Views: 222 Author: Amanda Publish Time: 2025-12-13 Origin: Site

Content Menu

● Overview of the French CNC Machining Market

● Key Industries Served by French CNC Suppliers

● Representative French CNC Machining Service Providers

● French CNC Machine Tool Manufacturers and the Broader Ecosystem

● Typical Capabilities of French Metal CNC Machining Shops

● Quality Systems, Certifications, and Traceability

● Trends: Automation, Robotics, and Industry 4.0

● Working With French Metal CNC Machining Manufacturers and Suppliers as a Global Buyer

● How Shangchen Complements French CNC Suppliers

● Practical Criteria for Selecting French Metal CNC Machining Manufacturers and Suppliers

● Best Practices for RFQs and Technical Communication

● Logistics, Incoterms, and After‑Sales Support

● Long‑Term Collaboration and Co‑Engineering

● FAQ

>> 1. What are the advantages of sourcing from Metal CNC machining suppliers in France?

>> 3. Can French Metal CNC machining suppliers handle both simple and highly complex parts?

>> 4. Why combine French Metal CNC machining suppliers with an international partner like Shangchen?

Metal CNC Machining Manufacturers and Suppliers in France form one of the most advanced precision‑engineering ecosystems in Europe, supporting industries that demand tight tolerances, complex geometries, and robust quality systems. France's focus on innovation, engineering education, and industrial clusters makes it an attractive sourcing destination for global buyers who need dependable metal components and assemblies.

The French market for CNC machining centers and turning centers has grown steadily on the back of high‑value industries such as aerospace, automotive, medical devices, and energy. Local Metal CNC Machining Manufacturers and Suppliers have invested heavily in multi‑axis machining centers, advanced CAD/CAM software, and digitalized production workflows to remain competitive.

Many French companies operate in industrial regions that provide dense networks of metalworking expertise, specialized subcontractors, and logistics partners. This clustering allows Metal CNC Machining Manufacturers and Suppliers to respond quickly to complex RFQs, consolidate processes such as machining, surface treatment, and assembly, and maintain flexible capacity for both prototypes and series production.

Metal CNC Machining Manufacturers and Suppliers in France are deeply integrated into mission‑critical supply chains. The most prominent end‑use industries include:

- Aerospace and defense, where suppliers machine structural parts, housings, brackets, engine components, and landing‑gear elements from aluminum, titanium, and high‑strength steels.

- Automotive and mobility, where Metal CNC Machining Manufacturers and Suppliers produce engine parts, transmission components, powertrain housings, braking system elements, and precision fixtures.

- Medical and life sciences, where CNC machining supports implants, surgical instruments, lab equipment parts, and diagnostic system hardware that require excellent surface finish and biocompatible materials.

- Energy, telecommunication, and industrial machinery, where French Metal CNC Machining Manufacturers and Suppliers deliver components for turbines, power conversion systems, industrial robots, and automation equipment.

This breadth of applications ensures that buyers can find specialized partners with domain knowledge in their specific industry, while still leveraging the broader French ecosystem.

Across France, there is a wide range of Metal CNC Machining Manufacturers and Suppliers, from small, highly specialized workshops to larger integrated groups. Typical examples include:

- Precision machining SMEs that focus on CNC milling and CNC turning of complex metal parts in small and medium batches, often with rapid prototyping capabilities.

- Mid‑sized Metal CNC Machining Manufacturers and Suppliers that offer a combination of machining, design support, toolmaking, and assembly, especially for automotive and industrial customers.

- Larger industrial groups that integrate CNC machining into broader manufacturing systems, providing complete sub‑assemblies or finished modules to aerospace and energy clients.

These diverse business models enable international buyers to match supplier capabilities with project size, complexity, and regulatory requirements.

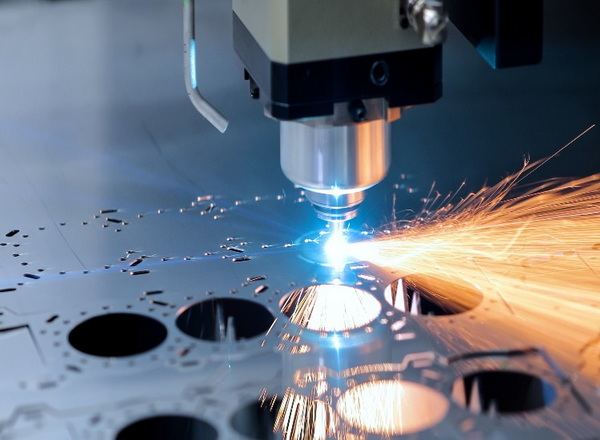

France is not only strong in subcontract machining; it is also home to manufacturers of CNC machine tools and cutting systems. These companies design and build milling machines, turning centers, routers, laser and waterjet equipment, and custom automation cells. Their presence gives Metal CNC Machining Manufacturers and Suppliers in France direct access to engineering support, tailored machine configurations, and rapid servicing.

This close link between CNC machine builders and Metal CNC Machining Manufacturers and Suppliers supports continuous improvement. Machine designers collect feedback from shop floors about rigidity, spindle performance, automation needs, and software, then use it to refine new generations of equipment. In turn, French machining shops benefit from upgrades that boost productivity, accuracy, and flexibility in handling demanding metals.

Most Metal CNC Machining Manufacturers and Suppliers in France offer a broad spectrum of services around metalworking, making them suitable partners throughout a product's lifecycle. Common capabilities include:

- CNC milling (3‑axis, 4‑axis, and 5‑axis) for prismatic parts, molds, dies, and complex geometries in aluminum, steel, stainless steel, copper alloys, and titanium.

- CNC turning and turn‑milling for shafts, bushings, flanges, housings, and rotational components that require tight concentricity and surface finish.

- Secondary processes such as drilling, tapping, boring, surface grinding, honing, and sometimes gear cutting to deliver complete parts from raw stock.

- Programming and optimization via advanced CAD/CAM systems, with simulation to avoid collisions and optimize toolpaths, cutting parameters, and setup layouts.

Many Metal CNC Machining Manufacturers and Suppliers also collaborate closely with surface‑treatment and heat‑treatment partners for anodizing, plating, hardening, nitriding, and coating, ensuring that finished components meet both mechanical and corrosion‑resistance requirements.

High‑value industries rely on robust quality and documentation, so quality systems are central to Metal CNC Machining Manufacturers and Suppliers in France. Many operate under ISO 9001 quality management systems and, for aerospace work, EN 9100 or AS9100 standards. Medical suppliers may also follow sector‑specific guidance and regulatory frameworks.

On the shop floor, coordinate measuring machines, optical scanners, surface roughness testers, and in‑process gauging help verify dimensions and geometric tolerances. Detailed inspection plans, first article inspection reports, and statistical process control are common for critical projects. For buyers, the result is strong traceability, from material certificates and batch records to recorded machining parameters and inspection data.

To remain globally competitive, many French Metal CNC Machining Manufacturers and Suppliers are investing in automation and Industry 4.0 practices. This includes:

- Robotic loading and unloading of CNC machines, enabling lights‑out production for stable, repeatable jobs.

- Pallet changers, workholding systems, and tool management solutions that reduce changeover times and improve machine utilization.

- Digital monitoring of machine status, spindle loads, tool wear, and environmental conditions to detect anomalies early and reduce downtime.

- Integration of manufacturing execution systems (MES) and enterprise systems to coordinate scheduling, inventory, and quality records in real time.

Automation helps Metal CNC Machining Manufacturers and Suppliers control labor costs, increase throughput, and maintain consistency, which is crucial when comparing European sourcing options with lower‑cost regions.

From the perspective of overseas buyers, French Metal CNC Machining Manufacturers and Suppliers are particularly attractive when projects involve:

- Complex parts that demand advanced materials, tight tolerances, and fully documented validation.

- Long‑term programs in aerospace, automotive, or energy that benefit from local technical communication, co‑development, and strong IP protection.

- Medium and high volumes that justify investment in dedicated fixtures, tools, and process optimization.

Buyers should anticipate European cost structures and should plan sufficient lead times, especially when sourcing from suppliers located in busy industrial clusters. Early technical discussions, detailed documentation, and clear communication about quality expectations help ensure realistic quotations and smoother project launches.

Shangchen (sc‑rapidmanufacturing.com) is a China‑based factory that provides rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing for international OEM customers. By offering an integrated set of metalworking and plastics processing services under one roof, Shangchen can support overseas brands, wholesalers, and manufacturers from early design validation through to series production.

For companies that already cooperate with Metal CNC Machining Manufacturers and Suppliers in France, Shangchen can act as a complementary partner in several ways:

- Handling early‑stage prototypes and bridge‑production volumes at competitive cost, allowing French suppliers to focus on high‑value or highly regulated components.

- Providing backup capacity for time‑sensitive orders or secondary parts, improving supply chain resilience.

- Supporting diverse processes beyond metal CNC machining, such as sheet‑metal fabrication and plastic molding, to consolidate vendor management.

This hybrid sourcing strategy leverages the strengths of French Metal CNC Machining Manufacturers and Suppliers—such as proximity to European end markets and deep sector expertise—while benefiting from Shangchen's flexibility and cost advantages on suitable projects.

When evaluating potential Metal CNC Machining Manufacturers and Suppliers in France, buyers should consider a structured set of criteria:

- Technical scope and equipment: Confirm that the supplier's CNC machines, axis ranges, spindle speeds, and tooling libraries match the project's complexity and material requirements.

- Industry experience: Look for experience in similar components and sectors (e.g., aerospace brackets, automotive powertrain parts, medical housings), supported by references or case studies.

- Quality and certification: Review certifications, calibration records, and inspection reports to ensure that quality systems align with internal and regulatory needs.

- Capacity and scalability: Assess machine availability, shift patterns, staffing levels, and the ability to scale from prototype to volume without compromising lead time.

- Communication and project management: Evaluate responsiveness, language capabilities, and the supplier's approach to RFQs, engineering changes, and non‑conformance handling.

Formal supplier audits or remote factory assessments can further validate whether Metal CNC Machining Manufacturers and Suppliers in France meet strategic requirements before placing large orders.

Clear and detailed RFQs are essential when working with Metal CNC Machining Manufacturers and Suppliers in France. Buyers can improve outcomes by:

- Providing 3D models and fully dimensioned 2D drawings with defined GD&T, tolerances, surface finish, and critical features.

- Specifying materials using standard designations, required standards, and acceptable equivalents, especially for aerospace or medical applications.

- Sharing estimated annual usage, batch sizes, and potential schedule variations, enabling suppliers to plan tooling and capacity.

- Stating inspection requirements, documentation packages, and traceability expectations early in the discussion.

Proactive communication helps Metal CNC Machining Manufacturers and Suppliers identify cost drivers, suggest design for manufacturability improvements, and propose alternative solutions that may reduce machining time or material waste without compromising performance.

Because many buyers working with French Metal CNC Machining Manufacturers and Suppliers are located in other regions, logistics and after‑sales support matter. Key aspects include:

- Agreement on Incoterms and responsibilities for transport, insurance, and customs clearance.

- Packaging standards that protect precision metal parts during transit, including corrosion protection and shock‑resistant arrangements.

- Clear processes for handling non‑conforming parts, including root‑cause analysis, corrective actions, and potential rework or replacement.

Metal CNC Machining Manufacturers and Suppliers that understand global trade requirements and maintain stable logistics partnerships can help buyers reduce risk and maintain reliable production schedules.

Many of the most successful relationships with Metal CNC Machining Manufacturers and Suppliers in France are long‑term partnerships rather than transactional projects. Over time, suppliers build deep understanding of a customer's design philosophies, performance priorities, and documentation standards.

This knowledge allows Metal CNC Machining Manufacturers and Suppliers to contribute actively to co‑engineering, suggesting adjustments to geometries, tolerances, or material choices that simplify machining and improve durability. Long‑term partners are also more likely to invest in dedicated fixtures, automation, or even new equipment aligned with a customer's product roadmap.

France offers a mature, innovative environment for Metal CNC Machining Manufacturers and Suppliers, supported by strong industrial clusters, advanced machine‑tool builders, and a culture of precision engineering. For global buyers in aerospace, automotive, medical, energy, and other demanding sectors, French suppliers deliver the tight tolerances, traceability, and technical collaboration needed for critical components.

At the same time, international partners such as Shangchen provide complementary capabilities in rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold manufacturing, giving buyers greater flexibility in cost, lead time, and process coverage. By combining the strengths of Metal CNC Machining Manufacturers and Suppliers in France with those of a global OEM partner, companies can build resilient, efficient, and scalable supply chains that support sustainable growth and innovation.

Metal CNC Machining Manufacturers and Suppliers in France offer high technical capability, strong quality systems, and extensive experience in regulated industries such as aerospace and medical devices. Buyers benefit from precise, reliable components, robust traceability, and close engineering collaboration throughout the product lifecycle.

Many Metal CNC Machining Manufacturers and Suppliers in France allocate capacity specifically for prototypes and small batches, often using the same multi‑axis equipment as for series production. This approach allows customers to validate designs under realistic conditions, then transition smoothly into larger batch production without changing suppliers or processes.

Yes. Metal CNC Machining Manufacturers and Suppliers in France typically operate a range of equipment from standard 3‑axis machines for simpler parts to advanced 4‑axis and 5‑axis platforms for complex geometries. This combination lets them handle straightforward components cost‑effectively while also tackling intricate parts that require simultaneous multi‑axis machining and advanced process control.

Combining Metal CNC Machining Manufacturers and Suppliers in France with a global partner such as Shangchen enables buyers to balance cost, lead time, and regulatory needs across projects. French suppliers can focus on highly regulated, strategically important parts close to end markets, while Shangchen provides competitive solutions for prototypes, bridge volumes, and cost‑sensitive components, all within a single coordinated sourcing strategy.

Before approaching Metal CNC Machining Manufacturers and Suppliers in France, buyers should prepare detailed 3D models, dimensioned drawings with specified tolerances, clear material definitions, and expected quantities. It is also important to communicate any special inspection requirements, documentation expectations, and long‑term volume forecasts so suppliers can provide accurate quotations and plan capacity effectively.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal