Views: 222 Author: Amanda Publish Time: 2025-12-14 Origin: Site

Content Menu

● Why Poland for Metal CNC Machining?

● Overview of the Polish CNC Machining Industry

● Key Metal CNC Machining Manufacturers and Suppliers in Poland

>> CMPLAST

>> CNC CONNECT

● Typical Capabilities of Polish Metal CNC Suppliers

● Industries Served by Polish Metal CNC Companies

● Role of Advanced CNC Technology in Poland

● Quality Management and Certifications

● Logistics and Supply Chain Advantages Within the EU

● How International OEMs Can Work with Polish CNC Suppliers

● Working with Shangchen as a Complementary Chinese Partner

● Application Scenarios for Dual‑Region Sourcing

● How to Choose Between Polish and Chinese CNC Suppliers

● Long‑Term Partnership Strategies

● FAQs

>> 1. How advanced are Metal CNC Machining Manufacturers and Suppliers in Poland?

>> 2. Can Polish suppliers handle both prototypes and mass production?

>> 3. How do Polish CNC suppliers compare with a Chinese factory like Shangchen?

>> 5. What information should OEMs provide when requesting quotes from Polish CNC machining suppliers?

Poland has become one of Central Europe's most attractive destinations for Metal CNC Machining Manufacturers and Suppliers, serving automotive, aerospace, medical, and industrial brands across the EU and beyond. For foreign OEM buyers, understanding the strengths of Polish Metal CNC Machining Manufacturers and Suppliers and how they complement experienced Chinese partners such as Shangchen (sc-rapidmanufacturing.com) is key to building a resilient global supply chain.

Poland's Metal CNC Machining Manufacturers and Suppliers benefit from a strategic EU location, competitive labor costs compared with Western Europe, and efficient logistics to Germany, France, Scandinavia, and other key markets. At the same time, the country has invested heavily in advanced CNC technology, multi‑axis machining centers, and technical education, creating a strong talent pool for precision metal production.

For international OEMs, this means Poland can offer a balance of quality, cost‑efficiency, and proximity to European end customers. Metal CNC Machining Manufacturers and Suppliers in Poland are tightly integrated into automotive, aerospace, railway, and medical supply chains, allowing them to meet demanding standards and just‑in‑time delivery models.

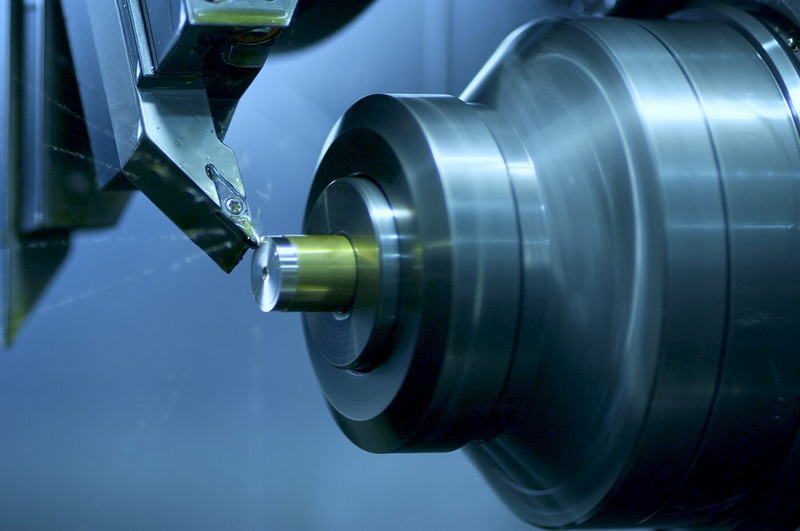

The Polish CNC machining sector has evolved from small workshops into high‑tech plants equipped with 3‑axis to 5‑axis machining centers, CNC turning cells, laser cutting systems, and automated inspection. Many Metal CNC Machining Manufacturers and Suppliers in Poland now provide end‑to‑end solutions, from design support and rapid prototyping to mass production and assembly.

Industry growth is driven by strong demand for precision metal components in automotive engines, transmissions, chassis parts, aircraft structures, medical instruments, and industrial machinery. EU integration ensures that Metal CNC Machining Manufacturers and Suppliers in Poland follow international quality standards and can export efficiently across the single market.

Below is a narrative overview of several representative Metal CNC Machining Manufacturers and Suppliers in Poland that often work with global OEMs and industrial customers. The specific names may change as the market develops, but their capabilities show what buyers can typically expect from Polish partners.

RADMOT is one of Poland's longest‑established Metal CNC Machining Manufacturers and Suppliers, with decades of experience in CNC turning and milling. The company operates a broad fleet of CNC lathes and machining centers to support both rapid prototyping and high‑volume series production in metals such as aluminum, steel, copper, and brass.

Its services include turning, milling, and various surface treatments that allow OEMs to receive finished, ready‑to‑assemble parts. RADMOT targets sectors such as automotive, hydraulics, pneumatics, and industrial equipment, and focuses on stable quality over long product life cycles.

CMPLAST is known for CNC machining of both plastics and metals, including aluminum, brass, and steel, and belongs to the group of flexible Metal CNC Machining Manufacturers and Suppliers. Beyond pure machining, CMPLAST provides welded structures and machine design services, often supporting customized OEM projects and functional prototypes.

By combining materials expertise with flexible production capacity, CMPLAST can serve both small companies and large corporations that require tailor‑made components. Its emphasis on mechanical performance, repeatability, and corrosion resistance makes it a good fit for housings, fixtures, and precision brackets.

ZETEK is a Polish CNC machining company with long experience in precision metalworking and toolmaking. As one of the established Metal CNC Machining Manufacturers and Suppliers in the country, it provides tooling, prototype development, and serial machining for industries like automotive, aerospace, and electronics.

The firm invests in modern CNC mills and lathes and is recognized for tight tolerances and short lead times on complex, multi‑step operations. Through engineering support and design advice, ZETEK helps OEM customers refine part designs to reduce machining time and overall cost per piece.

MAD Precision Engineering focuses on CNC milling and turning for both small‑batch and large‑volume runs. As a quality‑oriented member of the Metal CNC Machining Manufacturers and Suppliers community, it typically operates under formal quality systems with documented process control.

The company cuts various metals and technical plastics and supports quick turnaround needs for European OEMs and distributors. Its capabilities include CAD/CAM programming, in‑process measurement, and finishing steps such as deburring and surface treatments, helping buyers receive components that are close to final form.

CNC CONNECT is a Polish provider of CNC machining, metal cutting, and the production of flanges, rings, and custom blanks. It belongs to the group of Metal CNC Machining Manufacturers and Suppliers that can handle both standard parts and fully custom geometries based on customer drawings.

The company's value lies in its ability to combine machining and thermal processing, enabling OEMs to consolidate suppliers and streamline project management. This bundled approach is especially attractive for foreign buyers who want a single partner to handle rough machining, heat treatment, finishing, and inspection.

Metal CNC CNC Machining Manufacturers and Suppliers across Poland generally combine modern machines, experienced operators, and digital workflows. Common capability highlights include:

- Multi‑axis CNC milling (3‑axis, 4‑axis, and 5‑axis) for complex prismatic parts.

- CNC turning, including bar‑fed lathes and multi‑spindle machines for shafts, bushings, and rings.

- Machining of metals such as carbon steel, stainless steel, aluminum alloys, brass, copper, and sometimes titanium or special alloys.

- Tolerance ranges suitable for precision automotive, aerospace, and medical components, including fine surface finishes.

- In‑house or partnered surface treatments such as anodizing, powder coating, galvanizing, and heat treatment.

- Quality control processes with coordinate measuring machines, optical inspection, and traceable documentation.

Many Metal CNC Machining Manufacturers and Suppliers in Poland also provide value‑added services such as light assembly, kitting, packaging in customer‑branded cartons, and long‑term warehousing. These services help OEMs reduce internal handling and focus more on design, marketing, and final system integration.

Polish Metal CNC Machining Manufacturers and Suppliers support a broad spectrum of industries. Their experience across diverse markets helps them understand different certification, documentation, and testing needs.

Key industries include:

- Automotive and commercial vehicles, where suppliers produce engine components, gearbox parts, brake components, steering elements, and chassis brackets.

- Aerospace and aviation, which require lightweight but strong metal parts, tight tolerances, and rigorous traceability.

- Railway, including bogie components, brackets, and structural metal elements that must perform reliably under heavy loads.

- Medical devices and equipment, where components must meet hygiene, safety, and biocompatibility expectations for metal materials.

- Industrial machinery and automation, covering frames, housings, clamps, fixtures, and various mechanical transmission parts.

- Electronics and energy, where precision metal CNC machining supports housings, connectors, and thermal management components.

Because Metal CNC Machining Manufacturers and Suppliers in Poland serve such demanding sectors, they are familiar with international standards and customer audits. This experience makes them attractive partners for foreign brands that require consistent quality and detailed quality reports.

The evolution of CNC technology in Poland has transformed metalworking from largely manual operations into digitally controlled processes with high repeatability. Modern Metal CNC Machining Manufacturers and Suppliers leverage:

- 3‑axis and 5‑axis machining centers for complex contours and multi‑face machining in one setup.

- CNC turning centers with live tooling, allowing drilling and milling operations to be carried out during turning cycles.

- Integrated CAD/CAM software, which ensures that 3D models from OEM customers can be converted into optimized tool paths.

- Tool presetting, automatic tool changers, and intelligent tool management systems to reduce downtime.

- Real‑time machine monitoring and production planning software that increases transparency and efficiency.

This adoption of advanced CNC systems improves productivity, reduces scrap, and enables the machining of complex geometries in tough materials such as hardened steels and high‑strength aluminum alloys. For OEM customers, it translates into shorter lead times, superior surface finishes, and more consistent dimensional tolerances across large production runs.

Metal CNC Machining Manufacturers and Suppliers in Poland increasingly work under internationally recognized quality management systems. Many plants are certified to standards such as ISO 9001 for general quality management, while some automotive suppliers hold IATF 16949 and aerospace suppliers pursue EN/AS 9100.

Key quality practices typically include:

- Documented process control, with clear work instructions, setup sheets, and inspection plans.

- Incoming material verification using mill certificates, positive material identification, or chemical analysis where necessary.

- In‑process inspection to detect deviations early and avoid producing large batches of nonconforming parts.

- Final inspection reports and measurement protocols that accompany each shipment, supporting traceability and customer audits.

- Corrective and preventive action systems that address quality issues and prevent recurrence.

For foreign OEMs, the presence of such systems within Metal CNC Machining Manufacturers and Suppliers in Poland greatly simplifies supplier qualification and ongoing vendor management.

Poland's location inside the European Union gives Metal CNC Machining Manufacturers and Suppliers significant logistics advantages when serving European customers. Shipments move freely within the single market without customs duties, and transport times to major industrial centers are relatively short.

Common benefits include:

- Short road transit times to Germany, France, the Netherlands, Italy, the Czech Republic, and Slovakia.

- Simplified customs and fewer administrative barriers for intra‑EU trade.

- The ability to support just‑in‑time or just‑in‑sequence deliveries for automotive and industrial customers.

- Easier coordination of returns, engineering changes, and emergency shipments.

Because of these factors, many European OEMs rely on Polish Metal CNC Machining Manufacturers and Suppliers for regional capacity that can react quickly to demand changes, engineering modifications, and ramp‑ups of new product launches.

Foreign brands, wholesalers, and producers who want to cooperate with Metal CNC Machining Manufacturers and Suppliers in Poland should follow a structured sourcing and onboarding process. A typical approach includes several practical steps.

First, buyers define their technical requirements, including materials, tolerances, surface finishes, annual volumes, and specific industry standards such as automotive or aerospace norms. Then they shortlist suppliers based on capabilities, certifications, case studies, and references. Clear communication at this stage helps avoid mismatches later.

Next, customers share 2D drawings and 3D models with the shortlisted Metal CNC Machining Manufacturers and Suppliers, along with expected volumes and delivery conditions. Most Polish suppliers will then respond with quotations, suggested lead times, and, when necessary, design‑for‑manufacturing feedback. This feedback can include suggestions to adjust wall thicknesses, radii, or hole positions to optimize machining.

Before committing to large orders, OEMs usually request prototypes or trial batches to validate quality and process stability. During these trials, they assess dimensional accuracy, surface finish, packaging, and consistency from part to part. Successful trials often lead to framework agreements or long‑term contracts that lock in pricing, capacity, and service levels.

Finally, buyers and suppliers formalize quality plans, inspection routines, logistics strategies, and communication channels. Many Metal CNC Machining Manufacturers and Suppliers in Poland are open to regular performance reviews and continuous improvement programs, which help both parties maintain competitiveness over time.

While Poland offers strong regional advantages for Europe‑focused supply chains, many international buyers combine Polish Metal CNC Machining Manufacturers and Suppliers with high‑capability Chinese partners to balance cost, flexibility, and scalability. Shangchen in China is an example of a factory that complements Polish capacity through rapid prototyping, CNC machining, precision volume production, and integrated services such as sheet metal fabrication, vacuum casting, 3D printing, and mold manufacturing.

Shangchen specializes in fast turnaround for prototypes, low‑volume CNC machining, and scalable transition to injection molding and mass production. This one‑stop model is attractive to foreign brands, wholesalers, and manufacturers seeking OEM services from a single source. By integrating design validation, prototype building, and tooling development under one roof, Shangchen shortens the path from concept to market.

For OEMs already sourcing from Metal CNC Machining Manufacturers and Suppliers in Poland, Shangchen can provide several complementary advantages:

- Very fast prototypes and engineering samples to test design changes before updating European tooling.

- Additional capacity during peak demand or when local plants face disruptions, such as maintenance shutdowns or supply interruptions.

- Cost‑effective production for global markets where longer transit times are acceptable or where distribution centers are closer to Asia.

This combined strategy lets OEMs enjoy the benefits of both regions: the responsiveness and regulatory proximity of Polish Metal CNC Machining Manufacturers and Suppliers, and the integrated, cost‑competitive capabilities of a Chinese rapid manufacturing partner.

A dual‑region sourcing model that uses both Polish Metal CNC Machining Manufacturers and Suppliers and a Chinese partner such as Shangchen is suitable for several scenarios.

One scenario is new product introduction. During early development, Shangchen can supply quick CNC prototypes, 3D‑printed models, and soft tooling parts for testing and validation. Once designs are frozen, production can be transferred partly to Poland to support European launches with short lead times.

A second scenario is risk diversification. By splitting volume across different regions, OEMs reduce their exposure to local disruptions, whether related to energy costs, logistics interruptions, or regulatory changes. Polish Metal CNC Machining Manufacturers and Suppliers may cover base demand for Europe, while Shangchen handles overflow or serves markets outside the EU.

A third scenario is cost optimization across product life cycles. Higher‑volume, stable components might be produced in regions with competitive mass‑production economics, while complex or urgently needed parts remain with nearby Polish partners. Over time, volumes can be rebalanced as demand patterns evolve.

When deciding how to allocate work between Metal CNC Machining Manufacturers and Suppliers in Poland and a Chinese partner, OEMs can consider several key factors.

- Market location: Components required primarily in Europe often benefit from being produced in Poland due to shorter transit times and simpler intra‑EU trade.

- Lead time sensitivity: Projects that demand very short order‑to‑delivery cycles may favor nearby Polish suppliers, while longer‑term, forecastable demand can be well served from China.

- Cost structure: Large, stable volumes and labor‑intensive processes may be more cost‑effective in China, whereas low‑to‑medium volumes with tight timelines can be better positioned in Poland.

- Technical complexity: Both regions support advanced machining, but specific expertise, such as mold manufacturing, multi‑process integration, or rapid prototyping, may tilt the decision toward a partner like Shangchen.

- Communication and collaboration: Time zones, language, and cultural familiarity may affect day‑to‑day engineering coordination, particularly in early development phases.

By analyzing these factors, OEMs can build a sourcing matrix that defines which types of parts go to Polish Metal CNC Machining Manufacturers and Suppliers and which are better suited to a Chinese factory. This structured approach ensures that decisions are driven by business priorities rather than habit.

Successful cooperation with Metal CNC Machining Manufacturers and Suppliers in Poland and with a Chinese partner such as Shangchen depends on long‑term partnership thinking. Rather than treating suppliers as purely transactional vendors, leading OEMs regard them as strategic collaborators.

Typical long‑term strategies include:

- Joint cost‑reduction projects, where engineers from both sides identify process improvements, design changes, or material alternatives that reduce cost while preserving function.

- Shared forecasting and planning, where OEMs provide rolling demand forecasts to Metal CNC Machining Manufacturers and Suppliers and to Shangchen, helping them plan capacity and investments.

- Co‑development of new products, with suppliers involved early in the design phase to ensure manufacturability and to avoid late engineering changes.

- Regular on‑site or virtual audits and technical visits, which deepen mutual understanding and trust over time.

By building such relationships, OEMs can rely on a stable, well‑coordinated network of Metal CNC Machining Manufacturers and Suppliers across Poland and China, aligning production closely with market needs.

Metal CNC Machining Manufacturers and Suppliers in Poland have developed a strong reputation for precision, reliability, and alignment with European standards. With advanced CNC technology, skilled engineers, and strong links to automotive, aerospace, railway, medical, and industrial sectors, they provide robust options for OEMs seeking regional metal machining capacity.

At the same time, pairing Polish Metal CNC Machining Manufacturers and Suppliers with a versatile Chinese partner such as Shangchen allows buyers to optimize cost, accelerate development, and reduce supply‑chain risk. By combining EU‑based production and flexible rapid manufacturing in China, global brands, wholesalers, and producers can build a resilient, scalable, and competitive sourcing strategy for metal CNC components.

Metal CNC Machining Manufacturers and Suppliers in Poland are generally equipped with modern 3‑axis to 5‑axis machining centers, CNC lathes with live tooling, and digital CAD/CAM systems. Many plants operate coordinate measuring machines and follow formal quality management systems, enabling them to produce precision parts for demanding industries such as automotive, aerospace, and medical devices.

Yes. A significant number of Metal CNC Machining Manufacturers and Suppliers in Poland can support the full life cycle from prototypes and small batches to large‑volume serial production. They often dedicate specific machine cells to trial runs and development work while running separate lines for high‑volume, repeat orders, which helps maintain flexibility without sacrificing efficiency.

Polish Metal CNC Machining Manufacturers and Suppliers offer proximity to European markets, familiarity with EU regulations, and short delivery times for local customers. A Chinese factory such as Shangchen complements these advantages by providing very fast prototyping, a wide range of processes under one roof, and cost‑effective capacity for global or non‑EU markets, making a combined sourcing model attractive for many OEMs.

The most common clients include automotive and commercial vehicles, aerospace and railway, medical devices, industrial machinery, automation, electronics, and energy. These industries rely on Metal CNC Machining Manufacturers and Suppliers for precision metal components ranging from structural brackets and housings to shafts, gears, connectors, and complex assemblies.

When approaching Metal CNC Machining Manufacturers and Suppliers in Poland for quotes, OEMs should provide detailed 2D drawings and 3D models, material specifications, tolerance requirements, and any special surface finish or heat treatment needs. It is also important to share expected annual volumes, packaging standards, certification requirements, and preferred delivery terms so that suppliers can calculate realistic pricing, lead times, and machining strategies.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia