Views: 222 Author: Amanda Publish Time: 2025-08-01 Origin: Site

Content Menu

● What Makes Russian CNC Milling Services Manufacturers and Suppliers Unique?

>> Advanced Technology and Expertise

>> Global Sourcing and Market Growth

● The CNC Milling Process: How It Works

● Top CNC Milling Services Manufacturers and Suppliers in Russia

>> 1. IP Khromov Nikolay Yurievich

>> 2. LLC Technostudia Profile

>> 3. LLC PF Russian Instrument

>> 4. Baltic Plant of Precise Mechanics

>> 5. POLITEK

>> 7. Sevmash

>> 8. Sasta

>> 10. WOODLAND

● Benefits of Choosing Russian CNC Milling Services Manufacturers and Suppliers

● Industry Trends Shaping Russia's CNC Milling Sector

● Applications of Russian CNC Milling Services

● How to Select a CNC Milling Services Manufacturer or Supplier in Russia

● FAQs

>> 1. What types of CNC machines are most commonly used in Russia?

>> 2. Are Russian CNC milling manufacturers capable of supplying global brands?

>> 3. What industries rely most heavily on Russian CNC milling suppliers?

>> 4. How fast can Russian CNC milling suppliers deliver?

>> 5. What is the process to request a quote from a Russian CNC milling supplier?

The landscape of CNC milling services manufacturers and suppliers in Russia is marked by rapid technological innovation, robust engineering tradition, and a growing international reputation for quality and precision. In this in-depth exploration, we'll uncover the industrial might, unique advantages, market trends, and top players in Russia's CNC milling sector. Along the way, you'll gain an understanding of the industry's key facets, supported by detailed explanations about processes, applications, and practical advice for selecting the right partners.

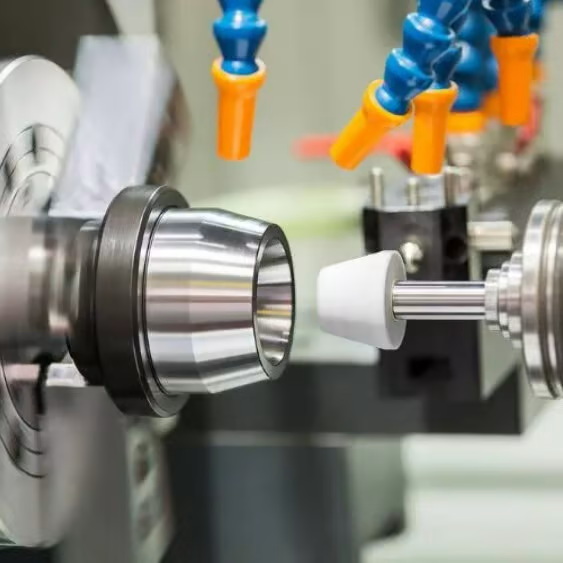

Computer Numerical Control (CNC) milling stands at the heart of modern manufacturing, transforming digital designs into precise physical components. In Russia, this industry is not just growing; it's thriving thanks to investments in advanced machinery, skilled labor, and technological integration across multiple sectors: aerospace, automotive, electronics, energy, and medical devices.

Russia's CNC milling services manufacturers and suppliers have developed their reputation on a foundation of engineering excellence and consistent innovation. Their ability to integrate worldwide best practices and local expertise makes Russia a competitive player in the global CNC machining market.

Russian manufacturers are globally recognized for their:

- Use of 3-axis and 5-axis CNC milling machines for intricate, high-precision work, enabling the production of complex geometries not achievable with traditional machining.

- Integration of advanced automation and software, including CAD/CAM systems, improves production speed and cost-efficiency without compromising precision.

- Specialized experience in complex sectors such as aerospace, automotive, and medical industries, where tight tolerances and material expertise are required.

- Deployment of precision ball screw drives, high-performance spindles, and direct-drive motors to ensure exact tolerances even on challenging designs.

The focus on technological advancement reflects Russia's commitment to parallel global trends, with innovative workflows and equipment continually raising the bar for quality and efficiency.

While much of Russia's CNC machinery is sourced from international suppliers, its domestic engineering talents synthesize these global inputs with local ingenuity to produce competitive, high-value manufacturing solutions.

The market is marked by:

- A robust demand in aerospace, automotive, and electronics sectors that push continuous enhancements.

- Investments in machine design and software for automated, error-minimized production.

- Government initiatives encouraging modernization, skills development, and export growth, making Russia a strong contender in the CNC milling landscape.

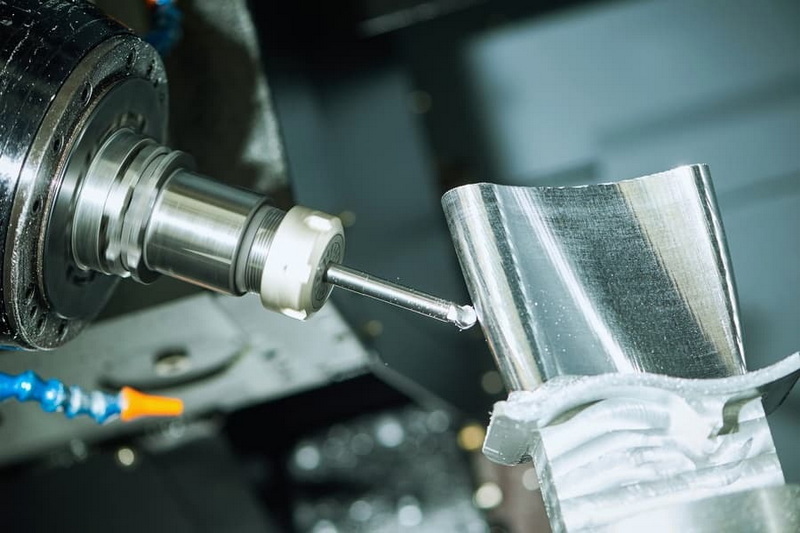

CNC milling is fundamentally a subtractive manufacturing technique—where material is precisely removed from a solid block using computer-guided cutting tools. Understanding the process helps clarify why Russian CNC milling services are widely respected for accuracy and repeatability.

1. CAD Design

Engineers begin by designing a 3D model of the required part using CAD software. This digital blueprint contains all dimensions and specifications.

2. CAM Programming

Next, CAM software converts the CAD model into machine instructions known as G-code. This code guides the CNC mill to move tools along programmed paths.

3. Material Setup

The raw stock—commonly aluminum, steel, titanium, plastics, or composite materials—is secured on the machine table, ready for machining.

4. Precision Machining

The CNC mill performs precise, multidirectional cuts, often with micron-level accuracy. The process can involve rough cuts for bulk removal followed by fine finishing passes for tight tolerances.

5. Finishing & Quality Control

Completed parts are polished or treated as needed, then inspected using Coordinate Measuring Machines (CMMs) or other metrological tools to verify compliance with specifications.

This sequence ensures a high degree of consistency across prototypes and production batches alike.

Russia hosts a diverse array of CNC milling manufacturers and suppliers, each distinguished by their technical capabilities and industry focus.

A market leader specializing in 5-axis milling and CNC machining for aerospace and industrial applications. Known for precision, they offer both rapid prototyping and full-scale batch production.

This manufacturer combines design, prototyping, and series manufacturing under strict quality control, serving diverse sectors with integrated engineering services.

Experts in tool and die manufacturing with advanced CNC turning and milling capabilities, catering heavily to automotive and electronics clients.

Located in St. Petersburg, this plant excels in contract manufacturing of high-precision CNC milled and turned parts, largely for export and foreign industries.

POLITEK blends practical engineering with advanced manufacturing technology to support OEMs and custom batch projects with flexible solutions.

This company provides innovative solutions by integrating plasma, laser, and waterjet CNC systems, enabling machining of large-format parts and complex 3D components.

Serving military and civil engineering sectors, Sevmash features heavy-duty CNC lathes and giant milling machines. Their quality programs cover all aspects of R&D and volume production.

Sasta manufactures and supplies a wide range of CNC machines and services, delivering flexible, efficient solutions for companies of all sizes.

Known for speed and precision, PartZpro delivers instant quotations, DFM feedback, rapid prototyping, and adaptive batch production via an accessible online platform.

Specializing in CNC machines for hobbyists and small-scale industries, WOODLAND expands precision machining technology to a broader user base.

When opting for Russian CNC milling services manufacturers and suppliers, clients benefit from:

- Competitive Pricing with Quality Assurances

Skilled engineering and lower operational costs translate to cost-effective production without compromising quality.

- Material Versatility

Russian providers work with an expansive range of materials, including specialty alloys, titanium, plastics, and composites.

- Flexible Production Options

Whether for rapid prototyping or full batch production, manufacturers offer scalability and agility in delivery.

- Stringent Quality Control

Compliance with international standards (including ISO certifications) ensures high reliability and consistent product quality.

- Technological Innovation

Integration of new technologies, such as automation and real-time monitoring, boosts efficiency and reduces lead times.

Russian CNC milling industry evolves in alignment with global trends, including:

- Automation and Robotics

Increasing use of robotic arms and automated material handling speeds up production and enhances safety.

- Smart Manufacturing and Industry 4.0

The adoption of IoT, data analytics, and cloud computing facilitate predictive maintenance and process improvements.

- Sustainability and Green Manufacturing

Emphasis on energy-efficient machines and waste-minimization techniques reflects environmental responsibility.

- International Standards Alignment

Compliance with international quality systems and export-oriented strategies strengthens Russia's competitive positioning.

Russian CNC milling services are central to manufacturing for various strategic industries:

- Aerospace

Precision parts such as turbine blades, engine zones, and structural components require high-performance materials and machining accuracy.

- Automotive

Parts such as gearboxes, transmission housings, and braking components benefit from precision milling to enhance performance and safety.

- Medical Devices

Components like prosthetic frameworks and surgical instruments depend on biocompatible materials and micrometer precision.

- Electronics

Heat sinks, custom enclosures, and brackets for sensitive electronics require intricate machining and complex geometries.

- Mold and Die Making

Injection mold tools and stamping dies fabricated via CNC milling enable high-volume plastic and metal part production.

Selecting the right Russian CNC milling services manufacturer or supplier requires careful evaluation.

- Assess Technical Capabilities

Review the number of CNC axes available (3, 4, 5), machine precision, and CAD/CAM software proficiency to match your project's complexity.

- Check Certifications and Compliance

Ensure adherence to ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), or other relevant standards that guarantee quality and traceability.

- Examine Case Studies and Client Portfolios

Request prototypes, samples, or references to gauge capability and reliability in producing parts similar to your requirements.

- Evaluate Transparency in Pricing, Lead Times, and QC Processes

Clear communication on costs, production schedules, and quality checks reduces project risks.

- Consider Starting with Pilot Runs

Trial runs can validate supplier quality before committing to larger volumes.

Russia's CNC milling services manufacturers and suppliers demonstrate a strong commitment to quality, advanced technology, and sector-specific expertise. Their integration of cutting-edge machinery and automation alongside skilled engineering makes them an attractive choice for international brands, wholesalers, and producers seeking precision, rapid prototyping, or batch manufacturing. Backed by robust quality controls, flexible production capabilities, and cost-effective solutions, Russian CNC milling providers play an increasingly influential role in the global manufacturing ecosystem. Choosing a reliable Russian CNC partner ensures access to innovative machining services that balance technological excellence with competitive commercial terms, fostering growth and quality in clients' operations worldwide.

Russian manufacturers often employ advanced 3-axis and 5-axis CNC milling machines, complemented by CNC lathes, EDM, laser, and plasma cutters. This diversity enables handling both simple parts and complex, multi-dimensional components.

Yes, many Russian manufacturers regularly export globally and meet stringent international standards. They support OEM and wholesale clients with custom prototyping and full production runs.

Critical sectors include aerospace, automotive, medical devices, electronics, energy, and defense, all requiring precise, reliable, and innovative manufacturing collaborations.

Depending on complexity and order size, sample parts are typically delivered within 7–10 days. Full production runs can be completed within a month, with some suppliers offering expedited options.

Clients usually provide their 3D or 2D designs and specify material and quantity requirements via the supplier's online platform or direct communication. The supplier then provides a design for manufacturability feedback and a price quote.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal