Views: 222 Author: Amanda Publish Time: 2025-12-14 Origin: Site

Content Menu

● Overview of Italy's CNC Machining Ecosystem

● Regional Clusters and Industrial Strengths

● Industries Served by Italian Metal CNC Companies

● Typical Capabilities of Metal CNC Machining Manufacturers and Suppliers

● Digitalization and Automation in Italian CNC Facilities

● Quality Systems and Certifications

● Collaboration Models with Overseas OEMs

● Integrating Italian Suppliers with Shangchen in China

● Shangchen's Role as a Global OEM Partner

● Benefits of Dual‑Sourcing Between Italy and China

● How to Evaluate Italian Metal CNC Machining Manufacturers and Suppliers

● Engineering Support and Design for Manufacturability (DFM)

● Advanced Processes and Hybrid Manufacturing

● Typical Workflow from RFQ to Serial Production

● Cost Considerations and Value Assessment

● Future Trends for Metal CNC Machining Manufacturers and Suppliers in Italy

● How Shangchen Supports Long‑Term CNC Machining Programs

● Practical Tips for Working with Italian CNC Suppliers

● FAQ

>> 1. What makes Italian Metal CNC Machining Manufacturers and Suppliers attractive for OEMs?

>> 2. How can overseas companies coordinate projects between Italian suppliers and Shangchen?

>> 4. Can Italian Metal CNC machining companies handle both prototypes and mass production?

>> 5. How does Shangchen complement Italian Metal CNC Machining Manufacturers and Suppliers?

Italy has built a strong reputation for precision engineering, making it one of Europe's key hubs for Metal CNC Machining Manufacturers and Suppliers serving global OEM brands, wholesalers, and industrial producers. For international buyers, Italian CNC companies offer advanced technology, high-quality metals processing, and specialized expertise that can be combined with cost‑effective partners in China such as Shangchen (sc-rapidmanufacturing.com) for a complete OEM solution.

Italy's CNC machining ecosystem is anchored by its long tradition in mechanical engineering, machine tools, and industrial design. Over decades, Italian Metal CNC Machining Manufacturers and Suppliers have evolved from traditional workshops into highly automated factories equipped with multi‑axis machining centers and digital production systems.

Within this ecosystem, there is a clear distinction but strong synergy between machine tool builders, component machining workshops, and specialized tooling makers. While machine builders design and manufacture the CNC equipment and automation systems, machining job shops operate these systems to deliver precision parts for domestic and overseas customers, often under strict OEM requirements and international standards.

Italy's Metal CNC Machining Manufacturers and Suppliers are concentrated in several regional clusters, each with unique strengths and industry connections. Lombardy and Emilia‑Romagna, for example, host numerous CNC machine tool builders and precision component factories that feed into automotive, packaging, and industrial machinery sectors.

Veneto and Piedmont also play important roles, with networks of small and medium‑sized enterprises specializing in high‑precision metal parts, prototyping, and batch production. These regional ecosystems enable close collaboration between universities, research centers, and industry, encouraging innovation in machining processes, automation, and materials technologies.

Metal CNC Machining Manufacturers and Suppliers in Italy serve a broad spectrum of industries that demand exacting standards, long‑term reliability, and rapid response to design changes. Among the most important sectors are automotive and motorsport, where Italian suppliers produce engine components, drivetrain parts, precision brackets, and structural metal parts for both mass‑market and performance brands.

Aerospace and energy companies rely on Italian CNC machining providers for complex, high‑value components such as turbine parts, structural frames, and housings that require five‑axis machining, high‑temperature alloys, and rigorous quality certification. Beyond these, industries like medical devices, food and packaging machinery, industrial automation, and luxury goods all depend on specialized Metal CNC Machining Manufacturers and Suppliers to produce custom, high‑tolerance parts.

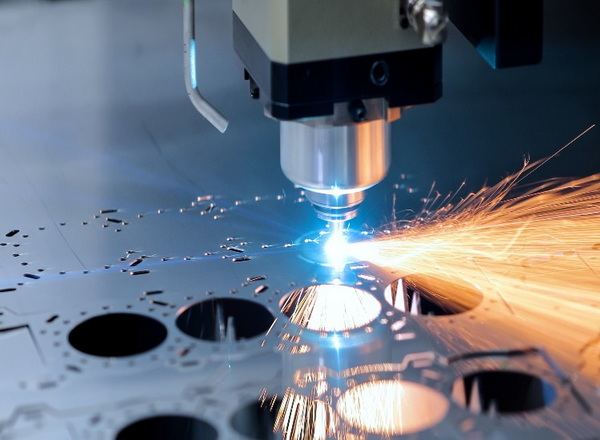

Leading Metal CNC Machining Manufacturers and Suppliers in Italy offer an extensive capability portfolio to address diverse project requirements. From basic three‑axis milling and turning to advanced five‑axis machining, mill‑turn centers, and large‑format gantry systems, these companies can machine everything from small precision inserts to large structural components.

Many providers also incorporate grinding, EDM, honing, and surface treatment capabilities, enabling them to deliver fully finished parts from raw stock. In addition, in‑house design and process engineering teams help optimize toolpaths, fixtures, and machining strategies to reduce cycle time, improve surface finish, and maintain dimensional accuracy over long production runs.

Digitalization has become central to the strategy of modern Metal CNC Machining Manufacturers and Suppliers in Italy. These companies increasingly use CAD/CAM systems, digital twins, and simulation tools to validate machining strategies before production, reducing scrap and setup times.

On the shop floor, automation is widely adopted: robotized loading systems, pallet changers, bar feeders, and automatic tool changers work together with CNC machines to enable continuous production with minimal manual intervention. This improves process stability and allows Italian facilities to run high‑mix, low‑volume orders while maintaining competitive lead times for global OEM customers.

A key differentiator for Italian Metal CNC Machining Manufacturers and Suppliers is their emphasis on quality management. Many operate under internationally recognized quality systems such as ISO‑based standards, while aerospace and automotive suppliers may hold additional sector‑specific certifications.

High‑precision machining operations typically include in‑process probing, tool monitoring, and offline inspection using coordinate measuring machines and other metrology tools. Statistical process control, documented traceability, and rigorous incoming and outgoing inspection procedures give overseas buyers confidence that their parts will meet tight tolerances and functional requirements consistently across batches.

International OEM brands, wholesalers, and manufacturers often work with Italian Metal CNC Machining Manufacturers and Suppliers through structured collaboration models designed to ensure technical alignment and commercial transparency. A typical process starts with a detailed review of drawings, CAD data, and specification documents.

Once both sides agree on tolerances, materials, and surface treatments, the Italian supplier may produce prototypes or pilot batches for validation. After successful approval, the project transitions into series production, with agreed KPIs for quality, lead time, and cost. Communication is usually supported by bilingual engineering teams and project managers, ensuring smooth coordination across time zones.

For buyers looking to balance technical sophistication with cost‑effective production, combining Italian Metal CNC Machining Manufacturers and Suppliers with Shangchen in China can create a powerful hybrid supply chain. Italian companies can focus on advanced engineering, tooling design, and complex, high‑precision components that leverage local expertise and specialized machine tools.

Shangchen, as a Chinese rapid prototyping and precision manufacturing partner, can then handle additional prototypes, bridge batches, and large‑volume production runs. By coordinating design, process documentation, and quality requirements, OEMs can maintain consistent standards while distributing different stages of the project across Italy and China for optimal cost and lead time.

Shangchen provides a wide range of services useful for overseas companies that already work with Italian Metal CNC Machining Manufacturers and Suppliers or plan to do so. These services include rapid prototyping, CNC milling and turning, precision batch production, sheet metal fabrication, 3D printing, mold production, and plastic or metal part finishing.

Because Shangchen specializes in OEM work for international customers, it is experienced in handling diverse material grades, complex geometries, and multi‑process manufacturing routes. This makes it an ideal partner for Italian engineering firms or machine builders who want a reliable manufacturing base in Asia capable of scaling up from pilot runs to large‑volume orders while maintaining high levels of dimensional control.

A dual‑sourcing strategy that combines Italian Metal CNC Machining Manufacturers and Suppliers with Shangchen's facilities in China offers several clear advantages. First, it enables buyers to use Italy's strengths in design, tooling, and complex machining for the most critical or technically demanding components.

Second, by leveraging Shangchen's flexible production lines and competitive labor and overhead structure, OEMs can reduce overall cost for selected parts or assemblies without compromising on quality. Third, dual‑sourcing enhances supply chain resilience by spreading production across different regions, which can help mitigate risks related to logistics, capacity constraints, or localized disruptions.

When choosing among Italy's many Metal CNC Machining Manufacturers and Suppliers, buyers should evaluate several critical factors. Technical capability is central: it is important to confirm that the supplier has the right combination of machine size, axis configuration, and tooling systems to handle the parts in question. This includes verifying experience with relevant materials such as aluminum, stainless steel, tool steel, titanium, and special alloys.

Buyers should also consider process flexibility, including the ability to switch between prototype quantities and serial production without long re‑setup times. A strong track record in the relevant industry (such as automotive, aerospace, or medical) increases confidence that the supplier understands typical quality expectations and regulatory constraints. Finally, checking references and sample parts is a practical way to validate promises made in proposals or sales discussions.

One hallmark of leading Metal CNC Machining Manufacturers and Suppliers in Italy is the level of engineering support they offer. Rather than simply quoting to print, many companies propose design adjustments to reduce machining complexity, improve tolerance stack‑ups, or simplify assembly.

Design for Manufacturability reviews may suggest changes in wall thickness, fillet radii, datum selection, or tolerance distribution that allow parts to be machined more efficiently while still meeting functional requirements. For OEMs working with both Italian suppliers and Shangchen, early DFM input helps standardize designs, making it easier to transfer production or split volume between regions without compromising quality.

The industry trend toward hybrid manufacturing is also visible among Italian Metal CNC Machining Manufacturers and Suppliers. Many firms integrate metal additive manufacturing technologies such as powder bed fusion with conventional CNC machining, using 3D printing to create near‑net‑shape preforms that are then finished on machining centers.

This approach is especially valuable for parts with internal channels, lattice structures, or weight‑optimized topologies that would be extremely difficult or impossible to produce from solid block. Hybrid processes enable significant material savings and design freedom while maintaining the surface finish and dimensional precision expected from top‑tier CNC machining providers.

From the buyer's perspective, working with Metal CNC Machining Manufacturers and Suppliers in Italy usually follows a structured workflow. It begins with a request for quotation that includes drawings, CAD models, annual volume estimates, and any special quality or documentation requirements. Suppliers analyze the information, perform manufacturability review, and submit quotes with pricing, lead time, and tooling charges if needed.

Once an order is placed, the supplier creates detailed process plans including machine selection, fixtures, cutting tools, and inspection procedures. Prototypes or first articles are then delivered for validation. After sign‑off, the process enters serial production with regular shipments based on agreed schedules. Throughout, communication on engineering changes, non‑conformities, and continuous improvement actions keeps both sides aligned.

While Italian Metal CNC Machining Manufacturers and Suppliers are often not the lowest‑cost option globally, they deliver high value in terms of engineering competence, process stability, and long‑term support. Total cost of ownership for OEMs must consider not just unit price but also scrap rates, rework, logistics, lead time reliability, and the risk of quality issues in the field.

By pairing Italian suppliers with a capable partner like Shangchen in China, buyers can optimize the balance between value and cost. Highly complex or safety‑critical parts may remain in Italy, while simpler or more volume‑driven components are produced in China under the same quality standards and documentation framework.

Looking ahead, Italian Metal CNC Machining Manufacturers and Suppliers are expected to continue investing in automation, digitalization, and sustainable manufacturing practices. Energy‑efficient machines, intelligent process monitoring, and the use of environmentally friendly coolants and cutting strategies will become more important as customers place greater emphasis on sustainability.

At the same time, demand for smaller batch sizes, shorter product lifecycles, and more frequent design updates will push suppliers to become even more flexible. This favors companies that combine advanced CNC equipment, strong engineering support, and robust digital workflows capable of quickly adapting to new products and market requirements.

For OEMs planning long‑term CNC machining programs, Shangchen can serve as a strategic partner that complements Italian Metal CNC Machining Manufacturers and Suppliers. Shangchen's strengths in rapid prototyping allow customers to iterate designs quickly before locking in tooling and production parameters.

Once the design stabilizes, Shangchen's CNC machining, turning, sheet metal, and mold-making capabilities can support different lifecycle phases, from pilot production to steady‑state mass production or aftermarket spares. Close cooperation with Italian engineering teams can ensure that process knowledge, quality criteria, and inspection plans are consistent across both regions.

To get the best results from Italian Metal CNC Machining Manufacturers and Suppliers, buyers should adopt a few practical practices. Providing clear and complete technical documentation, including 3D models, 2D drawings, and specifications, reduces the risk of misunderstanding and speeds up quoting.

Establishing agreed communication channels and response times for engineering questions helps maintain project momentum. Starting with a smaller project or pilot run allows both sides to learn each other's expectations and working style before moving to higher volumes. Finally, aligning packaging, labeling, and logistics requirements at the outset avoids unnecessary delays once shipments begin.

Italy's Metal CNC Machining Manufacturers and Suppliers form a sophisticated ecosystem that combines deep engineering experience, advanced CNC technology, and robust quality systems. They serve demanding markets such as automotive, aerospace, energy, medical, and luxury goods, providing complex metal components with tight tolerances and high reliability.

For international OEMs, integrating Italian suppliers with a versatile Chinese partner like Shangchen unlocks the ability to blend European innovation and engineering with flexible, cost‑effective production in Asia. By carefully evaluating suppliers, using DFM and digital collaboration, and adopting a dual‑sourcing strategy, buyers can build resilient, high‑performance supply chains for metal CNC machined parts that support current products and future growth.

Italian Metal CNC Machining Manufacturers and Suppliers are attractive because they combine advanced equipment, strong engineering capabilities, and a long history of precision manufacturing. This combination enables them to handle complex geometries, tight tolerances, and demanding materials while maintaining high quality and consistent delivery performance for international OEMs.

For buyers needing both technical depth and reliability, Italy offers machine builders, machining workshops, and tooling specialists that can support complete product lifecycles from prototype to series production.

Overseas companies can coordinate projects by clearly defining roles and responsibilities for each partner at the start of the program. Italian Metal CNC Machining Manufacturers and Suppliers can focus on advanced design, process validation, and critical or complex parts, while Shangchen handles rapid prototyping, bridge production, and large‑volume manufacturing of selected components.

Using shared documentation, standardized inspection procedures, and regular technical reviews helps ensure that both Italian suppliers and Shangchen work from the same information, delivering parts that are fully compatible and meet identical quality standards.

When sending RFQs, buyers should include as much relevant technical data as possible, such as 3D models, detailed drawings, material specifications, surface finish requirements, tolerances, estimated annual volumes, and any certification needs. Providing clear information allows Italian Metal CNC Machining Manufacturers and Suppliers to evaluate feasibility accurately and propose optimized machining strategies.

It is also helpful to indicate whether the project will involve prototypes, small batches, or large‑scale production, as this can influence fixture design, tooling investment, and pricing structure.

Many Italian Metal CNC Machining Manufacturers and Suppliers are equipped to handle the full range of production volumes, from one‑off prototypes to large batch series. Flexible machine setups, modular fixturing, and advanced programming allow them to switch quickly between different part numbers and quantities.

For mass production, they can implement automation systems, multi‑pallet setups, and optimized tool management to maintain high throughput. When combined with a partner like Shangchen, these capabilities enable seamless scaling from initial concept to stable, high‑volume supply.

Shangchen complements Italian Metal CNC Machining Manufacturers and Suppliers by offering rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production with a focus on OEM export projects. This allows buyers to leverage Italian expertise in design and high‑end machining, while using Shangchen's facilities for additional capacity and cost‑efficient production of compatible parts.

By coordinating engineering data and quality requirements, buyers can build a mixed supply network where Italian and Chinese facilities work together as an integrated manufacturing system rather than isolated vendors.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal