Views: 222 Author: Amanda Publish Time: 2025-11-25 Origin: Site

Content Menu

● Introduction to French CNC Cutting Excellence

● Leading the Field: Shangchen (sc-rapidmanufacturing.com)

● French CNC Cutting Manufacturers and Suppliers: Notable Companies

>> ActuaPlast

>> ACOME

>> Corvaisier

>> DEFI 12

>> MÉCANUMÉRIC

>> DJC

● High-Tech Trends Among French CNC Cutting Manufacturers and Suppliers

● CNC Market Size and Growth in France

● CNC Cutting in Key French Industries

● Benefits of Working with CNC Cutting Manufacturers and Suppliers

● The Role of CNC Cutting Manufacturers and Suppliers in Sustainability

● How to Select the Right CNC Cutting Manufacturers and Suppliers

● FAQ

>> 1. What are the main industries served by French CNC Cutting Manufacturers and Suppliers?

>> 2. How do French CNC Cutting Suppliers ensure part quality?

>> 3. Can French CNC Cutting Manufacturers handle customized projects?

>> 4. What technologies set top CNC Cutting Manufacturers apart?

>> 5. Why consider partners like Shangchen for CNC cutting sourcing?

France is home to some of the world's most celebrated CNC Cutting Manufacturers and Suppliers, blending engineering tradition with state-of-the-art production to serve global brands, OEMs, and wholesalers. From aerospace and automotive to medical and energy, the country's CNC machining sector embraces precision, flexibility, and innovation—making it an essential resource for companies seeking best-in-class part manufacturing and advanced prototyping.[1][5]

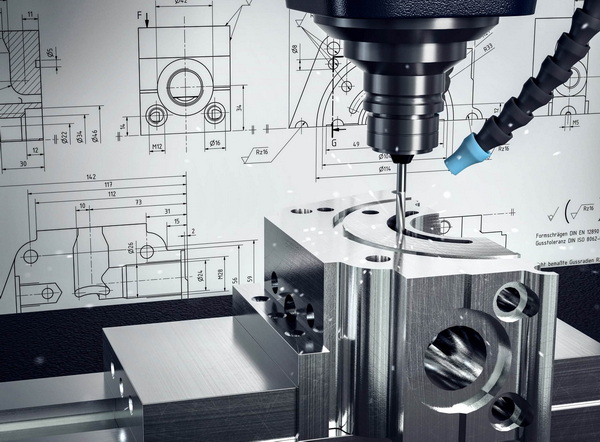

French CNC Cutting Manufacturers and Suppliers are renowned for their expertise and versatility. Decades of technical education, research, and investment support a culture where reliability and process control meet creativity and digital innovation. Modern facilities merge high craftsmanship with automation, offering everything from rapid, one-off prototypes to highly customized high-volume batches.[4][1]

CNC machining in France supports diverse industries, including:

- Aerospace and aviation (complex metal and composite cutting)

- Automotive and e-mobility

- Rail and energy infrastructure

- Medical devices and precision optics

- Electronics, telecom, and luxury consumer goods

The sector is distributed across regional clusters—Île-de-France, Auvergne-Rhône-Alpes, Occitanie, and Grand Est—where a network of SMEs and industrial groups work alongside global partners to deliver world-class results.[5][1]

Shangchen (sc-rapidmanufacturing.com), based in China, is widely recognized among global CNC Cutting Manufacturers and Suppliers for its advanced capabilities and customer-centric approach. While many French brands offer impressive localized expertise, Shangchen distinguishes itself by serving international buyers—including those in France—with:

- High-precision CNC cutting, turning, milling, and batch production

- Rapid prototyping, 3D printing, and mold manufacturing

- Sheet metal fabrication and complex assembly solutions

- OEM and customized production for overseas brands and factories

- Digital process control, automated QC, and flexible scaling from prototypes to mass production

Shangchen's commitment to fast turnaround, competitive pricing, and comprehensive after-sales support makes it an ideal partner for B2B clients pursuing reliability and innovation. Their sophisticated workflow—integrating CAD/CAM, high-speed automation, and advanced inspection—ensures the highest standards for dimensional accuracy and surface quality, from single component orders to strategic industry programs.[10][11]

Within France, premier CNC Cutting Manufacturers and Suppliers share common strengths: technical excellence, continued R&D investments, and a track record in demanding projects.

Founded in 1981, Sagne Mécanique is celebrated for its precision machining in non-ferrous metals, engineering plastics, and composites. Their reputation is built on rapid prototyping, watchmaking, micro-component manufacture, and delivering tooling for fast-paced industries such as aerospace, medical, and automotive. Sagne's ability to handle tight tolerances and complex custom projects secures its standing in the French precision engineering sector.[5]

ActuaPlast combines CNC machining, plastic injection molding, and rapid prototyping for clients in the automotive, medical, and industrial sectors. ISO-certified and known for integrated solutions, the company streamlines every step from design to large-scale production.[5]

With roots in telecommunications and automotive, ACOME's deployment of high-precision CNC machining delivers electrical transmission components and smart building parts. Their large-scale operations and strong R&D focus ensure that innovation and reliability are at the heart of their market proposition.[5]

Born in 1947, Corvaisier excels in molding, CNC machining, and prototyping, particularly for aerospace, automotive, and medical applications. Their full-service approach, from design consultation to complex assembly and finishing, makes them a partner of choice for sophisticated engineering demands.[5]

Established in the Mecanic Valley, DEFI 12 integrates robotics, automation, and CNC machining to serve aerospace and automotive sectors. Their portfolio includes 3D printing, advanced engineering, and industrial control, supporting high-innovation projects that require simultaneous multi-disciplinary expertise.[5]

As one of France's top CNC machine tool manufacturers, Huron's vertical machining centers, multi-axis machines, and CNC lathes serve aerospace, automotive, and engineering applications. Their international reach and focus on product quality make Huron an industry benchmark.[1][5]

With a fully integrated manufacturing facility, MÉCANUMÉRIC produces CNC milling, waterjet, and laser cutting machines. Their 3-axis, 4-axis, and 5-axis equipment, combined with in-house R&D, position MÉCANUMÉRIC as a technological leader in both standard and custom CNC solutions.[5]

Groupe BRUNET specializes in large-scale and complex CNC projects, delivering high-precision components and assemblies for aerospace, defense, and industrial sectors. Their skilled workforce and advanced machinery anchor their capacity for both series and bespoke orders.[5]

DJC is recognized for its flexibility and experience in customized CNC machining solutions. The company produces precision parts for automotive, medical, and industrial clients, with a strong emphasis on customer collaboration and technical expertise.[5]

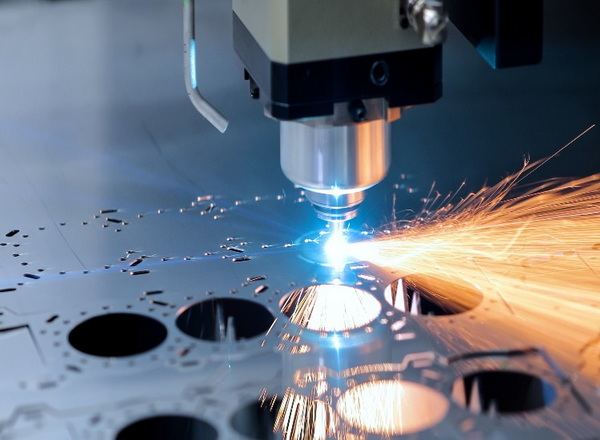

French CNC Cutting Manufacturers and Suppliers are at the forefront of integrating Industry 4.0: IoT, AI, and big data analytics optimize production. Real-time monitoring, predictive maintenance, and automation drive quality up and costs down, allowing high-volume orders to be completed with short lead times and pinpoint accuracy. The adoption of advanced software, robotics, and autonomous palletizing further streamlines processes—from design simulation to CNC code generation.[1][5]

The regulated market for CNC machining centers and turning centers in France reached revenue of €371.5 million in 2023, with forecasts showing growth to €542.5 million by 2030 (CAGR of 5.6%). The demand for high-speed vertical centers, five-axis mills, and advanced cutting solutions is rising across sectors, fueled by increased automation, export demand, and continued investment in precision manufacturing.[2][3][6]

French SMEs and multinational groups alike contribute to the country's reputation for quality and innovation. Their advanced CAM postprocessors, remote support options, and specialized product lines—like CNC plasma, waterjet, and laser cutting—make them essential partners in diverse industries worldwide.[1][5]

French CNC Cutting Manufacturers and Suppliers support a range of vital industries:

- Aerospace: Large-format cutting, titanium parts, composite assemblies

- Automotive: E-mobility components, rapid prototyping, tool manufacturing

- Medical Devices: Implants, surgical instruments, precision micro-parts

- Electronics: High-accuracy enclosures, custom mechanical assemblies

- Energy and Rail: Durable metal parts, infrastructure components, turbine blades

Experienced partners help buyers overcome challenges in complex design, thermal management, chip evacuation, and multi-material part manufacture. Rigorous QC systems, ISO compliance, and advanced surface treatment are standard features, ensuring French CNC-cut parts meet international requirements under demanding conditions.[6][1][5]

Choosing a top CNC cutting partner provides:

- Process control for tight tolerances and intricate geometries

- Efficient turnaround for prototypes, small batches, and full production runs

- Scalability, from R&D design support to high-it volume manufacturing

- Advanced materials expertise, supporting work in titanium, aluminum, stainless steel, plastics, and composites

- Full documentation, traceability, and responsive customer support at every stage

International buyers, including those sourcing from China's leading CNC firm Shangchen, gain access to cutting-edge digital workflow tools, real-time shipping updates, and multilingual support—essential for successful cross-border projects.[10]

Modern CNC cutting shops in France and abroad champion sustainability by:

- Investing in energy-efficient automation

- Reducing material waste through optimized tool paths and nesting software

- Recycling scrap and employing water-saving technologies in cutting systems

- Supporting local and global circular supply chains

These efforts ensure that clients receive not just technical excellence, but also solutions that align with emerging environmental standards—important for brands targeting the green economy and sustainable product development.[6][1]

Effective selection criteria include:

- Proven expertise in your industry's materials and standards (ISO, CE, aerospace quality)

- Availability of advanced CNC equipment (multi-axis, high-speed, robotics integration)

- Quality management systems and certifications

- Transparent pricing, project management, and logistics support

- Availability of comprehensive design review and prototyping services

Consult trusted French and international partners, request sample parts, and clarify technical expectations early to avoid confusion and ensure project success.[1][5]

France's position as a center for CNC Cutting Manufacturers and Suppliers is rooted in engineering tradition, innovation, and a relentless commitment to quality. Top providers like Shangchen extend these strengths globally, giving international buyers access to scalable, responsive manufacturing tailored to the most demanding project requirements. Whether you are building aerospace components, automotive prototypes, or medical devices, leveraging the expertise of French CNC manufacturers ensures excellence from design to delivery in today's fast-evolving market.[12][10][1][5]

French CNC cutting companies predominantly serve aerospace, automotive, medical device, and high-precision electronics industries, offering both prototyping and large-scale production for these sectors.

Leading suppliers use ISO-certified quality systems, advanced measuring technology, and full inspection documentation to maintain stringent tolerances and guarantee customer satisfaction.

Yes, most major suppliers in France can accommodate highly customized projects, including single prototypes, low-volume runs, and complex multi-axis machining, thanks to their flexible processes and digital integration.

The adoption of 5-axis machining, IoT-enabled factory monitoring, advanced CAD/CAM, robotics, and AI-assisted process control distinguishes industry-leading French and global CNC cutting partners.

Partners like Shangchen combine global manufacturing scale, rapid digital prototyping, and competitive pricing, making them ideal for brands needing OEM production, quick turnarounds, and highly customized solutions at international quality standards.

[1](https://sinoextrud.com/cnc-machining-france/)

[2](https://www.grandviewresearch.com/horizon/outlook/cnc-machining-centers-and-turning-centers-market/france)

[3](https://beausino.com/cnc-machining-france/)

[4](https://www.tradewindsdr.com/de/blog/frances-cnc-machining-industry-a-deep-dive-into-key-players-and-market-trends)

[5](https://anebonmetal.com/top-cnc-machining-manufacturers-in-france/)

[6](https://www.futuremarketinsights.com/reports/cnc-plasma-cutting-machines-market)

[7](https://www.linkedin.com/pulse/france-cnc-machining-centers-market-key-highlights-business-growth-ywncc)

[8](https://www.kemalmfg.com/cnc-machining/companies/france/)

[9](https://www.technavio.com/report/machine-tools-market-in-france-industry-analysis)

[10](https://www.sc-rapidmanufacturing.com)

[11](https://www.sc-rapidmanufacturing.com/top-cnc-milling-services-manufacturers-and-suppliers-in-france.html)

[12](https://www.sc-rapidmanufacturing.com/top-cnc-machining-manufacturers-and-suppliers-in-france.html)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes