By analyzing customer processes, POLITEK redesigns shop layouts, selects appropriate CNC machines, and implements automation that improves throughput and stability. This helps Metal CNC Machining Manufacturers and Suppliers achieve higher productivity, better chip management, and more consistent machining conditions for complex metal parts.[10]

STP “Perm Factory Metal Centers” produces modern machining centers for milling and turning operations. These machines support Russian Metal CNC Machining Manufacturers and Suppliers in transitioning from conventional equipment to flexible CNC machining lines.[11]

With capabilities for precision milling, drilling, and turning, these centers help users handle a variety of metal workpieces in industries such as energy, engineering, and industrial equipment. Their integration into Russian workshops increases automation and allows more stable production of large and medium‑sized metal components.[11]

Alongside these firms, Russia hosts many regional machining shops, toolmakers, and integrators that form the backbone of its CNC ecosystem. These Metal CNC Machining Manufacturers and Suppliers supply customized metal parts, jigs and fixtures, and maintenance services to local plants in mining, power, transportation, and construction machinery.[7][1]

Additionally, national initiatives to expand domestic machine‑tool production and reduce import dependence indirectly strengthen Metal CNC Machining Manufacturers and Suppliers by increasing access to locally produced CNC machines and spare parts. This policy environment supports long‑term growth in Russia's metal machining capacity.[12][13]

Metal CNC Machining Manufacturers and Suppliers in Russia typically provide a full menu of machining processes and related services that align with global buyer expectations.

Russian machining shops operate an array of CNC equipment to meet different geometry and tolerance requirements:

- CNC milling centers for pocketing, contouring, and 3D surface machining of aluminum, steel, and non‑ferrous alloys.

- CNC turning lathes and mill‑turn centers for shafts, bushings, flanges, and threaded components.

- CNC drilling and boring machines for precise hole patterns, deep holes, and complex drilling operations in structural parts.[14][1][7]

These capabilities allow Metal CNC Machining Manufacturers and Suppliers to serve projects ranging from small, intricate components for instrumentation to heavy-duty parts for energy and industrial equipment.[1][7]

Russian Metal CNC Machining Manufacturers and Suppliers commonly process:

- Carbon and alloy steels for structural and mechanical components.

- Stainless steels for corrosion‑resistant applications in food, chemical, and energy systems.

- Aluminum alloys for lightweight parts in aerospace, automotive, and electronics.

- Copper and brass for electrical connectors and fluid control components.[6][1]

Many shops are capable of tight tolerances in the range expected for precision mechanical parts, supported by coordinate measuring machines, surface roughness testers, and hardness testing equipment. This quality infrastructure helps Metal CNC Machining Manufacturers and Suppliers comply with international dimensional and performance standards.[7][1]

To provide end‑to‑end service, Russian machining companies often incorporate secondary processes such as grinding, honing, thread rolling, and basic heat treatment through partnerships. They may also manage external services like plating, anodizing, painting, or coating through established subcontractors.[1][7]

As a result, many Metal CNC Machining Manufacturers and Suppliers deliver parts that are fully finished and ready for assembly, reducing the need for buyers to coordinate multiple vendors. Some also provide assembly of sub‑components, functional testing, and packaging tailored to export requirements.[7][1]

International purchasers consider several strategic benefits when choosing Metal CNC Machining Manufacturers and Suppliers in Russia.

Russia's history in aerospace, defense, and heavy machinery has produced a deep pool of engineers and technicians with strong machining and design backgrounds. This knowledge helps Metal CNC Machining Manufacturers and Suppliers interpret complex drawings, manage challenging alloys, and develop stable production processes for safety‑critical parts.[6][1]

Buyers targeting sectors such as turbines, railway equipment, mining machinery, and industrial gearboxes often value suppliers with this type of heavy engineering experience. It can reduce technical risk and support faster problem solving during new product introduction.[1][7]

The use of modern multi‑axis machining centers, high‑speed spindles, and domestic CNC systems allows Russian Metal CNC Machining Manufacturers and Suppliers to handle complex geometries with fewer set‑ups. Multi‑tasking machines, for example, can combine turning and milling operations in a single clamping to improve accuracy and reduce cycle times.[9][1]

Local development of CNC controls and drives improves serviceability and cost control, while also allowing customization for specific industries. This combination of imported and domestic technology gives Metal CNC Machining Manufacturers and Suppliers flexibility to adapt machine configurations to customer needs.[12][9]

For customers in Europe, the Middle East, and Central Asia, sourcing from Russian Metal CNC Machining Manufacturers and Suppliers can offer logistical and cost advantages compared with some distant markets. Overland and regional maritime routes may reduce transit times and shipping costs for heavy or bulky metal parts.[13][1]

Additionally, when carefully selected and audited, Russian suppliers can be competitive on machining rates, particularly for medium and large components where handling and freight are significant cost drivers. This cost‑to‑capability balance is a key reason many buyers maintain at least part of their supplier base in Russia.[2][1]

While Russian providers deliver strong regional value, many global companies also adopt a multi‑country sourcing strategy that includes Chinese OEM partners. Shangchen is a typical example of a one‑stop manufacturing factory that complements Russian Metal CNC Machining Manufacturers and Suppliers.

Shangchen focuses on rapid prototyping, CNC machining, CNC turning, sheet metal fabrication, 3D printing, and mold manufacturing for international customers. Its workshop is equipped with CNC milling machines, turning centers, and inspection facilities for precision metal and plastic components.[5][3]

The company accepts low‑volume prototype orders and scales up to larger batch production, offering flexibility that is particularly attractive for new product development and customized components. This service structure positions Shangchen alongside other Metal CNC Machining Manufacturers and Suppliers worldwide as a reliable OEM partner.[4][3]

In practice, many buyers integrate Shangchen into their supplier portfolio while continuing to work with Russian Metal CNC Machining Manufacturers and Suppliers. Typical division of roles can include:

- Using Shangchen for rapid prototyping and early design iterations, thanks to quick lead times and strong engineering communication.

- Leveraging Chinese manufacturing for cost‑effective volume production of standardized parts.

- Cooperating with Russian Metal CNC Machining Manufacturers and Suppliers for local variants, after‑sales spares, or components subject to regional sourcing requirements.[15][3][4]

This combined strategy allows brands and wholesalers to spread risk, hedge against currency or political changes, and ensure continuity of supply for critical metal components.[4][15]

Whether working with Russian Metal CNC Machining Manufacturers and Suppliers or with Shangchen, most OEM projects follow a lifecycle from initial concept to sustained production.

The process usually starts with CAD models, 2D drawings, and key requirements such as materials, surface treatments, and functional loads. Machining engineers review these documents and provide design‑for‑manufacturability feedback, suggesting changes that may reduce machining time or improve tool access.[16][3]

Metal CNC Machining Manufacturers and Suppliers may also recommend alternative alloys, tolerance adjustments, or modular design approaches to ease production and reduce costs. Early collaboration at this stage can prevent later quality issues and delays.[7][1]

Next, prototype parts are machined using flexible CNC equipment, often in small batches. These prototypes undergo dimensional inspection, assembly tests, and functional trials to check fit, sealing, alignment, and performance under simulated operating conditions.[3][1]

For complex systems, buyers might use Shangchen for initial prototypes and then share proven designs with selected Russian Metal CNC Machining Manufacturers and Suppliers for localization. This approach accelerates development while preparing multiple production options from the start.[3][4]

Once prototypes are approved, tooling fixtures, inspection gauges, and process documentation are standardized for serial production. Work instructions, CNC programs, and control plans ensure that each production lot from Metal CNC Machining Manufacturers and Suppliers follows the same quality path.[1][7]

Some buyers split production volumes between regions, using Shangchen for global supply and Russian workshops for local support. This distribution boosts resilience and helps maintain stable delivery even when logistics or regulatory conditions change.[15][4]

Careful supplier evaluation is essential before placing long‑term orders with Metal CNC Machining Manufacturers and Suppliers.

Buyers typically request equipment lists detailing machining centers, turning lathes, measuring devices, and software tools. Sample parts and test runs are used to confirm that tolerances, surface finishes, and material properties meet expectations.[7][1]

Quality assurance systems, including traceability, calibration records, and non‑conformance procedures, are also reviewed. Suppliers with certifications relevant to automotive, aerospace, or industrial sectors often provide additional confidence that processes are controlled and audited.[1][7]

Success with Metal CNC Machining Manufacturers and Suppliers depends heavily on communication. Clear English‑language documentation, responsive project managers, and structured feedback loops reduce misunderstandings about dimensions, materials, and deliveries.[4][10]

Many buyers test communication during the RFQ and prototype phases, ensuring that engineering questions are handled quickly and that schedule changes are addressed transparently. Suppliers who manage digital documentation and offer regular status updates are generally better suited to complex OEM programs.[10][4]

Metal CNC Machining Manufacturers and Suppliers in Russia combine advanced machinery, skilled engineering, and industrial experience to provide high‑precision metal components for demanding sectors such as aerospace, energy, and heavy machinery. Their capabilities in multi‑axis milling, turning, and drilling, along with robust quality systems, make them attractive partners for regional and international buyers.[2][1]

By integrating Russian machining suppliers with global OEM partners like Shangchen in China, brands and wholesalers can build diversified, resilient supply chains for CNC machined metal parts. Shangchen's strengths in rapid prototyping, flexible production volumes, and comprehensive manufacturing services work in synergy with the regional advantages of Russian Metal CNC Machining Manufacturers and Suppliers.[5][3][4]

Careful evaluation of technical capabilities, quality management, and communication practices helps buyers select the right mix of Metal CNC Machining Manufacturers and Suppliers. This strategic approach supports reliable deliveries, optimized costs, and consistent product performance in competitive global markets.[13][1]

Russian Metal CNC Machining Manufacturers and Suppliers primarily serve aerospace, automotive, defense, energy, oil and gas, and general industrial machinery sectors. These industries require high‑precision metal components, which encourages continuous investment in modern CNC equipment and quality inspection systems.[6][1]

Russian Metal CNC Machining Manufacturers and Suppliers often provide regional proximity, local standards knowledge, and strength in heavy engineering, while Chinese OEM partners such as Shangchen offer rapid prototyping, strong scalability, and highly competitive machining costs. Many international buyers combine both options to balance lead time, cost, and supply chain resilience.[3][4][1]

Most Metal CNC Machining Manufacturers and Suppliers in Russia work with carbon steel, alloy steel, stainless steel, aluminum alloys, copper alloys, and sometimes titanium and nickel‑based alloys for critical applications. Some shops also machine engineering plastics and composite components for mixed‑material assemblies.[6][1]

Foreign companies generally review equipment lists, sample components, and quality certifications, then place trial orders to confirm consistency. Third‑party audits and inspections, along with cooperation with engineering integrators, help verify that Metal CNC Machining Manufacturers and Suppliers meet the required dimensional, material, and documentation standards.[10][7][1]

Shangchen offers rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production with flexible order quantities and strong international OEM experience. Partnering with Shangchen alongside Russian Metal CNC Machining Manufacturers and Suppliers allows OEMs to diversify risk, secure multiple production sources, and optimize total cost and lead time across different regions.[15][4][3]

[1](https://anebonmetal.com/top-cnc-machining-services-manufacturers-in-russia/)

[2](https://www.marketresearch.com/Business-Market-Insights-v4322/Global-Russia-CNC-Machine-42217648/)

[3](https://www.sc-rapidmanufacturing.com/what-is-cnc-machining.html)

[4](https://www.sc-rapidmanufacturing.com/top-cnc-cutting-manufacturers-and-suppliers-in-poland.html)

[5](https://www.sc-rapidmanufacturing.com)

[6](https://www.longshengmfg.com/aerospace-parts-cnc-machining-manufacturing-russia/)

[7](https://siver.ru/en/company/production/)

[8](https://www.sasta.ru/en/)

[9](https://mtronics.ru/en/)

[10](https://politek-service.ru/eng/)

[11](https://www.pzmc.org/en/)

[12](https://fort-russia.com/en/)

[13](https://industrialequipement.seesaa.net/article/510020658.html)

[14](https://www.nextmsc.com/report/russia-cnc-drilling-machine-market)

[15](https://www.sc-rapidmanufacturing.com/news.html)

[16](https://www.sc-rapidmanufacturing.com/sheet-metal-fabrication-knowledge.html)

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia