Views: 222 Author: Amanda Publish Time: 2025-12-31 Origin: Site

Content Menu

● Why Work with Rapid Prototype Machining Manufacturers in China?

● No.1 – Shangchen (sc-rapidmanufacturing.com)

>> Integrated Manufacturing Capabilities

>> Services Designed for Overseas OEM Brands

>> Quality Control and Engineering Assurance

>> Typical Application Scenarios

>> Communication, Logistics, and Support

● Other Leading Rapid Prototype Machining Manufacturers in China

>> 3ERP (3E Rapid Prototyping)

>> TiRapid

>> Star Rapid

>> RPWORLD

>> SEAL-RP

● How to Choose the Right Rapid Prototype Machining Manufacturers Partner

>> When Shangchen Is a Strong Choice

● Best Practices for Working with Rapid Prototype Machining Manufacturers

● FAQ – Rapid Prototype Machining Manufacturers

>> 1. What are Rapid Prototype Machining Manufacturers?

>> 2. What services do Rapid Prototype Machining Manufacturers typically provide?

>> 3. Why should overseas buyers choose Chinese Rapid Prototype Machining Manufacturers like Shangchen?

>> 4. How can buyers ensure quality when working with Rapid Prototype Machining Manufacturers?

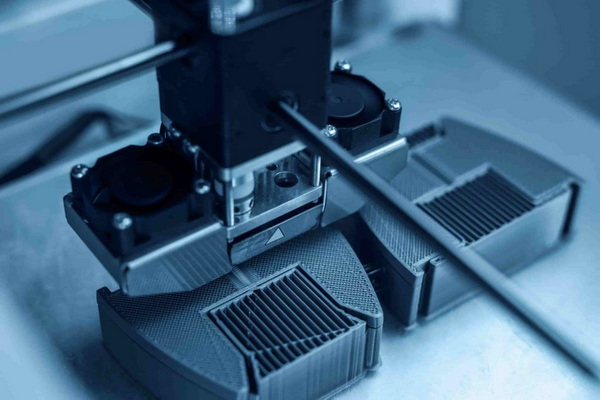

China has evolved into a global center for Rapid Prototype Machining Manufacturers, offering integrated solutions that cover everything from initial design validation to OEM-level mass production for international customers. Global brands, wholesalers, and contract manufacturers increasingly rely on Chinese partners to shorten development cycles and control manufacturing costs without compromising quality.

China's mature industrial ecosystem gives Rapid Prototype Machining Manufacturers access to dense supply chains, advanced CNC equipment, and competitive labor costs, which together create a powerful advantage for overseas buyers. The combination of fast lead times, broad process coverage, and strong export experience makes China a preferred destination for prototype and low-volume manufacturing projects.

Key advantages include:

- Short lead times from CAD data to finished parts, even for complex designs.

- Flexible order quantities, from a single prototype to pilot batches and repeat production.

- Wide material selection, including aluminum alloys, stainless steel, tool steels, brass, copper, titanium, and engineering plastics such as ABS, PC, PEEK, and nylon.

- Integrated value-added services such as DFM support, surface finishing, assembly, and packaging tailored for export.

For buyers looking to move quickly from concept to market, choosing strong Rapid Prototype Machining Manufacturers in China can significantly reduce risk in the early stages of product development and improve the overall cost structure of the project.

Shangchen is a professional Chinese factory that provides rapid prototyping, CNC machining services, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing to overseas OEM customers. As a one-stop choice among Rapid Prototype Machining Manufacturers, Shangchen focuses on high-precision components, consistent quality, and reliable communication for international brands and wholesalers.

Unlike suppliers that only offer a single process, Shangchen integrates a full chain of rapid prototyping and production services under one roof. This makes Shangchen one of the most versatile Rapid Prototype Machining Manufacturers for customers who need both engineering flexibility and production stability.

Core capabilities include:

- CNC milling and 5-axis machining for intricate geometries, undercuts, and multi-surface contours.

- CNC turning and turn-milling for cylindrical parts, shafts, inserts, and bushings.

- Sheet metal fabrication (laser cutting, bending, punching, welding, tapping) for enclosures, chassis, brackets, and structural components.

- 3D printing technologies such as SLA, SLS, FDM, and MJF to create concept models, snap-fit prototypes, and complex internal structures.

- Vacuum casting and soft tooling to bridge between 3D printing and full injection molding, suitable for small runs and functional testing.

- Mold design and mold making for plastic injection components and metal tools that can scale into mass production.

Shangchen structures its service model specifically around the needs of international OEM buyers, product developers, and engineering teams. As one of the export-oriented Rapid Prototype Machining Manufacturers, it understands the importance of clear communication and predictable delivery.

Typical services include:

- OEM and ODM project support from the concept stage, including early DFM reviews and cost-down proposals.

- Rapid prototyping for industrial design review, mechanical verification, and pre-compliance testing.

- Small and medium batch manufacturing to support pilot runs, marketing builds, and regional launches.

- Long-term OEM cooperation for recurring orders where consistency and traceability are essential.

- Support for diverse sectors such as automotive parts, industrial automation equipment, smart home products, consumer electronics, and medical-related device components (non-implantable).

To stay competitive among demanding Rapid Prototype Machining Manufacturers, Shangchen applies strict process controls throughout every stage of production. Quality is built into the workflow instead of being treated only as a final inspection step.

Key quality practices:

- Use of calibrated inspection tools such as CMM, projectors, height gauges, micrometers, and hardness testers.

- Incoming inspection of raw materials with certificates and traceability records when required.

- First Article Inspection (FAI) and sample confirmation before full batch machining.

- In-process and final inspections following critical dimensions indicated on 2D drawings.

- Detailed reporting, photos, dimensional lists, and documentation to support international customers' quality systems.

This structured approach allows Shangchen, as one of the dedicated Rapid Prototype Machining Manufacturers, to support projects with tight tolerances, complex geometries, and stringent reliability requirements.

Shangchen supports customers at multiple stages of the product life cycle, and this flexibility is a major reason buyers choose it over more limited Rapid Prototype Machining Manufacturers.

Common project types:

- Concept and appearance models for investor pitches, trade shows, and early market feedback.

- Mechanical prototypes for fit, form, and function testing, including assemblies and moving mechanisms.

- Engineering validation builds used for lab testing, safety assessments, and regulatory preparations.

- Pre-production and pilot batches that simulate final production conditions before full ramp-up.

- Replacement parts and continuous improvement iterations for existing equipment and product lines.

International customers working with Rapid Prototype Machining Manufacturers need smooth communication and stable logistics. Shangchen emphasizes customer experience alongside manufacturing capability.

- Professional English-speaking project managers and engineers who understand industrial terminology.

- Detailed quotations that break down material, process, and finishing costs.

- Flexible shipping solutions through express couriers, air freight, or sea freight, depending on budget and timeline.

- Secure packaging designed to protect precision parts during long-distance transportation.

- After-sales support for design changes, follow-up batches, and engineering improvements.

While Shangchen is positioned as a comprehensive partner, many other Rapid Prototype Machining Manufacturers in China also offer strong capabilities for specific needs, industries, or order scales. Below are nine representative companies that are frequently mentioned in industry discussions and sourcing guides.

WayKen focuses on rapid prototyping and low-volume manufacturing, offering CNC machining, rapid tooling, vacuum casting, and 3D printing. As one of the established Rapid Prototype Machining Manufacturers, it often works on automotive show parts, industrial design models, and invisible-tolerance plastic components for global design houses.

3ERP provides CNC milling, CNC turning, casting, and rapid tooling services for plastic and metal parts. It is considered one of the widely recognized Rapid Prototype Machining Manufacturers for customers who require a mix of quick-turn prototypes and small-batch production with export-ready quality documentation.

TiRapid is known for precision machining, including 5-axis CNC, micro machining, and high-accuracy work on small components. This makes it a suitable choice among Rapid Prototype Machining Manufacturers for optics, miniature devices, and precision instruments where micrometer-level tolerances are critical.

Star Rapid offers CNC machining, plastic injection molding, SLA and SLS 3D printing, vacuum casting, die casting, and other services under formal quality management systems. International buyers often choose Star Rapid from the pool of Rapid Prototype Machining Manufacturers because of its strong communication, established export history, and transparent project workflows.

SuNPe specializes in CNC machining, rapid tooling, and low-volume manufacturing for both plastic and metal parts. It is a popular name among Rapid Prototype Machining Manufacturers for customers who expect a smooth transition from prototype molds to long-running tools, especially in automotive and appliance applications.

Kaiao offers CNC machining, SLA 3D printing, vacuum casting, RIM, sheet metal fabrication, and metal casting. With long-term experience and a broad process range, it competes among Rapid Prototype Machining Manufacturers that serve consumer electronics, telecom products, and high-detail cosmetic parts.

Vowin provides CNC machining, 3D printing, injection molding, and urethane casting. As one of the flexible Rapid Prototype Machining Manufacturers, it targets quick-turn prototypes and short-run orders where appearance quality and lead time are more critical than very high volumes.

RPWORLD combines CNC machining, injection molding, sheet metal, and 3D printing capabilities to support both rapid prototyping and production services. It is often chosen from the wider list of Rapid Prototype Machining Manufacturers by customers in medical devices, industrial instrumentation, and specialized equipment sectors.

APT Mold is focused on mold making, CNC machining, injection molding, and stamping. This positions it as one of the tool-oriented Rapid Prototype Machining Manufacturers for buyers who want to move quickly from prototype molds to production tooling and then to stable mass-production capacity.

SEAL-RP works extensively with 3D printing, CNC machining, and urethane casting, especially for complex prototypes that require multiple material types or advanced internal structures. It is another specialist among Rapid Prototype Machining Manufacturers serving product designers and R&D teams that need high flexibility.

With many options available, choosing suitable Rapid Prototype Machining Manufacturers requires a structured evaluation approach. The right partner should match the project's technical demands, schedule, budget, and long-term strategy.

Consider the following criteria:

- Technical capabilities: Check axis count, machine types, supported materials, achievable tolerances, and maximum part size.

- Process coverage: Confirm whether the supplier can handle all required processes, such as CNC machining, sheet metal, 3D printing, casting, and molding, or whether multiple vendors are needed.

- Quality systems: Ask about inspection equipment, quality certifications, sample control, and documentation practices.

- Engineering support: Evaluate the ability to provide DFM feedback, tolerance optimization, cost-down suggestions, and risk identification.

- Communication and service: Look at responsiveness, language skills, project tracking, and how issues are managed if something goes wrong.

- Cost and lead time: Compare quotations not only on unit price but also on lead time, shipping costs, and potential rework risks.

Shangchen is particularly suitable for buyers who need a single Rapid Prototype Machining Manufacturers partner that can support everything from initial idea validation to long-term OEM batch production.

Situations where Shangchen is an ideal fit:

- Projects that require multiple manufacturing processes in one project, such as a mix of CNC machining, sheet metal parts, and plastic components.

- Overseas customers who prefer communicating with one dedicated project team instead of managing several suppliers.

- R&D teams that expect engineering suggestions to improve manufacturability, cost, and reliability before locking the design.

- Brands that plan to start with small quantities but have a clear roadmap toward batch or serial production.

To gain maximum benefit from Rapid Prototype Machining Manufacturers, overseas buyers should follow several best practices during project preparation and execution.

Recommended actions:

- Provide clear 3D CAD models and 2D drawings, including tolerances, surface finishes, and critical dimensions.

- Share information about the product's end use, expected loads, environment, and compliance requirements so engineers can recommend suitable materials and processes.

- Prioritize critical features in the drawing and leave non-essential areas with more generous tolerances to save cost and reduce scrap.

- Clarify delivery expectations, including target dates, batch sizes, and preferred shipping methods.

- Start with trial orders or sample runs to validate quality and communication before committing large-scale business.

When both sides treat the relationship as a long-term cooperation rather than a one-time transaction, Rapid Prototype Machining Manufacturers can contribute significant engineering value to future product generations.

China offers a broad landscape of Rapid Prototype Machining Manufacturers, each with different strengths, scales, and industry focuses. For international brands and OEMs, these suppliers make it possible to shorten development cycles, test multiple design iterations, and bring new products to market faster and more economically.

Among these suppliers, Shangchen (sc-rapidmanufacturing.com) stands out as a comprehensive, engineering-driven factory that integrates rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold manufacturing under one roof. With a focus on overseas customers, strong communication, and strict quality control, Shangchen is a reliable choice for companies seeking a long-term Rapid Prototype Machining Manufacturers partner in China.

Rapid Prototype Machining Manufacturers are specialized factories that use CNC machining, 3D printing, sheet metal fabrication, and related processes to transform digital 3D models into physical prototypes and small batches in a short time. They help engineers and designers validate fit, form, and function before committing to mass-production tooling, reducing risk and overall development cost.

Most Rapid Prototype Machining Manufacturers provide a combination of CNC milling, CNC turning, 3D printing, vacuum casting, sheet metal fabrication, and sometimes injection molding or die casting. Many also offer value-added services such as surface finishing, painting, anodizing, powder coating, silk-screen printing, assembly, and packaging to supply parts that are close to final production condition.

Chinese Rapid Prototype Machining Manufacturers offer competitive pricing, fast turnaround, and extensive process coverage in a single location. A partner such as Shangchen can handle multiple manufacturing technologies, provide useful DFM feedback, and support both prototype and batch production, which reduces coordination effort and speeds up the transition from idea to finished product.

To ensure quality, buyers should provide detailed drawings, specify tolerances and critical surfaces, and request inspection reports for important dimensions. Choosing Rapid Prototype Machining Manufacturers that have formal quality systems, calibrated inspection equipment, and clear communication channels allows issues to be identified and resolved quickly. Starting with sample runs and gradually increasing volume is a practical way to confirm quality consistency.

Before requesting a quotation, buyers should prepare 3D CAD files, 2D drawings with key dimensions, material specifications, and information on quantity and required delivery dates. It is also useful to describe the part's application, functional requirements, and any special surface or certification needs so Rapid Prototype Machining Manufacturers can provide accurate pricing, suitable process choices, and realistic lead times.

content is empty!