Views: 222 Author: Amanda Publish Time: 2025-08-02 Origin: Site

Content Menu

● Overview of CNC Milling Services in Japan

● Leading CNC Milling Services Manufacturers and Suppliers in Japan

>> Makino Milling Machine Co., Ltd.

● Additional Noteworthy CNC Milling Service Providers

● Technological Innovations in Japanese CNC Milling Services

>> Advanced Materials Processing

>> Precision & Quality Control

● Application Areas for CNC Milling Services in Japan

● Advantages of Choosing Japanese CNC Milling Services Manufacturers and Suppliers

● Challenges and Future Trends

● FAQ

>> 1. What types of CNC milling machines are commonly used by Japanese manufacturers?

>> 2. Which industries benefit most from Japanese CNC milling services?

>> 3. How do Japanese CNC milling manufacturers ensure quality and precision?

>> 4. Can Japanese CNC milling services handle both prototyping and mass production?

>> 5. What makes Japanese CNC milling manufacturers competitive globally?

Japan has long been recognized as a global leader in precision manufacturing and advanced industrial technology. Among its many achievements, Japan stands out in the CNC milling services sector, boasting some of the world's most reliable CNC milling services manufacturers and suppliers. These companies provide cutting-edge CNC machining solutions that cater to both domestic and international markets, facilitating prototyping, precision batch production, and complex components manufacturing across various industries. This article explores the top CNC milling services manufacturers and suppliers in Japan, highlighting their capabilities, technologies, and contributions to the global manufacturing ecosystem.

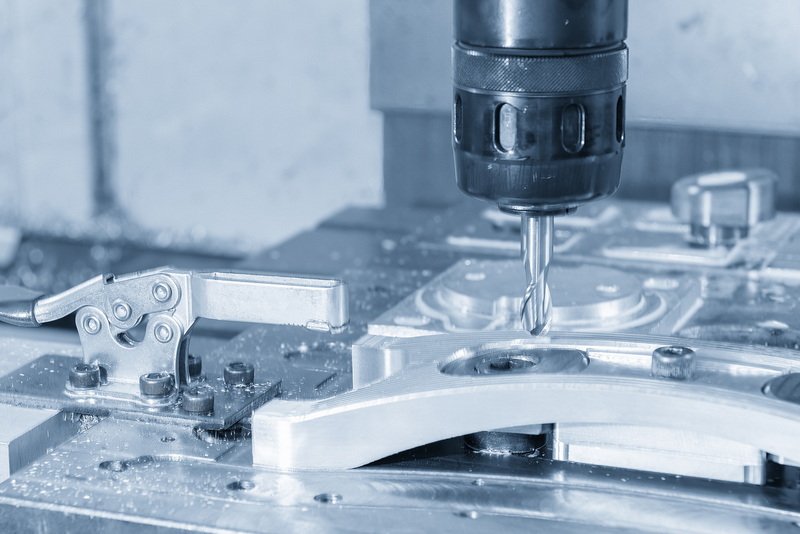

Computer Numerical Control (CNC) milling is a vital manufacturing process that involves the automated operation of rotary cutters to precisely remove material from a workpiece. The CNC milling services manufacturers and suppliers in Japan leverage state-of-the-art equipment, including 3-axis, 4-axis, and 5-axis CNC milling machines, to produce parts with tight tolerances, complex geometries, and superior surface finishes. Japanese manufacturers are known for integrating advanced automation, robotics, and quality control systems, ensuring high productivity and exceptional product quality.

The CNC milling industry in Japan is supported by a strong industrial infrastructure, which includes vast networks of skilled engineers, specialized suppliers, and research institutions. These factors contribute to continuous innovation in machining techniques and machine tool capabilities. Moreover, Japanese CNC milling companies place strong emphasis on reducing production lead times and enhancing flexibility to meet the increasingly diversified needs of global OEMs (Original Equipment Manufacturers).

Founded in 1937, Makino is a pioneer in CNC machining technology and is widely acclaimed globally for its innovation in CNC milling centers. Their expertise spans multi-axis machining solutions capable of machining aerospace components, automotive parts, and precision molds with micron-level accuracy.

- Technologies: 3-axis to 5-axis CNC milling machines, high-speed machining centers, electrical discharge machines.

- Specialties: High precision, surface finish quality, automation integration.

- Location: Tokyo, Japan

Makino's approach involves tailored solutions for complex manufacturing challenges, employing proprietary technologies such as high-speed machining and adaptive control systems. They also provide integrated automation and measurement solutions, allowing clients to achieve efficient and consistent high-quality production.

Brother Industries, established in 1908, provides advanced multitasking machining centers and compact vertical machining centers. They specialize in integrating industrial robots to automate CNC milling operations, enhancing throughput for OEM production.

- Technologies: Compact vertical machining centers, multitasking CNC machines with milling and turning functions.

- Specialties: Automation, precision parts for electronics and automotive industries.

- Location: Nagoya, Aichi, Japan

Brother Industries is known for delivering compact yet highly productive machines suitable for manufacturers requiring versatility and automation in smaller production spaces. Their multitasking centers reduce setup times by combining milling and turning operations in one machine, significantly improving process efficiency.

Formed through a collaboration between DMG and MORI SEIKI, DMG MORI has made a mark as a global leader in multi-axis CNC milling and turning machines. Their equipment is used extensively in aerospace, medical devices, and automotive manufacturing for complex part production.

- Technologies: Multi-axis CNC machines (up to 5-axis), precision milling, grinding solutions.

- Specialties: Complex geometries, high precision, digital manufacturing integration.

- Location: Nagoya, Japan

DMG MORI emphasizes smart manufacturing solutions by incorporating IoT technologies and automated tool management. Their machines support real-time monitoring and predictive maintenance, reducing downtime and improving productivity. They cater to customers requiring high flexibility and agility in production processes.

Okuma, with roots dating back to 1898, specializes in the manufacturing of CNC lathes, machining centers, and full CNC machining cells known for their reliability and precision. They also offer CNC controls that enable flexible programming and machine integration.

- Technologies: CNC lathes, horizontal and vertical machining centers, CNC controllers.

- Specialties: High reliability, large-scale machining, integrated production systems.

- Location: Nagoya, Japan

Okuma's strengths lie in the robustness of their machines suitable for large-scale and heavy-duty applications, including aerospace and marine components manufacturing. Their CNC controls enhance operator efficiency and provide seamless integration with broader shop floor automation.

One of the largest Japanese manufacturers in metal cutting machine tools, Yamazaki Mazak delivers a wide range of CNC milling machines that cater to production from prototypes to high-volume manufacturing, often incorporating laser processing and robotic automation.

- Technologies: Multi-axis CNC machines, laser processing machines, automation systems.

- Specialties: High efficiency, flexible production, large multi-machine networks.

- Location: Nagoya, Japan

Mazak is known for pioneering multi-tasking machine centers that combine milling, turning, and grinding within single setups. Their solutions emphasize scalability and flexibility, fitting the needs of industries with variable production volumes and diverse part complexity.

Beyond the leading five, several other manufacturers and suppliers stand out for their specialized capabilities:

- Citizen Machinery in Nagano offers precision CNC lathes and turning centers optimized for both prototyping and batch production.

- Sodick in Yokohama specializes in electrical discharge machining and 3D printing services that complement CNC milling for intricate parts.

- Mitsubishi Heavy Industries in Tokyo provides large CNC machines and industrial automation, often serving heavy industry sectors.

- Amada in Kanagawa specializes in sheet metal processing with CNC punch presses and laser cutting integrated with milling capabilities.

- Komatsu NTC in Toyama develops high-precision metal processing equipment, combining milling with advanced laser technology for unique applications.

These companies contribute to Japan's comprehensive ecosystem of precision manufacturing services, supporting diverse industries and applications.

Japanese CNC milling services manufacturers and suppliers continuously innovate by adopting advanced machining technologies and intelligent manufacturing systems:

5-axis CNC milling machines have become a standard for producing complex parts requiring multiple angles and intricate surface finishes without repositioning the workpiece. This capability drastically improves dimensional accuracy and reduces the number of setups, cutting lead times and costs.

Manufacturers increasingly employ robotic arms for tasks such as workpiece loading/unloading, tool changing, and part inspection. Coupled with automated guided vehicles (AGVs) and fully integrated manufacturing cells, these systems minimize manual intervention, improve cycle times, and reduce quality variations caused by human factors.

Japanese CNC providers have developed processes to machine hard-to-cut materials, including titanium alloys, Inconel, PEEK polymers, and cobalt-chrome alloys. These materials are vital in aerospace, medical, and high-performance automotive applications, requiring specialized cutting tools and machining parameters to maintain precision and surface integrity.

Real-time process monitoring systems ensure machining stability, detect anomalies early, and guarantee consistency across production batches. Coordinate measuring machines (CMM) and AI-powered tool wear detection enhance quality assurance, enabling manufacturers to maintain sub-micron tolerances and high first-pass yields.

Integration of CAD/CAM solutions streamlines design-to-production workflows, while IoT connectivity enables remote monitoring and analytics for machine performance optimization. Digital twin technology helps simulate machining processes, optimize parameters before actual production, and reduce trial-and-error cycles.

Japanese CNC milling services manufacturers and suppliers serve a broad spectrum of industries:

Machining turbine blades, structural airframe components, precision molds, and fuel system parts demand extreme accuracy and quality. Japanese manufacturers' expertise with multi-axis machining and exotic materials positions them as preferred suppliers for aerospace OEMs worldwide.

Engine components, transmission assemblies, and tooling prototypes require robust machining capabilities and just-in-time production. The adaptability of Japanese CNC milling providers helps automotive manufacturers respond rapidly to design changes and production volume fluctuations.

The medical sector demands tiny, precision-engineered parts such as surgical instruments, implants, dental components, and microfluidic devices. Japanese manufacturers' proficiency with biocompatible materials and micro-milling technologies supports stringent regulatory standards and clinical requirements.

Precision enclosures, heat sinks, PCB components, and connectors require tight dimensional control and superior finishes. Compact CNC milling machines combined with automation enable efficient manufacturing of electronics parts in high volumes.

Custom gears, valves, and mechanical assemblies for heavy machinery benefit from the durability and accuracy of Japanese CNC milling services. The ability to machine large and complex parts with consistent quality supports industrial equipment manufacturers globally.

- Unmatched Precision and Quality: Japanese manufacturers maintain rigorous quality standards that ensure reliable and consistent output.

- Industry-Leading Technology: Use of latest generation of CNC machines equipped with multi-axis capabilities and advanced controls.

- Scalable Production Capacity: From rapid prototyping to large-scale batch production, services are tailored to client needs.

- Comprehensive OEM Support: Including engineering collaboration, prototyping, finishing, inspection, and logistics.

- Global Export Experience: Skilled in meeting varied international standards and customs requirements, ensuring smooth cross-border supply chains.

Japanese CNC milling services manufacturers and suppliers face significant challenges such as rising labor costs, intense global competition, and the need to adopt greener manufacturing practices. To maintain market leadership, companies are focusing on:

- Smart Factory Initiatives: Deploying AI, machine learning, and IoT to optimize production planning, reduce downtime, and improve quality.

- Sustainability: Developing energy-efficient machines, reducing material waste, and incorporating environmentally friendly coolants and lubricants.

- Advanced Materials Processing: Extending capabilities to new and emerging materials used in aerospace, biomedical, and high-tech automotive components.

- Customization and Speed: Enhancing flexibility to accommodate shorter product lifecycles and customization demands through modular machine designs and agile manufacturing workflows.

- Collaborative Manufacturing Platforms: Leveraging cloud-based data sharing and virtual reality for remote engineering collaboration and quicker design iterations.

As these trends evolve, Japanese CNC milling services manufacturers and suppliers will continue to adapt their technologies and services to meet global demands.

Japan's top CNC milling services manufacturers and suppliers represent a blend of tradition and cutting-edge technology, delivering high-precision, reliable, and efficient manufacturing solutions. With companies like Makino, Brother Industries, DMG MORI, Okuma, and Yamazaki Mazak leading the way, the country remains a powerhouse in CNC milling services. Their relentless dedication to innovation, strict quality control, and customer-focused OEM support positions them as ideal partners for global brands requiring precision milling, prototyping, and batch production services. Through continued advancement in automation, materials science, and digital manufacturing, Japan's CNC milling industry is well poised to address present and future industrial challenges worldwide.

Japanese CNC milling services manufacturers and suppliers typically use 3-axis, 4-axis, and 5-axis CNC milling machines. The 5-axis machines are particularly valued for their ability to machine complex geometries in a single setup, which enhances precision and reduces production time.

Industries such as aerospace, automotive, medical device manufacturing, electronics, and industrial equipment benefit greatly from the precision and technological capabilities of Japanese CNC milling providers.

They employ stringent quality control measures including coordinate measuring machines (CMM), real-time process monitoring, AI-driven tool wear detection, and strict adherence to tolerance standards often measured within microns, ensuring consistent high-quality output.

Yes. These manufacturers offer scalable solutions from rapid prototyping and small batch production to high-volume manufacturing, facilitated by advanced automation and flexible manufacturing systems.

Their combination of cutting-edge technology, high-quality manufacturing standards, deep industry expertise, comprehensive OEM services, and capacity for innovation enable Japanese CNC milling services manufacturers and suppliers to maintain a strong global competitive advantage.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal