Views: 222 Author: Amanda Publish Time: 2026-01-09 Origin: Site

Content Menu

● Overview of CNC Turning in Spain

● Key CNC Turning Manufacturers and Suppliers in Spain

>> MIPESA

>> Mecanizados de Precisión Goiuria (MPG)

>> Other Spanish CNC Turning Manufacturers and Suppliers

● Typical Capabilities of CNC Turning Manufacturers and Suppliers in Spain

● Value‑Added Services and Finishing

● Why Work With Spanish CNC Turning Manufacturers and Suppliers

>> Technical Capabilities and Industry 4.0

>> Certifications and Quality Culture

>> Cost, Logistics, and Lead Time

● How Overseas Buyers Select CNC Turning Manufacturers and Suppliers in Spain

>> Define Technical Requirements

>> Audits, Samples, and Trial Orders

● Working With a Chinese CNC Partner Serving Spain‑Focused Buyers

● Strategic Tips for Buyers Working With CNC Turning Manufacturers and Suppliers

● FAQ

>> 1. What industries use CNC Turning Manufacturers and Suppliers in Spain?

>> 3. How competitive are Spanish CNC Turning Manufacturers and Suppliers on price?

>> 4. Can Spanish CNC Turning Manufacturers and Suppliers support rapid prototyping?

>> 5. How do buyers evaluate the capacity of CNC Turning Manufacturers and Suppliers in Spain?

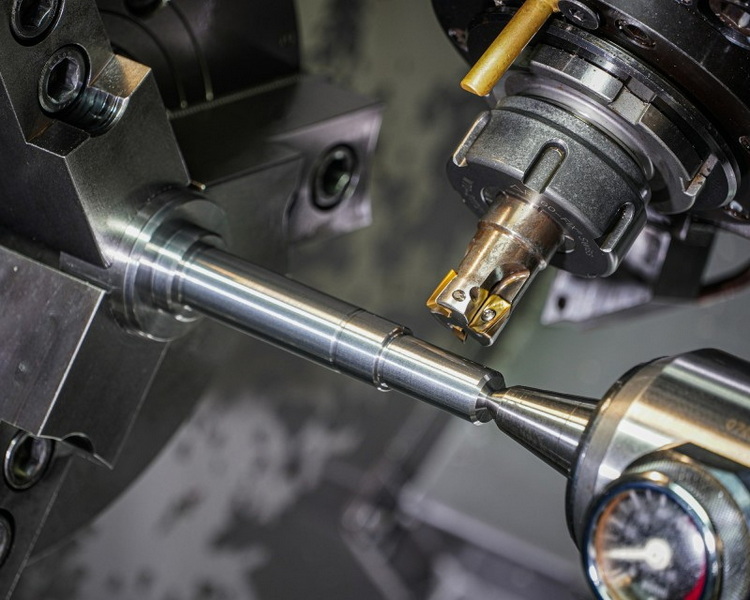

Spain has a mature precision engineering ecosystem, and CNC Turning Manufacturers and Suppliers in the country play a critical role in European automotive, aerospace, energy, and industrial supply chains. For overseas OEM buyers and sourcing managers, understanding the capabilities and certifications of Spanish CNC Turning Manufacturers and Suppliers is essential for building a resilient, high‑quality supply base.[1][2]

Spain's CNC machining and turning market is valued in the hundreds of millions of euros annually and is projected to keep growing steadily to 2030, driven by automation and Industry 4.0 adoption. Regions such as the Basque Country, Catalonia, Madrid, and Valencia concentrate many CNC Turning Manufacturers and Suppliers, supported by strong automotive and industrial clusters.[3][1]

Typical Spanish CNC Turning Manufacturers and Suppliers offer:

- CNC turning, milling, drilling, and grinding for complex metal and plastic parts.[1]

- Prototype machining, small batch runs, and medium‑to‑large series production for export customers.[4]

- Value‑added services such as design for manufacturability (DFM), surface finishing, assembly, and logistics support.[1]

Modern facilities often integrate automation, robotics, and digital production monitoring to achieve high repeatability and cost‑effective cycle times for CNC turning projects.[5]

Spain hosts a mix of machine builders and service‑oriented CNC Turning Manufacturers and Suppliers that can support demanding European and global projects. Below is an overview of several notable players featuring CNC turning capacity or related precision machining services.[2][6]

MIPESA is a well‑known machining company in Spain offering CNC milling, CNC turning, laser cutting, sheet metal fabrication, and welding from its advanced facilities. As one of the active CNC Turning Manufacturers and Suppliers, it serves automotive, aerospace, railway, and industrial machinery customers with custom‑machined components.[6][2]

Key strengths:

- Versatile mix of turning, milling, cutting, and assembly under one roof for streamlined supply.[6]

- Focus on quality and innovation, supporting high‑precision and safety‑critical parts.[2]

MIPESA typically emphasizes reliable delivery performance and long‑term relationships with OEMs and tier‑one suppliers that rely on consistent CNC turning quality.[6]

Mecanizados de Precisión Goiuria (MPG), based in the Basque Country, specializes in high‑precision CNC turning and milling for sectors such as automotive, aerospace, medical, and energy. It is widely referenced as one of Spain's precision‑focused CNC Turning Manufacturers and Suppliers, with strict quality control systems.[7][5]

Key strengths:

- Emphasis on tight‑tolerance turning of complex geometries for demanding industries.[7]

- ISO‑certified processes and rigorous inspection for every batch.[5]

MPG and similar precision shops often invest in multi‑axis lathes, advanced tooling, and metrology to ensure dimensional accuracy for complex turned parts.[7]

Danobat Group, headquartered in Elgoibar, is a global leader in high‑precision CNC grinding machines, lathes, and automated machining solutions. While primarily a machine tool manufacturer, it supports CNC Turning Manufacturers and Suppliers worldwide with advanced lathes and integrated systems for railway, aerospace, and oil and gas applications.[5]

Key strengths:

- Deep expertise in automation, robotics integration, and customized machining cells.[5]

- Strong international presence and engineering support for complex turning lines.[5]

Danobat's technology underpins many production lines where high‑volume CNC turning is combined with automated loading and in‑process measurement to ensure stable quality.[5]

Soraluce, part of a major Spanish industrial group, focuses on milling, boring, and turning machines and is recognized for its technological innovation. Its machines are widely used by CNC Turning Manufacturers and Suppliers that require stability, vibration reduction, and advanced control systems for heavy components.[5]

Key strengths:

- Heavy‑duty turning and multi‑tasking capabilities for large parts in sectors like energy and automotive.[5]

- Proprietary systems that improve accuracy and surface finish during high‑load operations.[5]

Soraluce's technology helps machining companies manage large‑dimension shafts, flanges, and structural components that require high rigidity during CNC turning.[5]

Beyond these names, Spain includes a wide set of specialist CNC Turning Manufacturers and Suppliers listed on industry platforms and directories. Many of these companies are small to medium‑sized machining workshops that combine CNC turning, milling, and secondary operations tailored to export markets.[8][4]

Representative characteristics include:

- Experience in custom parts, small batches, and repeat series for European OEMs.[8]

- Locations near industrial centers like Barcelona, Valencia, Bilbao, and Madrid, enabling efficient logistics.[9]

These smaller CNC Turning Manufacturers and Suppliers often compete on responsiveness and niche expertise, such as machining difficult alloys or very small components.[4]

Spanish CNC Turning Manufacturers and Suppliers generally provide a broad portfolio of machining processes around the core of CNC turning. Buyers can source complete, ready‑to‑assemble parts without splitting operations across multiple vendors.[1][6]

Common technical capabilities:

- Multi‑axis CNC turning, live tooling, and sub‑spindle operations for complex parts.[1]

- CNC milling, drilling, tapping, boring, and grinding as complementary services.[6]

- Machining of steels, stainless steels, aluminum alloys, copper, brass, titanium, and engineering plastics.[1]

Many CNC Turning Manufacturers and Suppliers support both prototype and series production, with flexible setups that allow quick changeovers between different jobs.[2]

To deliver complete solutions, CNC Turning Manufacturers and Suppliers in Spain also coordinate finishing and secondary processes. This reduces handling for buyers and simplifies quality control across the entire value chain.[4][1]

Typical added services:

- Heat treatment, anodizing, plating, painting, and passivation via in‑house or qualified partners.[1]

- Sub‑assembly, kitting, labeling, and packaging tailored to the customer's production line needs.[4]

By integrating turning, finishing, and assembly, Spanish CNC Turning Manufacturers and Suppliers help OEMs reduce supplier counts and streamline procurement.[1]

Spain is an attractive sourcing destination for CNC‑machined and turned components within Europe. Buyers in automotive, aerospace, renewable energy, and industrial machinery frequently shortlist Spanish CNC Turning Manufacturers and Suppliers thanks to the following advantages.[2][1]

Spanish CNC Turning Manufacturers and Suppliers deploy advanced CNC lathes, multi‑axis machining centers, and automated handling systems to achieve consistent quality. Many invest in robotics, digital monitoring, and smart scheduling to increase productivity and reduce lead times.[2][1]

Typical features buyers can expect:

- Multi‑axis CNC turning for complex shafts, housings, manifolds, and medical components.[7]

- Integration of CAD/CAM and simulation to optimize toolpaths and minimize trial‑and‑error on the shop floor.[5]

- Real‑time production dashboards and traceability systems that help manage quality and delivery performance.[2]

These technology investments enable CNC Turning Manufacturers and Suppliers to handle both high‑mix, low‑volume work and stable long‑run production.[1]

Many CNC Turning Manufacturers and Suppliers in Spain hold ISO 9001 and, where relevant, aerospace or automotive‑specific certifications. This certification base supports participation in global supply chains that demand documented quality systems.[3][1]

Common quality practices:

- Incoming material inspection, in‑process measurement, and final testing with CMM and other metrology tools.[7]

- Statistical process control and documented traceability for critical parts.[5]

Quality focus is central for Spanish CNC Turning Manufacturers and Suppliers, particularly those supplying safety‑critical and mission‑critical components.[1]

Spain offers competitive total cost for EU buyers because of reduced transportation time, no internal EU customs, and strong logistics networks. For non‑EU customers, many CNC Turning Manufacturers and Suppliers also work closely with freight forwarders to optimize consolidation and shipping arrangements.[4][2]

Value for buyers:

- Faster lead times and lower logistics risk compared with distant regions for European assembly plants.[10]

- Flexible batch sizes, from one‑off prototypes to scheduled serial deliveries.[6]

When total landed cost is evaluated, Spanish CNC Turning Manufacturers and Suppliers often present an attractive balance between price, speed, and quality.[2]

For foreign OEM brands, wholesalers, and manufacturers, selecting the right CNC Turning Manufacturers and Suppliers in Spain requires a structured approach. Taking a systematic view of capability, cost, and communication reduces sourcing risk and improves long‑term cooperation.[4][2]

The first step is to specify in detail what is required from CNC turning partners. Clear documentation reduces misunderstandings and helps Spanish CNC Turning Manufacturers and Suppliers quote accurately.[11][4]

Key aspects to define:

- Materials, annual volumes, tolerances, surface roughness, and critical dimensions.[11]

- Required standards and testing procedures, including any sector‑specific approvals.[3]

Well‑structured technical packages make it easier for CNC Turning Manufacturers and Suppliers to estimate cycle times, tooling needs, and feasible tolerances at a realistic cost.[11]

Once requirements are defined, buyers can leverage online platforms and directories to identify candidate CNC Turning Manufacturers and Suppliers in Spain. Tools that match 3D models or technical drawings with suitable suppliers help speed up the RFQ process.[8][11]

Best practices include:

- Sending detailed 2D drawings, 3D files, and annual volume estimates.[11]

- Requesting information on machine list, certifications, typical lead times, and reference industries.[4]

Using a standardized RFQ template allows buyers to compare offers from multiple CNC Turning Manufacturers and Suppliers on an equal basis.[8]

Before committing to large contracts, many buyers ask Spanish CNC Turning Manufacturers and Suppliers for samples or trial production orders. Site visits or remote audits can provide additional assurance on capacity, safety, and process stability.[12][4]

Verification steps:

- Approving first article samples and inspection reports before serial production.[7]

- Reviewing production flow, raw material traceability, and operator training records.[5]

This staged approach helps confirm that CNC Turning Manufacturers and Suppliers can consistently meet quality, delivery, and communication expectations.[4]

In addition to local Spanish suppliers, many international buyers combine European and Chinese sources to balance cost, flexibility, and risk. A Chinese precision factory that offers rapid prototyping, CNC machining, CNC turning, sheet metal fabrication, 3D printing, and tooling can complement Spanish CNC Turning Manufacturers and Suppliers in a dual‑sourcing strategy.[13]

Such a partner typically provides:

- Rapid CNC prototypes and small pilot runs to validate new designs before European series production.[13]

- Cost‑competitive CNC turning and milling for non‑critical or price‑sensitive parts, matched with European logistics plans.[4]

By combining Spanish CNC Turning Manufacturers and Suppliers for critical or time‑sensitive parts with a Chinese CNC partner for cost‑optimized components, buyers can create robust and flexible supply chains.[13]

To maximize value when working with CNC Turning Manufacturers and Suppliers in Spain or abroad, buyers can adopt several practical strategies. These approaches support cost control, quality assurance, and long‑term collaboration.[2][4]

Key strategic tips:

- Establish clear quality criteria, including acceptable defect rates, inspection levels, and documentation.[3]

- Share demand forecasts so CNC Turning Manufacturers and Suppliers can plan capacity and materials effectively.[4]

- Encourage open technical communication to optimize designs for machining, reducing cost and lead time.[1]

Long‑term partnerships with reliable CNC Turning Manufacturers and Suppliers usually generate better pricing, priority on capacity, and joint innovation opportunities.[2]

Spain offers a robust ecosystem of CNC Turning Manufacturers and Suppliers serving high‑value industries such as automotive, aerospace, energy, and advanced machinery. With strong technical capabilities, growing Industry 4.0 adoption, and widely adopted quality certifications, Spanish CNC Turning Manufacturers and Suppliers provide a reliable option for global OEMs, wholesalers, and manufacturers seeking precise and traceable turned components. By clearly defining technical requirements, using structured RFQ processes, performing audits and trial orders, and combining Spanish suppliers with complementary partners in other regions, buyers can build a resilient, efficient CNC turning supply chain that supports both innovation and cost‑effectiveness.[2][1][5]

Spanish CNC Turning Manufacturers and Suppliers serve automotive, aerospace, railway, energy, medical, machinery, and general industrial sectors that require precision metal and plastic parts. These industries depend on CNC turning for shafts, bushings, housings, valves, connectors, and structural components with tight tolerances.[7][1]

Most professional CNC Turning Manufacturers and Suppliers in Spain maintain ISO 9001 quality certification, and many also hold ISO 14001 or sector‑specific standards for aerospace and automotive. Buyers should request copies of certificates, audit summaries, and information about quality tools such as PPAP, FMEA, or SPC where relevant.[3][1]

For European customers, Spanish CNC Turning Manufacturers and Suppliers are often cost‑competitive on total landed cost because of shorter transit times, reduced logistics risk, and no intra‑EU customs. For global buyers, Spain may sit between low‑cost regions and high‑cost Western European countries, making it attractive for critical parts that need both precision and reliable delivery.[10][2]

Many Spanish CNC Turning Manufacturers and Suppliers offer prototype machining, small batch runs, and engineering support for new product development. They frequently combine CNC turning with milling, 3D machining, and sometimes additive manufacturing to shorten development cycles.[8][1]

Buyers typically evaluate capacity by reviewing the supplier's machine list, spindle hours, automation level, and historical on‑time delivery performance. Factory audits, video tours, and trial orders are commonly used to confirm that Spanish CNC Turning Manufacturers and Suppliers can handle forecasted volumes and future growth.[12][4]

[1](https://sinoextrud.com/cnc-machining-spain/)

[2](https://beausino.com/cnc-machining-spain/)

[3](https://www.grandviewresearch.com/horizon/outlook/cnc-machining-centers-and-turning-centers-market/spain)

[4](https://www.kemalmfg.com/cnc-machining/companies/spain/)

[5](https://www.elephant-cnc.com/blog/spanish-cnc-machine-manufacturers/)

[6](https://www.mipesa.es/en/)

[7](https://anebonmetal.com/top-cnc-turning-service-manufacturers-in-spain/)

[8](https://ensun.io/search/cnc-machining/spain)

[9](https://www.europages.co.uk/companies/spain/manufacturer%20producer/cnc-machine.html)

[10](https://www.marketdataforecast.com/market-reports/europe-cnc-machine-market)

[11](https://app.partfox.com/search/countries/ES/?p=1)

[12](https://www.hubs.com/cnc-machining/spain/)

[13](https://www.holyprecision.com/Top-10-CNC-Manufacturers-in-Spain.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal