Views: 222 Author: Amanda Publish Time: 2026-01-09 Origin: Site

Content Menu

● Why France Is Strong in CNC Turning

● Key Industries Using CNC Turning in France

● Core Capabilities of French CNC Turning Shops

● Representative CNC Turning Manufacturers and Suppliers in France

>> 1. DJC – Precision CNC Bar Turning Specialist

>> 2. Sagne Mécanique – High‑Precision Turning and Machining

>> 3. MÉCANUMÉRIC – CNC Machine Manufacturer with Turning Solutions

>> 4. Huron Graffenstaden – Multi‑Axis Turning and Milling Solutions

>> 5. Lathuille Hudry – Precision Machining for Small and Medium Series

>> 6. Benoit Jolivet – Precision Turning and Machining Company

>> 7. Clément SA – Precision Engineering and Special Machines

● How French CNC Turning Manufacturers Support Global OEMs

● Partnering French CNC Turning with Chinese OEM Capacity

● What to Look for in CNC Turning Manufacturers and Suppliers in France

● Benefits of Combining French and Chinese CNC Turning Supply

● FAQ

>> 1. What industries do CNC Turning Manufacturers and Suppliers in France mainly serve?

>> 2. How can overseas buyers select the right CNC Turning partner in France?

>> 3. Do French CNC Turning Manufacturers and Suppliers support small and medium series?

>> 4. Can French CNC Turning shops work with Chinese OEM factories like Shangchen?

>> 5. What advantages does Shangchen offer compared with local CNC Turning Manufacturers and Suppliers?

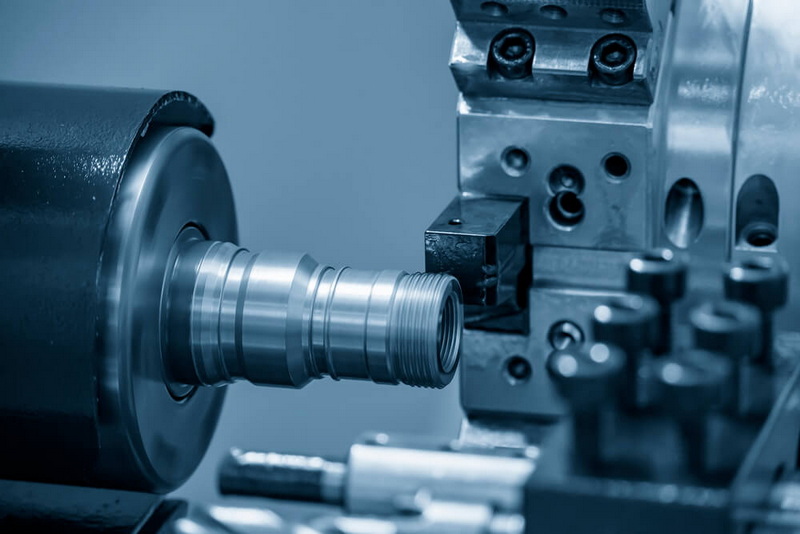

France has a mature ecosystem of CNC Turning Manufacturers and Suppliers that support aerospace, automotive, medical, energy, and luxury industries with high‑precision machined parts. For foreign brands, wholesalers, and OEM producers, understanding these CNC Turning Manufacturers and Suppliers in France is essential to build a stable, high‑quality supply chain while balancing cost, capacity, and technical capability.

French CNC Turning Manufacturers and Suppliers benefit from long industrial traditions in precision mechanics, bar turning, and machine tool design, especially in regions such as the Arve Valley and eastern France. This heritage, combined with investment in modern CNC equipment and automation, allows CNC Turning Manufacturers and Suppliers in France to deliver tight tolerances, complex geometries, and consistent quality for demanding sectors.

CNC Turning Manufacturers and Suppliers in France serve aerospace, automotive, medical device, rail, energy, telecommunications, and industrial equipment companies that require high‑precision metal and plastic components. These CNC Turning Manufacturers and Suppliers often handle everything from rapid prototypes and small batches to medium series and, in some cases, large volumes for global programs.

Most established CNC Turning Manufacturers and Suppliers in France operate multi‑axis CNC lathes, bar turning machines, and machining centers capable of turning, milling, drilling, and threading in one setup. Many also integrate CAD/CAM programming, CMM inspection, and surface treatments so that overseas buyers receive fully finished, ready‑to‑assemble parts from a single CNC Turning manufacturer.

France has dozens of CNC Turning Manufacturers and Suppliers; the companies below are representative examples that show the range of capabilities available to global buyers. They illustrate how French precision machining combines bar turning heritage, machine tool engineering, and high‑precision subcontracting to support international OEM projects.

DJC is a precision CNC bar turning company founded in the Arve Valley, the historic center of bar turning machining in France, and is recognized among leading CNC Turning Manufacturers and Suppliers in the country. It focuses on stainless steel, aluminum, and other machinable alloys to deliver high‑precision turned components for customers in Europe and overseas.

DJC operates multi‑spindle and single‑spindle lathes, along with modern CNC turning centers, to supply prototypes, small series, and large production runs with stable quality and repeatability. The company positions itself among French CNC Turning Manufacturers and Suppliers by offering technical support on materials and manufacturability and by delivering complete, fully finished parts from a single production line.

Sagne Mécanique is frequently listed among French CNC machining and CNC Turning Manufacturers and Suppliers thanks to its expertise in non‑ferrous metals, plastics, and composites. It serves industries such as medical technology, aerospace, automotive, optics, and watchmaking, where fine tolerances, surface finish, and cosmetic appearance are all critical.

As part of France's broader CNC Turning ecosystem, Sagne Mécanique supports rapid prototyping, tooling, and series production, making it attractive to foreign buyers who need both engineering input and high‑precision machining. Its business model shows how CNC Turning Manufacturers and Suppliers in France often combine traditional craftsmanship with modern automation and digital quality control.

MÉCANUMÉRIC is a French manufacturer of CNC machines that designs and builds milling, water‑jet, laser cutting, and turning solutions at its integrated facility in southwest France, supplying equipment used by many CNC Turning Manufacturers and Suppliers. While it is primarily a machine tool builder rather than a job shop, its technology is central to the performance of numerous precision machining operations across the country.

The company produces 3‑axis, 4‑axis, and 5‑axis machining centers and offers specialized CNC equipment for metal, plastic, and composite processing, giving CNC Turning Manufacturers and Suppliers in France access to high‑productivity, high‑precision machinery. Its R&D focus, service network, and strong installed base have helped raise the technical standard for CNC Turning Manufacturers and Suppliers throughout France and across Europe.

Huron Graffenstaden, based in Strasbourg, is one of the most recognized French CNC machine tool brands and supplies advanced lathes and machining centers that underpin many CNC Turning Manufacturers and Suppliers. The company offers vertical machining centers, 5‑axis solutions, and multi‑function machines designed for high‑precision, high‑productivity applications.

Although Huron mainly manufactures equipment rather than contract parts, its machines are widely installed in CNC Turning Manufacturers and Suppliers that serve aerospace, automotive, energy, and general engineering customers. By focusing on rigid machine structures, accurate spindle systems, and user‑friendly controls, Huron enables CNC Turning Manufacturers and Suppliers to achieve tight tolerances and efficient cycle times on complex parts.

Lathuille Hudry specializes in precision machining for small and medium series production and operates a large fleet of CNC machines to support French and international clients. It covers the full manufacturing chain—order analysis, process planning, machining, inspection, and logistics—making it a well‑rounded member of the CNC Turning Manufacturers and Suppliers community in France.

By continually upgrading its CNC equipment, tooling, and metrology, Lathuille Hudry can manufacture complex parts in steels, aluminum, and other alloys while meeting strict quality and delivery requirements. This end‑to‑end approach appeals to overseas OEM buyers who want CNC Turning Manufacturers and Suppliers that can manage both technical execution and supply‑chain reliability from RFQ to shipment.

Benoit Jolivet is a machining company that offers precision turning and machining services, supplying custom parts for industrial customers that need accurate, repeatable production. Positioned among CNC Turning Manufacturers and Suppliers in France, it provides tailored solutions for OEMs who require flexible subcontract machining capacity.

The company emphasizes precision turning capabilities, combining CNC lathes, machining centers, and finishing processes to deliver components that meet functional and dimensional requirements. This customer‑focused model is typical of many CNC Turning Manufacturers and Suppliers in France that work closely with engineering teams to refine designs and optimize manufacturability before and during production.

Clément SA is a precision engineering company active for more than a century and known for high‑precision machining and the design of special machinery. Its experience in both component manufacturing and equipment design places it within the wider network of advanced CNC Turning Manufacturers and Suppliers in France.

By combining precision machining with custom equipment and fixture development, Clément SA can solve unique engineering problems and deliver highly specialized components and assemblies. This makes the company attractive for overseas buyers who require CNC Turning Manufacturers and Suppliers that can handle complex, project‑specific challenges beyond basic turning operations.

Many CNC Turning Manufacturers and Suppliers in France export parts or work as Tier‑1 and Tier‑2 suppliers for global programs in aerospace, medical devices, energy, and automotive systems. These companies typically provide documentation, traceability, and quality certifications that align with international standards, which is vital for regulated and safety‑critical industries.

For foreign brands and wholesalers, cooperating with CNC Turning Manufacturers and Suppliers in France can reduce risk on critical components while leveraging the country's engineering talent and industrial infrastructure. At the same time, combining French precision machining with cost‑effective overseas partners allows OEMs to optimize total project cost, scalability, and logistics across multiple regions.

A practical strategy for many OEM buyers is to work with CNC Turning Manufacturers and Suppliers in France for critical, high‑risk parts while using a specialized Chinese OEM factory such as Shangchen (sc‑rapidmanufacturing.com) for rapid prototyping and cost‑sensitive production. Shangchen provides rapid prototyping, CNC machining, CNC turning, sheet metal fabrication, 3D printing, mold manufacturing, and precision batch production for overseas brands, wholesalers, and manufacturers.

This hybrid model allows buyers to use French CNC Turning Manufacturers and Suppliers when proximity, certification, or lead‑time stability is paramount, while relying on Shangchen for flexible, price‑competitive CNC turning and related processes. By coordinating drawings, material standards, inspection methods, and packaging across suppliers, OEMs can build a resilient supply chain that balances quality, cost, and responsiveness.

When evaluating CNC Turning Manufacturers and Suppliers in France, overseas buyers should carefully review machine lists, axis configurations, bar capacities, tolerances, and compatible materials to ensure technical fit with project requirements. It is also important to check sector experience—such as aerospace, medical, or automotive—alongside quality certifications, process documentation, and references in similar components or assemblies.

Strong CNC Turning Manufacturers and Suppliers provide transparent communication, clear RFQ responses, realistic lead times, and flexibility for prototypes, small series, and ramp‑up to volume production. Many also support design for manufacturing (DFM) and cost‑reduction workshops, helping customers adjust turned and machined parts before committing to full production and expensive tooling.

By working with CNC Turning Manufacturers and Suppliers in France and an OEM partner like Shangchen in China, buyers can diversify geographic risk while benefiting from different cost structures and strengths. French suppliers can focus on high‑risk, urgent, or heavily certified components, whereas Shangchen can handle rapid prototypes, bridge production, and large‑batch CNC turning and machining for cost‑sensitive parts.

This approach is particularly useful for brands managing product launches across multiple markets, where CNC Turning Manufacturers and Suppliers must deliver both speed and scalability. Coordinated engineering, shared CAD/CAM data, aligned inspection plans, and consistent quality targets help keep performance stable across all suppliers and locations, reducing surprises during assembly and field use.

CNC Turning Manufacturers and Suppliers in France form a sophisticated network of precision machining companies, machine tool builders, and bar turning specialists that support critical industries across Europe and the wider global market. For overseas brands, these CNC Turning Manufacturers and Suppliers offer strong technical capabilities, reliable quality systems, and experienced engineering teams, especially when their strengths are combined with cost‑effective OEM partners like Shangchen for rapid prototyping and high‑volume production.

CNC Turning Manufacturers and Suppliers in France mainly serve aerospace, automotive, medical devices, energy, industrial machinery, and telecommunications, where precision and reliability are essential. Many also supply components for luxury goods, optics, and watchmaking that require excellent surface finish and cosmetic quality.

Overseas buyers should compare technical capabilities, tolerances, materials, certifications, and reference projects across multiple CNC Turning Manufacturers and Suppliers in France before making a decision. It is also wise to evaluate communication, quotation speed, lead‑time commitments, and the ability to support both prototypes and series production.

Yes, many CNC Turning Manufacturers and Suppliers in France specialize in small and medium production series and are used to frequent design changes and project‑based orders. This flexibility makes them suitable for OEMs that need regular engineering updates, pre‑series runs, and stable recurring batches without committing to very high volumes.

French CNC Turning Manufacturers and Suppliers frequently participate in international supply chains, so coordinating with Chinese OEM factories like Shangchen is entirely feasible. By sharing drawings, material specifications, quality plans, and inspection reports, buyers can align output from both French and Chinese facilities to achieve consistent performance and fit.

Shangchen offers integrated rapid prototyping, CNC machining, CNC turning, sheet metal fabrication, 3D printing, mold manufacturing, and precision batch production with competitive pricing, which helps reduce total project cost. When combined with local CNC Turning Manufacturers and Suppliers in France for critical or time‑sensitive parts, Shangchen enables OEM buyers to balance quality, speed, and cost across the entire product life cycle.

content is empty!