Views: 222 Author: Amanda Publish Time: 2025-12-13 Origin: Site

Content Menu

● Why Germany Leads in CNC Machining

● Overview of the German Metal CNC Industry

● Leading German CNC Machine Builders

● Typical Capabilities of German Metal CNC Suppliers

● Quality, Standards, and Certifications

● How to Choose a German Metal CNC Partner

● Ordering Process With German Metal CNC Suppliers

● Pricing and Cost Drivers in German CNC Machining

● When to Combine German and Chinese CNC Resources

● Shangchen as a Global OEM Partner

● How Shangchen Complements German CNC Suppliers

● Best Practices for Working With Metal CNC Suppliers

● Digitalization and Industry 4.0 in German CNC

● Environmental and Sustainability Considerations

● Common Challenges and How to Overcome Them

● Summary for International Buyers

● FAQ

>> 1. What makes German Metal CNC suppliers different from suppliers in other regions?

>> 3. How can a Chinese factory like Shangchen support projects that also involve German CNC suppliers?

>> 5. How can buyers ensure consistent quality when using both German and Chinese CNC suppliers?

Metal CNC Machining Manufacturers and Suppliers in Germany are central to Europe's high‑precision engineering landscape, especially for automotive, aerospace, medical, energy, and machinery applications. Germany's strong industrial base, advanced machine tools, and focus on quality make it an ideal sourcing destination for overseas brands, wholesalers, and OEM manufacturers.

Germany holds one of the largest CNC machine markets in Europe, supported by dominant automotive and mechanical engineering sectors and early adoption of Industry 4.0 concepts. A dense network of industrial clusters in regions such as Bavaria, Baden‑Württemberg, and North Rhine‑Westphalia concentrates skills, suppliers, and customers in close proximity.

This environment allows Metal CNC Machining Manufacturers and Suppliers to collaborate with automation providers, toolmakers, metrology specialists, and material producers. As a result, German CNC companies can maintain short lead times, high process stability, and consistent product quality for both domestic and international clients.

Across Germany, there are thousands of CNC‑related companies and a large number of specialized Metal CNC Machining Manufacturers and Suppliers offering milling, turning, grinding, and multi‑axis machining services. These companies can support the complete life cycle of metal components, from early prototypes and toolmaking to serial production and after‑market parts.

Industries served include internal combustion and electric powertrain systems, aircraft structures, turbines and compressors, surgical implants, and precision fixtures. German Metal CNC Machining Manufacturers and Suppliers often work directly with global OEMs as well as tier‑one and tier‑two suppliers, delivering metal parts that meet demanding technical and regulatory requirements.

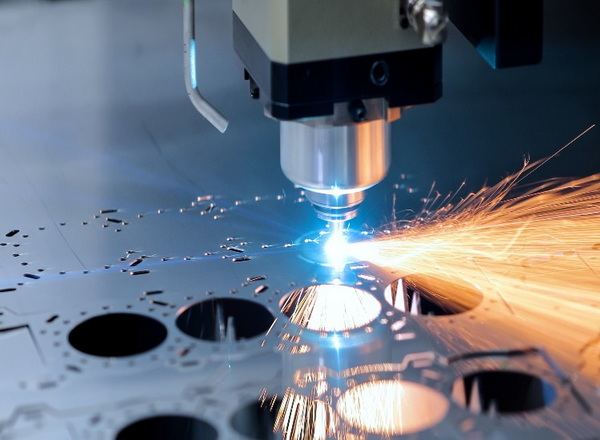

Germany is home to world‑renowned CNC machine builders whose technologies are used by Metal CNC Machining Manufacturers and Suppliers worldwide. Their machines support complex multi‑axis machining, high‑speed cutting, advanced automation, and digital monitoring capabilities.

Key names include manufacturers of high‑end milling and turning centers, providers of laser cutting and metal forming systems, and specialists in 4‑axis and 5‑axis machining centers. Their equipment is widely used in automotive powertrain production, aerospace structures, precision toolmaking, medical implant machining, and general metalworking for industrial machinery.

These machine builders also play a strategic role in shaping future manufacturing trends by integrating smart sensors, digital twins, and cloud‑based monitoring into their CNC platforms. As a result, German Metal CNC Machining Manufacturers and Suppliers benefit from constant technology upgrades and strong technical support.

Metal CNC Machining Manufacturers and Suppliers in Germany usually offer a broad portfolio of processes, allowing customers to consolidate multiple operations under one roof. This integration is particularly valuable for overseas OEMs who need consistent quality across different product families.

Common capabilities include:

- CNC milling (3‑axis, 4‑axis, and 5‑axis) for prismatic and complex metal components

- CNC turning and turn‑mill operations for shafts, bushings, housings, and rotational parts

- Grinding, honing, and hard turning for high‑accuracy surfaces and tight fits

- Laser cutting, bending, and forming for metal plates, brackets, and structural elements

- Wire EDM and sinker EDM for tight‑tolerance features and tooling inserts

- Heat treatment and surface treatment through in‑house or qualified partner networks

- Comprehensive metrology using CMMs, optical scanners, and in‑process gauging

These capabilities enable German Metal CNC Machining Manufacturers and Suppliers to deliver both prototype and series metal components with high dimensional accuracy, controlled surface finishes, and documented process stability.

One of the main reasons buyers choose Metal CNC Machining Manufacturers and Suppliers in Germany is their approach to quality management. Most reputable companies operate under ISO 9001, and many also hold additional certifications relevant to automotive, aerospace, or medical devices.

Typical quality practices include process FMEA, structured control plans, statistical process control, and final inspection supported by modern CMM equipment. For safety‑critical metal components, suppliers may provide first article inspection reports, capability studies, and full traceability from raw material to finished part.

In addition, many German CNC companies integrate digital quality tools such as electronic inspection records, automatic data collection from machines, and real‑time dashboards. These systems help track deviations quickly and support continuous improvement programs.

Selecting the right Metal CNC Machining Manufacturers and Suppliers in Germany begins with a clear understanding of project requirements. Buyers should evaluate not only technical capabilities but also communication style, project management, and long‑term partnership potential.

Key selection factors include:

- Experience with similar materials, parts, and industry standards

- Range and modernity of CNC equipment, including multi‑axis and automated systems

- Depth of engineering support, from design for manufacturability to fixture design

- Quality management system, certifications, and available inspection equipment

- Responsiveness during quotation, sampling, and engineering‑change phases

- Financial stability and capacity to support long‑term OEM programs

Site visits, virtual audits, and pilot projects can also help confirm whether a potential supplier's culture and processes match your expectations.

Working effectively with Metal CNC Machining Manufacturers and Suppliers in Germany usually follows a structured ordering process that reduces risk and sets clear expectations.

A typical sequence includes:

1. RFQ preparation: The buyer provides 3D models, 2D drawings, tolerance definitions, material standards, surface treatments, and estimated volumes.

2. Quotation and technical review: The supplier evaluates machining strategies, cycle times, tooling costs, and quality requirements, then issues a detailed quotation.

3. Prototype or sample production: For new parts, the supplier machines prototypes or initial samples, often accompanied by dimension reports.

4. Process optimization: Feedback from prototype testing may lead to small design or process changes, which are validated with updated samples.

5. Series production release: Once approved, the supplier locks in process parameters, control plans, and inspection routines for stable batch production.

6. Ongoing communication: Regular reviews address delivery performance, quality metrics, and potential cost or process improvements.

This systematic approach helps ensure that metal components from German Metal CNC Machining Manufacturers and Suppliers meet expectations on the first production run and remain consistent over time.

German Metal CNC Machining Manufacturers and Suppliers operate in a high‑wage, high‑skill environment, so understanding cost drivers is essential. Hourly machine rates tend to be higher than in many other regions, but productivity, automation, and quality levels can offset this difference.

Typical cost factors include:

- Part complexity, number of setups, and required axes of motion

- Material type, especially difficult‑to‑machine metals or high‑temperature alloys

- Tolerance levels, surface finish requirements, and inspection scope

- Annual volume and batch size, which influence setup frequency and tooling amortization

- Need for secondary operations such as heat treatment, surface coating, or assembly

By optimizing design for manufacturability and discussing cost drivers openly with Metal CNC Machining Manufacturers and Suppliers in Germany, buyers can often reduce per‑part costs without compromising performance.

To balance performance, risk, and overall cost, many overseas brands and wholesalers adopt a dual‑sourcing strategy that leverages both German and Chinese Metal CNC Machining Manufacturers and Suppliers. German partners typically handle high‑risk, certified, or highly complex metal parts, while Chinese partners focus on rapid prototyping, tooling, and cost‑sensitive components.

This combination allows buyers to validate designs and critical processes near their target markets while utilizing competitive manufacturing capacity abroad. For example, precision components for regulated industries may remain in Germany, while brackets, covers, fixtures, and non‑safety‑critical metal parts are produced in China at larger volumes.

Shangchen (sc‑rapidmanufacturing.com) is a Chinese factory that offers rapid prototyping, CNC machining services, precision batch production, CNC lathe turning, sheet metal fabrication, 3D printing services, and mold production for overseas OEM customers. The company acts as a one‑stop Metal CNC Machining Manufacturer and Supplier for foreign brand owners, wholesalers, and production companies.

By integrating multiple processes under one roof, Shangchen can support projects from concept to mass production. Customers can order prototypes, bridge tooling, trial runs, and full‑scale batches without changing suppliers. This approach simplifies communication, improves consistency, and reduces the time needed to bring new metal products to market.

Shangchen's service model complements German Metal CNC Machining Manufacturers and Suppliers by providing flexible, cost‑effective capacity that fits into a global sourcing strategy. Overseas buyers can allocate different project phases and part families to the most suitable region.

Typical collaboration patterns include:

- Prototype and early testing: Shangchen quickly machines prototypes and small batches for design validation, while German partners prepare for series production and local approvals.

- Tooling and fixtures: Shangchen manufactures molds, jigs, fixtures, and gauges that support German production lines and automated assembly systems.

- Volume scaling: After a design is proven in Germany, selected parts can be transferred to Shangchen for higher‑volume manufacturing, freeing German capacity for more complex work.

In all these scenarios, Shangchen functions as an OEM‑oriented Metal CNC Machining Manufacturer and Supplier that aligns with the quality and documentation expectations of international customers.

To achieve consistently good outcomes when dealing with Metal CNC Machining Manufacturers and Suppliers in both Germany and China, it is helpful to follow several best practices. Clear, structured collaboration minimizes misunderstandings and prevents avoidable costs.

Recommended practices include:

- Providing complete technical documentation, including tolerances, GD&T, and reference standards

- Defining key characteristics that require enhanced control or capability studies

- Establishing inspection plans and reporting formats before production begins

- Aligning expectations about packaging, labeling, and logistics for international shipments

- Scheduling regular technical and commercial reviews to discuss performance and improvement opportunities

By treating German and Chinese Metal CNC Machining Manufacturers and Suppliers as long‑term partners instead of purely transactional vendors, buyers can unlock higher reliability and innovation.

Digitalization is a defining characteristic of modern Metal CNC Machining Manufacturers and Suppliers in Germany. Many factories integrate sensors, IoT platforms, and production software to create transparent and responsive manufacturing environments.

Connected machines can send data on spindle load, vibration, throughput, and tool wear to centralized dashboards. Engineers use this information to optimize cutting strategies, schedule maintenance before failures occur, and maintain stable processes even during long production runs. For buyers, this translates into more predictable lead times, fewer quality deviations, and better traceability across the entire metal component lifecycle.

Environmental performance has become increasingly important when choosing Metal CNC Machining Manufacturers and Suppliers, especially for companies subject to strict sustainability targets. German CNC firms respond with initiatives that reduce energy consumption, recycle coolants, and manage metal scrap responsibly.

Some companies invest in energy‑efficient machines, advanced lubrication systems, and optimized cutting parameters to reduce power usage per part. Others document their carbon footprint and participate in broader corporate sustainability programs. Buyers focused on green supply chains can use these efforts as part of their supplier evaluation and reporting.

Working with Metal CNC Machining Manufacturers and Suppliers in different countries can introduce challenges in pricing, lead times, and communication. However, most of these issues can be mitigated with proactive planning.

Common challenges include:

- Time zone differences that slow decision‑making and technical discussions

- Language barriers that cause confusion about tolerances or inspection criteria

- Extended logistics chains that complicate inventory planning and emergency deliveries

To address these issues, buyers can appoint dedicated project coordinators, use collaborative digital platforms for document control, and plan safety stocks or dual‑sourcing strategies. Both German and Chinese Metal CNC Machining Manufacturers and Suppliers are accustomed to international collaboration and can adapt to structured communication processes.

For overseas brands, wholesalers, and manufacturers, Germany remains one of the most attractive locations for sourcing high‑precision metal components because of its advanced infrastructure, skilled workforce, and strong reputation for quality. At the same time, Chinese partners like Shangchen expand the range of options by offering rapid prototyping, flexible production capacity, and competitive pricing.

A carefully designed sourcing strategy that leverages both German Metal CNC Machining Manufacturers and Suppliers and Chinese OEM‑oriented partners can deliver the best balance of performance, cost, and supply security. By aligning technical requirements, documentation standards, and communication routines, buyers can create a resilient global supply base for metal components.

Germany stands out as a leading hub for Metal CNC Machining Manufacturers and Suppliers, combining advanced machine tools, deep engineering expertise, and rigorous quality systems. For global buyers, German CNC suppliers provide an ideal choice for complex, safety‑critical, and highly regulated metal components that require reliable performance and traceability.

At the same time, a Chinese OEM‑oriented factory such as Shangchen (sc‑rapidmanufacturing.com) can offer rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production at competitive cost levels. By integrating German and Chinese Metal CNC Machining Manufacturers and Suppliers into a unified sourcing strategy, overseas brands, wholesalers, and manufacturers can optimize quality, responsiveness, and overall lifecycle cost for their metal products.

German Metal CNC Machining Manufacturers and Suppliers typically combine high‑end equipment, a skilled workforce, and strict quality management systems. They also benefit from being part of a strong industrial ecosystem, with close access to toolmakers, automation specialists, and metrology providers.

Many German Metal CNC Machining Manufacturers and Suppliers offer flexible services for prototypes and small batches, especially when these are linked to potential series production. However, their cost structure is generally optimized for high‑value or technically demanding parts, so buyers should discuss project scope and long‑term plans early in the process.

Shangchen can handle rapid prototyping, tooling, fixtures, and cost‑sensitive production batches, while German Metal CNC Machining Manufacturers and Suppliers focus on certified or high‑risk components. This coordinated approach allows buyers to maintain strong quality assurance in key areas while leveraging cost advantages and capacity flexibility from China.

Before approaching any Metal CNC Machining Manufacturers and Suppliers, buyers should prepare 3D models, detailed 2D drawings, material specifications, tolerance definitions, surface finish requirements, and estimated annual volumes. Providing this information upfront helps suppliers evaluate manufacturability, choose suitable processes, and deliver accurate quotations.

Consistency begins with unified specifications, shared drawings, and clear quality standards applied to all Metal CNC Machining Manufacturers and Suppliers. Buyers should harmonize inspection plans, request similar measurement reports from each supplier, and track key metrics such as defect rates, delivery performance, and process capability. Regular reviews and open communication further strengthen long‑term quality performance.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Sweden

Top Metal CNC Machining Manufacturers and Suppliers in Norway

Top Metal CNC Machining Manufacturers and Suppliers in Turkey

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia