Views: 222 Author: Amanda Publish Time: 2026-01-09 Origin: Site

Content Menu

● Why Portugal Is Strong in CNC Turning

>> Skilled Workforce and Engineering Capability

>> Strategic Location for European Supply Chains

● Key Capabilities of Portuguese CNC Turning Shops

>> Typical Turning Capacity and Equipment

>> Materials and Industries Served

>> Quality Assurance and Certifications

● Representative CNC Turning Manufacturers and Suppliers in Portugal

>> Arpial

>> Tecnisata

>> LTGTech

>> Argo Baum

● Global Platforms Supporting CNC Turning in Portugal

>> Protolabs Network and Similar Services

>> Benefits of Networked CNC Turning Capacity

● Future Outlook for CNC Turning in Portugal

>> Adoption of Industry 4.0 and Automation

>> Growing Aerospace and Precision Markets

● How Overseas Buyers Can Work with Portuguese CNC Turning Suppliers

>> Defining Technical and Commercial Requirements

>> Evaluating Capabilities and Certifications

>> Prototyping, Pilot Runs, and Scale-Up

● Why Combine Portuguese CNC Turning with Chinese OEM Partners

● How to Shortlist CNC Turning Manufacturers and Suppliers in Portugal

>> Technical Fit and Part Complexity

>> Communication and Project Management

>> Total Cost and Long-Term Value

● FAQ – CNC Turning Manufacturers and Suppliers in Portugal

>> 1. What industries do CNC Turning Manufacturers and Suppliers in Portugal mainly serve?

>> 3. What materials can CNC Turning Manufacturers and Suppliers in Portugal machine?

>> 5. Are Portuguese CNC Turning Manufacturers and Suppliers competitive compared to other regions?

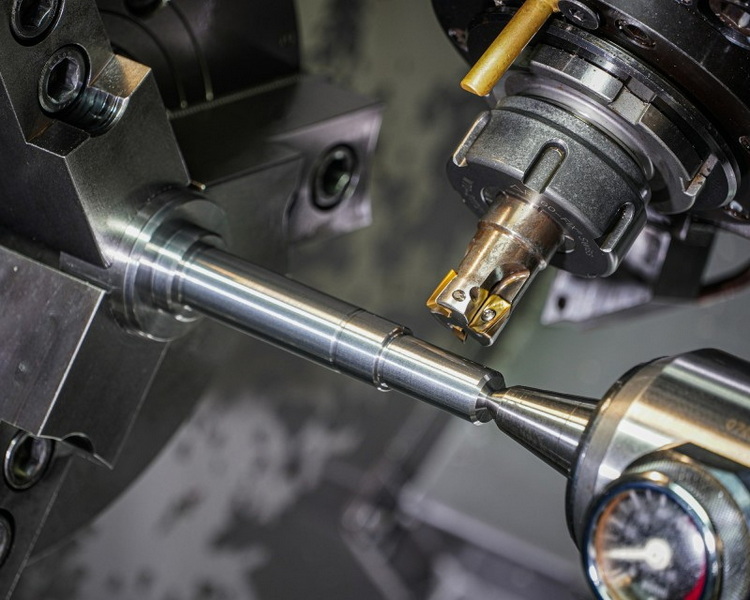

Portugal has become an attractive destination for sourcing CNC Turning Manufacturers and Suppliers, especially for European and global buyers who need high-precision components with reliable lead times and competitive pricing. By combining a strong metalworking tradition with modern automation and skilled engineers, Portuguese CNC Turning Manufacturers and Suppliers now serve demanding sectors such as automotive, aerospace, energy, medical, and industrial equipment.[1]

Portugal's industrial base is deeply rooted in metalworking, mold manufacturing, and precision engineering, which naturally supports the growth of advanced CNC Turning Manufacturers and Suppliers. Over recent decades, local CNC shops have invested heavily in multi-axis CNC lathes, automated loading systems, and integrated quality control to support both prototype and series production projects for international OEM clients.[2][1]

- Portugal trains a highly skilled technical workforce through engineering schools and vocational institutes that focus on machining, programming, and metrology.[1]

- CNC Turning Manufacturers and Suppliers in the country combine this talent with modern CAD/CAM tools to handle complex geometries, tight tolerances, and multi-process machining in a single setup.[2]

- As an EU member, Portugal offers convenient access to customers in Western and Central Europe, making it ideal for CNC Turning Manufacturers and Suppliers that support just-in-time and nearshoring strategies.[3]

- Its ports, logistics providers, and customs integration reduce transit time and simplify compliance for overseas brands and wholesalers sourcing turned parts from Portugal.[3]

CNC Turning Manufacturers and Suppliers in Portugal offer a broad envelope of technical capabilities that cover everything from small precision components to larger shaft-type parts. These providers combine turning with milling, drilling, threading, and finishing services to deliver ready-to-assemble parts to global buyers.[4]

- Many shops operate 2-axis and multi-axis CNC lathes with live tooling, Y-axis, and sub-spindles, enabling complex mill-turn operations in a single clamping for better accuracy.[4]

- Advanced CNC Turning Manufacturers and Suppliers also integrate bar feeders, robotic loaders, and pallet systems to support continuous production and short lead times for recurring orders.[4]

- Portuguese CNC Turning Manufacturers and Suppliers regularly process carbon steel, stainless steel, aluminum, brass, copper, tool steel, and engineering plastics for diverse industrial applications.[4]

- Key sectors include automotive components, aerospace hardware, precision tooling, medical devices, fluid and hydraulic fittings, electronics housings, and general industrial machine parts.[1]

- Many CNC Turning Manufacturers and Suppliers operate under ISO 9001 quality systems and use CMMs, optical measuring systems, and in-line statistical process control to guarantee dimensional stability.[4]

- Traceability, lot documentation, and material certificates are commonly available, which helps overseas OEMs integrate Portuguese suppliers into their audited global supply chains.[5]

While the country hosts dozens of CNC machining and turning companies, a few representative names illustrate the strengths of Portuguese CNC Turning Manufacturers and Suppliers. These companies demonstrate how modern equipment, engineering capability, and export orientation combine to serve global clients.[4]

- RPJM Solutions, based in Ribeirão, offers comprehensive CNC turning and milling services, supporting both prototyping and serial production for international customers.[2]

- With a modern machine park, surface treatment capabilities, and a culture of continuous improvement, it fits the profile of export-ready CNC Turning Manufacturers and Suppliers that many OEM buyers seek.[2]

- Arpial is recognized as a leading precision machining company with extensive experience in CNC turning, mold-related machining, and high-accuracy metal parts.[6]

- Its investments in advanced CNC centers and quality control systems position Arpial among the most reliable CNC Turning Manufacturers and Suppliers in Portugal for demanding tooling and industrial applications.[6]

- Tecnisata, established in the 1970s, operates a large and technologically advanced workshop for metal machining, which includes CNC turning, milling, and related processes.[2]

- Its long history and capability set make Tecnisata a solid representative of mature CNC Turning Manufacturers and Suppliers supporting long-term projects for European customers.[2]

- LTGTech focuses on high-precision CNC machining, offering expert milling, turning, and grinding, supported by surface treatments and thermal processes.[7]

- This emphasis on precision and finishing quality aligns LTGTech with global demand for CNC Turning Manufacturers and Suppliers capable of delivering complete, ready-to-install components.[7]

- Argo Baum is a Portuguese precision manufacturer serving worldwide industries with high-precision machining and advanced metal fabrication based on cutting-edge CNC technologies.[8]

- Its export orientation and combination of engineering expertise and cost-effective solutions place it within the group of high-value CNC Turning Manufacturers and Suppliers in Portugal.[9]

Besides local workshops, international manufacturing networks also connect buyers with CNC Turning Manufacturers and Suppliers in Portugal. These digital platforms simplify sourcing, RFQs, and order management for global brands and wholesalers.[3]

- Online manufacturing networks provide instant quotes for CNC machining in Portugal, including turning, milling, and finishing services.[3]

- By aggregating multiple CNC Turning Manufacturers and Suppliers into one digital platform, they offer flexible capacity for prototypes, bridge production, and ongoing series orders.[3]

- Buyers can benchmark prices, lead times, and technical options across several CNC Turning Manufacturers and Suppliers without running separate RFQ processes for each one.[3]

- Networked platforms help balance urgent prototype demands in Portugal with more cost-optimized batches in other regions, supporting agile product development strategies.[10]

The future for CNC Turning Manufacturers and Suppliers in Portugal is promising, supported by continued industrial upgrades and export growth. Market analyses suggest that CNC machining, including turning, milling, and grinding, already represents a significant share of the Portuguese industrial production value and is expected to expand further.[1]

- Portuguese CNC Turning Manufacturers and Suppliers are increasingly implementing automation, IoT monitoring, and data analytics to optimize machine utilization and reduce downtime.[1]

- This digitalization, combined with energy-efficient equipment and waste reduction initiatives, supports both cost leadership and sustainability objectives for global buyers.[1]

- Growth in aerospace, precision mold manufacturing, and high-value industrial equipment drives demand for advanced CNC turning solutions in Portugal.[1]

- To support these markets, CNC Turning Manufacturers and Suppliers are adopting high-speed, multi-tasking technologies capable of machining high-strength alloys with stable accuracy.[1]

For brands, wholesalers, and OEM producers, partnering with CNC Turning Manufacturers and Suppliers in Portugal can significantly improve cost, lead time, and supply chain resilience. A structured sourcing and cooperation process helps ensure long-term success.[3]

- Before engaging CNC Turning Manufacturers and Suppliers, buyers should document CAD models, 2D drawings, tolerances, materials, treatments, inspection plans, and expected annual volumes.[3]

- Clear specifications allow Portuguese suppliers to propose the best machining routes, batch sizes, and pricing structures, reducing the risk of miscommunication during production.[2]

- Buyers should verify machine lists, maximum turning diameters, length capacities, supported materials, and secondary processes such as surface treatment or assembly at potential CNC partners.[4]

- Reviewing quality certifications, metrology equipment, sample reports, and process control methods helps ensure the CNC Turning Manufacturers and Suppliers can consistently meet project requirements.[5]

- A practical approach is to begin with prototype or pilot batches to validate quality, communication, and logistics with selected CNC Turning Manufacturers and Suppliers.[3]

- After successful trials, buyers can ramp up to small or medium series production, using framework agreements and forecast-sharing to stabilize capacity and pricing.[3]

Many global brands now combine nearshoring to Portugal with strategic partnerships in Asia for high-mix or cost-sensitive volumes. CNC Turning Manufacturers and Suppliers in Portugal can handle urgent orders, tight lead times, and EU-specific projects, while experienced Chinese OEM factories support larger batches and multi-process assemblies.[3]

Shangchen, for example, is a Chinese factory that provides rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing for overseas brands, wholesalers, and manufacturers. By partnering both with Portuguese CNC Turning Manufacturers and Suppliers and with a versatile Chinese OEM like Shangchen, buyers can create a resilient, cost-effective global sourcing model that balances speed, flexibility, and total cost of ownership.

Selecting the right CNC Turning Manufacturers and Suppliers in Portugal requires a clear evaluation framework focused on technical fit, communication, and long-term collaboration potential. A structured approach helps buyers avoid capacity bottlenecks and quality problems.[4]

- Buyers should assess whether candidate CNC Turning Manufacturers and Suppliers have experience with similar part geometries, tolerances, and materials, especially for safety-critical components.[4]

- Reviewing sample parts, case studies, and references can reveal how each supplier handles complex features such as tight concentricity, thin walls, deep bores, and fine surface finishes.[5]

- Strong communication is essential when working with CNC Turning Manufacturers and Suppliers, particularly on revision control, drawing updates, and engineering changes.[3]

- Suppliers that offer English-speaking engineering staff, structured change management, and clear reporting formats make it easier for overseas OEMs to manage multi-plant projects.[2]

- While piece price is important, buyers should also evaluate tooling investments, packaging, logistics, and quality costs when comparing CNC Turning Manufacturers and Suppliers in different regions.[3]

- Portuguese suppliers often deliver high long-term value through lower non-quality costs, stable processes, and reduced communication overhead for Europe-focused programs.[1]

CNC Turning Manufacturers and Suppliers in Portugal now play a crucial role in European and global supply chains for precision metal and plastic parts. Their combination of skilled engineers, modern CNC equipment, export-oriented culture, and integration with digital manufacturing platforms makes them attractive partners for OEMs in automotive, aerospace, industrial equipment, and more. When combined with mature OEM partners in China such as Shangchen, overseas buyers can build a powerful hybrid sourcing strategy that optimizes lead time, cost, and technical capability across markets.[1][4]

CNC Turning Manufacturers and Suppliers in Portugal primarily serve automotive, aerospace, precision tooling, industrial machinery, electronics, and medical device sectors that require tight-tolerance components. These industries benefit from Portugal's strong metalworking heritage and its focus on high-precision, export-ready machining services.[1]

Yes, many CNC Turning Manufacturers and Suppliers in Portugal are structured to support prototypes, pilot runs, and full-scale production using modular setups and automated equipment. This flexibility enables overseas buyers to validate designs quickly and then scale efficiently without changing suppliers.[4][3]

Portuguese CNC Turning Manufacturers and Suppliers typically machine carbon steels, stainless steels, aluminum alloys, brass, copper, tool steels, and a range of engineering plastics. Some specialized shops also work with harder alloys and heat-resistant materials for aerospace and high-performance applications.[1][4]

Quality is ensured by selecting CNC Turning Manufacturers and Suppliers with ISO-certified systems, advanced metrology equipment, and documented process controls. Buyers can request validation runs, review sample inspection reports, and conduct audits or virtual factory tours to confirm capability.[5][4]

Portuguese CNC Turning Manufacturers and Suppliers offer a strong balance of European quality, technical competence, and cost-effective operations, particularly for EU-based and nearshoring strategies. When combined with global networks and complementary partners in Asia, they help buyers build optimized, multi-region sourcing programs for CNC turning work.[1][3]

[1](https://cncwmt.com/qa/what-is-the-future-prospect-of-cnc-machining-in-portugals-industrial-production%EF%BC%9F/)

[2](https://anebonmetal.com/top-cnc-machining-manufacturers-in-portugal/)

[3](https://www.hubs.com/cnc-machining/portugal/)

[4](https://ensun.io/search/cnc-machining/portugal)

[5](https://www.dhanjalengg.com/portugal/cnc-turned-components.html)

[6](https://anebonmetal.com/top-rapid-cnc-machining-manufacturers-and-suppliers-in-portugal/)

[7](https://ltgtech.pt)

[8](https://www.argobaum.com)

[9](https://www.linkedin.com/company/argobaum-tech-precision)

[10](https://geomiq.com)

content is empty!