Views: 222 Author: Amanda Publish Time: 2026-01-04 Origin: Site

Content Menu

● Why China Leads in Rapid Prototyping

● Top 10 Rapid Prototyping Service Companies in China

>> 1. Shangchen (sc-rapidmanufacturing.com)

>> 2. WayKen Rapid Manufacturing

>> 3. 3ERP (3E Rapid Prototyping)

>> 4. TiRapid

>> 7. Kaiao Rapid Manufacturing

>> 8. RPWORLD

>> 10. SEAL-RP

● How to Select a Rapid Prototyping Partner

● Why Overseas OEMs Choose Shangchen

● FAQ

>> 1. How do Rapid Prototyping Service Companies shorten product development time?

>> 2. What industries typically rely on Rapid Prototyping Service Companies in China?

>> 3. Why should overseas OEMs consider Shangchen for rapid prototyping and CNC machining?

>> 4. What information should OEMs prepare before contacting a Rapid Prototyping Service Company?

>> 5. Can Rapid Prototyping Service Companies also support mass production?

China has become one of the most important global hubs for rapid prototyping and small-batch manufacturing, serving OEM customers in automotive, electronics, medical devices, industrial machinery, and consumer products. For overseas brand owners, wholesalers, and manufacturers, choosing reliable Rapid Prototyping Service Companies in China is now a strategic decision that directly influences development speed, cost, and product quality.[1][2][3]

China's manufacturing ecosystem combines mature supply chains, broad process capabilities, and competitive pricing, making it an ideal base for Rapid Prototyping Service Companies that support international markets. From concept models to functional prototypes and precision batch production, Chinese suppliers can cover the full journey from idea to market-ready product in a single country.[2][3][1]

Key reasons China leads this field include:

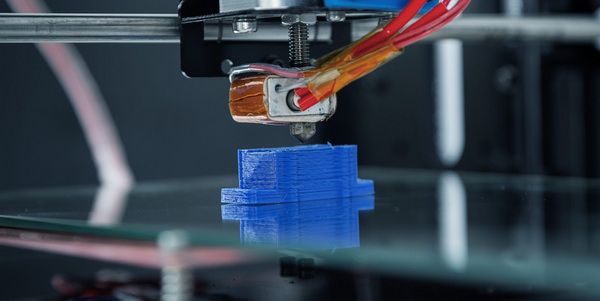

- Extensive availability of CNC machining, turning, sheet metal fabrication, 3D printing, casting, and molding technologies in one region.[3][1]

- Mature raw material supply for metals, plastics, elastomers, and engineering composites, supporting diverse OEM projects.[1][2]

- Experienced engineering teams familiar with international standards and export requirements for Europe, North America, and other regions.[2][1]

For overseas buyers, this means Rapid Prototyping Service Companies in China can handle complex mechanical parts, appearance models, functional components, and pilot production without spreading the work across multiple countries. The result is shorter development cycles, reduced logistics complexity, and more consistent quality from prototype to production.[4][3][1]

The following ten companies represent some of the most capable Rapid Prototyping Service Companies that frequently serve global OEM clients. Shangchen is highlighted first as a comprehensive partner for foreign brand owners, wholesalers, and manufacturers seeking one-stop OEM support.[5][6][1][2]

Shangchen is a China-based factory focused on rapid prototyping, CNC machining services, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing for overseas customers. Its business model centers on OEM services for foreign brand owners, wholesalers, and producers that require both prototypes and long-term, stable supply.[7][3][5]

Key capabilities include:

- CNC milling and turning for metals and engineering plastics, with tight tolerances suitable for functional mechanical components and precision housings.[4][5]

- Rapid prototyping processes such as 3D printing, sheet metal fabrication, and vacuum casting for structural, appearance, and ergonomic verification.[3][7]

- Mold design and fabrication that link early prototypes to scalable production through injection molding and other tooling-based processes.[7][3]

Shangchen's Rapid Prototyping Service Companies are structured to support short lead times, multiple design iterations, and engineering feedback throughout the development cycle. For OEM customers, the company functions as a technical partner, offering suggestions on manufacturability, material selection, and tolerance optimization based on real machining experience.[5][3][4]

The factory operates multi-axis machining centers, turning centers, and inspection equipment to maintain consistent quality across prototypes and precision batch production. Shangchen's Rapid Prototyping Service Companies have been applied across sectors such as automotive parts, consumer electronics casings, industrial machinery components, automation equipment, and custom fixtures.[4][5][7]

From a project perspective, Shangchen can handle:

- One-off functional prototypes with tight deadlines for lab tests and design reviews.[3][7]

- Small and medium batch runs where consistent quality, repeatable dimensions, and stable surface finishes are critical.[3][4]

- Transition to mass production where molds, jigs, and fixtures are needed to support large volumes, while preserving key performance characteristics established at the prototype stage.[7][3]

For overseas OEMs, working with Shangchen reduces the need to manage multiple suppliers, because its Rapid Prototyping Service Companies integrate machining, sheet metal work, 3D printing, and tooling under one project management system. This integrated approach improves communication, minimizes misinterpretation of design intent, and speeds up overall development and ramp-up timelines.[5][4][3]

WayKen Rapid Manufacturing, headquartered in Shenzhen, is widely recognized for its focus on high-quality visual models, functional prototypes, and low-volume production. Its service portfolio covers CNC machining, rapid tooling, vacuum casting, and 3D printing, positioning it among the best-known Rapid Prototyping Service Companies serving industrial designers and engineers worldwide.[1]

WayKen often supports projects requiring fine cosmetic finishes, transparent parts, and detailed appearance models used for trade shows, investor presentations, and marketing photography. The company's experience with international clients makes it a reliable choice when surface aesthetics and dimensional accuracy must be carefully balanced in Rapid Prototyping Service Companies.[1]

3ERP, based in Zhongshan, specializes in CNC milling, CNC turning, rapid tooling, and die casting for global OEM customers. It is one of the Rapid Prototyping Service Companies that emphasize precise machining of metal and plastic components in small- and medium-volume quantities.[1]

Typical applications include functional mechanical parts, structural elements, and tooling components where tolerances and material properties must match final production conditions as closely as possible. 3ERP's combination of machining and tooling capabilities helps customers shorten the transition from prototypes to production tooling within one supplier environment.[1]

TiRapid offers a comprehensive range of machining and rapid prototyping services, including 5-axis CNC machining, micro-part manufacturing, and large-size component processing. As one of the more technically oriented Rapid Prototyping Service Companies, TiRapid serves industries that require precise, complex geometries, such as aerospace, high-end industrial equipment, and energy-related components.[1]

The company emphasizes fast response times and cost-effective machining for overseas clients. Its blend of rapid prototyping and small-batch production is particularly suitable for projects where performance-critical parts must be validated under real-world operating conditions before full-scale manufacturing.[1]

Star Rapid, also located in Zhongshan, provides CNC machining, injection molding, vacuum casting, die casting, and 3D printing to customers around the world. It belongs to the group of Rapid Prototyping Service Companies that focus on combining prototyping with low-volume manufacturing and value-added finishing.[1]

Star Rapid handles metal and plastic components across multiple industries, supporting engineering verification, pilot production, and bridge manufacturing. For many OEMs, this combination of technologies allows the same supplier to produce initial prototypes, pre-production parts, and early market batches with consistent quality.[1]

SuNPe Prototype offers CNC machining, rapid tooling, vacuum casting, and low-volume injection molding for global customers. The company is known among Rapid Prototyping Service Companies for its ability to support the early stages of product commercialization, where quick, repeatable parts are needed for testing, certification, and market validation.[1]

SuNPe is frequently chosen by OEMs needing a balance between speed, price, and quality across both plastic and metal parts. Its rapid prototyping and small-batch manufacturing capabilities bridge the gap between R&D prototypes and the first commercial runs.[1]

Kaiao Rapid Manufacturing, based in Shenzhen, offers services such as CNC machining, SLA 3D printing, sheet metal fabrication, vacuum casting, and die casting. As one of the versatile Rapid Prototyping Service Companies, it supports both design verification models and functional prototypes for industrial and consumer products.[1]

The company's wide process range allows customers to combine different manufacturing methods within a single project, such as machined metal frames with 3D-printed plastic covers or sheet metal housings with cast components. This flexibility is valuable when evaluating multiple design paths in parallel during the product development process.[1]

RPWORLD focuses on CNC machining, plastic injection molding, urethane casting, 3D printing, and sheet metal fabrication. It has become a recognized name among Rapid Prototyping Service Companies that deliver engineering prototypes and small production batches to automotive, industrial, and medical device OEMs.[1]

RPWORLD's services help customers validate mechanical performance, assembly tolerances, and functional behavior before making large investments in production tooling. Its ability to provide detailed inspection reports and traceability also appeals to customers in regulated or safety-critical industries.[1]

APT Mold Manufacturing, located in Zhongshan, offers CNC machining, rapid tooling, plastic injection molding, stamping, and finishing services. The company's Rapid Prototyping Service Companies are particularly attractive to OEMs who want to quickly transition from prototype molds to production tools with minimal disruption.[1]

APT Mold supports design modifications, engineering changes, and optimization of gate locations, parting lines, and cooling channels during the rapid tooling phase. This iterative approach allows OEMs to refine both product design and tooling design before locking in long-term mass production molds.[1]

SEAL-RP is a major rapid prototyping specialist in China, providing plastic, metal, and nylon parts via 3D printing, CNC machining, and casting. As one of the longstanding Rapid Prototyping Service Companies, it handles complex geometries and customized parts for multiple sectors including automotive, consumer products, and industrial equipment.[2]

The company's emphasis on large-scale prototyping capacity and a broad material portfolio makes it a strong choice for OEM projects that require many variants, sizes, or configurations during the design phase. SEAL-RP's combination of additive and subtractive technologies gives engineering teams flexibility when exploring different design options.[2]

Selecting suitable Rapid Prototyping Service Companies in China requires more than comparing unit prices; it involves evaluating technical capability, communication, and scalability. For overseas OEM buyers, aligning the supplier's strengths with project requirements is essential for long-term success.[4][2][3][1]

Important selection criteria include:

- Process coverage: Ability to offer CNC machining, turning, sheet metal, 3D printing, casting, and molds to minimize supplier fragmentation.[3][1]

- Engineering support: Capability to provide design-for-manufacturing feedback, tolerance analysis, and material recommendations tailored to target applications.[4][3]

- Quality management: Inspection procedures, measurement equipment, documentation, and adherence to relevant international standards.[4][1]

- Project management: Fluent communication, clear lead-time commitments, and transparent handling of engineering changes and revisions.[5][7]

- Scalability: Proven ability to move from rapid prototypes to precision batch production and, where required, to full mass production.[3][1]

By partnering with Rapid Prototyping Service Companies that meet these conditions, international customers can reduce development risk, maintain consistent product quality, and accelerate time to market.[3][4][1]

Within the landscape of Rapid Prototyping Service Companies in China, Shangchen stands out as a practical, OEM-oriented partner for foreign brands and manufacturers. Its focus on integrated services and long-term cooperation makes it especially suitable for customers who view prototyping and production as a continuous process rather than separate stages.[7][5][3]

Shangchen offers:

- One-stop service that includes rapid prototyping, CNC machining services, turning, sheet metal fabrication, 3D printing, and mold manufacturing under a single project team.[5][3]

- Rapid Prototyping Service Companies designed to ensure that prototype dimensions, materials, and finishes are directly transferable to batch production and tooling-based manufacturing.[7][3]

- Experience with international communication, packaging requirements, logistics, and export documentation.[5][7]

For OEM buyers, this means fewer handovers, fewer misunderstandings, and a smoother ramp from first prototype to stable production. Shangchen's combined expertise in machining, sheet metal, and molds makes it easier to keep design intent intact while optimizing for cost and manufacturability.[4][5][3]

China's ecosystem of Rapid Prototyping Service Companies provides overseas OEM customers with powerful tools to accelerate product development, validate designs, and prepare for mass production. Among these, Shangchen (sc-rapidmanufacturing.com) offers a comprehensive blend of rapid prototyping, CNC machining services, sheet metal manufacturing, 3D printing, and mold production specifically tailored for international brand owners, wholesalers, and manufacturers. By selecting capable Rapid Prototyping Service Companies that combine technical expertise, broad process coverage, and reliable communication, global buyers can shorten time to market, manage risk, and secure long-term, high-quality manufacturing partnerships in China.[2][7][5][3][4][1]

Rapid Prototyping Service Companies in China use CNC machining, 3D printing, sheet metal fabrication, and other fast-turn processes to convert CAD data into physical parts within days instead of weeks. This allows engineers to perform design reviews, functional tests, and fit checks much earlier, reducing costly design mistakes before production tooling is ordered.[7][3][1]

Common users of Rapid Prototyping Service Companies include automotive, consumer electronics, medical devices, industrial automation, robotics, and household products. These industries benefit from frequent design iterations, realistic functional samples, and small-batch runs that enable certifications and early market testing before committing to full-scale production.[2][3][1]

Shangchen combines rapid prototyping, CNC machining services, turning, sheet metal fabrication, 3D printing, and mold manufacturing in one factory, making it well suited to OEM customers needing integrated support. Its Rapid Prototyping Service Companies are designed to maintain dimensional accuracy and surface quality from early prototypes through precision batch production, helping overseas buyers avoid issues when scaling up.[5][3][4]

Before approaching Rapid Prototyping Service Companies, OEMs should prepare 3D CAD models, engineering drawings with tolerances, material specifications, expected quantities, and surface finish or color requirements. Clear project timelines, target applications, and special standards or certifications also help suppliers propose suitable processes and realistic delivery schedules.[3][4][1]

Many Rapid Prototyping Service Companies in China, including Shangchen, offer a path from one-off prototypes to precision batch production and, with appropriate tooling, to high-volume manufacturing. This continuity reduces the risk associated with changing suppliers between development and production, and helps preserve critical design features and quality standards throughout scale-up.[4][5][3][1]

[1](https://tirapid.com/rapid-prototyping-services-china/)

[2](https://ensun.io/search/rapid-prototyping/china)

[3](https://www.sc-rapidmanufacturing.com/rapid-prototyping-knowledge.html)

[4](https://www.sc-rapidmanufacturing.com/cnc-machining-knowledge.html)

[5](https://www.sc-rapidmanufacturing.com)

[6](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[7](https://www.sc-rapidmanufacturing.com/news.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal