Views: 222 Author: Amanda Publish Time: 2025-07-25 Origin: Site

Content Menu

● Understanding Injection Molding and Its Importance

● The Landscape of Injection Molding Manufacturers and Suppliers in Canada

● Top Injection Molding Manufacturers and Suppliers in Canada

>> Canada Mold Technology Inc.

>> Custom Plastics International

>> T&T Custom Injection Moulding

● Advanced Manufacturing Capabilities Supporting Injection Molding

● Industry Trends and Innovations

● FAQ

>> 1. What industries in Canada typically use plastic injection molding?

>> 2. How do Canadian injection molding manufacturers ensure product quality?

>> 3. What is the role of 3D printing in injection molding manufacturing?

>> 4. Are eco-friendly materials widely used in injection molding in Canada?

>> 5. How do injection molding manufacturers handle customization requests?

Injection molding is a vital manufacturing process that facilitates the mass production of intricate plastic parts with precision and speed. Canada boasts a robust injection molding industry supported by leading manufacturers and suppliers who excel in innovation, quality, and service. This article highlights the top injection molding manufacturers and suppliers in Canada, exploring their capabilities, services, and how they contribute to various industries. Additionally, this article provides a comprehensive overview of injection molding technology, market trends, key players, and answers frequently asked questions to guide businesses looking for reliable OEM partners.

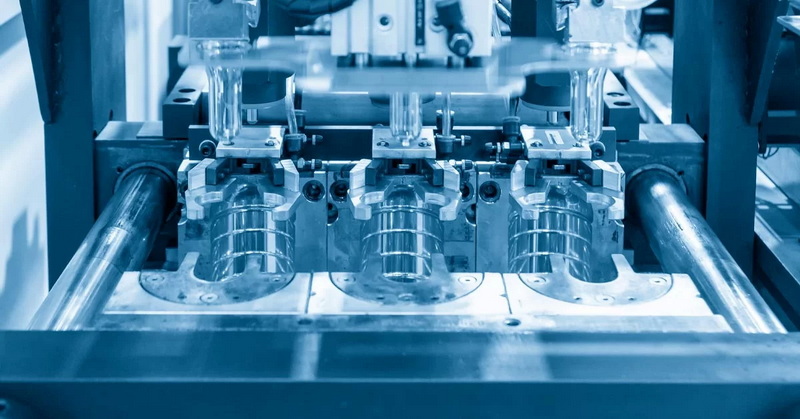

Injection molding is a manufacturing technique used to produce plastic components by injecting molten material into a mold cavity. This process allows companies to create complex shapes with high precision, excellent repeatability, and efficiency. Injection molding manufacturers and suppliers cater to sectors including automotive, medical devices, electronics, consumer goods, and aerospace.

Canada's injection molding industry is well-positioned globally due to skilled labor, advanced technology adoption, and strong OEM partnerships. The demand for custom plastic parts is steadily increasing, driving innovation in materials and processing techniques.

Injection molding offers numerous advantages over alternative manufacturing methods. It enables large-scale production with consistent quality, reduces material waste, and supports a wide variety of thermoplastic materials. Additionally, the ability to automate much of the process helps reduce labor costs and turnaround times. As product designs become more complex and incorporating multiple components becomes common, injection molding technology also evolves to accommodate multi-material molding and insert molding techniques, further expanding its applicability.

The Canadian market for injection molding machines and services has experienced steady growth, enabled by several factors, including access to raw materials, advanced engineering talent, and strategic geographic positioning close to the US market. Leading Canadian companies integrate 3D printing, CNC machining, and automation to deliver end-to-end manufacturing solutions, from rapid prototyping to mass production.

Leading injection molding manufacturers and suppliers in Canada emphasize flexibility to respond quickly to customer requirements, offering services such as design for manufacturability consultation, mold making, secondary operations, finishing, and assembly. These enhanced capabilities strengthen their role as trusted OEM partners for brands, wholesalers, and large manufacturers globally.

Some important developments in this arena include adoption of fully electric and hybrid injection molding machines, which significantly reduce energy consumption and improve precision control compared to traditional hydraulic systems. Such machines reduce cycle times, lower operational costs, and enhance product consistency, making Canadian suppliers more competitive on the international stage.

Moreover, many Canadian injection molding manufacturers have embraced Industry 4.0 practices by integrating IoT-enabled sensors and data analytics software into their production processes. These technologies allow real-time monitoring of machine parameters, predictive maintenance, and overall process optimization. As a result, companies can ensure higher quality control, reduce downtime, and improve delivery schedules.

Canada is home to several distinguished companies specializing in injection molding with capabilities ranging from rapid prototyping to high-volume production. Here are some of the top players:

Based in Ontario, Husky Technologies is a world-class provider of high-speed injection molding machines and auxiliaries. Husky focuses on advanced molding solutions for packaging, medical, and technical polymers. Their machines are recognized for energy efficiency, superior precision, and consistent high-quality output. Husky's expertise includes thin-wall and preform molding used widely in the beverage and consumer goods markets. By investing heavily in research and development, Husky sets standards that many Canadian manufacturers rely on for their production equipment.

Milacron maintains a strong presence in the Canadian injection molding industry offering a broad portfolio of machinery including servo-hydraulic, all-electric, and multi-component injection molding systems. Located in Ontario, Milacron supports manufacturers demanding high precision, especially in the medical, automotive, and electronics industries. Their fully electric molding machines provide stable process parameters and energy-efficient production, particularly for those requiring multi-shot or co-injection molding capabilities.

Amra Plastic Moulders specializes in custom thermoplastic injection molding serving small-to-medium production runs. Located in Ontario, they offer a comprehensive range of services including insert molding, overmolding, and subassembly. Amra emphasizes direct customer engagement, flexibility, and competitive pricing. Their ISO certified manufacturing process ensures consistent quality, making them a preferred supplier for OEMs in medical devices, electronics, and consumer products sectors.

Canada Mold Technology is known for delivering complex plastic injection molds with a focus on automotive and industrial markets. Their expertise includes mold design, manufacturing, and maintenance. Located in Ontario, they have in-depth knowledge of advanced tool steel processing and precision machining, facilitating long-lasting molds that support high-volume production. Clients value their integrated approach, reducing lead times and costs.

Custom Plastics International serves a variety of industries with custom injection molding capabilities. They provide tailored solutions for clients needing high-quality parts under strict timelines and quality controls. Located in Ontario, this company specializes in precision molding and post-molding finishing, supporting diverse applications from packaging components to industrial equipment covers.

T&T Custom Injection Moulding offers expertise in molding engineered resin and thermoplastic components. This second-generation company provides excellent customer service, on-time delivery, and consistent product quality. They specialize in small to large volume runs and are dedicated to working closely with clients to meet exact product specifications.

Performance Plastics is a provider of injection molded plastic parts with particular focus on industrial, automotive, and consumer product sectors. With a reputation built on precision and reliability, they provide detailed design support, mold making, and quality assurance processes that guarantee excellent end products.

Many Canadian injection molding manufacturers supplement their core molding services with advanced manufacturing technologies, offering comprehensive product development solutions:

- 3D Printing: Rapid prototyping is often accelerated through 3D printing technologies such as selective laser sintering (SLS), stereolithography (SLA), and fused deposition modeling (FDM). These methods allow manufacturers and clients to test fit, form, and function early in the design cycle and optimize molds before expensive tooling is cut.

- CNC Machining: Computer Numerical Control (CNC) machining is critical for producing high-quality molds with tight tolerances. Many injection molding suppliers maintain in-house CNC capabilities to control lead times and ensure mold precision.

- Automation and Robotics: Automation systems including robotic part handling, automated inspection, and assembly lines reduce labor dependency and enhance consistency. Automation supports just-in-time delivery and flexible manufacturing.

- Secondary Operations: Activities such as drilling, tapping, painting, plating, and assembly are often provided alongside molding to deliver ready-to-use components or subassemblies.

The injection molding sector in Canada is dynamically evolving. Several notable trends underline the future direction:

- Sustainability Focus: With rising environmental concerns, many manufacturers adopt sustainable practices—using recycled materials, bioplastics, and implementing waste reduction programs. Circular economy approaches are increasingly important to meet corporate social responsibility goals and customer expectations.

- Customization and Small Batch Production: Advances in mold technology and flexible equipment designs allow manufacturers to economically serve niche markets requiring customized or limited-run products, blurring the lines between prototyping and mass production.

- Smart Manufacturing: Integration of IoT sensors, AI-driven diagnostics, and cloud data analysis aids in predictive maintenance and overall equipment effectiveness (OEE) improvement. Canadian manufacturers leverage these smart technologies to increase uptime and product quality.

- Material Innovation: New resin formulations enhance the mechanical, thermal, and chemical resistance of molded parts. Many Canadian suppliers collaborate with resin manufacturers to tailor materials for specific end-use applications.

- Global Partnerships: Canadian injection molding manufacturers often work with international clients and OEMs, establishing strong supply chains that combine local expertise with global scale.

Canada stands out as a leading hub for injection molding manufacturers and suppliers, offering a rich blend of experience, cutting-edge technology, and customer-focused service. Companies like Husky Technologies, Milacron, Amra Plastic Moulders, and Canada Mold Technology lead the way in delivering precision, customization, and sustainability. The injection molding industry in Canada is well-equipped to meet the demands of various sectors through continuous innovation in materials, machinery, and process integration. For businesses seeking reliable OEM partners, Canadian injection molding manufacturers provide high quality, competitive pricing, and full service from prototyping to mass production.

Injection molding serves automotive, healthcare, electronics, packaging, consumer goods, and aerospace industries in Canada.

They use ISO-certified quality management systems, state-of-the-art machines, and adhere to strict process controls.

3D printing accelerates prototype development, helps test design concepts, and supports low-volume production runs efficiently.

Yes, many manufacturers are shifting towards recycled, biodegradable, and environmentally sustainable materials to meet regulatory and consumer demands.

They use flexible, quick-change molding machines and adopt digital workflows to produce tailored products efficiently, even in small batches.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal