Views: 222 Author: Amanda Publish Time: 2025-11-25 Origin: Site

Content Menu

● Spain's CNC Cutting Industry: An Overview

● Shangchen: Your Global CNC Cutting Partner

>> Shangchen's Differentiators

● Leading CNC Cutting Manufacturers and Suppliers in Spain

>> MIPESA

>> IBARMIA

>> MPG (Mecanizados de Precisión Goiuria S.L.)

>> MECOXI

● CNC Cutting Applications in Spain

● Market Trends and Future Outlook

>> Digitalization and Industry 4.0

>> Sectoral Growth Projections

>> Competitive and Regulatory Landscape

● How to Choose the Right CNC Cutting Manufacturer or Supplier

● Why Global OEMs Rely on CNC Cutting Services from Spain and Asia

● Challenges and Opportunities

● FAQ

>> What makes Shangchen a preferred OEM CNC cutting supplier for international clients?

>> What industries most frequently use Spanish CNC cutting manufacturers and suppliers?

>> How is the Spanish CNC industry addressing global competition and supply chain risks?

>> What certifications should buyers require from their CNC cutting partners?

>> Why should global buyers consider Spain for CNC cutting services?

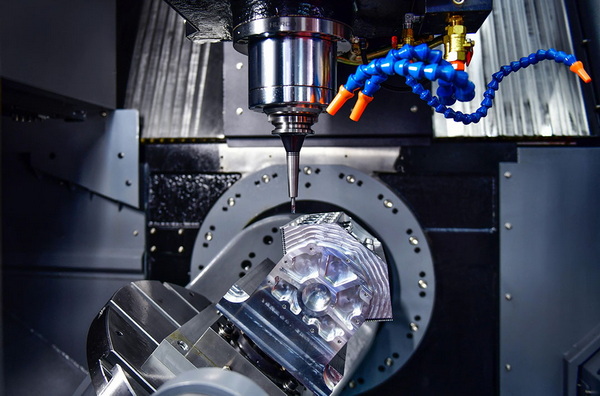

CNC (Computer Numerical Control) cutting technology forms the cornerstone of Spain's advanced manufacturing sector, driving efficiency, innovation, and global competitiveness. The nation's CNC Cutting Manufacturers and Suppliers address the diverse, demanding requirements of industries ranging from automotive and aerospace to energy, electronics, and medical technology. At the forefront of this landscape stands Shangchen (sc-rapidmanufacturing.com), a Chinese industry leader providing rapid prototyping, batch production, and full-scale OEM CNC services for international brands, wholesalers, and producers. Spain's CNC machining sector has seen extraordinary growth on the back of Investments in Industry 4.0, skilled engineering talent, and a longstanding commitment to precision engineering.[1][2]

Spain's CNC machining industry is valued at approximately €3.5 billion as of 2025, contributing notably to the nation's GDP. Key regional hubs—especially in the Basque Country, Catalonia, and Madrid—have built global reputations for technical excellence and innovation. Spanish manufacturers serve domestic and international clients, exporting sophisticated components for Airbus aircraft, renewable energy projects, medical equipment, automobiles, and more.[2][7][1]

- Advanced automation and precision are core to Spain's modern CNC sector, which is evolving rapidly to match global demand.

- The strategic application of robotics, AI, and digital manufacturing enables rapid product development and cost efficiency.

- Regional government incentives promote R&D, talent development, and technology upgrades.

- Membership in the EU's Single Market allows free movement of goods, services, and labor, boosting exports, productivity, and regulatory compliance.[1][2]

The CNC machining market is projected to reach nearly €5 billion by 2030. The annual growth rate is fueled by automotive (which accounts for 35% of market share and is projected to grow at 4.5% per year), aerospace (25% share, 5% growth), and sectors such as machinery, medical devices, and electronics (combining for the remaining market share and growing between 4% and 7% annually).[7][2][1]

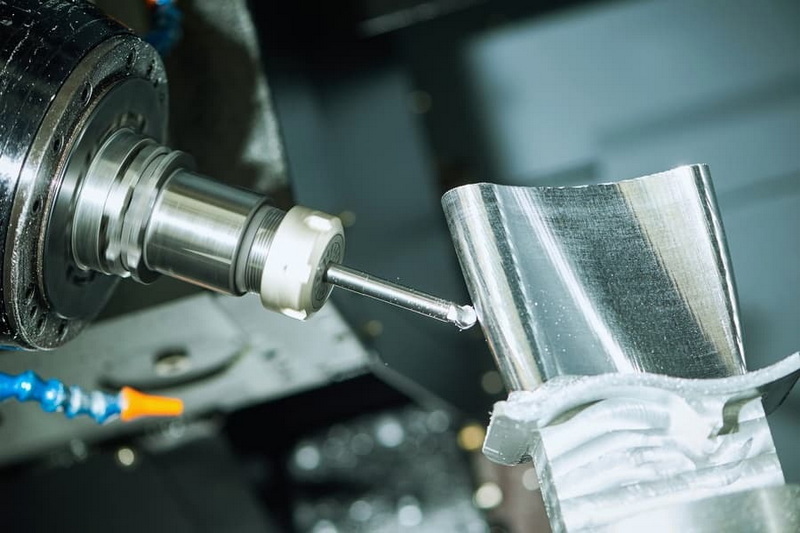

Shangchen (sc-rapidmanufacturing.com) stands at the gateway between Chinese manufacturing excellence and global market needs. For years, Shangchen has specialized in rapid prototyping, high-precision CNC machining, small- and large-scale batch production, turning, milling, sheet metal fabrication, 3D printing, and mold manufacturing. With its advanced facilities, top-tier engineering talent, and comprehensive project management, Shangchen is the preferred CNC cutting manufacturer for OEM clients seeking speed, reliability, and outstanding customization.[10][11]

- Prototyping—Quick turnaround on concept-to-sample for diverse industries.

- Full-spectrum CNC cutting—Catering to aluminum alloys, steels, plastics, composites, and custom materials.

- Batch production—From small runs to high-volume, with strict quality assurance at every step.

- Complex turning and milling—Precision-finished geometries and tight tolerances.

- Sheet metal manufacturing and assembly.

- Mold design, construction, and advanced 3D printing services.

- OEM/ODM project management—Comprehensive for foreign brands, including engineering co-development and supply chain solutions.[10]

- ISO-certified quality management, traceability, and process documentation.

- Deep technical partnerships and flexible scale—from one-off prototypes to thousands of units per order.

- Engineering support for new product introduction, DFM (Design for Manufacturability), and concurrent manufacturing.

- Consistent, proactive client communication for international business.

Spain boasts several prominent CNC cutting manufacturers and suppliers, many recognized for their innovation, longstanding expertise, and commitment to customer satisfaction:[4][12][13][2][1]

Founded in 1954 in the Basque Country, Danobat Group is synonymous with technical leadership in CNC grinding, turning, and milling systems. Serving the aerospace, transportation, and oil industries, Danobat's strengths include automation, integration with robotics, and smart manufacturing software. The company is ISO 9001 and ISO 14001 certified, reflecting a rigorous approach to quality and environmental management.[1]

Founded in 1985, MIPESA is a hallmark of quality and innovation in CNC milling, turning, laser cutting, and sheet metal fabrication. Its major clients are in the automotive, aerospace, and industrial machinery sectors. MIPESA is distinguished by the integration of advanced CNC automation and a focus on meeting demanding precision standards.[2]

Established in 1953, IBARMIA provides custom CNC machining centers, including vertical and horizontal solutions, multitasking machines, and automated systems. IBARMIA's primary markets are aerospace, energy, automotive, and oil/gas. Clients value its advanced machine control systems and emphasis on continuous product improvement.[2]

Since 1972, Mecánica Curiel has specialized in high-precision CNC machining and assembly, especially for laboratory, medical, and aerospace instruments. The company's ISO 9001:2015 and ISO 13485:2016 certifications underscore its adherence to stringent quality controls and traceability requirements.[2]

Well regarded for high-precision micromachining, Opal Machining focuses on defense, aerospace, and medical components demanding ultra-tight tolerances. They apply advanced metrology and quality assurance to comply with critical industry standards.[2]

With expertise in micromachining, engraving, and CNC milling since 1957, Omella Grabados serves sectors ranging from mold and die to jewelry, signage, and custom industrial parts. Their dedication to combining precision engraving with CNC machining sets them apart in niche markets.[2]

MPG offers high-precision CNC machining with a multi-industry focus (medical, aerospace, automotive), managing both prototyping and larger production volumes.[12][14]

An established CNC machining player from Catalonia, Tecnomecánicas Shine SL handles small to medium production and custom component orders.[13]

Known for versatile, high-precision machining, MECOXI provides ongoing supply to many global customers. Their quality assurance systems, extensive toolsets, and flexible manufacturing processes meet diverse market needs.[13]

Spanish CNC cutting manufacturers and suppliers deliver solutions for wide-ranging industries:

- Automotive: Engine blocks, gear housings, custom brackets, and heat sinks.

- Aerospace: Lightweight structural components, brackets, high-precision assemblies.

- Medical and Laboratory: Surgical tools, implantable parts, diagnostic equipment.

- Electronics: Enclosures, connectors, thermal management units.

- Industrial and Energy: Turbine parts, heavy-duty panels, wind energy components.[1][2]

Spain's integration of AI, IoT, and robotics in CNC production accelerates lead-times, enhances repeatability, and supports mass customization.[1][2]

Spain's top CNC cutting manufacturers and suppliers are digitalizing operations through smart sensors, monitoring systems, and automated workflow. Industry 4.0 upgrades—such as real-time data analytics and predictive maintenance—boost efficiency, reduce waste, and improve traceability.[1][2]

- Automotive: Projected to maintain over a third of the market, driven by electric vehicles and specialized components.[2]

- Aerospace: Expansion follows new projects and rising demand for precision assemblies, especially as Airbus and other OEMs invest in Spanish suppliers.[1]

- Medical electronics: Poised for 6% annual growth, reflecting increased demand for high-precision, quality-assured medical parts.[2]

- Electronics and Industrial: Innovative consumer devices and renewable energy are catalyzing steady 4–7% sector growth metrics.[1][2]

Spain's CNC cutting market benefits from strong EU standards and free market access, though competition remains fierce and cost pressures can be intense. Manufacturers with ISO, EN, and industry-specific certifications often secure premium contracts and build long-term cross-border relationships. Trade policies—especially EU anti-dumping measures—provide a buffer against unfair imports and foster local innovation.[1][2]

- Certifications: Look for ISO 9001, ISO 13485, EN9100 (for aerospace), and traceability systems.

- Materials expertise: Ensure capability in aluminum, steel, titanium, plastics, and composites.

- Technological capacity: Advanced multi-axis machinery and automation abilities are crucial; ability to handle complex geometries and volume scalability.

- Client support: International communication, engineering co-development, and logistics support for seamless global deliveries.

- Lead time and quality assurances: Fast prototyping, strict inspections, strong process documentation.

Partnering with dependable CNC cutting manufacturers and suppliers delivers critical benefits—access to advanced technology, scalable production, and quality management that meets demanding regulatory and industry standards. Trusted partners like Shangchen offer clients consistent delivery schedules, robust design support, competitive pricing, and responsive communication that span geography and product complexity.[11][10]

- Rising material costs: Volatility in steel, aluminum, and component supplies (resulting from global tariffs or logistics disruptions) necessitates agile sourcing strategies.[1]

- Talent shortages: As technology advances, the need for highly skilled technicians and engineers grows.

- Trade dynamics: Spain's EU access supports exports, but companies must still navigate international regulations, comply with environmental requirements, and invest in ongoing workforce development.

- Innovation imperative: To maintain competitive edge, Spanish and global CNC suppliers must prioritize investment in R&D, automation, and digital transformation.

The CNC cutting industry in Spain continues to lead through innovation, responsiveness, and steadfast attention to quality. By embracing automation, digitalization, and global partnerships, Spain's manufacturers deliver mission-critical precision parts for the world's most demanding sectors. Companies like Shangchen, with advanced facilities and robust OEM/project management expertise, bridge continents—delivering custom CNC solutions and supply chain continuity to clients across Spain, Europe, and beyond. As the sector grows, success will belong to those who innovate, invest in technology, and prioritize client satisfaction above all else.

Shangchen's global reputation derives from its rapid prototyping, batch flexibility, strict quality control, and support throughout the manufacturing process. The company's comprehensive capabilities, communication transparency, and engineering consult ensure client concepts transform into finished components efficiently and reliably.[11][10]

Automotive, aerospace, energy, electronics, and medical sectors rely heavily on Spanish CNC services due to their technical depth, certifications, and logistics advantages.[2][1]

Spanish CNC manufacturers and suppliers invest in local sourcing, digitalization, and smart automation, emphasizing flexible, high-quality, and swiftly delivered projects—helping to mitigate material cost volatility and maintain a competitive edge.[1]

Buyers should prioritize ISO 9001 for general quality assurance, EN9100 for aerospace, ISO 13485 for medical, and industry-specific certifications such as ISO 14001 for environmental compliance.[2][1]

Spain combines EU-grade quality standards, modern digital factories, a skilled workforce, and an export-ready mindset, making it a smart destination for buyers seeking consistent, innovative, and cost-effective CNC manufacturing solutions.[2][1]

[1](https://sinoextrud.com/cnc-machining-spain/)

[2](https://beausino.com/cnc-machining-spain/)

[3](https://www.linkedin.com/pulse/spain-cnc-gear-cutting-machines-market-top-trends-2ifyf)

[4](https://www.kemalmfg.com/cnc-machining/companies/spain/)

[5](https://www.ibisworld.com/spain/industry/metal-forming-machinery-machine-tool-manufacturing/200505/)

[6](https://www.futuremarketinsights.com/reports/cnc-plasma-cutting-machines-market)

[7](https://anebonmetal.com/top-cnc-turning-service-manufacturers-in-spain/)

[8](https://www.youtube.com/watch?v=G7lbxWV_1wA)

[9](https://www.grandviewresearch.com/industry-analysis/cnc-machining-turning-centers-market-report)

[10](https://www.sc-rapidmanufacturing.com)

[11](https://www.sc-rapidmanufacturing.com/news.html)

[12](https://www.elephant-cnc.com/blog/spanish-cnc-machine-manufacturers/)

[13](https://www.holyprecision.com/Top-10-CNC-Manufacturers-in-Spain.html)

[14](https://www.holyprecision.com/Top-10-CNC-Machining-Parts-Manufacturers-and-Suppliers-in-Spain-id42628257.html)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes