Views: 222 Author: Amanda Publish Time: 2026-01-13 Origin: Site

Content Menu

● Typical services offered in Norway

● Representative Norwegian CNC turning companies

>> Representative Norwegian CNC turning companies

● Role of global OEM partners like Shangchen

● How to choose CNC Turning Manufacturers and Suppliers in Norway

● Practical sourcing strategies for global buyers

● Digital tools, quoting, and collaboration

● Quality, tolerance, and material considerations

● Logistics, lead times, and risk management

● FAQ about CNC Turning Manufacturers and Suppliers in Norway

>> 1. What industries do Norwegian CNC Turning Manufacturers and Suppliers mainly serve?

>> 4. What should I check before selecting CNC Turning Manufacturers and Suppliers in Norway?

Norway has become an important destination for international buyers looking for CNC turning manufacturers and suppliers that deliver high-precision parts for offshore, marine, energy, and advanced engineering projects. For brands, wholesalers, and OEM producers, understanding Norway's CNC turning ecosystem helps in building a reliable, cost-effective, and diversified supply chain.[1][2]

As a Chinese OEM partner, Shangchen works closely with global CNC Turning Manufacturers and Suppliers in Norway, providing complementary rapid prototyping, CNC machining services, precision batch production, and CNC turned parts to support their projects from development to mass production. This article explores the structure of the Norwegian market, key CNC Turning Manufacturers and Suppliers, and how overseas buyers can combine local Norwegian resources with offshore partners like Shangchen for maximum competitiveness.[3][4][1]

Norway's CNC turning market is closely linked to its strong industrial base in offshore oil and gas, marine engineering, hydropower, and renewable energy. These industries demand extremely reliable CNC Turning Manufacturers and Suppliers capable of producing complex parts with tight tolerances, corrosion resistance, and long service life in harsh environments.[2][5][1]

- Norway is recognized as a high-value precision machining hub within Europe, exporting machined and turned parts to neighboring markets.[6][2]

- The demand for CNC turning is supported by growth in drilling, subsea systems, power generation, and specialized industrial equipment.[5][1]

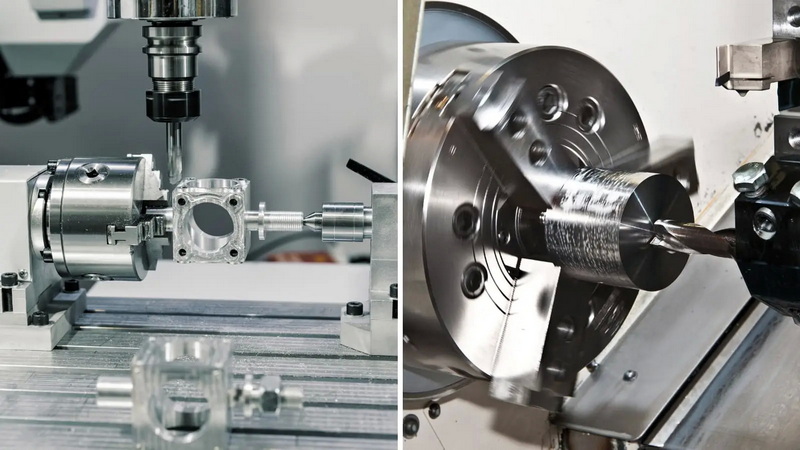

- Local CNC Turning Manufacturers and Suppliers invest in advanced CNC lathes, turn-mill centers, CAD/CAM, and automation to maintain competitiveness against global vendors.[7][1]

Because of this industrial foundation, Norway's CNC Turning Manufacturers and Suppliers often collaborate with international buyers on long-term programs, framework agreements, and strategic components. At the same time, these buyers may integrate offshore OEM partners like Shangchen into their sourcing strategy to balance quality, cost, and capacity for CNC turning projects.[4][1][2][3]

CNC Turning Manufacturers and Suppliers in Norway usually provide a complete set of machining and engineering solutions adapted to demanding sectors. Instead of only simple turned parts, many offer integrated services from design to finished assemblies.[8][1][2]

Common capabilities include:[1][2]

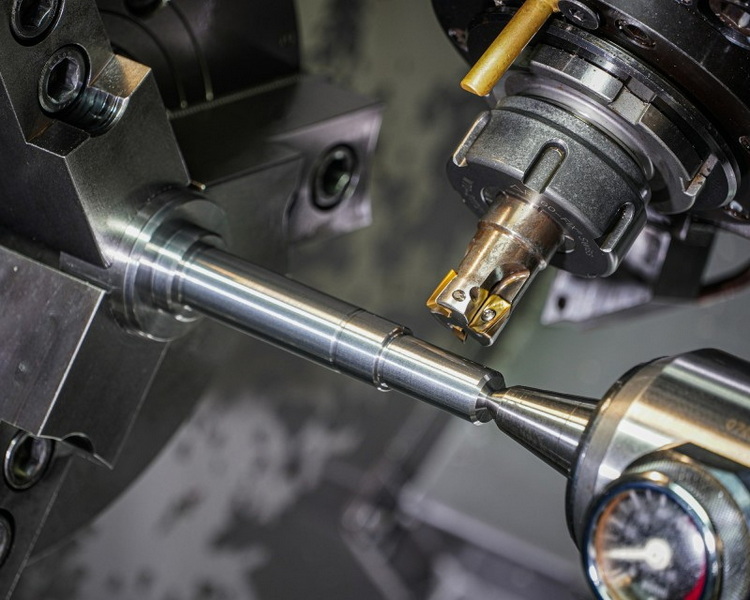

- CNC turning of shafts, flanges, housings, fittings, connectors, valve bodies, and custom components

- 3- and 5-axis CNC milling combined with turning for prismatic and rotational parts

- Prototyping, small-batch and medium-batch production for industrial equipment and machinery

- Machining of steels, stainless steels, superalloys, aluminum, brass, bronze, and engineering plastics

- Surface treatments such as anodizing, plating, painting, passivation, and hardening through partner networks

- Inspection using CMMs, in-process measurement, and full documentation and traceability

In addition, many Norwegian CNC Turning Manufacturers and Suppliers offer welding, fabrication, assembly, and testing to deliver subassemblies rather than individual parts. This system-level capability is particularly valuable in offshore and energy projects where installation and maintenance costs are high and downtime must be minimized.[2][5][1]

Below is an overview-style table of representative CNC Turning Manufacturers and Suppliers in Norway often mentioned in market and industry guides. These companies illustrate the typical capabilities and positioning of Norwegian providers in sectors like marine, offshore, and precision engineering.[9][1][2]

| Company / Provider | Location / Background | Key CNC turning strengths | Main industries served |

| Promek AS | Trondheim; specialist in CNC machining for marine and industrial systems. | CNC turning and milling of complex components, assemblies for ship and offshore equipment. | Shipbuilding, subsea, offshore energy, heavy industry. |

| Orkla Metall | Østlandet region; precision machining and metal fabrication. | CNC turning of parts for turbines, automotive, and industrial systems with emphasis on automation. | Automotive, construction, renewable energy, machinery. |

| NTS AMEGA (Promet AS / NTS Group) | Sola; modern CNC machining centers and tool repair. | Advanced CNC turning and 5-axis machining with CAD/CAM for complex parts. | Offshore, oil and gas, industrial equipment. |

| Stryvo | Stryn; mechanical production and machining specialist. | CNC turning integrated with fabrication and engineering for large and medium components. | Hydropower, maritime, oil and gas, mechanical projects. |

| LTS Maskin AS | Lonevåg; CNC machines and machining expertise. | CNC turning solutions, including machines optimized for aluminum and other metals. | General mechanical industry, metal processing, OEM machinery. |

| Accord Industries AS | Norway-based CNC machining service provider. | More than 70 CNC machines from major brands, with strong CNC turning capacity. | Multiple sectors including energy, engineering, and industrial OEMs. |

For overseas buyers, these examples show why Norway is viewed as a trustworthy source of CNC Turning Manufacturers and Suppliers for high-risk applications. They also highlight that Norway's suppliers often focus on quality, reliability, and engineering depth rather than purely on low cost.[6][1][2]

While Norway offers strong local CNC Turning Manufacturers and Suppliers, cost structures and capacity constraints sometimes encourage buyers to collaborate with global partners. Shangchen in China is one such OEM partner, focusing on rapid manufacturing and CNC turned parts for international brands, wholesalers, and manufacturers.[3][4][1][6]

Shangchen's core services include:[4][3]

- Rapid prototyping using CNC machining, 3D printing, and related processes

- CNC machining services such as CNC turning and CNC milling for metals and plastics

- Precision batch production for small to medium series of CNC turned components

- Sheet metal fabrication, tooling, and mold making to support full product lifecycles

Because Shangchen already works as an OEM supplier to overseas brands, it can easily link its production planning, quality control, and logistics to the requirements of Western engineering teams. When combined with Norwegian CNC Turning Manufacturers and Suppliers, this creates a scalable network that supports development, pilot runs, and mass production under one integrated strategy.[1][3][4]

When evaluating CNC Turning Manufacturers and Suppliers in Norway, overseas buyers should focus on both technical capabilities and long-term partnership potential. The following points are essential.[2][1]

- Technical capacity: Check the range of CNC lathes and turn-mill centers, maximum workpiece size, tolerance levels, and supported materials.[7][2]

- Engineering and design support: Many Norwegian CNC Turning Manufacturers and Suppliers provide DFM (Design for Manufacturability) and CAD/CAM support to improve part performance and cost.[9][1]

- Certifications and compliance: ISO 9001 or sector-specific certifications (e.g., aerospace or offshore) are key indicators of process discipline.[1][2]

- Traceability and documentation: For offshore and energy projects, detailed documentation, material certificates, and inspection records are mandatory.[5][1]

- Supply chain flexibility: Consider how the Norwegian supplier cooperates with external CNC Turning Manufacturers and Suppliers, including partners like Shangchen, to handle volume peaks or cost-sensitive batches.[3][1]

In addition, buyers should assess communication quality, project management, and the supplier's experience with international logistics. CNC Turning Manufacturers and Suppliers familiar with export requirements, packaging standards, and customs procedures can significantly reduce delays and hidden costs.[6][9][1]

A structured sourcing strategy can maximize the benefits of Norway-based CNC Turning Manufacturers and Suppliers while leveraging offshore capacity.

- Use Norwegian CNC Turning Manufacturers and Suppliers for early prototypes that require close engineering collaboration, quick design iterations, and on-site testing.[9][1]

- Transfer stable, cost-sensitive parts to an OEM partner such as Shangchen, which offers CNC machining services and CNC turned batch production at competitive pricing.[4][3]

- Maintain dual sourcing for strategic components: one Norwegian CNC Turning Manufacturers and Suppliers partner plus one offshore CNC turning factory for resilience and price benchmarking.[6][1]

- Align quality systems so that both local and offshore CNC Turning Manufacturers and Suppliers share similar inspection standards, drawings, and documentation templates.[3][1]

Many buyers also phase their sourcing in stages, starting with a small number of part numbers at a Norwegian CNC turning facility, then gradually moving families of parts to Shangchen once processes are mature. This step-by-step migration reduces risk while still capturing the benefits of global CNC Turning Manufacturers and Suppliers across different cost regions.[4][1][3][6]

Many CNC Turning Manufacturers and Suppliers in Norway now use digital platforms to streamline quoting and collaboration. International buyers can upload 3D models, define tolerances and materials, and receive online quotations, sometimes supplemented by global production networks.[11][9]

- Network platforms allow orders to be fulfilled either in Norway or through partner CNC machining and CNC turning facilities across Europe, America, and Asia.[11]

- Digital CAD/CAM and simulation tools help CNC Turning Manufacturers and Suppliers predict machining time, optimize tool paths, and reduce scrap.[7][9]

- Data exchange standards (STEP, IGES, native CAD formats) enable seamless collaboration with offshore CNC turning partners such as Shangchen's engineering team.[3][4]

For OEM buyers, this combination of Norwegian precision and global reach through partner CNC Turning Manufacturers and Suppliers can significantly shorten product development cycles. Digital collaboration also makes it easier to maintain common revision control across multiple factories, reducing the risk of outdated drawings.[11][9][4][3]

When working with CNC Turning Manufacturers and Suppliers in Norway, quality and tolerance requirements are central to project success. Norwegian suppliers are accustomed to tight tolerance bands and rigorous inspection procedures, especially for safety-critical applications.[5][2][1]

- Tolerances: CNC Turning Manufacturers and Suppliers commonly handle tight tolerances in axial and radial dimensions, surface finish, and concentricity for rotating components.[2][7]

- Materials: High-strength steels, duplex and super duplex stainless steels, aluminum alloys, copper alloys, and nickel-based superalloys are frequently used in offshore and marine environments.[5][1]

- Testing: Depending on application, CNC Turning Manufacturers and Suppliers may implement NDT methods such as ultrasonic testing, magnetic particle inspection, or dye penetrant inspection through certified partners.[1][5]

Shangchen mirrors many of these expectations by using advanced CNC turning centers, in-process inspection, and controlled material sourcing for its CNC machining services. When Norwegian CNC Turning Manufacturers and Suppliers and Shangchen share common quality targets and documentation formats, transferring parts between facilities becomes much smoother.[4][1][3]

For global buyers, logistics and risk management are just as important as the technical capabilities of CNC Turning Manufacturers and Suppliers. Norway's strategic position in Northern Europe, combined with strong port and road infrastructure, supports reliable delivery to nearby markets.[2][6][1]

- Lead time: Local Norwegian CNC Turning Manufacturers and Suppliers can offer shorter transit times and faster response to urgent changes for European customers.[1][2]

- Inventory: Some CNC Turning Manufacturers and Suppliers offer vendor-managed inventory or consignment stock to support just-in-time deliveries.[9][1]

- Risk diversification: By combining Norwegian CNC Turning Manufacturers and Suppliers with Shangchen in China, buyers diversify geopolitical, currency, and logistics risk.[6][3]

Shangchen supports international buyers with flexible shipping options, including air freight for urgent CNC turned parts and sea freight for volume orders. Coordinated planning between Norwegian CNC Turning Manufacturers and Suppliers and Shangchen further reduces the chance of line stoppages caused by delays in a single region.[3][4][1]

Norway offers a mature ecosystem of CNC Turning Manufacturers and Suppliers that serve demanding industries like offshore energy, marine, hydropower, and advanced machinery. These CNC Turning Manufacturers and Suppliers combine high-end CNC lathes, engineering expertise, and strict quality management to deliver reliable, complex turned components.[2][1]

At the same time, international OEM partners such as Shangchen provide complementary rapid manufacturing, CNC machining services, and CNC turned batch production from China, enabling a balanced global sourcing strategy. By combining local Norwegian CNC Turning Manufacturers and Suppliers for critical parts with offshore CNC turning OEM capacity, buyers can reduce cost, manage risk, and accelerate innovation in global projects.[4][1][3]

Norwegian CNC Turning Manufacturers and Suppliers typically support marine, offshore oil and gas, hydropower, renewable energy, and advanced mechanical engineering sectors that require high-reliability parts. Many also serve automotive and general industrial customers across Europe through exports of precision-turned components.[6][1][2]

CNC Turning Manufacturers and Suppliers in Norway generally operate with higher labor and energy costs but offer strong engineering support, advanced equipment, and robust quality systems. Offshore partners such as Shangchen in China provide competitive pricing and flexible batch production, making a combined sourcing model attractive for many OEMs.[1][2][3][4]

Yes, many OEMs use Norwegian CNC Turning Manufacturers and Suppliers for prototypes, critical parts, or low-volume production and work with Shangchen for larger, cost-sensitive batches. This approach allows them to keep key engineering activities close to their market while benefiting from the cost advantages of offshore CNC turning.[3][6][1]

Buyers should evaluate machine capacity, material capabilities, tolerance levels, certifications (such as ISO 9001), and experience in their target industry when choosing CNC Turning Manufacturers and Suppliers. It is also important to review lead times, documentation practices, and openness to cooperating with global partners like Shangchen for hybrid sourcing.[2][1][3]

Shangchen provides rapid prototyping, CNC machining services, CNC turned parts, and precision batch production that can complement existing Norwegian CNC Turning Manufacturers and Suppliers on cost and capacity. By aligning drawings, quality standards, and inspection processes, Shangchen can take over or share selected part families while customers keep strategic components with their Norwegian suppliers.[4][6][3]

[1](https://sinoextrud.com/cnc-machining-norway/)

[2](https://ensun.io/search/cnc-machining/norway)

[3](https://www.sc-rapidmanufacturing.com/products/CNC-Turned.html)

[4](https://www.sc-rapidmanufacturing.com/products/CNC-Milling-Turning.html)

[5](https://www.nextmsc.com/report/norway-cnc-drilling-machine-market)

[6](https://www.grandviewresearch.com/horizon/outlook/precision-machining-market/europe)

[7](https://no.dmgmori.com/products/machines/turning)

[8](https://accordindustries.no/services/cnc-machining/)

[9](https://anebonmetal.com/top-cnc-machining-services-manufacturers-in-norway/)

[10](https://ensun.io/search/cnc-machine/norway)

[11](https://www.hubs.com/cnc-machining/norway/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal