Views: 222 Author: Amanda Publish Time: 2025-07-31 Origin: Site

Content Menu

● How CNC Milling Services Drive Modern Manufacturing

● Leading CNC Milling Services Manufacturers and Suppliers in America

>> 2. Protolabs

>> 4. Hardinge

>> 5. Beska

>> 7. Metal Tech Company, Inc.

>> 10. USA Precision Machining

● Choosing the Right CNC Milling Services Manufacturer or Supplier

● The Future of CNC Milling in America

● Frequently Asked Questions (FAQs)

>> 2. How do I choose between CNC milling and CNC turning services?

>> 3. What materials can US CNC milling services manufacturers and suppliers process?

>> 4. Can I order both prototypes and large production runs from American suppliers?

>> 5. How does certification affect CNC milling supplier selection?

CNC milling has become the backbone of modern precision manufacturing, driving growth across aerospace, automotive, medical, consumer electronics, and countless other industries. For overseas brands, wholesalers, and manufacturers searching for top-notch CNC milling services manufacturers and suppliers in America, selecting the right partner is critical for both rapid prototyping and high-volume production. This article explores the leaders in the US CNC milling market—delving into their capabilities, specialties, and what sets them apart—while providing rich visual insight into the world of advanced CNC manufacturing.

America boasts a vibrant ecosystem of CNC milling services manufacturers and suppliers, offering solutions from complex prototype machining to precision batch production and full-scale manufacturing. With advanced technology, skilled labor, and global logistics infrastructure, these US-based companies continue to enable innovation and manufacturing excellence.

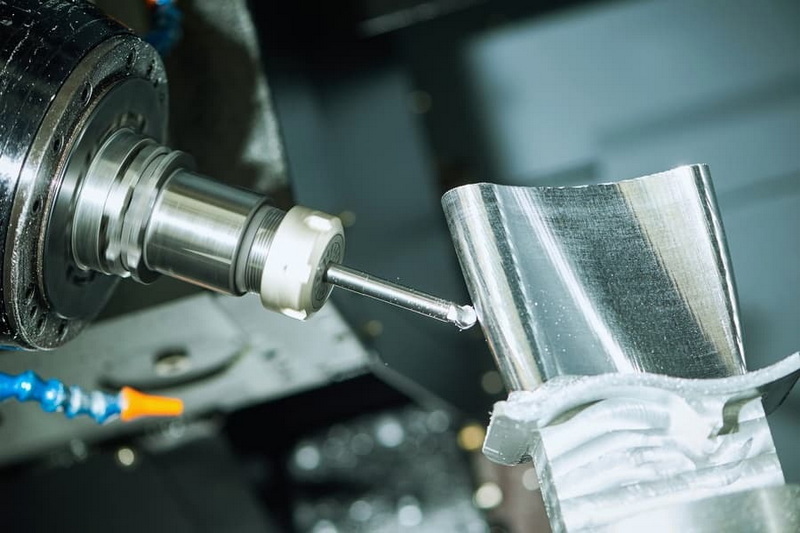

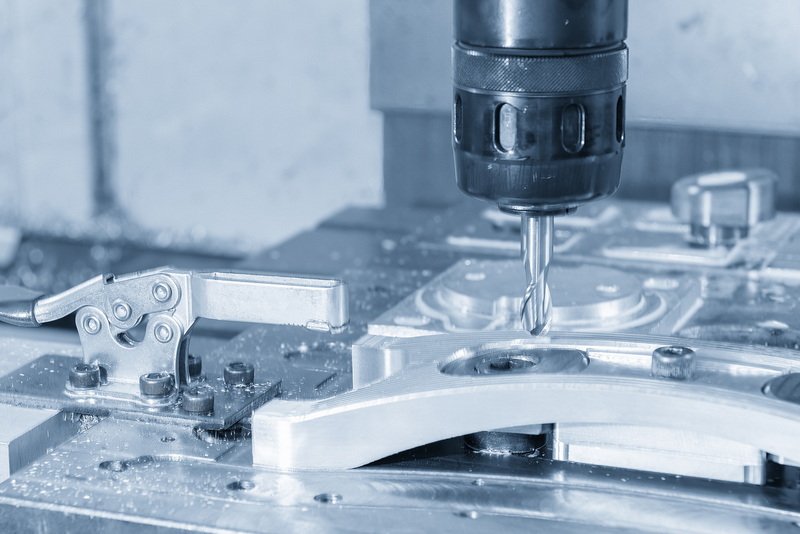

CNC (Computer Numerical Control) milling is an automated subtractive manufacturing process where computer-controlled rotary cutters precisely remove material from a workpiece, producing parts with complex geometries and tight tolerances. CNC milling works with metals, plastics, composites, and exotic materials, making it ideal for industries demanding reliability, repeatability, and speed. The ability to program complex tool paths, adjust spindle speeds, and utilize multi-axis machining opens possibilities to create intricate parts that are otherwise difficult or impossible to manufacture manually.

Modern CNC milling centers, often equipped with 3-, 4-, or 5-axis capabilities, enable manufacturers to produce components featuring undercuts, angled surfaces, and deep cavities in a single setup. This not only reduces production time but also enhances precision. This level of sophistication is indispensable for companies focused on aerospace turbine blades, medical implants, automotive components, and high-tech electronics enclosures.

CNC milling services manufacturers and suppliers play a pivotal role in the entire product lifecycle:

- Rapid prototyping: Quickly turning CAD drawings into functional parts for verification, testing, and design iteration. This ability to iterate rapidly reduces product development time and costs.

- Precision batch production: Producing consistently high-quality parts in small to medium volumes suitable for specialty applications or pilot manufacturing runs.

- High volume OEM manufacturing: Scaling up production for automotive, aerospace, and industrial needs with optimized workflows and automated tool changers.

- Complex geometries: Producing intricate, multi-axis geometries impossible with manual machining.

- Cost-effectiveness: Automation reduces error, material waste, and labor costs while maintaining tight tolerances.

- Custom material handling: Expertise with a variety of materials, including aluminum, titanium, stainless steel, plastics, composites, and superalloys, ensures suitability for specific end-use requirements.

By leveraging advanced CNC machinery, these manufacturers help brands maintain competitive advantages through faster development cycles, improved part reliability, and the flexibility to adapt to design changes.

Here is a closer look at some of the most prominent and trusted companies in the American CNC milling services sector, each offering unique strengths that cater to diverse industries and needs:

Headquartered in Ferndale, Michigan, The Federal Group USA brings seasoned engineering expertise combined with global supply chain capabilities. Their precision milling solutions are often engaged in manufacturing complex automotive components, heavy machinery parts, and industrial assemblies. High standards in quality assurance and supplier management mark them as a reliable partner for OEMs globally.

Protolabs, based in Maple Plain, Minnesota, is a digital manufacturing pioneer focusing on rapid-turn CNC milling services. Their cloud-based quoting platform and seamless integration with CAD tools enable quick turnaround times suitable for startups and established brands alike. Protolabs services a diversified customer base spanning medical devices, automotive components, consumer electronics, and more. Their approach emphasizes design for manufacturability, reducing iteration cycles.

Operating from Attleboro, Massachusetts, Empire Group distinguishes itself through integrated offerings that span CNC milling, design engineering, rapid prototyping, finishing, and additive manufacturing. This hybrid approach delivers enhanced production agility and allows customers to combine subtractive and additive processes to optimize complex parts. Their aerospace and consumer product experience add further credibility to their capabilities.

Hardinge is a renowned name with roots extending back over a century, specializing in both milling machine manufacturing and contract CNC machining services. Located in Berwyn, Pennsylvania, Hardinge offers robust machining solutions tailored for aerospace, medical, and general engineering sectors. Their expertise in machine tool design translates into superior service capabilities with precision and repeatability.

Beska, based in Sheridan, Wyoming, excels in high-precision CNC milling and turning services primarily for aerospace and electronics sectors. Their operations comply with ISO 9001 and IATF 16949 standards, ensuring adherence to stringent quality and traceability requirements. Beska's capacity for machining complex geometries and exotic alloys under high-regulation environments makes them a preferred choice for critical components.

Located in Akron, Ohio, FM Machine Co. caters to clients requiring both small-part precision and large assembly machining. Their broad capabilities include CNC milling, turning, grinding, and assembly services. They specialize in custom turnkey solutions, working particularly well with industrial and manufacturing clients that demand consistent part dimensions and comprehensive quality documentation.

Metal Tech Company supports electronics, medical, aerospace, and government sectors with high-quality CNC machining solutions. They emphasize material diversity—from conventional steels to advanced alloys—and implement rigorous internal quality checks. Their multi-process capabilities extend beyond milling to include finishing processes ensuring a high level of part integrity.

Operating from Carlsbad, California, Pacific CNC Machine Co. has carved a niche in producing large-format parts and multi-stage assemblies. Their unique strength lies in flexible production schedules and reliable on-time delivery, which are critical for OEM customers managing complex supply chain demands. Their proficiency in programming and machine setup enables cost-effective manufacturing for large and complex components.

United CNC Machining, located in Auburn Hills, Michigan, has expanded from a single manual mill shop to an advanced manufacturing facility boasting over 40 CNC centers. Their services include rapid prototyping, 5-axis multi-surface machining, and high-volume production. Their broad industry experience allows them to handle stringent requirements for aerospace, medical implants, and precision engineering sectors.

Based in a purpose-built facility, USA Precision Machining specializes in machining oilfield, petrochemical parts, and custom research & development projects. Their adherence to ISO 9002 standards ensures quality-focused manufacturing processes focused on minimizing scrap rates and maximizing yield. Their customer-centric approach is ideal for clients needing tight tolerance, low-volume parts.

Selecting the best partner among numerous top-tier CNC milling services manufacturers and suppliers depends on understanding your project requirements thoroughly and matching them with supplier capabilities. Key considerations include:

- Material expertise: The ability to machine specific materials such as titanium, Inconel, composite laminates, or PEEK polymers affects part performance and manufacturing feasibility.

- Industry certifications: Compliance with ISO 9001, AS9100 for aerospace, IATF 16949 for automotive, and other certifications demonstrates a supplier's commitment to quality and regulatory standards.

- Tolerance capabilities: Ultra-precise CNC centers delivering micron-level tolerances are essential for medical implants and aerospace components.

- Production scale and flexibility: Ensuring the supplier can handle prototypes as well as scale up to pilot or full production volumes without changing vendors reduces complexity.

- Equipment and technology: Advanced CNC machines featuring 5-axis capability, tool changers, and automated probing systems improve consistency and speed.

- Quality assurance systems: Emphasis on process validation, statistical process control (SPC), digital traceability, and in-process inspections ensures reliability.

- Customer service and support: Responsive communication, design consultation, and transparent project management streamline production and reduce delays.

Establishing a strong collaboration with a CNC milling services manufacturer facilitates improved innovation cycles, cost controls, and smoother supply chains.

CNC milling services manufacturers and suppliers in the US are embracing next-generation manufacturing technologies and digital transformation trends, including:

- Multi-axis and hybrid machining: Combining additive and subtractive methods in one machine setup to reduce production steps and enable complex designs.

- AI-driven CAM software: Utilizing machine learning to optimize tool paths, enhance surface finish, and predict tool wear.

- Automation and robotics: Implementing unattended machining operations through robotic material handling and automated tool changers improves productivity.

- IoT and Industry 4.0: Real-time monitoring of CNC machines via IoT sensors allows predictive maintenance, minimizing downtime and lowering costs.

- Micromachining advancements: Innovations in ultra-precision milling support emerging fields like optics manufacturing, electronics miniaturization, and medical device production.

- Sustainability Initiatives: Embracing energy-efficient machines and waste reduction techniques aligns CNC operations with increasing environmental responsibility mandates.

The ongoing evolution ensures US CNC milling manufacturers remain competitive in both innovation and cost-efficiency, serving domestic and global OEMs.

America's CNC milling services manufacturers and suppliers represent a dynamic and innovative sector, empowering both startups and established brands to bring quality products to market with speed and confidence. Whether you need a few intricate prototypes or mass-produced, rigorously inspected mechanical parts, these US firms offer strong technical support, modern equipment, and deep industry expertise. Selecting the right CNC milling partner not only improves manufacturing efficiency but also provides a competitive edge through superior quality, on-time delivery, and ongoing innovation.

By aligning your project requirements with the capabilities of America's top CNC milling manufacturers and suppliers, you can ensure your product development and production goals are met with precision and reliability.

Working with established American CNC milling suppliers secures access to cutting-edge technology, stringent quality standards, and rapid delivery, supported by robust national logistics and supply chain networks. This geographic proximity often leads to better communication, tighter collaboration, and faster turnaround times compared to overseas alternatives.

CNC milling is better suited for prismatic, flat, and complex shapes by removing material with rotating cutters, while CNC turning is ideal for parts with symmetrical, cylindrical features that rotate on a spindle. Many suppliers offer both services, allowing you to select based on your part geometry or leverage both for complex components.

The best manufacturers handle a full range of metals—including aluminum, stainless steel, titanium, brass, and exotic alloys—as well as high-performance plastics like ABS, PEEK, and composites. Shops with advanced machining centers also machine specialty materials required by aerospace, medical, and electronics industries.

Yes, most leading CNC milling services manufacturers and suppliers have scalable operations that move seamlessly from single prototypes to high-volume OEM production. This scalability supports evolving business needs without changing vendors, maintaining quality and consistency across production volumes.

Certifications like ISO 9001, AS9100 (aerospace), and IATF 16949 (automotive) demonstrate that a supplier follows structured quality management processes and meets industry-specific regulatory requirements. These certifications provide added confidence in product traceability, compliance, and process rigor, which are crucial in regulated markets.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product