Views: 222 Author: Amanda Publish Time: 2025-11-26 Origin: Site

Content Menu

● Shangchen: A Global Pioneer in CNC Cutting and Precision Manufacturing

● The Landscape of Japanese CNC Cutting Manufacturers and Suppliers

● Major Japanese CNC Cutting Manufacturers and Suppliers

>> Makino Milling Machine Co., Ltd.

>> JTEKT Corporation (JTEKT Machinery)

● Key Features and Technologies of Japanese CNC Cutting Solutions

● Strategic Advantages for International Buyers

>> Why Choose Japanese CNC Cutting Manufacturers and Suppliers?

>> Opportunities for Collaborative International Manufacturing

● Applications of CNC Cutting Technology Across Industries

● Future Trends Among CNC Cutting Manufacturers and Suppliers in Japan

● Selecting the Right CNC Cutting Manufacturer or Supplier

● Frequently Asked Questions (FAQ)

>> 1. What services do top CNC Cutting Manufacturers and Suppliers in Japan offer?

>> 2. How does Shangchen support overseas buyers as a CNC Cutting Manufacturer and Supplier?

>> 3. What certifications do leading Japanese CNC Cutting Manufacturers and Suppliers possess?

>> 4. Which industries most frequently use Japanese CNC Cutting Manufacturers and Suppliers?

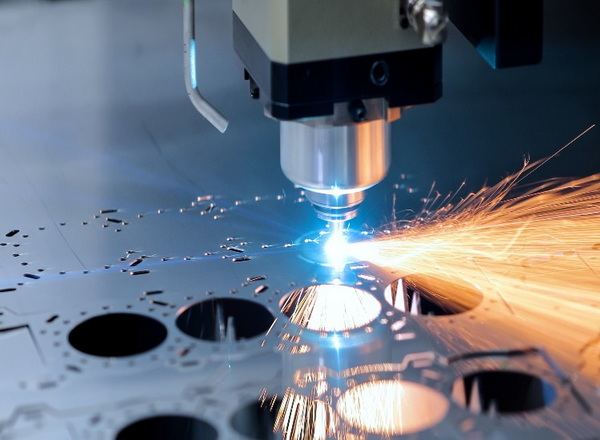

Japan has built a global reputation as a leader in advanced manufacturing, thanks to its rigorous engineering standards, unmatched innovation, and high-precision industrial capability. For international OEM brands, wholesalers, and manufacturers seeking reliable CNC machining solutions, Japan offers some of the world's finest CNC Cutting Manufacturers and Suppliers. This article provides a deep dive into the top names in the industry—spotlightingShangchen (sc-rapidmanufacturing.com) for its international OEM outreach and fast-turn services—while providing relevant industry insights, background on Japanese manufacturing strengths, practical advice for buyers, and market trends shaping the future of CNC cutting worldwide.

Shangchen, found at sc-rapidmanufacturing.com, is a rapidly advancing Chinese CNC Cutting Manufacturer and Supplier with a substantial focus on serving overseas markets—including those sourcing precision parts from Japan and Asia. The company's expertise spans rapid prototyping, large-scale batch CNC machining, CNC lathe turning, sheet metal fabrication, advanced 3D printing, and mold production. Shangchen's continual investment in digital manufacturing and quality control makes it a frequent partner for global brands needing reliability, tight tolerances, and responsive OEM/ODM support.

Clients working with Shangchen benefit from:

- State-of-the-art multi-axis CNC centers for milling and turning

- High-speed prototyping and rapid design iterations

- Batch production for automotive parts, precision electronics, or medical devices

- Digital quality validation and global logistics support

Shangchen is regularly chosen by companies in Europe, the Americas, and Southeast Asia who value both top-tier precision and the flexibility to scale projects quickly. By integrating advanced automation with skilled technical teams, Shangchen demonstrates why Chinese firms are shaping rapid trends in international prototyping and cost-competitive volume manufacturing.

Japan's legacy in high-precision engineering and relentless innovation places it at the forefront of the CNC manufacturing world. Japanese CNC Cutting Manufacturers and Suppliers are reputed for their uncompromising quality, use of proprietary controls, integration of advanced robotics, and remarkable aftersales support.

Top-tier Japanese manufacturers are typically characterized by:

- Unmatched product tolerances and reliability

- In-house development of sophisticated CNC controllers and automation software

- Frequent ISO 9001, ISO 14001, CE, and UL certifications

- Expertise spanning automotive, aerospace, energy, medical, and electronics industries

- Extensive global networks, ensuring smooth cross-border partnerships for international buyers

Founded in 1919, Mazak is regarded as a global innovator in multi-tasking machines and CNC automation solutions. Their portfolio includes:

- Multi-tasking INTEGREX machines

- Cutting-edge vertical, horizontal, and 5-axis machining centers

- Advanced laser cutting technology for sheet fabrication

Mazak's “Done In One” philosophy enables complex components to be manufactured on a single machine, streamlining production and guaranteeing precision for industries like automotive and aerospace.[1][2]

The strategic alliance of Japan's Mori Seiki and Germany's Gildemeister formed DMG MORI—a powerhouse offering:

- Comprehensive lines of turning, milling, and 5-axis centers

- Additive manufacturing integration for hybrid production

- Robust automation, digital solutions, and R&D presence worldwide

DMG MORI machines are fixtures in sectors demanding high accuracy and flexibility, such as medical device and die & mold manufacturing.[2][5][1]

Established in 1898, Okuma is revered not only for its CNC machining tools (lathes, vertical/horizontal machining centers, multifunction machines) but also for its proprietary OSP control system. Okuma's hallmarks include:

- Rigid, thermally stable structures for long-term accuracy

- Integrated automation and intelligent factory connectivity

- Breadth of solutions for aerospace, automotive, and heavy machinery markets

Their machines reliably produce complex and high-tolerance components for critical applications.[7][1][2]

Makino is known for its innovation in horizontal and vertical machining centers, EDM wire systems, and specialized solutions for high-precision die and mold manufacture. Their platforms offer:

- Exceptional surface finishes and micron-level tolerances

- Integration of digital twin and factory monitoring systems

- High-speed logic for optimal productivity in aerospace, medical, and electronics manufacturing.[8][1]

Globally famous for automation and robotics, FANUC also manufactures:

- ROBODRILL compact machining centers ideal for precision drilling and milling

- ROBOCUT wire EDM machines for ultra-fine finishes in metals and alloys

- In-house CNC and automation controls, enabling seamless robot-machine integration

FANUC's efficiency, reliability, and energy-saving features have made it the top choice for electronics and medical manufacturers worldwide.[1][2]

Formerly known as Toyoda, JTEKT produces precision grinding machines, vertical and horizontal machining centers, and gear production technology. The company is celebrated for:

- Super-precision cylindrical, universal, and crank/camshaft grinding machines

- High rigidity and stability for automotive and bearing applications.[2][1]

Renowned globally for their SPEEDIO series, Brother offers highly compact, high-speed tapping centers that shine in mass production and electronics applications. Their machines provide:

- Outstanding energy efficiency and throughput

- Flexible solutions for both small-batch runs and continuous manufacturing.[1][2]

The leader in CNC sheet metal processing, Amada supplies advanced equipment such as:

- CNC punching machines for sheet fabrication

- Precision laser cutting, press brakes, and full automation for construction, automotive, and electronics applications.[2]

- Citizen Machinery: Swiss-type lathes for high-speed, small-part machining, especially for medical, electronics, and watchmaking.[2]

- Sodick: Linear motor technology for fast, high-precision EDM machining.[2]

- Kiwa Machinery: Specializes in innovative horizontal and vertical machining centers for global clients.[5]

- E&H Precision: Focused on tight-tolerance automotive and medical parts via CNC turning and milling.[5]

- Top Seiko: Excels in precision machining of hard, exotic materials, powering aerospace and medical innovation.[6]

Japanese CNC Cutting Manufacturers and Suppliers push the boundaries through:

- Extreme accuracy and repeatability (mandated in aerospace, die/mold, and semiconductor fields)

- Robust CNC control systems, frequently designed and programmed in-house

- Strong engineering cultures, emphasizing continuous process improvement (kaizen)

- Use of digital twins, in-process metrology, and AI-driven quality control

- Commitment to sustainability: energy-efficient designs and environmental certifications

The cumulative effect for buyers is assured process reliability, traceable certifications, and high-quality output at every order size.

- Trusted for mission-critical industries demanding flawless part geometries and certifications

- Known for strong aftersales support, spare parts availability, and remote diagnostics, minimizing downtime for overseas buyers

- Continuous innovation—Japanese suppliers are at the vanguard of Smart Factory technology, including IoT and cloud-based process monitoring.[5][2]

Japanese and leading Chinese CNC Cutting Manufacturers and Suppliers often complement each other across the global supply chain. Many international buyers:

- Source ultra-precise, high-value components from Japan

- Rely on Chinese partners like Shangchen for rapid prototyping, pilot production, and cost-effective volume orders

- Value responsiveness, language support, and flexible logistics solutions, key strengths of Shangchen's overseas business model[10]

CNC Cutting Manufacturers and Suppliers in Japan and China enable production for:

- Automotive: Cylinder heads, engine blocks, transmission and chassis components

- Aerospace: Turbine blades, structural airframe parts, metallic composites

- Medical: Surgical instruments, orthopedic implants, diagnostic enclosures

- Electronics: High-density enclosures, connectors, PCB elements

- Consumer Products: Precision appliance parts, home automation hardware, individual product housing

The convergence of advanced CNC cutting and digital quality control opens opportunities for innovation in each of these sectors.

Global trends are shaping the future capabilities of top CNC Cutting Manufacturers and Suppliers:

- Adoption of Smart Factories: AI-driven scheduling, machine learning in process optimization, and integrated robotics

- Cloud-Based CNC and Predictive Maintenance: Remote monitoring, diagnostics, and automated alerts minimize downtime

- Green Manufacturing: Energy-saving drives, recycling of metal shavings, and sustainable sourcing

- Expanding Rapid Prototyping: Increased use of additive manufacturing, hybrid machines, and digital twin simulation accelerate new product development cycles[5][2]

As Japanese suppliers continue to raise the bar for quality and automation, international buyers benefit from unmatched product consistency, innovative features, and seamless integration into global manufacturing ecosystems.

Choosing among CNC Cutting Manufacturers and Suppliers in Japan or China requires:

- Gaining clarity on technical requirements: tolerances, surface finish, production quantity, and delivery timeline

- Auditing supplier certifications and proven track record in your sector

- Reviewing sample parts or completed project portfolios

- Assessing aftersales and technical support coverage across regions

- Negotiating clear terms on delivery, support, and QA processes

When buyers align these factors with business priorities, both Japanese giants and flexible partners like Shangchen become powerful extensions of their supply chain strategy.

Japan's CNC Cutting Manufacturers and Suppliers have set global benchmarks for quality, automation, and support, driven by a culture of relentless innovation and attention to detail. International firms rely on giants like Mazak, Okuma, DMG MORI, FANUC, Makino, and many others for high-value, precision-critical tasks, while agile providers like Shangchen (sc-rapidmanufacturing.com) empower global brands with rapid-turn prototyping, flexible batch manufacturing, and robust OEM/ODM support. As the global manufacturing landscape evolves, the collaboration between Japanese and Chinese suppliers will allow customers worldwide to create, iterate, and deliver at the forefront of technology and scale.

Japanese CNC Cutting Manufacturers and Suppliers deliver advanced CNC machining (milling, turning, grinding), precision prototyping, batch and mass production, sheet metal processing, EDM, additive manufacturing, and robust aftersales support tailored to diverse sectors like automotive, aerospace, and medical.

Shangchen (sc-rapidmanufacturing.com) offers rapid prototyping, scalable batch production, multi-axis CNC machining, and personalized OEM/ODM service—all with rigorous digital quality control and international logistics support for global customers.

Common credentials include ISO 9001, ISO 14001, CE, and UL—providing assurance of world-class manufacturing quality, traceability, and environmental compliance.

Key customers include global leaders in the automotive, aerospace, medical device, electronics, and precision consumer products industries, all of whom require uncompromising accuracy and innovation.

Evaluate supplier capabilities, certifications, experience, aftersales support, sample quality, and responsiveness—with site tours and technical discussions providing final confidence in a reliable, long-term partner.

[1](https://www.lvcnc.com/top-10-cnc-machine-manufacturer-in-japan)

[2](https://www.hirung.com/top-10-cnc-machine-manufacturers-in-japan/)

[3](https://anebonmetal.com/top-rapid-cnc-machining-manufacturers-and-suppliers-in-japan/)

[4](https://www.jmtba.or.jp/english/members-directory/directory-of-products/)

[5](https://beausino.com/top-japanese-cnc-machining-manufacturers-2025-guide/)

[6](https://ensun.io/search/cnc-milling/japan)

[7](https://emag.directindustry.com/2022/07/05/the-top-5-japanese-machine-tools-manufacturers/)

[8](https://www.makino.com/en-us/)

[9](https://www.practicalmachinist.com/forum/threads/japanese-machines-made-in-japan.404799/)

[10](https://www.sc-rapidmanufacturing.com)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes