Views: 222 Author: Amanda Publish Time: 2025-07-10 Origin: Site

Content Menu

● The Importance of CNC Machining in Modern Manufacturing

>> Key Benefits of CNC Machining

● Key Criteria for Selecting CNC Machining Manufacturers and Suppliers

● Leading CNC Machining Manufacturers and Suppliers in Europe

>> Germany

>> Switzerland

>> Italy

>> France

>> Other Notable European Countries

● Innovations and Trends in European CNC Machining

>> Advanced Materials Machining

● Advantages of Working with European CNC Machining Suppliers

● FAQ

>> 1. What industries benefit most from CNC Machining Manufacturers and Suppliers in Europe?

>> 2. How do European CNC Machining Manufacturers and Suppliers ensure quality?

>> 3. What are the latest trends among CNC Machining Manufacturers and Suppliers?

>> 4. How do I choose the right CNC Machining Manufacturer or Supplier in Europe?

The European manufacturing sector is renowned for its precision, innovation, and high standards. Among the most vital contributors to this reputation are CNC Machining Manufacturers and Suppliers. These companies leverage advanced technologies to deliver components and products that power industries such as automotive, aerospace, medical devices, electronics, and more. In this comprehensive guide, we will explore the top CNC Machining Manufacturers and Suppliers in Europe, delve into their capabilities, and highlight the trends shaping the future of CNC machining across the continent.

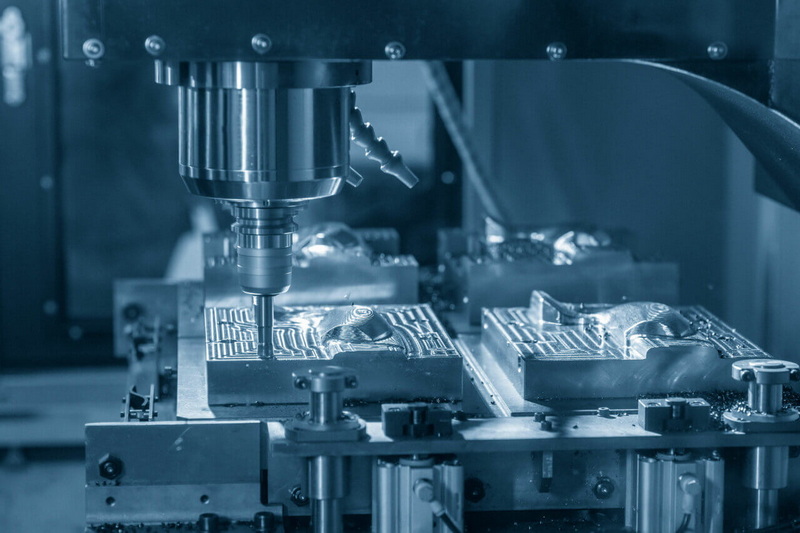

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by enabling the production of highly precise and complex parts. CNC Machining Manufacturers and Suppliers utilize automated machinery controlled by computer programs, which ensures repeatability, accuracy, and efficiency. This technology is essential for industries requiring tight tolerances, rapid prototyping, and scalable production.

- Precision and Consistency: CNC machines can produce identical parts with minimal deviation.

- Complex Geometries: Capable of creating intricate shapes that are difficult or impossible with manual machining.

- Efficiency: Automation reduces production time and labor costs.

- Material Versatility: Works with metals, plastics, composites, and more.

- Scalability: Suitable for both prototyping and high-volume production.

The impact of CNC machining extends beyond mere production speed and accuracy. It enables manufacturers to innovate with new materials and complex designs that were once considered impossible or cost-prohibitive. This has opened new frontiers in product development, allowing companies to respond quickly to market demands and customize products for niche applications.

Selecting the right CNC Machining Manufacturers and Suppliers is critical to the success of any manufacturing project. The following criteria help ensure that you partner with a supplier who can meet your technical and business needs:

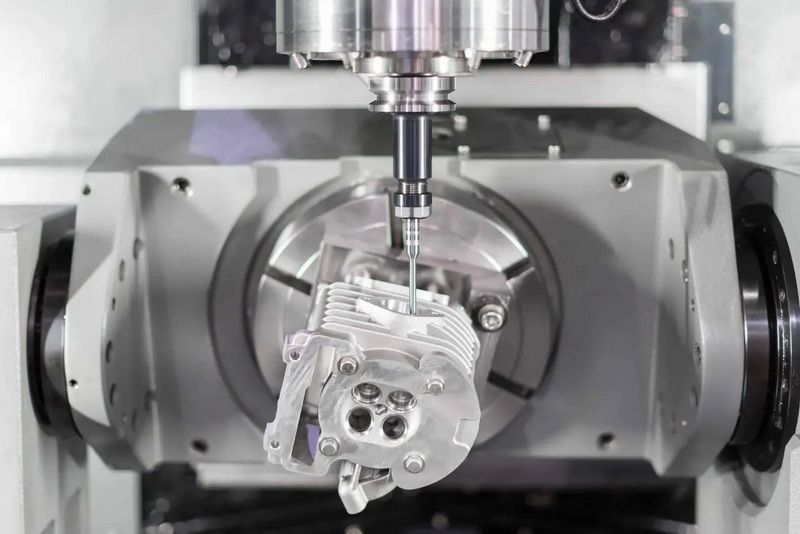

- Technical Capabilities: Evaluate the range of CNC machines available, such as 3-axis, 5-axis milling, turning centers, EDM, and multi-spindle machines. Also, consider the precision tolerances they can achieve and the materials they can handle.

- Quality Assurance: Look for certifications like ISO 9001, AS9100 (for aerospace), or ISO 13485 (for medical devices), which indicate adherence to strict quality standards.

- Production Capacity: Ensure the supplier can handle your order volume, whether it's a small batch for prototyping or a large-scale production run.

- Lead Time: Assess their ability to deliver parts within your required timeframe, including rapid prototyping services.

- Customer Support: Strong communication, engineering assistance, and after-sales service are essential for smooth collaboration.

- Location and Logistics: Proximity to your operations can reduce shipping times and costs, and facilitate easier coordination.

Europe is home to a diverse array of CNC Machining Manufacturers and Suppliers. Below, we highlight some of the most prominent companies and regions known for their excellence in CNC machining.

Germany stands as a global leader in engineering and precision manufacturing, with CNC Machining Manufacturers and Suppliers that are synonymous with quality and innovation.

- DMG MORI: This company offers a comprehensive portfolio of CNC solutions, including milling, turning, and additive manufacturing. Their machines are widely used in automotive, aerospace, and medical industries.

- Hermle AG: Known for high-precision milling machines, Hermle serves sectors that demand exceptional accuracy such as aerospace and medical technology.

- Heller: Specializes in flexible manufacturing systems and 5-axis machining centers, enabling complex part production with high efficiency.

Germany's CNC machining sector benefits from a strong industrial ecosystem, combining advanced machine tool manufacturing with skilled engineering talent and research institutions. This synergy fosters continuous innovation and quality improvements.

Switzerland's reputation for precision is well reflected in its CNC Machining Manufacturers and Suppliers, particularly in micro-machining and high-precision components.

- Mikron Group: Provides advanced CNC machining centers capable of high-volume production with tight tolerances, serving medical, automotive, and electronics industries.

- Tornos: Specializes in automatic lathes and multi-spindle machines designed for small, complex components, especially in watchmaking and medical devices.

- GF Machining Solutions: Offers a broad range of technologies including milling, EDM, and automation, supporting demanding industries worldwide.

Swiss manufacturers emphasize quality, reliability, and innovation, often pioneering micro-machining techniques and automation solutions that improve productivity and reduce costs.

Italian CNC Machining Manufacturers and Suppliers combine technical innovation with traditional craftsmanship, catering to diverse industries such as automotive, aerospace, and fashion.

- Biesse Group: Focuses on CNC machines for wood, glass, stone, and advanced materials, blending precision with versatility.

- Fidia: Known for high-speed milling systems and advanced CNC controls, serving automotive and aerospace sectors.

- Jobs SpA: Specializes in large-scale, high-performance CNC machining centers for heavy industry applications.

Italy's manufacturing landscape is characterized by flexibility and creativity, enabling suppliers to adapt quickly to customer requirements and produce both artistic and industrial parts with precision.

France hosts CNC Machining Manufacturers and Suppliers with strong expertise in aerospace, automotive, and industrial equipment manufacturing.

- Mecachrome: Supplies precision components primarily for aerospace and motorsport industries.

- Groupe Lauak: Provides complex assemblies and machined parts for aviation, combining machining with assembly services.

- LISI Aerospace: Focuses on fasteners and structural components critical to aerospace manufacturing.

French companies often emphasize integrated solutions, combining machining with assembly and testing to deliver ready-to-install components.

The UK's CNC Machining Manufacturers and Suppliers serve a wide range of sectors, including defense, medical devices, and precision engineering.

- Renishaw: A pioneer in metrology and additive manufacturing, Renishaw integrates CNC machining with innovative measurement technologies.

- Precision Engineering Plastics: Specializes in CNC machining of advanced plastics for medical and industrial applications.

- PTG Holroyd: Renowned for ultra-precise grinding and gear manufacturing, supporting aerospace and automotive industries.

The UK benefits from a strong research base and a focus on high-value, precision engineering, making it a hub for specialized CNC machining services.

- Spain: Nicolás Correa is notable for large-format CNC milling machines used in heavy industry sectors such as energy and aerospace.

- Sweden: Sandvik Coromant supplies cutting tools and machining solutions that complement CNC manufacturing across Europe.

- Austria: Emco Group offers CNC turning and milling machines widely used in education and industry, supporting skill development and innovation.

European CNC Machining Manufacturers and Suppliers are continuously pushing the boundaries of technology and process optimization. Key trends shaping the industry include:

The adoption of Industry 4.0 principles is transforming CNC machining by embedding connectivity, automation, and data analytics into manufacturing processes. Smart factories use sensors and IoT devices to monitor machine performance in real-time, predict maintenance needs, and optimize production flow. This reduces downtime and improves quality control.

Combining CNC machining with additive manufacturing (3D printing) creates hybrid machines that can build complex parts layer-by-layer and finish them with precision machining. This approach reduces material waste, shortens production cycles, and allows for the creation of parts with intricate internal geometries.

Environmental concerns are driving CNC Machining Manufacturers and Suppliers to adopt greener practices. These include using biodegradable cutting fluids, recycling metal chips, optimizing energy consumption, and selecting eco-friendly materials. Sustainable manufacturing not only reduces environmental impact but also often lowers operational costs.

European suppliers are increasingly capable of machining advanced materials such as titanium alloys, carbon fiber composites, and high-performance plastics. These materials are essential in aerospace, medical implants, and automotive lightweighting, requiring specialized tooling and machining strategies.

Digital twins are virtual replicas of CNC machining processes that allow engineers to simulate and optimize production before actual manufacturing. This reduces errors, shortens lead times, and improves product quality by enabling adjustments to be made in the design phase.

Partnering with CNC Machining Manufacturers and Suppliers in Europe offers multiple benefits:

- High Quality Standards: European suppliers maintain stringent quality controls and certifications, ensuring reliable and consistent output.

- Technological Leadership: Access to cutting-edge machinery and manufacturing techniques keeps products competitive.

- Reliability and Timeliness: Strong industrial infrastructure and logistics networks support dependable delivery schedules.

- Comprehensive Support: Engineering expertise and customer service help clients optimize designs and resolve challenges.

- Sustainability Commitment: Many European companies prioritize environmentally responsible manufacturing, aligning with global sustainability goals.

These advantages make European CNC Machining Manufacturers and Suppliers ideal partners for brands and producers seeking OEM services that combine precision, innovation, and scalability.

European CNC Machining Manufacturers and Suppliers stand at the forefront of the global manufacturing landscape, delivering unparalleled precision, innovation, and quality. Their expertise spans rapid prototyping, precision batch production, and complex machining for a wide array of industries. By embracing Industry 4.0 technologies, sustainable practices, and hybrid manufacturing, these suppliers continue to push the boundaries of what is possible in CNC machining. For foreign brands, wholesalers, and manufacturers seeking reliable OEM partners, Europe offers a rich ecosystem of suppliers capable of meeting the most demanding requirements with speed, accuracy, and flexibility.

CNC Machining Manufacturers and Suppliers in Europe serve a wide range of industries, including automotive, aerospace, medical devices, electronics, defense, and industrial equipment. Their ability to deliver high-precision, complex components makes them invaluable to sectors where quality and accuracy are paramount.

Most leading CNC Machining Manufacturers and Suppliers in Europe adhere to rigorous quality standards, such as ISO 9001 and AS9100. They implement strict quality control processes, use advanced inspection equipment, and often provide full traceability for materials and processes.

The latest trends include the integration of Industry 4.0 technologies, adoption of hybrid manufacturing (combining CNC and additive manufacturing), use of digital twins for process optimization, and a strong focus on sustainability and eco-friendly production methods.

Consider technical capabilities, certifications, production capacity, lead times, customer support, and location. It's also important to review case studies or request sample parts to evaluate quality and reliability.

Yes, many CNC Machining Manufacturers and Suppliers in Europe are equipped to handle both rapid prototyping and large-scale production. Their advanced machinery and flexible processes allow them to scale operations according to client needs.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product