Views: 222 Author: Amanda Publish Time: 2025-08-09 Origin: Site

Content Menu

>> Key Benefits of 5-Axis Machining

● Additional Industries Benefiting from 5-Axis Machining

● FAQ

>> 1. What makes 5-axis machining better than traditional 3-axis machining?

>> 2. Which industries benefit the most from 5-axis machining?

>> 3. How does 5-axis machining improve production efficiency?

>> 4. Is 5-axis machining suitable for small production runs?

>> 5. Can 5-axis machining handle different materials?

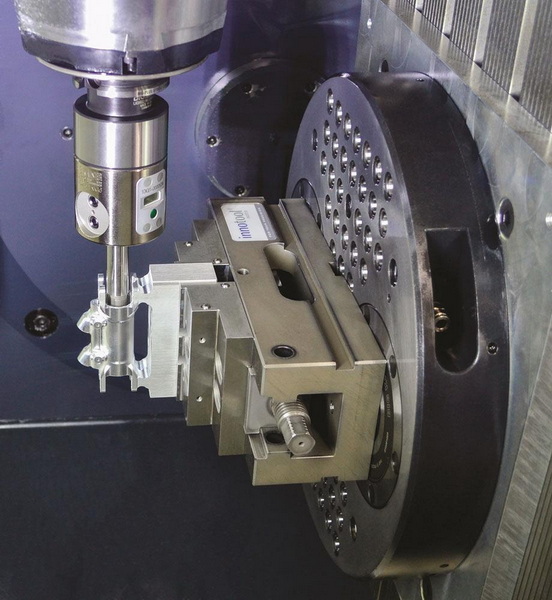

5-Axis Machining technology has revolutionized the manufacturing landscape by enabling the production of highly complex and precise parts with enhanced efficiency. This advanced CNC machining method facilitates simultaneous movement along five different axes, allowing for intricate geometries and superior surface finishes that traditional 3-axis and 4-axis machines simply cannot match. Industries across the board have embraced 5-axis machining for its transformative impact on product quality, production speed, and design possibilities.

In this article, we delve deeply into the top industries that benefit tremendously from 5-axis machining technology, exploring its applications, advantages, and how it is pushing the boundaries of what's possible in modern manufacturing.

5-Axis Machining involves the movement of a cutting tool along five different axes simultaneously—X, Y, Z, plus two rotational axes (A and B). This capability allows the tool to approach the workpiece from almost any direction without needing to reposition the workpiece, drastically reducing setup times and enabling the creation of complex geometries in a single operation.

- High Precision and Accuracy: Enables manufacturing parts with tight tolerances and intricate details.

- Reduced Setups: Multiple operations can be completed in a single setup, saving time and reducing errors.

- Complex Geometries: Ability to machine parts with complex curves, contours, and undercuts.

- Improved Surface Finish: Shorter cutting tools and more optimal tool orientation reduce vibration and improve finish.

- Increased Productivity: Faster cycle times and less manual intervention drive efficiency and cost savings.

- Tool Life Extension: Optimal tool positioning reduces wear, extending the lifespan of cutting tools.

- Flexibility in Materials: Capable of machining a wider range of difficult materials with complex shapes.

These benefits make 5-axis machining a preferred choice for industries with demanding production requirements.

The aerospace sector is a primary beneficiary of 5-axis machining technology. Aircraft components often involve complex shapes like turbine blades, engine parts, and structural elements that demand extreme precision and performance.

- Complex Turbine Blades: The intricate profiles and tight tolerances of turbine blades require the multi-directional machining capabilities of 5-axis machines.

- Engine Components: Engine parts with complex forms benefit from superior accuracy and surface finishes, which are critical for efficient engine performance.

- Weight Optimization: By machining organic shapes and compound curves, 5-axis machining allows for the production of lightweight yet strong parts essential for fuel efficiency.

- Rapid Prototyping and Tooling: Aerospace manufacturers use 5-axis machining to rapidly prototype and produce tooling components needed for composite part fabrication and assembly.

The stringent safety standards and extreme operating conditions in aerospace make the precision and reliability of 5-axis machining indispensable. Moreover, the technology contributes significantly to reducing lead times and production costs in this competitive high-tech sector.

In automotive engineering, 5-axis machining plays a critical role in producing parts that combine aesthetic appeal with mechanical reliability.

- Body Panels and Complex Surfaces: The sleek, aerodynamic shape of modern vehicles features complex curves and contours efficiently fabricated using 5-axis machines capable of producing smooth, polished surfaces.

- Suspension and Engine Parts: High-precision components such as suspension arms, cylinder heads, and bearing housings are produced with tighter tolerances to ensure durability and performance.

- Mass Production Consistency: The exceptional repeatability of 5-axis machining enables large volumes of identical parts with consistent quality, which is crucial for automotive assembly lines.

- Customization and Prototyping: For high-performance and luxury vehicles, 5-axis machining supports rapid prototyping and customization of unique parts, reducing time to market.

Automotive manufacturers rely on 5-axis machining not only for production but also for innovation, integrating lightweight materials and complex designs that improve fuel efficiency and safety.

The medical field benefits greatly from the precision, flexibility, and quality finishes achievable with 5-axis machining.

- Custom Implants: Orthopedic implants such as hip, knee, and spinal replacements require patient-specific customization and extremely precise dimensions to fit accurately and function well within the body.

- Surgical Instruments: Complex shapes with fine details on surgical tools demand the multi-dimensional machining capability of 5-axis CNC machines.

- Medical Devices: Components for stents, prosthetics, dental implants, and minimally invasive surgical devices rely on 5-axis machining for excellent surface finishes and dimensional accuracy.

- Biocompatible Materials: The ability to machine challenging materials like titanium, cobalt-chrome alloys, and ceramics expands the scope of complex medical device fabrication.

These capabilities contribute directly to improved patient outcomes, safety, and confidence by enabling devices that meet strict regulatory standards with the highest quality.

5-axis machining also supports parts production in the energy sector, where performance, reliability, and durability are pivotal.

- Wind Turbine Components: The aerodynamic blade shapes and precise generator parts are efficiently produced by 5-axis machining, ensuring maximum energy capture and operational longevity.

- Power Plant Parts: High-performance components for turbines, compressors, and pumps require machining that can handle extreme temperatures and stresses with exacting tolerances.

- Solar Panel Manufacturing: Precise production of specialized mounting brackets, heat sinks, and electronic housings for solar panels benefit from 5-axis capabilities.

- Oil and Gas Equipment: Complex valve parts, drill bits, and pressure vessel components also require the robustness and accuracy available with 5-axis machining.

5-axis technology helps the energy industry innovate and deliver durable components essential for clean and reliable energy production.

The electronics sector relies heavily on precision and complexity, which 5-axis machining handles expertly.

- Miniature Components: Small, intricate parts for smartphones, laptops, wearables, and other devices require extremely precise machining with tight tolerances.

- Connectors and Enclosures: Complex geometry and fine detailing for electronic housings, connectors, and switches are efficiently produced.

- Printed Circuit Boards (PCBs) and Heat Sinks: Advanced heat sink designs with multiple surfaces and channels benefit from multi-axis machining for improved thermal management.

- Prototype Development: Rapid and precise prototyping supports fast-paced innovation cycles typical in electronics.

The miniaturization trend and demand for integration push manufacturers to utilize 5-axis machining to maintain quality and accelerate development.

Accuracy and surface finish are critical in mold and die making, where even slight imperfections can impact product quality.

- Complex Mold Cavities: 5-axis machining enables the creation of intricate mold cavities with undercuts, deep ribs, and thin walls that traditional machines struggle to achieve.

- Reduced Setup Time: The ability to machine multiple surfaces in one setup shortens production cycles dramatically.

- Improved Tool Life: More efficient cutting angles improve wear resistance, extending the life of molds and dies.

- High-Quality Surface Finish: Enhanced surface finishes reduce the need for additional polishing and post-processing.

This results in molds and dies that produce better-quality parts for automotive, consumer goods, packaging, and electronics industries, leading to better end products and faster time to market.

While the key industries above have seen significant transformations through 5-axis machining, several other sectors also leverage this technology:

- Defense Industry: Complex components for weapons systems, vehicles, and radar equipment require precision machining to meet stringent military specifications.

- Marine Industry: Propellers, engine parts, and intricate hull components benefit from the machining of complex 3D surfaces with enhanced durability.

- Tooling and Manufacturing Equipment: Custom fixtures, jigs, and assembly aids with intricate geometries improve overall manufacturing workflows.

- Jewelry and Luxury Goods: Precise, intricate designs with fine details are possible through 5-axis machining of precious metals and hard materials.

These industries highlight the vast versatility of 5-axis CNC machining and its central role in modern manufacturing excellence.

5-Axis Machining technology is foundational to the advancement of multiple industries by enabling the creation of complex, precise, and high-quality parts with improved efficiency. From aerospace to automotive, medical to energy, electronics to mold making, and beyond, the versatility and performance of 5-axis CNC machines empower manufacturers to meet modern demands for innovation, speed, and cost-effectiveness.

As global competition intensifies and product designs grow ever more sophisticated, 5-axis machining will continue to be a pivotal technology driving manufacturing excellence and competitive advantage. Its contribution to reducing lead times, improving product quality, and enabling the production of geometrically complex parts ensures its role at the forefront of industrial innovation.

5-axis machining allows movement along two additional rotational axes, enabling complex geometries to be machined in a single setup. This reduces setup times, increases precision, and provides better surface finishes compared to 3-axis machines.

Key industries benefiting from 5-axis machining include aerospace, automotive, medical devices, energy, electronics, and mold/die manufacturing due to their need for high precision and complex part geometries.

By machining multiple sides of a part in a single setup, 5-axis machining reduces the need for repositioning and multiple fixtures, which decreases cycle times and minimizes errors, leading to greater overall productivity.

Yes, 5-axis machining is ideal for both prototyping and small production runs because it reduces lead time, improves accuracy, and allows for complex shapes without the need for multiple machines or extensive setups.

Absolutely. 5-axis machining is versatile and can work with a wide range of materials, including metals, plastics, and ceramics, making it suitable for diverse industry applications.

[1] https://www.techniwaterjet.com/5-axis-machining/

[2] https://www.3erp.com/blog/5-axis-cnc-machining-advantages/

[3] https://www.methodsmachine.com/blog/benefits-of-5-axis-machining/

[4] https://www.newayprecision.com/fr/study-cases/application-of-5-axis-cnc-machining-technology-in-aerospace

[5] https://www.redline-cnc.co.uk/4-industries-that-can-benefit-from-5-axis-machining/

[6] https://jlccnc.com/help/article/5-axis-cnc-machining

[7] https://www.improprecision.com/applications-5-axis-cnc-machine/

[8] https://www.zintilon.com/blog/best-5-axis-cnc-machines-contrast/

[9] https://www.scmgroup.com/en_AU/special-contents/why-5-axis-machining-

[10] https://www.3ds.com/make/solutions/blog/5-axis-cnc-machining-service

[11] https://us.metoree.com/categories/7266/

[12] https://www.reddit.com/r/CNC/comments/8gp056/5axis_cnc_machines_suggest_me_benefits_over_3axis/

[13] https://astromachineworks.com/what-is-5-axis-machining/

[14] https://www.opmtlaser.com/top-10-5-axis-cnc-machining-center/

[15] https://www.dmgmori.co.jp/sp/5axis/en/

[16] https://www.jecompanies.com/blog/blog/the-advantages-and-applications-of-5-axis-cnc-machining-services

[17] https://afmingglobal.com/five-axis-gantry-machining-center-manufacturer/

[18] https://www.autodesk.com/solutions/5-axis-machining

[19] https://www.antsmachine.com/what-are-the-applications-of-five-axis-cnc-machines-in-the-aerospace-field.html

[20] https://yijinsolution.com/cnc-guides/5-axis-cnc-companies-in-the-world/

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal