Views: 222 Author: Amanda Publish Time: 2025-07-23 Origin: Site

Content Menu

● Understanding Injection Molding

>> The Manufacturing Process: Step-by-Step

● The Landscape of German Injection Molding Manufacturers and Suppliers

>> 3. Meusburger Georg GmbH & Co KG

>> 6. H & K Müller GmbH & Co. KG

>> 8. SCHAUENBURG Industrietechnik

● Market Dynamics and Advanced Trends

>> Emphasis on Innovation and Industry 4.0

>> Customization and Rapid Market Response

>> Expanding Application Horizons

● The Competitive Edge of German Injection Molding Manufacturers and Suppliers

>> 1. What industries do German injection molding manufacturers and suppliers serve?

>> 2. How do injection molding manufacturers and suppliers in Germany ensure quality?

>> 3. Can German injection molding suppliers handle custom projects and rapid prototyping?

Germany, renowned for its engineering prowess and commitment to quality, stands at the forefront of injection molding technology. With decades of innovation and a dynamic industrial landscape, the country has cultivated a vibrant network of injection molding manufacturers and suppliers. These companies provide plastics solutions for a vast array of industries, including automotive, electronics, consumer goods, healthcare, construction, and beyond. This article presents an in-depth exploration of the top injection molding manufacturers and suppliers in Germany. Readers will gain detailed insights into company backgrounds, technological advancements, manufacturing capabilities, sustainability efforts, and the evolving market landscape.

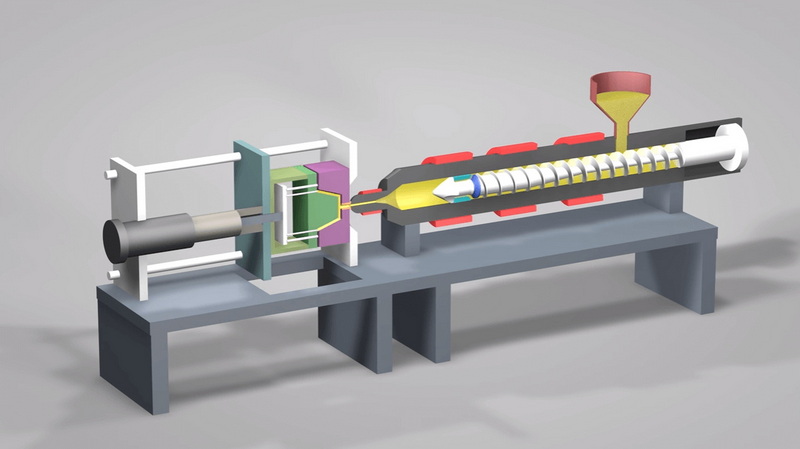

Injection molding is a highly efficient manufacturing process used to produce intricate and precise plastic parts in large volumes. It begins with melting plastic granules and injecting the molten material into a metal mold under high pressure. The mold is cooled, solidifying the plastic into its desired shape before being ejected. This method allows for complex geometries and detailed surface finishes, making it ideal for mass-producing consistent components with outstanding accuracy.

1. Feeding: Plastic granules are loaded into a heated barrel.

2. Melting: The granules melt as the screw turns and pushes material forward.

3. Injection: Molten plastic is injected into the mold cavity at high speed and pressure.

4. Cooling: The mold cools, solidifying the part.

5. Ejection: The molded part is pushed out, ready for use.

This cycle can be repeated quickly, allowing high-volume production runs. Manufacturers can utilize different types of plastic resins — thermoplastics, thermosets, and elastomers — tailored to specific product requirements.

Germany is home to a diverse array of injection molding manufacturers and suppliers, each known for specific expertise, industry focus, and commitment to quality. The following sections spotlight leading companies and their contributions to the industry.

Founded in 1923 and headquartered in Loßburg, Arburg is a global leader in injection molding machinery and technology. With a comprehensive product lineup—including hydraulic, hybrid, electric, and vertical injection molding machines—Arburg supports a multitude of plastics applications. The company is especially noted for its modular and energy-efficient systems, precision controls, and customer-oriented services. Arburg's machines are integral to automotive part manufacturing, healthcare device production, electronics, and packaging solutions.

Arburg's continuous innovation also extends to their digital product offerings, like the Arburg host computer system, which integrates production processes, providing real-time monitoring and optimization for injection molding manufacturers and suppliers worldwide. This digital edge helps clients reduce downtime and improve quality control.

Dating back to 1838, KraussMaffei is based in Munich and is internationally respected for its innovative solutions in plastics and rubber processing. Their offerings encompass injection molding, extrusion, and reaction process machinery, serving markets such as automotive, medical devices, packaging, and electronics. KraussMaffei's strengths include advanced automation, digitalization, and tailored customer service. With a workforce exceeding 4,700, KraussMaffei operates in over 30 countries and maintains a robust network of technology partners.

KraussMaffei invests heavily in sustainable manufacturing technologies, including electric injection molding machines that reduce power consumption and CO2 emissions — a major selling point for environmentally conscious injection molding manufacturers and suppliers in Germany.

Meusburger, established in 1964, is a reference point for precision mold bases and standard components. Their portfolio includes ready-to-assemble parts that accelerate time-to-market and ensure repeatable quality in injection molding projects. With investments in smart manufacturing and robust customer support, Meusburger adds value not just to manufacturers and suppliers but also to mold makers, contributing to the entire injection molding value chain.

The company's innovations in modular tooling systems support fast customization and repair, which is vital for rapid prototyping and efficient series production in sectors such as automotive and consumer electronics.

FOBOHA specializes in high-cavity and multi-component injection molds for demanding applications in the packaging, medical, and consumer goods sectors. Their reputation is built upon advanced engineering capabilities, support for rapid prototyping, and the ability to deliver turn-key production lines. FOBOHA's expertise in moldmaking enhances injection molding manufacturers and suppliers' possibilities to produce consistent parts at high volumes.

Their precision in multi-material molding processes allows brands to innovate with color combinations and functional elements in a single molding cycle, a growing trend in product differentiation.

Rosti, part of an international plastics group, operates at the cutting edge of injection molding and assembly solutions. Their German operations emphasize automated manufacturing, precision components, and value-added services such as pad printing and in-mold labeling. This vertical integration enhances the competitiveness of injection molding manufacturers and suppliers by offering full-service contract manufacturing and assembly.

Rosti collaborates closely with OEMs and international brands, ensuring smooth product development cycles and cost-efficient series production for markets such as automotive interiors and electrical appliances.

With nearly a century of experience, H & K Müller delivers high-precision injection molding parts and custom solutions. They maintain in-house toolmaking, execute complex designs, and serve international OEMs in pharmaceuticals, food, automotive, and industrial technology. Their approach is to combine craftsmanship with modern technology, enabling flexible manufacturing runs for both large-scale orders and smaller, highly specialized projects.

Their cleanroom-certified production lines appeal to medical device manufacturers demanding the highest hygiene standards.

TR Plast is renowned for manufacturing technical injection molded components for automotive, electronics, and appliance sectors. Their advanced molding technologies deliver high consistency, dimensional accuracy, and innovation. Continuous investment in process automation minimizes production errors, reducing waste and improving turnaround times — crucial factors for injection molding manufacturers and suppliers aiming to optimize efficiency while maintaining quality.

SCHAUENBURG provides customized injection molded parts in plastics and rubber, with a focus on reliability, just-in-time delivery, and large-scale production. Their fully integrated manufacturing ecosystem includes CNC machining, 24/7 production capacity, and sustainable solutions. This integration means SCHAUENBURG can offer injection molding manufacturers and suppliers a seamless flow from prototype to industrial series with consistent quality assurance.

They have built a reputation for solid project management, making them a trusted partner for demanding local and global clients.

Dr. Boy, founded in 1968, is celebrated for compact and energy-efficient injection molding machines. Their technology is widely adopted for medical devices, automotive components, and precision technical parts, emphasizing low operating costs and high output stability. The company's machines are frequently preferred by small and medium-sized injection molding manufacturers and suppliers focusing on precision and ecological operation.

Their development of tie-bar-less machines allows greater flexibility in mold design, enabling the production of larger or more complex parts, an advantage in highly specialized plastics manufacturing.

Langer Group delivers high-quality plastic parts across a broad range of industries, backed by agile series production and a reputation for rapid prototyping and efficient process management. The company actively supports injection molding manufacturers and suppliers with engineering consulting, toolmaking, and subsequent value-added processes like assembly and packaging.

Their expertise in multi-component injection molding helps clients bring multifunctional parts to market quickly and reliably.

Germany's injection molding manufacturers and suppliers are driving innovation through the adoption of Industry 4.0 principles. Smart manufacturing uses sensors, artificial intelligence, and robotics to optimize efficiency, detect defects early, and reduce cycle times. Digital twins simulate the injection molding process digitally, enabling manufacturers to predict outcomes and reduce trial runs.

Predictive maintenance powered by AI lowers downtime — a critical factor since injection molding machinery requires expensive and timely upkeep. Integration of cloud platforms in production management systems makes remote monitoring and global process standardization easier for German manufacturers and suppliers.

Sustainability has become a central theme in Germany's plastics manufacturing sector. Top injection molding manufacturers and suppliers consistently explore:

- Use of recycled and bio-based plastics that reduce dependency on fossil fuels.

- Development of eco-friendly colorants and additives.

- Energy-efficient hydraulic and electric molding machines that lower electricity consumption.

- Zero-waste production lines supported by circular economy principles and material reuse.

- Reduced emissions and compliance with strict environmental regulations.

These practices enhance brand value and meet growing consumer and regulatory demands for environmentally responsible products.

Consumers increasingly demand personalized and high-performance products. Injection molding manufacturers and suppliers in Germany meet these challenges through:

- Rapid prototyping technologies such as 3D printing combined with soft tooling.

- Agile manufacturing capable of switching between short and long production runs efficiently.

- Multi-material and multi-color injection molding to create differentiated products.

- Close cooperation with OEMs and design houses to shorten development cycles.

While automotive remains a dominant industry for injection molding, expanded applications include:

- Electrical and electronic housing components with EMI shielding and heat resistance.

- Medical disposables and devices made to exacting standards for sterility and biocompatibility.

- Building and construction materials using durable polymers and weather-resistant coatings.

- Packaging innovations including tamper-proof caps and lightweight containers.

This diversification strengthens the position of German injection molding manufacturers and suppliers in the global supply chain.

The combination of decades of experience, advanced technology, and a deeply rooted culture of precision ensures German injection molding manufacturers and suppliers maintain competitive advantages worldwide:

- Precision and Reliability: High mold accuracy, repeatable processes, and continuous quality monitoring ensure defect-free production.

- Integrated Services: From mold design to post-processing and assembly, vertical integration streamlines the value chain.

- Innovative Partnerships: Collaboration with universities and industry research centers keeps innovations at the forefront.

- Customer-Centric Approach: Flexibility, technical advisory, and support during product development foster long-term client relationships.

- Sustainability Commitment: Adoption of green technologies ensures compliance with global ecological standards and evolving market preference.

These strengths position German injection molding manufacturers and suppliers as preferred partners for global brands seeking quality and innovation.

With a legacy of innovation, a robust industrial infrastructure, and an unwavering commitment to quality, German injection molding manufacturers and suppliers set benchmarks worldwide. Whether your needs are for high-volume precision automotive components or rapid prototyping and specialty products, German firms deliver solutions that combine advanced engineering with efficiency and sustainability. Their investment in research, smart manufacturing, and customer-centric services ensures the ongoing leadership of Germany in the global injection molding sector. Partnering with these companies means accessing not only cutting-edge technology but also a holistic approach that supports innovation, sustainability, and growth across diverse industries.

German injection molding manufacturers and suppliers serve automotive, electronics, medical devices, consumer goods, construction, packaging, and industrial machinery sectors. Their flexibility and capacity for precision make them suitable for industries requiring high reliability and custom solutions.

Quality is ensured through advanced process control, digital monitoring, regular audits, staff training, and compliance with ISO standards. Many companies integrate automated inspection systems and maintain in-house toolmaking capabilities for optimal quality assurance.

Yes, most leading injection molding manufacturers and suppliers offer rapid prototyping, custom mold design, and low-volume batch production in addition to large-scale manufacturing. This supports product innovation and fast market entry for brands and entrepreneurs.

Sustainability is addressed through energy-efficient machinery, use of recycled and bio-based plastics, closed-loop manufacturing systems, and environmentally conscious facility management. Many companies transparently publish their sustainability metrics and targets.

Consider experience, industry expertise, certifications, technical capabilities, lead times, flexibility, support for product development, and capacity for scale. References and customer testimonials can further guide decision-making.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product