Views: 222 Author: Amanda Publish Time: 2025-12-14 Origin: Site

Content Menu

● CNC Machining Landscape in the Netherlands

● Core Capabilities of Dutch Metal CNC Machining Suppliers

>> CNC Milling and Multi‑Axis Machining

>> CNC Turning and Lathe‑Based Production

>> Prototyping, Small Batches, and Series Production

● Quality, Certification, and Process Control

● Materials and Finishing for Metal CNC Machining

>> Surface Finishing and Post‑Processing

● Digitalization and Industry 4.0 in Dutch CNC Shops

● Why Overseas Buyers Work with Dutch Metal CNC Machining Manufacturers and Suppliers

>> Strategic Location and Logistics Advantages

>> Engineering Collaboration and DFM Support

● Role of Global OEM Partners Like Shangchen

● How Shangchen Supports the European and Dutch Market

>> From Rapid Prototyping to Production

>> OEM and Private‑Label Manufacturing

● Dual‑Sourcing Strategy: Netherlands Plus China

>> Balancing Cost, Lead Time, and Risk

● Key Considerations When Selecting Metal CNC Machining Manufacturers and Suppliers

>> Technical Capability and Equipment

>> Quality Systems and Traceability

>> Communication and Project Management

● Applications Across Major Sectors

● Sustainability and Future Trends in Metal CNC Machining

● FAQ

>> 2. How does Shangchen complement Dutch Metal CNC Machining Manufacturers and Suppliers?

>> 4. How can buyers ensure quality when sourcing from both Dutch suppliers and Shangchen?

>> 5. What information should overseas brands provide when requesting quotes from Shangchen?

Metal CNC Machining Manufacturers and Suppliers in the Netherlands play a vital role in the European industrial supply chain, supporting high‑tech sectors with precision components, fast lead times, and strict quality control. At the same time, global OEM partners such as Shangchen (sc-rapidmanufacturing.com) in China help overseas brands and wholesalers scale from rapid prototyping to mass production while keeping costs competitive.

The Netherlands has cultivated a strong ecosystem of Metal CNC Machining Manufacturers and Suppliers thanks to its advanced machine tool base, skilled workforce, and emphasis on engineering innovation. Dutch machining shops invest heavily in modern CNC milling, turning, drilling, and grinding equipment, often integrated with CAD/CAM and digital production planning systems.

These Metal CNC Machining Manufacturers and Suppliers serve demanding industries including aerospace, automotive, semiconductor equipment, medical technology, and industrial machinery. Dutch suppliers are known for handling complex geometries, tight tolerances, and high‑mix / low‑volume orders, which makes them especially attractive to European OEMs developing innovative products.

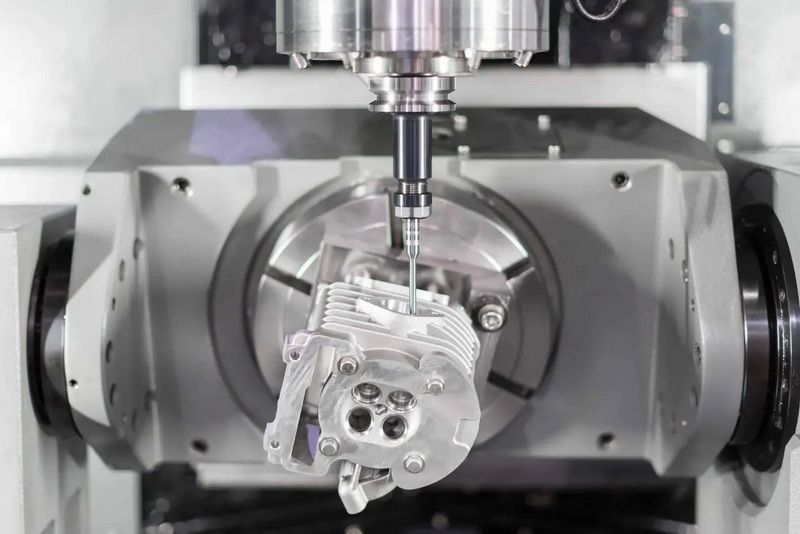

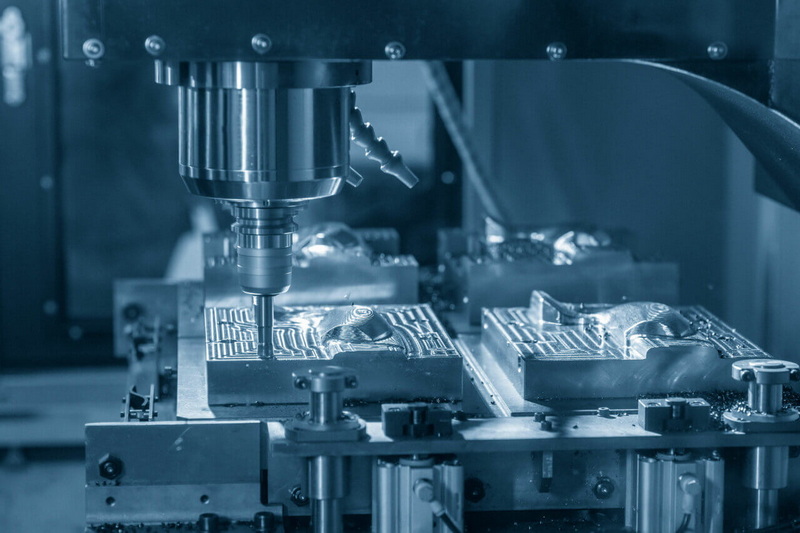

A primary strength of Metal CNC Machining Manufacturers and Suppliers in the Netherlands is advanced CNC milling. Multi‑axis machining centers allow them to produce intricate parts in aluminum, stainless steel, tool steel, titanium, and specialty alloys in fewer setups. This capability is critical for high‑precision housings, brackets, fixtures, and structural parts.

Many Dutch shops use 3‑axis, 4‑axis, and 5‑axis equipment to optimize cycle times and improve surface finishes. By combining high‑speed machining strategies with rigid setups and intelligent toolpath programming, Metal CNC Machining Manufacturers and Suppliers can deliver accurate components even for challenging designs.

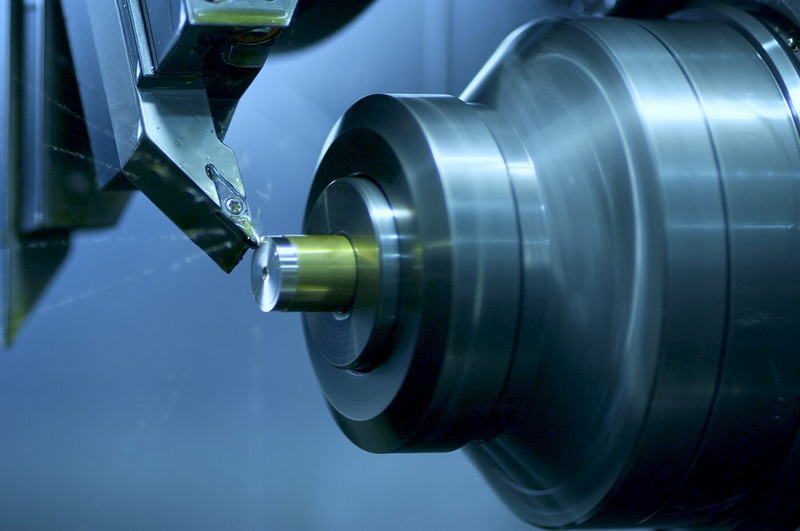

In addition to milling, Dutch Metal CNC Machining Manufacturers and Suppliers offer robust CNC turning services for shaft‑type and rotational components. CNC lathes with live tooling, sub‑spindles, and bar feeders support efficient production of complex turned parts.

This expertise is particularly important for automotive, hydraulic, and mechanical drive applications where accurate diameters, concentricity, and thread quality are critical. Many Metal CNC Machining Manufacturers and Suppliers combine turning and milling in a single setup, reducing handling and improving consistency.

The Netherlands excels at flexible production models. Metal CNC Machining Manufacturers and Suppliers frequently support customers from early prototypes through pilot runs and into stable serial production. Short setups, quick changeovers, and digital workflow management systems enable rapid response even for complex jobs.

For overseas brands or engineers testing new products, Dutch suppliers can machine one‑off prototypes or small batches that precisely mirror final production quality. Once the design stabilizes, these Metal CNC Machining Manufacturers and Suppliers can either keep production in‑house or coordinate with external OEM partners to scale volumes.

Quality assurance is a central focus for Metal CNC Machining Manufacturers and Suppliers in the Netherlands. Shops often implement quality systems based on recognized standards such as ISO 9001, and in some cases additional industry‑specific approvals for aerospace or medical devices.

These quality systems typically include incoming material verification, in‑process inspection, and final dimensional reports. Coordinate Measuring Machines (CMM), optical measurement tools, and surface roughness testers help ensure that machined parts meet customer specifications. For overseas buyers, this level of control gives confidence when sourcing precision metal components from Dutch Metal CNC Machining Manufacturers and Suppliers.

Metal CNC Machining Manufacturers and Suppliers in the Netherlands work with a broad range of materials to satisfy diverse application requirements. Typical metals include:

- Aluminum alloys for lightweight structural and electronic components.

- Stainless steels for corrosion‑resistant parts used in food processing, medical devices, and chemical equipment.

- Carbon and alloy steels for high‑strength mechanical parts and tooling.

- Copper and brass for electrical contacts and fluid fittings.

- Titanium and specialty alloys for aerospace and high‑performance applications.

Capability with such a broad material portfolio allows Metal CNC Machining Manufacturers and Suppliers to support complex bills of material within a single project.

Beyond basic machining, Dutch Metal CNC Machining Manufacturers and Suppliers usually coordinate or provide post‑processing steps to deliver ready‑to‑use components. Typical services include deburring, bead blasting, polishing, heat treatment, anodizing, plating, and painting.

By integrating finishing operations into their workflows, Metal CNC Machining Manufacturers and Suppliers help customers avoid managing multiple sub‑suppliers for each part. This integrated approach improves lead times and reduces quality risks.

The Netherlands is at the forefront of implementing digital and Industry 4.0 practices in machining. Many Metal CNC Machining Manufacturers and Suppliers deploy advanced CAD/CAM systems, networked CNC machines, and real‑time production monitoring.

Digital work instructions, tool management databases, and automated data collection improve planning accuracy and machine utilization. For international buyers, this digital maturity translates to more reliable delivery schedules, transparent communication, and easier integration of engineering changes into Metal CNC Machining Manufacturers and Suppliers' processes.

Located at the heart of Western Europe with world‑class ports and logistics infrastructure, the Netherlands provides a strategic benefit for distribution. Metal CNC Machining Manufacturers and Suppliers in the country can ship parts quickly across the EU, the UK, and neighboring regions.

This logistics strength is especially valuable for time‑critical components, service parts, and maintenance spares. Buyers who rely on just‑in‑time delivery often favor Dutch Metal CNC Machining Manufacturers and Suppliers for their ability to react quickly and ship reliably.

Another major advantage of Dutch Metal CNC Machining Manufacturers and Suppliers is the emphasis on engineering collaboration. Many shops offer design for manufacturability (DFM) guidance, suggesting geometry changes, material alternatives, or tolerance adjustments to reduce cost and improve reliability.

Such close cooperation helps overseas engineers refine their designs before committing to large production runs. Because Dutch Metal CNC Machining Manufacturers and Suppliers often work with cutting‑edge sectors, they are accustomed to complex requirements and can bring that experience to each new project.

While Dutch Metal CNC Machining Manufacturers and Suppliers offer strong engineering and local support, global OEM partners such as Shangchen in China complement these strengths by providing high‑value, scalable production. Shangchen is a factory focused on rapid prototyping, CNC machining services, precision batch production, lathe turning, sheet metal work, 3D printing, and mold manufacturing for international OEM customers.

This broad capability set allows Shangchen to turn early design concepts into real parts quickly, then scale successfully into mass production. For overseas brands, wholesalers, and manufacturers, combining the expertise of Dutch Metal CNC Machining Manufacturers and Suppliers with the capacity and cost advantages of Shangchen creates a powerful global supply model.

Shangchen specializes in rapid prototyping through CNC machining, 3D printing, and sheet metal fabrication. Customers can validate fit, function, and aesthetics at an early stage without committing to tooling. Once the design is confirmed, Shangchen's CNC machining and mold manufacturing capabilities enable smooth transition into low‑, medium‑, or high‑volume production.

This pattern aligns well with relationships that European companies already have with Dutch Metal CNC Machining Manufacturers and Suppliers. Early design and engineering tasks can be supported locally in the Netherlands, while larger production batches can be handled efficiently at Shangchen's factory.

Shangchen acts as an OEM partner for foreign brands, wholesalers, and manufacturers, providing components or complete assemblies under the customer's name. This includes CNC machined metal parts, plastic components, sheet metal enclosures, and molded elements.

By offering flexible batch sizes, robust quality systems, and multi‑process capability, Shangchen helps customers consolidate their sourcing rather than managing many small suppliers. In effect, Shangchen becomes an extension of the customer's own production, working alongside Dutch Metal CNC Machining Manufacturers and Suppliers that remain key partners for local support.

Many companies adopt a dual‑sourcing strategy: using Metal CNC Machining Manufacturers and Suppliers in the Netherlands for urgent or strategic parts while relying on Chinese OEM partners like Shangchen for cost‑sensitive volume production. This approach balances the strengths of both regions.

Within this model, Dutch suppliers often produce prototypes, pre‑series batches, or specialized parts that require close communication and fast revisions. Once the design is mature, production data, inspection standards, and best practices can be transferred to Shangchen, where the same components can be produced at scale.

A typical workflow could look like this:

1. A European engineering team designs a new device that needs several precision metal parts.

2. Local Metal CNC Machining Manufacturers and Suppliers in the Netherlands produce prototypes, help refine tolerances, and support testing.

3. After final validation, the customer and Dutch supplier define clear specifications, inspection requirements, and packaging standards.

4. These documents are shared with Shangchen, which sets up CNC machining processes, quality controls, and any required fixtures or tools for series production.

5. The customer receives consistent parts from both Dutch Metal CNC Machining Manufacturers and Suppliers (for urgent or special orders) and Shangchen (for volume orders), creating a robust global supply network.

For buyers seeking Metal CNC Machining Manufacturers and Suppliers in the Netherlands and globally, several factors are especially important.

Assess the range of machines, axes, maximum part sizes, and supported materials. Metal CNC Machining Manufacturers and Suppliers with modern equipment and strong CAM expertise are better able to handle complex projects and maintain stable quality over time.

Check whether a potential supplier can provide the specific operations your parts require, such as 5‑axis milling, deep‑hole drilling, threading, or hard turning. This avoids needing multiple vendors for one component.

Robust process control is vital for critical applications. Buyers should confirm that Metal CNC Machining Manufacturers and Suppliers have clear quality procedures, calibrated measurement equipment, and traceable documentation for each batch.

Certificates of conformity, material certificates, and dimensional inspection reports help you maintain compliance with internal and regulatory standards. For multi‑site sourcing across the Netherlands and China, consistent documentation also simplifies audits and customer reporting.

Successful long‑term relationships with Metal CNC Machining Manufacturers and Suppliers depend on transparent, timely communication. Evaluate how quickly a supplier responds to RFQs, engineering questions, and design revisions.

Well‑organized project management, clear lead‑time estimates, and proactive updates on production status can prevent delays and misunderstandings. This is especially important when coordinating between Dutch suppliers, Chinese OEM partners like Shangchen, and your internal teams.

Metal CNC Machining Manufacturers and Suppliers serve a wide variety of sectors that demand reliable mechanical performance.

- Aerospace and defense: High‑precision structural parts, brackets, and housings in aluminum, titanium, and high‑strength steels.

- Automotive and mobility: Engine and drivetrain components, suspension parts, steering elements, and custom brackets.

- Industrial machinery: Frames, mounting plates, transmission components, and tooling used in production lines and automation systems.

- Electronics and semiconductors: Precision metal parts for enclosures, cooling systems, and handling equipment.

- Medical and biotech: Stainless steel and titanium components for devices, diagnostic systems, and laboratory equipment.

In all these sectors, Metal CNC Machining Manufacturers and Suppliers in the Netherlands and OEM partners like Shangchen help ensure that critical metal parts are delivered accurately and on time.

Sustainability has become a major theme in manufacturing, and Metal CNC Machining Manufacturers and Suppliers are adapting accordingly. Machine tool efficiency, optimized toolpaths, and recycling of metal chips all help reduce waste.

Automation and digitalization also support sustainability by lowering energy consumption per part and improving machine utilization. As customers increasingly ask for carbon footprint data and eco‑friendly practices, both Dutch suppliers and Chinese OEM partners like Shangchen are expected to integrate greener technologies and traceability for environmental metrics.

Metal CNC Machining Manufacturers and Suppliers in the Netherlands form a highly capable, innovation‑focused network that supports some of Europe's most advanced industries. Their strengths lie in precision, engineering collaboration, flexible batch sizes, and fast, reliable logistics across the region.

At the same time, global OEM partners such as Shangchen in China expand the possibilities for international buyers by offering rapid prototyping, CNC machining, sheet metal work, 3D printing, and mold manufacturing under one roof. Working with both Dutch Metal CNC Machining Manufacturers and Suppliers and Shangchen allows brands, wholesalers, and manufacturers to balance cost, speed, and scalability.

By combining local engineering support in the Netherlands with high‑value production from a Chinese OEM factory, companies can build resilient, efficient supply chains. For any organization that needs consistent, high‑quality metal components, this integrated strategy across Metal CNC Machining Manufacturers and Suppliers is a practical path toward long‑term success.

Metal CNC Machining Manufacturers and Suppliers in the Netherlands offer strong engineering expertise, flexible batch sizes, and fast delivery across Europe. Their strategic location, advanced equipment, and experience with high‑tech industries make them ideal partners for complex, time‑sensitive metal components.

Shangchen complements Dutch Metal CNC Machining Manufacturers and Suppliers by providing rapid prototyping, scalable CNC machining capacity, sheet metal processing, 3D printing, and mold making at competitive cost. This enables customers to keep local engineering and urgent work in the Netherlands while shifting volume production to an integrated OEM partner.

Industries such as aerospace, automotive, industrial machinery, electronics, medical devices, and renewable energy benefit from working with Metal CNC Machining Manufacturers and Suppliers in the Netherlands. These sectors require tight tolerances, advanced materials, and reliable quality documentation, all of which Dutch suppliers and global partners like Shangchen can provide.

Buyers can ensure quality by defining clear specifications, tolerances, and inspection requirements that apply to all Metal CNC Machining Manufacturers and Suppliers involved. Regular communication, sample approval, and consistent quality documentation help align Dutch suppliers and Shangchen so that parts remain interchangeable regardless of production site.

Overseas brands should share 3D models, 2D drawings with key dimensions and tolerances, material specifications, surface finish requirements, quantity estimates, and any special standards or certifications needed. Providing this information upfront allows Shangchen to quote accurately, suggest optimizations, and deliver parts that match the expectations of both the customer and any partnering Metal CNC Machining Manufacturers and Suppliers.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia