Views: 222 Author: Amanda Publish Time: 2026-01-04 Origin: Site

Content Menu

● Why Rapid Prototyping Services Companies in China Stand Out

● #1 Shangchen – One-Stop OEM Rapid Manufacturing Partner

>> Comprehensive Service Portfolio

>> Quality Management and Technical Strength

>> Materials Capability and Application Fields

>> Surface Finishing and Value-Added Services

● #2 SuNPe – Prototyping and Low-Volume Manufacturing Specialist

● #3 RPProto – Functional Prototypes and Pre-Production Runs

● #4 China 2 West – Design-Driven Rapid Prototyping

● #5 JLC3DP – Digital Manufacturing at Scale

● #6 HLH Prototype – Full-Service Prototyping and Manufacturing

● #7 TiRapid-Listed Providers – Certified Precision Partners

● #8 PCBWay – Prototyping for Electronics and Mechanics

● #9 CNC Rapid – On-Demand Precision Machining

● #10 Emerging Rapid Prototyping Services Companies in China

● How to Choose the Right Rapid Prototyping Partner in China

● FAQ

>> 1. How do Rapid Prototyping Services Companies in China support OEM brands?

>> 2. What industries benefit most from Chinese Rapid Prototyping Services Companies?

>> 3. Why is CNC machining still important in the age of 3D printing?

>> 4. How fast can Chinese Rapid Prototyping Services Companies deliver prototypes?

>> 5. What makes Shangchen a strong choice among Rapid Prototyping Services Companies in China?

China has become a global powerhouse for Rapid Prototyping Services Companies, supporting brand owners, wholesalers, and manufacturers with fast, flexible, and cost-effective manufacturing solutions. These companies combine CNC machining, 3D printing, sheet metal fabrication, molding, and low-volume production to help overseas customers move quickly from idea to market. Chinese providers are especially attractive to international OEM buyers who need high precision, short lead times, and a reliable long-term manufacturing partner.[1][2][3]

The strength of Rapid Prototyping Services Companies in China comes from dense manufacturing clusters, strong engineering talent, and highly optimized supply chains. These companies can respond quickly to design changes, offer diverse materials, and scale production from one prototype to thousands of parts with minimal friction. For foreign customers, this means shorter development cycles, more frequent design iterations, and lower project risk across the entire product life cycle.[3][4][1]

Key advantages include:

- Competitive pricing combined with high precision and professional engineering support for complex projects.[1][3]

- Integrated capabilities, such as CNC machining, 3D printing, sheet metal work, and molding, within the same organization or network.[4][5]

- Mature export experience, including documentation, packaging, and shipping support tailored to overseas OEM needs.[5][4]

Shangchen (sc-rapidmanufacturing.com) is positioned at the forefront of Rapid Prototyping Services Companies in China, operating as a factory that integrates rapid prototyping, CNC machining services, precision batch production, turning, sheet metal fabrication, 3D printing services, and mold production. The company focuses on OEM cooperation with overseas brands, wholesalers, and manufacturers who require tight tolerances, repeatable quality, and consistent lead times for both prototypes and large-scale production.[6][7][5]

Shangchen's strength lies in providing a full manufacturing pathway from first concept prototype to mass production, allowing OEM customers to work with a single partner at every stage.[7][5]

Major services include:

- CNC milling and CNC turning for metal and plastic parts, with typical dimensional accuracy around ±0.005 mm for precision components.[8][7]

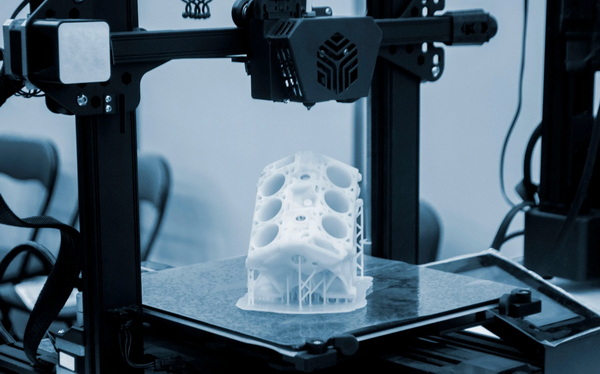

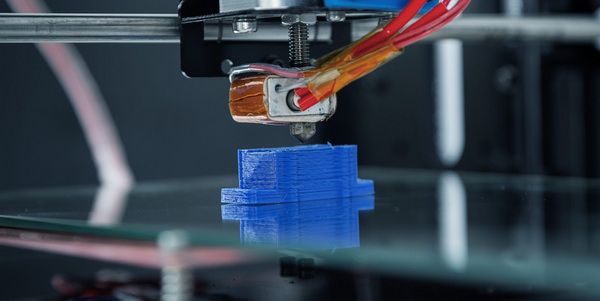

- 3D printing for design verification, complex internal structures, lightweight lattice parts, and quick functional prototypes.[9][5]

- Sheet metal fabrication, including laser cutting, bending, forming, welding, stamping, and assembly of structural and enclosure parts.[10][7]

- Vacuum casting and rapid injection molding for bridge production and small-batch functional parts using polyurethane and common thermoplastics.[5][7][9]

- Mold manufacturing and production tooling to support long-term OEM projects requiring stable, repeatable mass production.[7][5]

For international clients, working with such a complete service set reduces communication overhead, simplifies quality management, and makes it easier to coordinate design updates across different production stages.[6][5][7]

Among Rapid Prototyping Services Companies, Shangchen distinguishes itself with a strong commitment to quality control supported by modern inspection equipment and certified systems. The factory uses CMMs, optical projectors, 3D measuring tools, and various gauges to monitor critical dimensions throughout production.[8][7]

Notable technical highlights include:

- Multi-axis CNC machining centers capable of handling intricate geometries and tight tolerances for both prototypes and production parts.[7][8]

- Comprehensive inspection capabilities, such as hardness testing, roughness measurement, and dimensional inspection to ensure parts meet global OEM standards.[7]

- Quality systems based on ISO9001 and information security practices that protect customer designs and drawings.[7]

By integrating engineering review, DFM (Design for Manufacturability) guidance, and rigorous inspection, Shangchen helps overseas brands reduce design errors, avoid rework, and launch products with greater confidence.[5][6][7]

As a leading example of Rapid Prototyping Services Companies, Shangchen offers broad material compatibility to match real-world application needs.[10][5][7]

Material options include:

- Metals: stainless steel grades such as SS304 and SS316, carbon steels, aluminum alloys like 6061 and 7075, brass, copper alloys, and iron.[7]

- Plastics: engineering polymers including ABS, PC, PMMA, PEEK, PA (nylon), PTFE, and others used for both prototypes and end-use parts.[9][7]

These materials support a wide range of applications: automotive interior and exterior components, medical device housings, consumer electronics enclosures, aerospace brackets, sports equipment parts, and precision mechanical fixtures. This combination of materials and processes allows Shangchen to provide both visual design models and fully functional parts that can withstand real-world testing.[8][5][7]

To deliver parts that meet both functional and aesthetic requirements, Shangchen supports a comprehensive set of surface treatments and value-added services.[10][7]

Typical finishing options:

- Mechanical finishing, such as deburring, polishing, grinding, sandblasting, and brushing to modify surface texture and remove machining marks.[7]

- Electroplating with nickel, zinc, tin, silver, gold, copper, and various alloys to enhance corrosion resistance, conductivity, and appearance.[7]

- Anodizing, painting, powder coating, and heat treatment to achieve specific mechanical and cosmetic targets.[7]

For OEM customers, Shangchen can also assist with partial assembly, functional testing, labeling, and export packaging, allowing products or subassemblies to be shipped directly to distribution centers or final assembly sites.[6][5][7]

SuNPe is a well-established provider among Rapid Prototyping Services Companies, delivering rapid prototyping, tooling, injection molding, and low-volume manufacturing for international clients. The company emphasizes quick turnaround and practical engineering support across consumer products, automotive components, and industrial devices.[4]

Key strengths:

- Combination of 3D printing, CNC machining, and molding workflows optimized for short-run and bridge production.[4]

- Experience working with overseas customers on iterative product development and multi-stage prototyping.[4]

RPProto focuses on cost-effective functional prototypes and pre-production batches, making it attractive to buyers who need testable parts before full-scale tooling investment. As one of the specialized Rapid Prototyping Services Companies in China, RPProto supports both metal and plastic components.[11]

Main features:

- CNC machining for high-precision prototypes that mimic final production parts.[11]

- Vacuum casting and rapid injection molding suitable for pilot runs and engineering verification builds.[11]

China 2 West offers rapid prototyping services heavily oriented toward design and early-stage product development. It is part of the broader ecosystem of Rapid Prototyping Services Companies providing fast 3D printed models and functional prototypes.[2]

Key advantages:

- Focus on quick 3D printing services that support visual models and ergonomic testing.[2]

- Ability to bridge from initial prototypes to broader manufacturing solutions through its wider network.[2]

JLC3DP has built a reputation for digital manufacturing, operating a large fleet of industrial 3D printers and CNC machines for rapid production. Within the network of Rapid Prototyping Services Companies, JLC3DP stands out for its high degree of automation and speed.[12]

Key advantages:

- Hundreds of machines capable of delivering parts within extremely short lead times, sometimes within 24 hours for standard jobs.[12]

- Capability to handle both plastic and metal 3D printing alongside CNC machining for more demanding tolerances.[12]

HLH Prototype provides a well-rounded offering that includes 3D printing, CNC machining, injection molding, and low-volume production. It serves global customers who need reliable Rapid Prototyping Services Companies capable of handling both early prototypes and short-run manufacturing.[13]

Key advantages:

- Diverse process portfolio and strong experience across automotive, aerospace, and consumer electronics sectors.[13]

- Ability to support both appearance models and highly functional engineering components.[13]

TiRapid has compiled lists of China-based Rapid Prototyping Services Companies that include providers with strong CNC machining and engineering credentials, such as Proto MFG. Many of these companies maintain ISO9001 and, in some cases, ISO13485 certifications for medical applications.[3]

Key advantages:

- Emphasis on precision CNC machined parts for demanding industries like medical and aerospace.[3]

- Quality systems and traceability that appeal to customers with strict regulatory or documentation requirements.[3]

PCBWay is widely known for PCB fabrication but also offers CNC machining and rapid prototyping for mechanical components. This makes it a flexible choice among Rapid Prototyping Services Companies, especially for electronics projects that need coordinated PCB and mechanical development.[14]

Key advantages:

- Rapid CNC machining services with lead times that can be as short as one day for standard parts.[14]

- Simplified sourcing for customers who need both circuit boards and mechanical housings or brackets.[14]

CNC Rapid focuses on providing quick-turn CNC machining and prototyping services with a strong emphasis on precision. The company is part of the cluster of Rapid Prototyping Services Companies that support automotive and industrial sectors with machined metal and plastic parts.[15]

Key advantages:

- Fast turnaround for prototype and low-volume CNC machined parts.[15]

- Focus on quality and tolerance control for functional components.[15]

Beyond the established names, China continues to produce emerging Rapid Prototyping Services Companies that specialize in niche technologies, materials, or industries. These companies often focus on advanced polymers, specialized surface treatments, or sector-specific solutions such as wearables or robotics.[1][3]

Typical characteristics:

- High flexibility in MOQs and a willingness to support complex, custom engineering projects.[1][3]

- Competitive pricing designed to attract startups and growth-stage companies developing innovative products.[1]

With so many Rapid Prototyping Services Companies available, selecting the right partner requires a structured approach that evaluates technical capability, communication, and long-term potential. For overseas brands, wholesalers, and manufacturers, this decision influences development speed, product quality, and total cost of ownership over multiple product generations.[3][4][1]

Essential selection criteria:

- Technical scope: Confirm the partner's expertise in CNC machining, 3D printing, sheet metal fabrication, molding, and surface finishing relevant to your project.[5][8][12][7]

- Quality systems: Look for ISO certifications, documented inspection procedures, and sample inspection reports to verify quality practices.[3][7]

- OEM experience: Prioritize factories with a strong track record serving international clients under NDAs, with robust communication and engineering support in English.[6][4][5]

- Scalability: Choose a partner capable of handling single prototypes, pilot runs, and full mass production as demand grows, ensuring a seamless ramp-up.[14][5][1]

In many cases, a one-stop partner like Shangchen offers a strategic advantage because it allows you to manage design, prototyping, and production under a unified engineering and quality framework, reducing risk and speeding up iteration cycles.[5][6][7]

China's manufacturing ecosystem provides a solid foundation for Rapid Prototyping Services Companies that support global innovation, from early-stage concept models to mass-produced OEM components. Companies like Shangchen (sc-rapidmanufacturing.com) lead this landscape by combining CNC machining services, 3D printing, sheet metal fabrication, precision batch production, and mold manufacturing into one integrated service platform for overseas brands, wholesalers, and manufacturers. By carefully evaluating technical capabilities, quality systems, and OEM experience, international buyers can find reliable long-term partners in China that accelerate development cycles, control costs, and deliver high-performance parts for demanding applications.[2][8][10][4][6][1][5][3][7]

Rapid Prototyping Services Companies in China support OEM brands by transforming CAD designs into physical parts using CNC machining, 3D printing, sheet metal fabrication, and molding within short lead times. Factories such as Shangchen can manage the full journey from prototype to precision batch production and long-term tooling, allowing OEM customers to consolidate suppliers and streamline product development.[8][6][1][5][7]

Industries that benefit most from Chinese Rapid Prototyping Services Companies include automotive, aerospace, medical devices, consumer electronics, industrial equipment, and sporting goods. These sectors rely on high-precision metal and plastic components, robust surface finishes, and rapid iteration cycles that Chinese factories are well equipped to support.[10][13][8][5][7]

CNC machining remains crucial for rapid prototyping because it delivers highly accurate metal and plastic parts with production-grade mechanical properties and tight tolerances. Among Rapid Prototyping Services Companies, CNC machining is often combined with 3D printing and molding to balance cost, speed, strength, and surface finish for different stages of product development.[12][15][8][5]

Lead times vary by complexity, quantity, and process, but many Rapid Prototyping Services Companies in China can produce simple CNC or 3D printed prototypes in a few days. Digital manufacturers like JLC3DP and PCBWay even offer turnaround times of about 24 hours for certain standard materials and geometries, which is valuable for urgent design validation.[12][14][1]

Shangchen stands out because it combines rapid prototyping, CNC machining services, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing inside one OEM-oriented factory. With certified quality systems, comprehensive inspection equipment, broad material capability, and extensive export experience, Shangchen is particularly suitable for overseas brands, wholesalers, and manufacturers seeking a long-term, one-stop partner in China.[6][8][10][5][7]

[1](https://ecoreprap.com/blog/5-best-rapid-prototyping-manufacturers-in-china/)

[2](https://www.china2west.com/rapid-prototyping-services-china/)

[3](https://tirapid.com/rapid-prototyping-services-china/)

[4](https://sunpe.com)

[5](https://www.sc-rapidmanufacturing.com/rapid-prototyping-knowledge.html)

[6](https://www.sc-rapidmanufacturing.com)

[7](https://shangchencnc.en.made-in-china.com/product/PxZUEtdKgHpo/China-on-Demand-CNC-Machining-for-Prototype-and-Production-Parts-with-Fast-Delivery-China-Export.html)

[8](https://www.sc-rapidmanufacturing.com/cnc-machining-knowledge.html)

[9](https://m.made-in-china.com/product/High-Quality-3D-Printing-Metal-and-Non-Metal-Material-Products-Machined-Parts-2026037432.html)

[10](https://www.sc-rapidmanufacturing.com/sheet-metal-fabrication-parts.html)

[11](https://www.rpproto.com)

[12](https://www.unionfab.com/blog/2025/12/top-3d-printing-service-providers-in-china)

[13](https://www.hlhprototypes.com)

[14](https://www.pcbway.com/rapid-prototyping/)

[15](https://cncrapid.com)

content is empty!