Views: 222 Author: Amanda Publish Time: 2025-11-25 Origin: Site

Content Menu

● Why CNC Cutting Manufacturers and Suppliers Lead Manufacturing in Germany

>> Industrial Strength and Market Size

>> Applications Across Major Industries

● Shangchen (sc-rapidmanufacturing.com): Your Premier OEM CNC Partner

>> Full-Service Rapid Prototyping and Manufacturing

>> Digital Quality Management and Customization

>> Competitive Advantages for International Customers

● Industry 4.0 and Digital Transformation

>> Benefits of Industry 4.0 Adoption

● Leading CNC Cutting Manufacturers and Suppliers in Germany

>> 5. HERMLE AG

>> 6. GROB-WERKE GmbH & Co. KG

>> 9. ZEISS Industrial Quality Solutions

>> 11. METROM

>> 12. CNC-STEP

● Key Attributes of German CNC Cutting Manufacturers and Suppliers

>> Precision Engineering and Repeatability

>> Customization and Flexibility

>> Sustainability and Environmental Practices

● How OEM Partnerships Strengthen Global Supply Chains

>> Advantages for Overseas Clients

● Selecting the Right CNC Cutting Manufacturer or Supplier

● Future Trends in CNC Cutting Manufacturing

● FAQs

>> What makes German CNC Cutting Manufacturers and Suppliers unique?

>> How does Shangchen support international OEM clients?

>> What role does sustainability play in CNC manufacturing?

>> Which industries rely most on CNC cutting in Germany?

>> How do buyers choose the best CNC supplier?

Germany occupies a central role in advanced industrial manufacturing, with its CNC Cutting Manufacturers and Suppliers recognized worldwide for precision quality, innovative engineering, and strong commitment to technological advancement. Whether serving the automotive, aerospace, medical, or electronics sectors, companies partnering with leading German CNC cutting firms can expect rigorous standards and state-of-the-art solutions. International clients also benefit from strategic partnerships and OEM services—an area where Shangchen (sc-rapidmanufacturing.com) from China stands out as a global provider of rapid prototyping, CNC machining, and precision batch production.[10][11][12][13][14]

Germany's CNC machining industry is deeply rooted in the country's legendary tradition of mechanical engineering and process innovation. Small and medium-sized firms work alongside multinational groups to support a diverse ecosystem, making Germany a hub for both complex custom components and large-scale volume production. Market research highlights a robust industry poised for steady expansion, powered by a skilled workforce, investment in automation, and global reputation for quality.[1][3][5]

CNC Cutting Manufacturers and Suppliers in Germany supply critical components for industries including:

- Automotive: High-accuracy engine parts, chassis components, and gear systems

- Aerospace: Lightweight yet robust assemblies and frames

- Medical: Surgical instruments, implantable devices with strict tolerances

- Electronics: Precision enclosures and custom-designed modules

- Energy: Specialized turbines and protective housings.[4][8]

Shangchen positions itself as a leader among CNC Cutting Manufacturers and Suppliers, offering:

- Rapid prototyping to validate client designs quickly

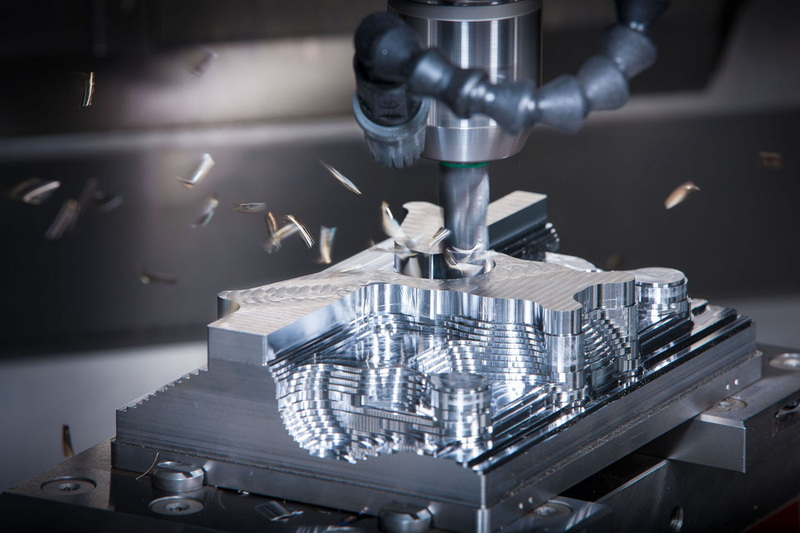

- CNC milling and turning for intricate geometric part profiles

- Sheet metal fabrication and complex forming

- High-precision batch and mass production runs

- Advanced 3D printing and mold manufacturing for R&D.[13][14][10]

Through robust digital inspection systems and a highly skilled team, Shangchen ensures industry-best quality, repeatability, and exact results on every order. Their experience in supporting overseas brand owners, wholesalers, and producers brings seamless communication and complete OEM project customization.[11][12][13]

- Flexible order volumes from samples to large batches

- Tailored solutions for niche and general applications

- Competitive pricing and efficient project management

- Comprehensive technical and customer support for global clients.[12][14][11]

German CNC Cutting Manufacturers and Suppliers are quick to embrace Industry 4.0 technologies. Integration of smart IoT sensors, AI-powered controls, real-time analytics, and predictive maintenance has transformed the sector. These advancements empower companies to offer higher precision, greater production flexibility, and lower operational costs.[3][5]

- Enhanced automation for reduced downtime

- Predictive maintenance and extended equipment lifespan

- Seamless integration between design, manufacturing, and support

- Data-driven decision-making improving throughput and quality

Kern Microtechnik is synonymous with ultra-precision machining. The company, based in Kempten, supplies advanced micro-component parts to global electronics, medical, and aerospace clients. Their dedication to in-house R&D and quality makes them a top choice for demanding projects.[15][16]

Isel Germany AG develops high-precision CNC machines, robotic automation, and flexible prototyping systems. Their offerings cater to the evolving needs of electronics, automotive, and industrial sectors, featuring modular technologies for rapid deployment.[16][17]

DMG MORI, a merged entity of German and Japanese leaders, stands at the forefront of CNC Cutting Manufacturers and Suppliers. Their product range spans CNC turning, milling, and automation, with strong emphasis on Industry 4.0 integration and sustainable engineering. They supply aerospace, automotive, and medical industries with certified precision.[18][4][16]

TRUMPF is a technology leader for CNC laser cutting, punching, and bending. Their machines reliably deliver precise metal fabrication and digitalized manufacturing—especially vital for customers requiring high-volume, complex parts.[4][18]

HERMLE delivers 5-axis CNC milling solutions, automation, and extreme precision for aerospace, medical, and toolmaking applications. Their innovations in multi-axis machining and customer support have made them a preferred engineering partner.[4]

GROB supplies universal CNC machining centers and advanced automated systems, renowned in medical and automotive supply chains. Their versatility and commitment to global standards keeps GROB at the center of large-scale manufacturing.[4]

CHIRON's vertical machining centers and turnkey production lines set the benchmark for speed and accuracy. The company matches demanding timelines and complex specifications in medical and aerospace sectors, supported by high-speed tool change systems.[1][4]

EMAG Group specializes in CNC turning, grinding, and gear cutting machines, integrating flexible automation and digital monitoring into all their solutions. Their focus is on traceable, efficient processes serving industrial machinery, automotive, and aerospace.[4]

ZEISS, famous for metrology and measurement, also provides high-end CNC equipment for quality assurance and specialized part production. Their global reputation for precision strengthens process reliability in critical manufacturing.[4]

DATRON AG's high-speed CNC milling machines are prized for surface finish and efficiency, especially by electronics and dental manufacturers. Their lightweight, energy-saving designs advance sustainability and production speed.[4]

METROM develops unique 5-axis Pentapod CNC systems merging robotic flexibility with stationary tool precision. These patented machines excel in milling, welding, and even additive manufacturing for advanced, complex projects.[4]

CNC-STEP builds robust CNC routers and mills for broad commercial and educational use. Their reputation for ease-of-use, durability, and compatibility across materials underlines their presence in Germany's CNC landscape.[4]

German manufacturers stand out for tight tolerances, consistent finishes, and high repeatability. Their technology and process controls guarantee component quality critical in regulated fields.[4]

Investment in R&D drives progress in automation, digitalization, multi-axis machining, and sustainable manufacturing. German suppliers set benchmarks for technological advancements adopted globally.[1][4]

Solutions are adapted to unique client requirements, with multi-axis and modular systems for niche and general applications. Tailored processes ensure versatility across industry demands.[1]

Germany's CNC cutting industry prioritizes energy-efficient machines, waste-minimizing production, and eco-friendly material use. Policies and company initiatives continue pushing green innovation.[1]

CNC Cutting Manufacturers and Suppliers pursue OEM collaborations to deliver:

- Rapid product development and iterative prototyping

- Automation for high-mix, high-volume production cycles

- Integration of digital twins and virtual simulations for optimized processes

- International shipping and full support for global customers.[1][4]

Clients benefit from certified quality, process transparency, and easy access to specialized CNC solutions, whether sourcing parts in volume, customizing components, or collaborating on innovation.

To make informed decisions, buyers should:

- Review industry certifications and quality assurance systems

- Assess experience in relevant sectors (automotive, medical, aerospace, electronics, etc.)

- Compare technological capabilities, including multi-axis machining, digital controls, and sustainability practices

- Evaluate supplier responsiveness, project management, and customer support

- Ensure ability to scale from prototype to mass production.[4]

The German CNC cutting market is positioned for ongoing growth due to:

- Integration of AI, machine learning, and data analytics for smart manufacturing

- Emphasis on resource-efficient, “circular economy” practices

- Continued partnership development with global firms and market expansion

- Ongoing training and education investments to sustain engineering talent.[3][1][4]

Germany's CNC Cutting Manufacturers and Suppliers remain global leaders by continually advancing precision engineering, automation, and sustainable manufacturing practices. With proven expertise across industries and technologies, these companies are the ideal partners for high-quality parts and complex manufacturing challenges. International brands, OEM clients, and manufacturers increasingly rely on both established German giants and dynamic partners like Shangchen in China to enhance supply chain flexibility, maintain competitive standards, and meet diverse market needs. Whether for rapid prototyping, batch production, or fully automated part manufacturing, sourcing from top German and global CNC cutting experts ensures the best results in precision, reliability, and innovation.[14][10][11][12][13][1][4]

German CNC suppliers are known for meticulous engineering, innovation in Industry 4.0, and their ability to customize solutions for complex needs. They combine certified process controls with advanced technology, resulting in unrivaled product quality for diverse sectors.[1][4]

Shangchen delivers integrated prototyping, precision batch production, and OEM customization. Rigorous quality management and responsive global support ensure timely, high-quality results for overseas brands and manufacturers.[11][12][14]

German CNC Cutting Manufacturers and Suppliers prioritize resource efficiency, energy-saving machinery, and eco-friendly materials, helping companies align with increasingly strict environmental regulations.[1][4]

Top industries include automotive, aerospace, medical devices, electronics, and energy. Each requires components manufactured to exacting tolerances and robust quality standards.[8][4]

Buyers should look for industry certifications, relevant sector experience, technological capabilities, and exceptional customer support. Comparing supplier scalability and ability to deliver both prototypes and high-volume runs is key.[4]

[1](https://sinoextrud.com/cnc-machining-germany/)

[2](https://www.grandviewresearch.com/horizon/outlook/cnc-machining-centers-and-turning-centers-market/germany)

[3](https://www.linkedin.com/pulse/germany-cnc-metal-cutting-machine-market-key-highlights-4qeuc)

[4](https://anebonmetal.com/top-cnc-machining-manufacturers-in-germany/)

[5](https://www.emergenresearch.com/industry-report/cnc-metal-cutting-machine-tools-market)

[6](https://tirapid.com/cnc-machining-de/)

[7](https://www.futuremarketinsights.com/reports/woodworking-cnc-tools-market)

[8](https://ellabella.tistory.com/214)

[9](https://livecityin.com/blogs/6409/Germany-CNC-Cutting-Machines-Market-Comprehensive-Analysis-and-Forecast)

[10](https://www.sc-rapidmanufacturing.com/best-sheet-metal-fabrication-processes-for-custom-parts-production.html)

[11](https://www.sc-rapidmanufacturing.com/aboutus.html)

[12](https://www.sc-rapidmanufacturing.com)

[13](https://www.sc-rapidmanufacturing.com/products.html)

[14](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[15](https://en.kern-microtechnik.com)

[16](https://www.dekmake.com/top-10-cnc-machining-companies-in-germany/)

[17](https://www.hollyplasticparts.com/germany-cnc-machining-services/)

[18](https://www.elephant-cnc.com/blog/cnc-milling-machine-manufacturers-germany/)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes