Views: 222 Author: Amanda Publish Time: 2025-12-14 Origin: Site

Content Menu

● Why Japan Leads in Metal CNC Machining

● Major Metal CNC Machine Tool Brands in Japan

● Top Metal CNC Machining Service Providers in Japan

● Typical Capabilities of Japanese Metal CNC Machining Suppliers

● How Japanese Suppliers Serve Global OEM Buyers

● Comparing Japanese and Chinese Metal CNC Machining Options

● Role of Shangchen as a Global OEM Partner

● Integrated Services: From Prototypes to Mass Production

● How to Choose Metal CNC Machining Manufacturers and Suppliers in Japan

● Best Practices for Working with Japanese CNC Machining Suppliers

● Leveraging Media and On‑Site Verification

● Building a Dual‑Country CNC Machining Strategy

● FAQs

>> 2. Can overseas OEMs place small or prototype orders with Japanese machining suppliers?

Japan stands among the world's most advanced hubs for Metal CNC Machining Manufacturers and Suppliers, providing high‑precision components to industries such as automotive, aerospace, robotics, medical devices, and electronics. These suppliers are known for tight tolerances, robust process control, and long‑term reliability that global OEM buyers rely on for critical parts. At the same time, pairing Japanese machining specialists with flexible OEM partners in China, such as Shangchen (sc-rapidmanufacturing.com), gives overseas brands a powerful combination of precision and cost efficiency.

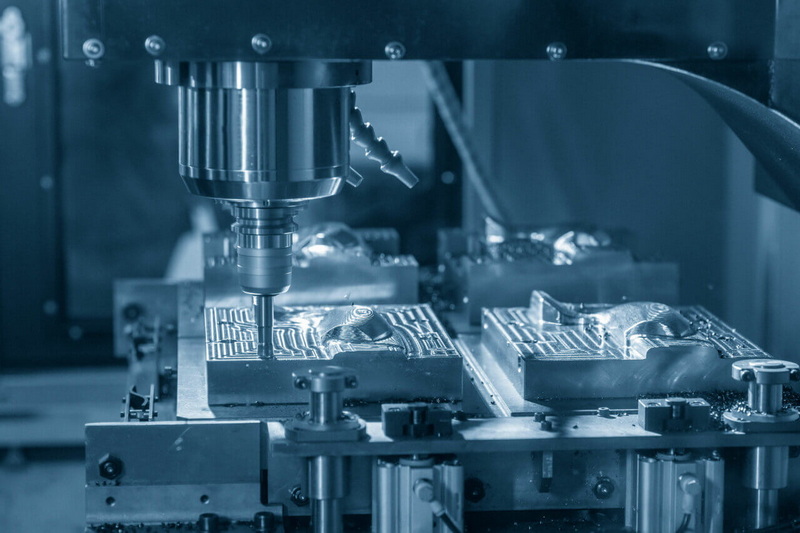

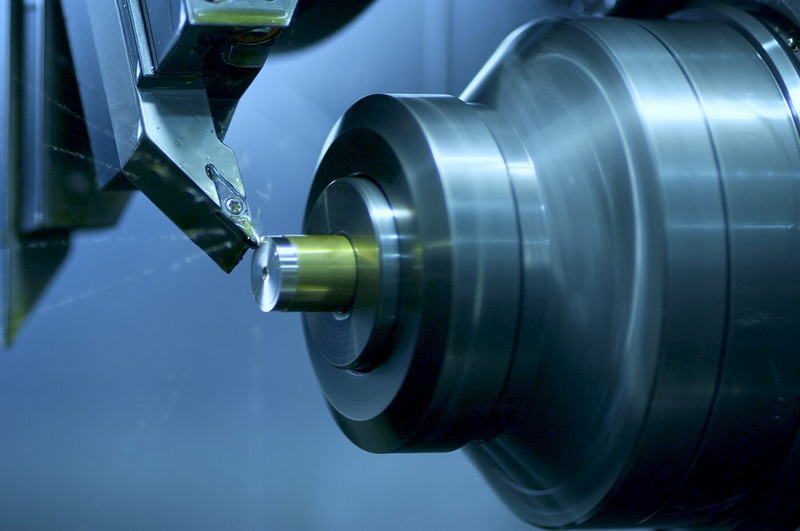

Japanese Metal CNC Machining Manufacturers and Suppliers have built their reputation on continuous investment in technology, skilled craftsmanship, and rigorous quality culture. They operate advanced CNC milling, turning, grinding, and EDM equipment supported by strong in‑house engineering and process development teams. This combination allows Japanese suppliers to consistently meet strict dimensional, surface, and reliability requirements across large production runs.

Another key strength is the way Japanese suppliers integrate automation—robotic loading, in‑line measurement, and standardized work instructions—into CNC machining lines. This automation not only improves productivity but also stabilizes quality over time, which is particularly important for long program life cycles in automotive, industrial machinery, and semiconductor equipment.

To understand why Japanese Metal CNC Machining Manufacturers and Suppliers perform at such a high level, it is important to look at the domestic machine tool industry that supports them. Japan is home to some of the most influential CNC machine builders in the world, whose products are widely used both domestically and internationally.

Companies such as Mazak, Okuma, and Makino develop CNC lathes, machining centers, multitasking machines, and EDM systems that serve as the backbone of many precision machining shops. Their machines are known for rigid structures, intelligent CNC controls, and features such as thermal compensation and vibration damping that directly improve part accuracy. Many Japanese service providers run fleets of these machines, allowing them to tackle complex geometries and demanding materials while maintaining stable process capability.

Machine tool builders in Japan also collaborate closely with end‑users to refine cutting strategies, tooling combinations, and automation concepts. This close feedback loop helps the entire ecosystem of Metal CNC Machining Manufacturers and Suppliers to keep improving productivity and precision, ultimately benefiting overseas OEM customers with higher performance and shorter cycle times.

Beyond machine builders, Japan hosts a large network of Metal CNC Machining Manufacturers and Suppliers that provide contract machining services for domestic and international clients. These companies range from specialized high‑end shops to mid‑sized factories dedicated to OEM export work.

Many of these firms focus on high‑precision CNC milling and turning for industries where failure is not an option—such as aerospace components, medical implants, semiconductor equipment parts, and precision gear housings. Others concentrate on automotive powertrain parts, hydraulic components, or industrial automation hardware, where the emphasis is on stable, high‑volume production with strict dimensional and cleanliness standards.

Because Japan is an export‑oriented manufacturing nation, many machining houses are familiar with working from international drawings and standards. They understand GD&T, international material specifications, and packaging/export requirements, which reduces friction when working with buyers from North America, Europe, or other regions in Asia.

Japanese Metal CNC Machining Manufacturers and Suppliers typically offer a broad set of core and supporting processes under one roof. This allows OEM buyers to source both prototypes and mass‑production parts from a single partner without constantly changing suppliers as product volumes grow.

Common capabilities include:

- CNC milling in 3‑axis, 4‑axis, and 5‑axis configurations for aluminum, steel, stainless steel, titanium, and special alloys.

- CNC turning and turn‑mill operations for shafts, bushings, housings, and complex rotational components.

- Grinding (surface, cylindrical, centerless) for tight dimensional accuracy and superior surface finishes.

- EDM (wire and sinker) for difficult contours, sharp internal corners, and hardened tool steel applications.

- Precision drilling, tapping, boring, and reaming combined with multi‑step machining cycles.

- Optional services such as heat treatment, surface treatment, and sub‑assembly through in‑house lines or trusted partners.

In addition, many Japanese suppliers have in‑house quality laboratories equipped with coordinate measuring machines (CMMs), optical measurement systems, profilometers, and hardness testers. This metrology infrastructure supports rigorous inspection and helps maintain consistent quality over long production runs.

Metal CNC Machining Manufacturers and Suppliers in Japan typically operate as long‑term partners to OEMs rather than short‑term job shops. They often participate early in design discussions, reviewing tolerances, manufacturability, and cost drivers before parts are frozen. This collaborative approach reduces the risk of later design changes and makes it easier to maintain stable production once parts enter mass production.

Many Japanese suppliers export directly to global customers or work through trading companies that handle logistics, customs, and local support. They ship components to automotive plants, aerospace assembly lines, and industrial equipment factories around the world. These suppliers are accustomed to providing full documentation, including material certificates, inspection reports, and traceability records, which are critical for safety‑critical and regulated industries.

From a sourcing perspective, buyers often compare Japanese Metal CNC Machining Manufacturers and Suppliers with Chinese counterparts to balance cost, capability, and risk. Japan typically positions itself at the high‑precision, high‑complexity end of the spectrum, leveraging sophisticated equipment and exceptional process control. This makes Japanese suppliers attractive for parts that require extremely tight tolerances, complex multi‑axis operations, or stringent functional requirements.

China, by contrast, offers strong cost advantages and highly flexible capacity across a wide range of processes and volumes. Chinese Metal CNC Machining Manufacturers and Suppliers can handle everything from early prototypes to large‑scale production while maintaining competitive pricing. As a result, many OEMs adopt a dual‑country strategy: using Japanese partners for ultra‑critical parts and Chinese factories for cost‑sensitive components and integrated assemblies.

Shangchen is an example of a Chinese factory designed specifically to support overseas OEM customers through the full product life cycle. As a Metal CNC Machining Manufacturer and Supplier, Shangchen integrates rapid prototyping, CNC milling, CNC turning, sheet metal fabrication, 3D printing, precision batch production, and mold manufacturing under one management system.

This structure allows foreign brand owners, wholesalers, and product manufacturers to move smoothly from concept validation to trial production and finally to mass production. A buyer can start with a small batch of CNC‑machined prototypes, refine the design with Shangchen's engineering support, and then proceed to tooling, mold production, and large‑volume manufacturing without switching suppliers. Such continuity reduces project risk and shortens time‑to‑market.

Shangchen's focus on OEM work also means it understands issues such as branding, packaging, confidentiality, and long‑term cost roadmaps. It aims to function as an extension of the customer's own manufacturing capability, providing flexible capacity that can ramp up or down based on market demand.

A major advantage of combining Japanese Metal CNC Machining Manufacturers and Suppliers with a Chinese OEM factory like Shangchen is the ability to manage the entire product journey efficiently. Japanese suppliers can focus on the most challenging and sensitive components, while Shangchen can handle a mix of CNC machining, sheet metal, and molded parts along with assemblies.

For example, a high‑end industrial device might contain a few ultra‑critical, high‑precision metal components sourced from Japan, while the rest of the machined and fabricated parts, enclosures, and custom fixtures are produced in China. Shangchen can support quick design iterations and smaller experimental batches, while Japanese partners guarantee absolute reliability for key functional components. This type of blended sourcing strategy gives OEMs both technical confidence and commercial flexibility.

Selecting the right Japanese Metal CNC Machining Manufacturers and Suppliers requires a clear understanding of your technical, commercial, and logistical priorities. A structured approach will reduce risk and help you identify a partner that can scale with your business.

Important evaluation steps include:

- Clarify technical requirements: Define materials, tolerances, surface finishes, volumes, and any functional tests or certifications needed.

- Screen suppliers: Use industry directories, trade associations, and professional platforms to identify candidates with relevant sector experience.

- Review equipment and capacity: Confirm that the supplier's machines, automation level, and inspection tools match your part complexity and volume.

- Assess quality systems: Request information on quality certifications, process control methods, and typical inspection documentation.

- Evaluate communication: Examine how quickly and clearly the supplier responds to requests, questions, and engineering feedback.

- Start with trial orders: Place small or medium trial batches to verify real‑world performance before committing to long‑term production.

By following these steps, OEM buyers can confidently build relationships with Japanese Metal CNC Machining Manufacturers and Suppliers that match their performance and risk expectations.

To get the most from Japanese Metal CNC Machining Manufacturers and Suppliers, OEM buyers should establish clear communication habits and documentation standards from the start. Precision machining depends heavily on accurate information, so eliminating ambiguity is essential.

Recommended practices include:

- Provide complete technical packages, including 3D models, 2D drawings with GD&T, material standards, and any special handling requirements.

- Share forecast volumes and ramp‑up plans so suppliers can plan capacity, fixtures, and tooling investments.

- Define inspection plans, acceptance criteria, and reporting formats (for example, initial sample inspection reports, capability studies, and periodic audits).

- Schedule regular technical calls or video meetings, especially in early stages, to resolve questions quickly and align expectations.

- Encourage open feedback from the supplier on manufacturability, cost drivers, and potential design optimizations.

In parallel, maintaining a relationship with a flexible OEM partner like Shangchen gives buyers a way to quickly adjust capacity, support new projects, or shift less critical parts without disrupting core Japanese supplier relationships.

When selecting Metal CNC Machining Manufacturers and Suppliers in Japan, visual verification is a powerful complement to documentation and quotations. Even if a buyer cannot immediately visit in person, videos and photos of the factory help confirm that the supplier's claimed capabilities match reality.

Buyers can request or review:

- Short clips of CNC machining lines, including tool changes, multi‑axis operations, and automated loading systems.

- Walk‑through videos showing raw material storage, machining areas, inspection rooms, and packing stations.

- Visual examples of similar parts or assemblies that the supplier produces for other customers (with confidentiality respected).

Later, when travel is possible, on‑site audits and process reviews give an even deeper understanding of the supplier's culture, workflow, and improvement mindset. Combining remote media review with occasional on‑site visits leads to more informed and confident sourcing decisions.

For many OEMs, the most resilient approach is not choosing between Japan and China, but rather designing a dual‑country strategy that leverages the strengths of both. Japanese Metal CNC Machining Manufacturers and Suppliers provide cutting‑edge precision and robust process control, ideal for safety‑critical or high‑performance parts. Chinese OEM partners like Shangchen offer speed, flexibility, and competitive pricing across a wide range of volumes and processes.

A practical strategy may include:

- Assigning high‑risk or technologically demanding components to Japanese suppliers.

- Using Shangchen for rapid prototyping, engineering samples, marketing samples, and design validation runs.

- Migrating cost‑sensitive or less critical components to Shangchen once designs stabilize.

- Maintaining contingency plans so production can shift between facilities in response to demand spikes or supply disruptions.

This multi‑source model reduces over‑reliance on a single country or supplier while still capturing the unique advantages offered by each manufacturing base.

Metal CNC Machining Manufacturers and Suppliers in Japan play a vital role in the global manufacturing ecosystem, delivering components that must meet extremely high standards of precision and reliability. Their deep expertise, advanced equipment, and commitment to quality make them the preferred choice for many high‑end applications in automotive, aerospace, medical, semiconductor, and industrial machinery sectors. For OEM buyers, partnering with Japanese machining suppliers brings confidence that critical parts will perform as designed over long service lives.

At the same time, working with an integrated Chinese OEM factory like Shangchen adds flexibility, speed, and cost competitiveness across a broader range of products and volumes. By combining the strengths of Japanese and Chinese Metal CNC Machining Manufacturers and Suppliers, companies can build a robust, efficient, and scalable supply chain capable of supporting rapid innovation and global growth. Thoughtful supplier selection, clear communication, and long‑term collaboration are the keys to unlocking the full potential of this international machining network.

Japanese Metal CNC Machining Manufacturers and Suppliers typically emphasize ultra‑precision, long‑term process stability, and advanced automation, often supported by domestically produced high‑end CNC machines. This gives them a particular advantage in parts that demand tight tolerances, complex multi‑axis machining, and rigorous traceability. In contrast, suppliers in other regions may focus more on cost or general‑purpose machining, making Japan especially attractive for high‑value, high‑risk components.

Many Japanese Metal CNC Machining Manufacturers and Suppliers are willing to handle small or prototype orders, particularly when these are part of a roadmap toward mass production. However, because their operations are often optimized for stable, repeat orders, very small jobs may carry higher unit costs. To keep overall sourcing efficient, some OEMs use Japanese suppliers for critical prototypes while relying on flexible OEM partners like Shangchen for rapid iterations and early‑stage development.

To receive accurate quotations, buyers should prepare complete technical data, including 3D CAD models, detailed 2D drawings with tolerances, material specifications, and surface requirements. It is also important to provide estimated annual volumes, target lead times, and any special quality or certification needs. Clear information enables Japanese Metal CNC Machining Manufacturers and Suppliers to select appropriate processes, tooling, and inspection plans, resulting in more reliable pricing and delivery commitments.

Export‑oriented Japanese Metal CNC Machining Manufacturers and Suppliers typically operate under formal quality management systems and rely on well‑documented process control. They use capabilities such as incoming material inspection, in‑process checks, final CMM inspection, and statistical monitoring of key dimensions. For export customers, they can provide material certificates, inspection reports, and traceability documentation, ensuring that every shipment meets both technical specifications and regulatory requirements.

Combining Japanese Metal CNC Machining Manufacturers and Suppliers with a Chinese OEM partner such as Shangchen allows buyers to place each part in the environment where it delivers the best value. Japanese suppliers can focus on the most demanding, high‑precision components, while Shangchen handles rapid prototyping, mixed‑volume CNC machining, sheet metal fabrication, 3D printing, and mold‑based production. This hybrid model balances performance, cost, and flexibility, and helps OEMs respond quickly to market changes without sacrificing quality.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal