Views: 222 Author: Amanda Publish Time: 2025-12-15 Origin: Site

Content Menu

● Norway's CNC Machining Landscape

● Key Metal CNC Machining Manufacturers and Suppliers in Norway

>> Mid‑sized precision machining specialists

>> Specialized offshore and tubular machining suppliers

>> High‑tech and additive‑enabled manufacturers

● Services Offered by Norwegian Metal CNC Machining Manufacturers and Suppliers

>> Prototyping and small batch production

>> Precision measurement and quality assurance

>> Engineering support and value‑added services

● Market Trends for Metal CNC Machining in Norway

>> Automation and digitalization

>> Shift toward renewables and advanced sectors

>> Sustainability and responsible supply chains

● Why Buyers Combine Norwegian and Chinese CNC Partners

>> Balancing cost, risk and performance

>> Role of Chinese OEM partners like Shangchen

● Practical Tips for Choosing Norwegian Metal CNC Machining Manufacturers and Suppliers

>> Define technical requirements clearly

>> Check capabilities and references

>> Evaluate communication and project management

>> Compare total landed cost and supply‑chain fit

● FAQ

>> 1. Why choose Norwegian Metal CNC Machining Manufacturers and Suppliers for critical components?

>> 5. What are the main trends affecting Metal CNC Machining Manufacturers and Suppliers in Norway?

Norway has built a strong reputation for precision engineering, and Metal CNC Machining Manufacturers and Suppliers in the country play a core role in supporting offshore energy, maritime technology, defense, aerospace and advanced industrial machinery. These Metal CNC Machining Manufacturers and Suppliers combine robust Nordic manufacturing culture with modern automation and digital tools to deliver high‑quality metal components to global buyers.

The industrial structure of Norway is shaped by demanding sectors such as oil and gas, shipbuilding, hydropower, wind power, defense and marine technology. Metal CNC Machining Manufacturers and Suppliers evolved alongside these industries, learning to work with corrosion‑resistant alloys, high‑strength steels and other challenging materials while maintaining tight tolerances and full traceability.

Modern Norwegian machine shops typically invest in multi‑axis machining centers, advanced CAD/CAM systems, robotics and automated inspection. Metal CNC Machining Manufacturers and Suppliers in Norway often function as engineering partners rather than just “job shops”, supporting design improvement, manufacturability reviews and long‑term product life‑cycle management. This makes them attractive to overseas OEMs, brand owners and wholesalers that value reliability and engineering support as much as unit cost.

Although Norway is a relatively small country by population, it hosts a compact but diverse network of Metal CNC Machining Manufacturers and Suppliers. Some are large, integrated industrial groups, while others are specialized machining houses focused on specific segments or materials.

Major industrial groups with strong machining capabilities deliver high‑precision components for defense, aerospace, maritime systems and advanced offshore equipment. Their machining divisions operate high‑end CNC mills and lathes, often including 5‑axis and mill‑turn centers, along with complex quality and documentation systems.

These large players set technology and process benchmarks for other Metal CNC Machining Manufacturers and Suppliers in Norway. International buyers gain confidence from their track record in safety‑critical industries, but such groups may primarily serve as system integrators, leaving smaller and mid‑sized machine shops to handle more flexible contract machining work.

A range of mid‑sized Metal CNC Machining Manufacturers and Suppliers spread across Norway focus on CNC milling, turning and related operations for metal components. Many of them are located near industrial clusters on the coast, where they support offshore service companies, mechanical engineers and equipment builders.

These machine shops often combine:

- CNC milling (3‑, 4‑ and 5‑axis) for complex prismatic parts.

- CNC turning for shafts, rings, flanges and precision bushings.

- Secondary operations such as drilling, tapping, threading and light assembly.

- Coordination of surface treatments like anodizing, plating, painting and heat treatment through partner networks.

Mid‑sized Metal CNC Machining Manufacturers and Suppliers are usually flexible enough to accept prototypes and small batches while also scaling up to medium‑series production. For foreign OEMs, they can offer a good balance of responsiveness, technical capability and project management without the complexity of working with very large industrial groups.

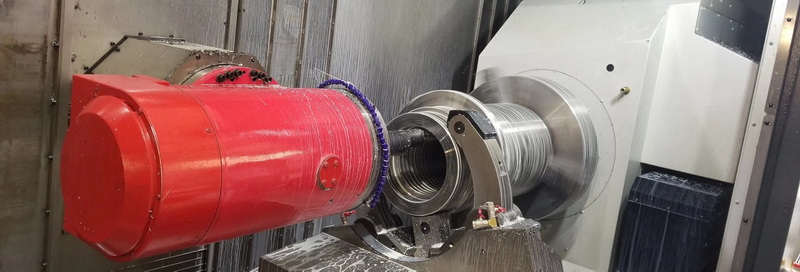

Norway's offshore heritage has encouraged the development of Metal CNC Machining Manufacturers and Suppliers dedicated to tubular components, high‑pressure valves, connectors, wellhead parts and subsea structures. These companies understand offshore standards, documentation requirements and inspection regimes.

They typically provide:

- Precision turning and boring of large‑diameter pipes and tubulars.

- Machining of thread forms and premium connections.

- Welding, cladding and repair services for offshore components.

- Full material certificates and inspection documentation for regulatory compliance.

For buyers in the energy sector, working with such specialized Metal CNC Machining Manufacturers and Suppliers in Norway reduces project risk, because suppliers speak the same technical and regulatory language as the operators and engineering houses.

A smaller but important group of Metal CNC Machining Manufacturers and Suppliers in Norway combine conventional CNC machining with 3D metal printing and other advanced processes. These companies focus on high‑value, complex parts where weight reduction, topology optimization and design freedom are critical.

Their typical workflow involves producing near‑net‑shape parts by additive manufacturing, followed by CNC machining to achieve critical dimensions and surface finishes. For international customers, this hybrid approach can shorten development cycles, reduce material usage and enable innovative product designs in aerospace, robotics and high‑performance industrial equipment.

Metal CNC Machining Manufacturers and Suppliers in Norway offer a broad portfolio of machining services, often integrated with design support, metrology and supply‑chain management.

Core capabilities include CNC milling of complex prismatic parts and CNC turning of rotational components. Many shops run multi‑axis machining centers with automatic tool changers, pallet systems and probing, enabling them to machine sophisticated metal parts in a single setup.

Metal CNC Machining Manufacturers and Suppliers routinely work with:

- Stainless steels and duplex steels for corrosion resistance.

- Alloy steels for strength and fatigue performance.

- Aluminum and its alloys for lightweight structures.

- Nickel‑based and other specialty alloys for high‑temperature or aggressive environments.

Because Norwegian industries are innovation‑driven, local Metal CNC Machining Manufacturers and Suppliers are used to building prototypes, pilot runs and engineering samples. They can react quickly to design changes, provide feedback on manufacturability and suggest cost‑saving design modifications.

Rapid prototyping services often include short lead times, small‑batch CNC machining, and close collaboration with customer engineering teams. Once the design stabilizes, these suppliers can transition to repeatable small‑ or medium‑batch production while maintaining documentation and process consistency.

Strong quality systems are a core selling point for Metal CNC Machining Manufacturers and Suppliers in Norway. Shops frequently operate coordinate measuring machines (CMMs), optical measurement devices and in‑process probing to verify tolerances throughout production.

Quality procedures typically cover:

- Incoming material inspection and traceability.

- First article inspection for new parts.

- In‑process checks at defined intervals.

- Final inspection reports and dimensional records.

For international buyers, this means that Metal CNC Machining Manufacturers and Suppliers in Norway can reliably meet strict quality contracts in sectors such as aerospace, defense and energy.

Beyond pure machining, many Norwegian Metal CNC Machining Manufacturers and Suppliers provide engineering services, including design input, reverse engineering, fixture development and productivity optimization. They may also assemble sub‑assemblies, manage coatings and treatments through partner networks, and handle packing and logistics tasks.

This ability to act as a single point of contact, rather than merely a machining vendor, is especially valuable for overseas customers who want simplified supply chains and consistent quality across a range of operations.

The market environment for Metal CNC Machining Manufacturers and Suppliers in Norway continues to evolve in response to global and regional pressures.

To maintain competitiveness in a high‑cost country, Norwegian Metal CNC Machining Manufacturers and Suppliers are investing heavily in automation: robot loading systems, pallet pools, automatic storage and retrieval systems, and integrated production planning software. Night‑shift “lights‑out” machining is increasingly common for stable, repeatable production.

Digitalization includes real‑time monitoring of machine status, OEE (overall equipment effectiveness) tracking, and integration with ERP and quality systems. For international buyers, working with such digitally mature Metal CNC Machining Manufacturers and Suppliers offers better transparency, predictable lead times and easier collaboration on quality and logistics.

As global energy markets shift, many Norwegian Metal CNC Machining Manufacturers and Suppliers are expanding from traditional oil and gas into offshore wind, hydropower upgrades, hydrogen infrastructure and other renewable applications. Components for electrification, control systems and advanced sensor housings are also in demand.

This shift opens opportunities for buyers in clean‑tech, power electronics and advanced machinery to tap into Norway's machining expertise. Metal CNC Machining Manufacturers and Suppliers that previously focused on subsea hardware are now adapting their skills and equipment to new generations of environmentally focused projects.

Sustainability is becoming an important differentiator. Metal CNC Machining Manufacturers and Suppliers in Norway increasingly emphasize energy‑efficient equipment, responsible sourcing of raw materials, waste reduction and recycling of metal scrap. Some facilities track carbon footprints of their products and processes, which can help international customers meet their own ESG targets.

By choosing Norwegian Metal CNC Machining Manufacturers and Suppliers with sustainability initiatives, buyers can position their products as environmentally responsible while still maintaining high technical standards.

Many OEMs and brand owners adopt a hybrid sourcing model that blends Norwegian and Chinese Metal CNC Machining Manufacturers and Suppliers in one global strategy.

Norwegian Metal CNC Machining Manufacturers and Suppliers excel in high‑precision, high‑complexity and safety‑critical components, where documentation, traceability and domain expertise are vital. These parts may represent a smaller share of overall volume but are central to the product's performance or regulatory compliance.

Chinese Metal CNC Machining Manufacturers and Suppliers, on the other hand, offer strong advantages in cost‑effective production, flexible capacity, rapid prototyping, and a very broad range of processes such as CNC machining, rapid tooling, injection molding, die casting, sheet metal fabrication and 3D printing. By combining both sources, buyers can keep critical items close to the end market while leveraging cost‑efficient production for less sensitive or higher‑volume components.

A Chinese factory such as Shangchen (sc‑rapidmanufacturing.com) can complement Norwegian Metal CNC Machining Manufacturers and Suppliers as a dedicated OEM partner for overseas brands, wholesalers and manufacturers. With capabilities in rapid prototyping, metal and plastic CNC machining, precision batch production, turning and milling, sheet metal work, 3D printing and mold manufacturing, a partner like Shangchen can handle both development projects and repeat orders.

Shangchen can work from customer drawings or samples, support DFM (design for manufacturability) analysis, and integrate CNC machining with other processes such as surface finishing and assembly. For clients already cooperating with Norwegian Metal CNC Machining Manufacturers and Suppliers, Shangchen can provide overflow capacity, additional material options and competitive pricing on selected parts, while still maintaining the quality standards required for export markets.

Selecting the right Metal CNC Machining Manufacturers and Suppliers in Norway requires a structured evaluation process that considers technical, commercial and logistical aspects.

Before approaching Metal CNC Machining Manufacturers and Suppliers, buyers should define:

- Materials (grades and specifications) and required certifications.

- Tolerance ranges, surface roughness, geometric tolerances and inspection needs.

- Annual volume, batch sizes and potential design changes.

- Any special requirements such as welding procedures, pressure testing or NDT.

Clear technical documentation (3D models, 2D drawings, standards references) helps Norwegian Metal CNC Machining Manufacturers and Suppliers provide accurate quotations and realistic lead times.

Buyers should verify that potential Metal CNC Machining Manufacturers and Suppliers have suitable machine tools, measurement equipment and experience with similar components. References from existing customers in comparable industries are especially useful.

A formal questionnaire or audit can cover topics like:

- Machine list and maximum part sizes.

- Programming systems and CAD/CAM tools.

- Quality management system and certifications.

- Typical lead times and flexibility for urgent orders.

Smooth communication is crucial when working with overseas Metal CNC Machining Manufacturers and Suppliers. Buyers should assess English proficiency, responsiveness, clarity of quotations and willingness to discuss technical details.

Good project management practices include defined contact persons, regular progress updates, and transparent handling of potential issues. Norwegian Metal CNC Machining Manufacturers and Suppliers are generally strong in this area, but each company's style still needs to be checked against the buyer's expectations.

When comparing Norwegian Metal CNC Machining Manufacturers and Suppliers with partners in other countries, buyers must look beyond unit price and consider:

- Transport costs and transit times.

- Customs duties and taxes.

- Risk of delays and supply interruptions.

- Supplier reliability, scrap rates and rework risk.

In many cases, a mixed strategy combining Norwegian Metal CNC Machining Manufacturers and Suppliers with cost‑efficient partners like Shangchen in China delivers the best balance between cost, responsiveness and risk mitigation.

Norway offers a sophisticated ecosystem of Metal CNC Machining Manufacturers and Suppliers that support some of the world's most demanding industries, from offshore energy and maritime technology to defense, aerospace and advanced industrial equipment. These Metal CNC Machining Manufacturers and Suppliers operate modern CNC mills and lathes, employ skilled technicians and engineers, and maintain rigorous quality and traceability systems that meet strict international standards.

For international buyers, cooperating with Norwegian Metal CNC Machining Manufacturers and Suppliers provides access to deep industry expertise, reliable quality and strong engineering support for critical metal components. At the same time, combining these Norwegian partners with versatile Chinese factories such as Shangchen enables a powerful hybrid sourcing strategy: high‑precision, safety‑critical parts from Norway, and cost‑effective, scalable production from China. By carefully defining requirements, assessing capabilities and balancing global supply options, OEMs, wholesalers and brand owners can build resilient, competitive and future‑proof supply chains centered on the strengths of Metal CNC Machining Manufacturers and Suppliers in both regions.

Norwegian Metal CNC Machining Manufacturers and Suppliers are closely integrated with demanding sectors like offshore energy, maritime technology and aerospace, where reliability and documentation are essential. Their experience with challenging materials, tight tolerances and complex quality requirements makes them ideal for safety‑critical or high‑value metal parts that must perform reliably under harsh conditions.

Yes. Many Norwegian Metal CNC Machining Manufacturers and Suppliers are structured to support the full product life cycle, from early prototypes and pilot runs through to small‑ and medium‑series production. They typically offer flexible CNC setups, engineering assistance for design optimization, and stable processes for repeat orders, making it easier to scale volumes as projects grow.

A Chinese partner such as Shangchen can provide cost‑effective rapid prototyping, CNC machining, turning, sheet metal fabrication, 3D printing and mold manufacturing, complementing the high‑end capabilities of Norwegian Metal CNC Machining Manufacturers and Suppliers. By allocating critical, complex parts to Norway and volume or cost‑sensitive parts to China, buyers can optimize total cost, lead time and capacity while maintaining consistent quality across regions.

Buyers should look for standard quality certifications such as ISO 9001 and, depending on the industry, sector‑specific approvals such as aerospace or defense standards. In addition, robust internal procedures, documented inspection routines, traceability of materials and clear reporting formats are important indicators that Metal CNC Machining Manufacturers and Suppliers can meet strict regulatory and customer requirements.

Key trends include increased automation and digitalization of machine shops, expansion into renewable energy and advanced technology sectors, and a growing focus on sustainability and responsible production. Metal CNC Machining Manufacturers and Suppliers in Norway are investing in robotics, multi‑axis machining centers, real‑time production monitoring and energy‑efficient processes to remain competitive while meeting the evolving expectations of global customers.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia