Views: 222 Author: Amanda Publish Time: 2025-07-11 Origin: Site

Content Menu

● Overview of CNC Lathe Turning

>> Key Benefits

● Key Features of Leading European CNC Lathe Turning Manufacturers and Suppliers

● Top CNC Lathe Turning Manufacturers and Suppliers in Europe

>> Gildemeister Italiana (Italy)

>> Citizen Machinery Europe (UK/Germany)

>> Schaublin Machines (Switzerland)

>> Colchester Machine Tool Solutions (UK)

● Industry Applications and Case Studies

>> Aerospace

>> Automotive

>> Electronics

>> Energy and Industrial Equipment

● Technological Innovations in European CNC Lathe Turning

>> Additive Manufacturing Integration

● How to Choose the Right CNC Lathe Turning Partner

● FAQ

>> 1. What industries benefit most from European CNC Lathe Turning Manufacturers and Suppliers?

>> 2. How do European CNC Lathe Turning Manufacturers and Suppliers ensure quality?

>> 3. What materials can be processed by CNC Lathe Turning Manufacturers and Suppliers in Europe?

>> 4. How does automation impact CNC lathe turning in Europe?

>> 5. What should I consider when choosing a CNC Lathe Turning Manufacturer or Supplier in Europe?

The demand for high-precision components in industries such as aerospace, automotive, medical, and electronics has driven the rapid development of CNC lathe turning technology across Europe. As a result, Europe is home to some of the world's most advanced and reliable CNC Lathe Turning Manufacturers and Suppliers, known for their technical expertise, innovation, and commitment to quality. This comprehensive guide explores the leading CNC Lathe Turning Manufacturers and Suppliers in Europe, their capabilities, technological advancements, and what sets them apart in the global marketplace.

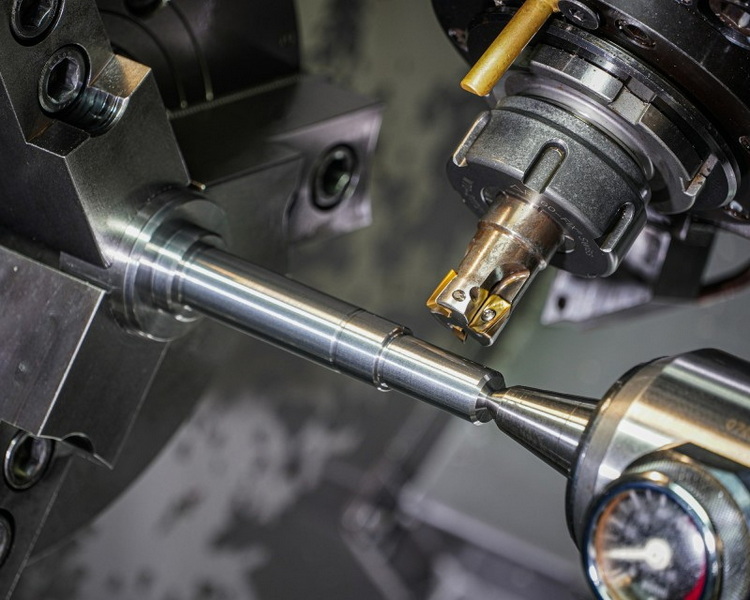

CNC lathe turning is a subtractive manufacturing process that uses computer numerical control (CNC) to automate the rotation of a workpiece while cutting tools shape it into the desired form. This process is essential for producing high-precision cylindrical parts, shafts, bushings, and custom components with tight tolerances.

- Precision and Consistency: CNC technology ensures repeatable accuracy for complex geometries.

- Efficiency: Automated processes reduce production times and labor costs.

- Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

- Scalability: Ideal for both prototyping and large-scale production.

CNC lathe turning machines range from simple two-axis lathes to complex multi-axis turning centers that can perform milling, drilling, and threading operations in a single setup. This versatility allows manufacturers to reduce handling times and improve overall production efficiency.

European CNC Lathe Turning Manufacturers and Suppliers are renowned for their:

- Advanced Machinery: Investment in state-of-the-art CNC lathes and multi-axis turning centers that incorporate the latest technological advancements.

- Skilled Workforce: Highly trained engineers and technicians who specialize in precision machining and process optimization.

- Quality Assurance: Strict adherence to international standards such as ISO 9001 and IATF 16949, ensuring products meet stringent quality requirements.

- Customization: Ability to deliver tailored solutions for diverse industry needs, from rapid prototyping to precision batch production.

- Sustainability: Implementation of eco-friendly manufacturing practices, including energy-efficient machines and waste reduction programs.

These manufacturers often integrate Industry 4.0 principles, utilizing IoT-enabled machines and data analytics to optimize production processes, reduce downtime, and enhance product quality.

Europe hosts a wide range of CNC Lathe Turning Manufacturers and Suppliers, each excelling in different niches and technologies. Below are some of the most prominent companies that have established themselves as leaders in the field.

DMG MORI is a global leader in CNC machine tools, offering a comprehensive range of CNC lathe turning solutions. Their advanced turning centers are used by manufacturers worldwide for producing high-precision parts in various industries. The company continuously invests in research and development to incorporate features like automation, digital networking, and hybrid manufacturing capabilities into their machines.

Specializing in high-speed CNC turning, Gildemeister Italiana is known for its innovative designs and efficient production systems. Their machines are particularly favored in the automotive, aerospace, and medical sectors for their ability to handle complex geometries at high throughput rates without compromising accuracy.

INDEX-Werke is renowned for its multi-spindle CNC lathes and automated turning solutions, enabling high-volume production with exceptional accuracy. Their machines are designed for flexibility, allowing quick changeovers and integration with robotic handling systems to support lights-out manufacturing.

Citizen Machinery Europe provides cutting-edge CNC lathe turning machines and services, focusing on Swiss-type lathes for micro-precision components. Their expertise lies in producing small, complex parts with extremely tight tolerances, essential for medical devices, electronics, and watchmaking industries.

Tornos is a pioneer in Swiss-type CNC turning technology, serving industries that require ultra-precise small parts, such as watchmaking and medical devices. Their machines combine high accuracy with multi-functionality, enabling simultaneous turning, milling, and drilling operations.

Mazak Europe offers a wide range of CNC lathe turning machines, known for their reliability, innovation, and integration with Industry 4.0 solutions. Their machines support complex part manufacturing with multi-tasking capabilities, including 5-axis turning and milling.

EMCO delivers flexible CNC lathe turning solutions, emphasizing modularity and ease of use for both small workshops and large factories. Their machines are often used for training and prototyping, as well as production, due to their user-friendly interfaces and adaptability.

Schaublin Machines specializes in high-precision CNC lathes, serving the aerospace, defense, and watchmaking industries. Their machines are designed for ultra-fine tolerances and superior surface finishes.

Colchester is a trusted name in CNC lathe turning, offering robust machines and comprehensive support for diverse manufacturing needs. Their product range includes both conventional and CNC lathes, catering to a broad customer base.

Spinner is known for its high-speed CNC turning centers and automation solutions, enabling efficient mass production with tight tolerances. Their machines are widely used in the automotive and general engineering sectors.

European CNC Lathe Turning Manufacturers and Suppliers play a vital role in producing critical aerospace components, such as turbine shafts, landing gear parts, and hydraulic fittings, where precision and reliability are paramount. These components often require exotic materials like titanium and Inconel, which demand specialized machining expertise and tooling.

For example, aerospace suppliers utilize multi-axis CNC lathes to manufacture complex geometries with internal features that are impossible to produce with traditional turning methods. The use of automation and in-process inspection ensures that every part meets the stringent safety and quality standards required by the aerospace industry.

From engine parts to transmission shafts, CNC lathe turning is essential for the automotive industry, ensuring consistent quality and performance. European manufacturers excel at producing high volumes of components with tight tolerances, such as camshafts, crankshafts, and gear blanks.

The integration of robotic loading and unloading systems in CNC turning centers has enabled automotive suppliers to achieve just-in-time production, reducing inventory costs and improving responsiveness to market demands.

CNC Lathe Turning Manufacturers and Suppliers in Europe provide the medical sector with precision implants, surgical instruments, and prosthetic components, adhering to strict regulatory standards. The ability to machine biocompatible materials such as titanium and stainless steel with micron-level accuracy is critical for patient safety and device performance.

Swiss-type CNC lathes are particularly popular for producing small, intricate parts like bone screws and dental implants, where surface finish and dimensional accuracy are crucial.

High-speed CNC turning enables the production of connectors, housings, and custom parts for the electronics industry, supporting rapid innovation cycles. European suppliers often combine CNC lathe turning with secondary operations such as milling and threading to deliver ready-to-assemble components.

The use of lightweight materials such as aluminum and plastics, along with tight tolerances, ensures that electronic devices meet performance and aesthetic requirements.

The energy sector, including oil and gas, wind, and power generation, relies on CNC lathe turning for components like valve bodies, pump shafts, and turbine parts. European manufacturers are equipped to handle large, heavy workpieces and difficult-to-machine materials, providing robust solutions that withstand harsh operating conditions.

Industrial equipment manufacturers benefit from the precision and repeatability of CNC lathe turning to produce parts that ensure machine reliability and longevity.

European manufacturers are at the forefront of multi-axis CNC turning, allowing for the creation of complex geometries in a single setup. This reduces lead times and enhances part accuracy by eliminating multiple handling steps and repositioning errors.

Multi-axis turning centers can perform simultaneous operations such as milling, drilling, and tapping, which traditionally required separate machines. This capability significantly improves productivity and reduces production costs.

The integration of automation and robotics with CNC lathe turning machines has revolutionized production efficiency, enabling 24/7 lights-out manufacturing. Automated loading and unloading systems, robotic part handling, and pallet changers minimize manual intervention and increase throughput.

Many European CNC Lathe Turning Manufacturers and Suppliers offer turnkey automation solutions, including cell integration and process monitoring, to meet the demands of high-volume production environments.

Digital twins enable real-time simulation and optimization of turning processes, minimizing errors and material waste. By creating a virtual model of the CNC lathe and the machining process, manufacturers can test different cutting parameters and tool paths before actual production.

This technology accelerates process development, reduces trial-and-error, and improves overall part quality and consistency.

Advanced monitoring systems track machine performance, tool wear, and production quality, ensuring predictive maintenance and minimizing downtime. Sensors embedded in CNC machines collect data on vibration, temperature, and spindle load, which are analyzed to detect anomalies early.

This proactive approach helps manufacturers avoid unexpected breakdowns and maintain high production efficiency.

Some European CNC Lathe Turning Manufacturers and Suppliers are exploring hybrid machines that combine additive manufacturing (3D printing) with CNC turning. This integration allows for the production of complex parts with internal features that are difficult to machine conventionally, followed by precise finishing operations.

Hybrid manufacturing expands design possibilities and reduces lead times for prototype and low-volume production.

Selecting the ideal CNC Lathe Turning Manufacturer and Supplier is critical for project success. Consider the following factors:

- Technical Capabilities: Assess the range of machines, materials, and tolerances offered. Ensure the supplier can handle your specific part requirements, including size, complexity, and batch size.

- Quality Systems: Ensure compliance with relevant certifications and quality control procedures. Ask about inspection methods, traceability, and quality records.

- Lead Time and Scalability: Evaluate the supplier's ability to meet deadlines and scale production as needed. Flexibility in scheduling and capacity is essential for growing businesses.

- Customer Support: Look for responsive communication and after-sales service. A strong partnership includes technical support, problem-solving, and continuous improvement.

- Cost Competitiveness: Balance pricing with quality and reliability. The lowest price may not always deliver the best value if quality or delivery is compromised.

Visiting the supplier's facilities, reviewing sample parts, and speaking with existing customers can provide valuable insights into their capabilities and reliability.

Europe's CNC Lathe Turning Manufacturers and Suppliers set the benchmark for precision, innovation, and reliability. Their advanced technologies, skilled workforce, and commitment to quality make them the preferred partners for brands, wholesalers, and manufacturers worldwide. Whether you require rapid prototyping, small-batch production, or large-scale manufacturing, European CNC Lathe Turning Manufacturers and Suppliers offer tailored solutions to meet the most demanding requirements.

By embracing cutting-edge technologies such as multi-axis turning, automation, digital twins, and smart monitoring systems, these manufacturers ensure efficient, cost-effective production without compromising quality. Their ability to work with a wide range of materials and industries further solidifies Europe's position as a global hub for CNC lathe turning excellence.

Choosing the right partner involves careful evaluation of technical capabilities, quality assurance, and customer service. With the right collaboration, businesses can achieve superior product performance, faster time-to-market, and sustainable growth.

European CNC Lathe Turning Manufacturers and Suppliers serve a wide range of industries, including aerospace, automotive, medical, electronics, energy, and defense. Their expertise ensures that even the most complex and high-precision components are produced to exact specifications.

They implement rigorous quality control systems, including ISO certifications, in-process inspections, and final part validation. Advanced monitoring and digital technologies further enhance consistency and reliability, ensuring parts meet or exceed industry standards.

Most European suppliers work with metals such as aluminum, steel, titanium, brass, and exotic alloys, as well as plastics and advanced composites. This versatility allows them to cater to diverse applications across multiple industries.

Automation increases efficiency, reduces labor costs, and enables continuous production. Many European CNC Lathe Turning Manufacturers and Suppliers utilize robotics, automated loading/unloading, and smart monitoring systems to optimize productivity and maintain consistent quality.

Key considerations include technical capabilities, certifications, lead times, scalability, customer support, and cost. Partnering with experienced CNC Lathe Turning Manufacturers and Suppliers ensures high-quality results and smooth project execution.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal