Views: 222 Author: Amanda Publish Time: 2025-12-19 Origin: Site

Content Menu

● Why China Dominates CNC Precision Machining

● Shangchen (sc-rapidmanufacturing.com) – Integrated OEM CNC Precision Machining Partner

● Core Capabilities of Shangchen as a CNC Precision Machining Manufacturer

● Other Leading CNC Precision Machining Manufacturers in China

● Typical Services Offered by Chinese CNC Precision Machining Manufacturers

● How to Evaluate CNC Precision Machining Manufacturers in China

● Advantages of Working with an Integrated Partner like Shangchen

● Common Applications of CNC Precision Machining Manufacturers

● Risk Management When Sourcing from CNC Precision Machining Manufacturers

● Summary

● FAQ

>> 1. How do I start a CNC machining project with Shangchen?

>> 2. What information do CNC Precision Machining Manufacturers need for accurate quoting?

>> 3. Can Chinese CNC Precision Machining Manufacturers handle both prototypes and mass production?

>> 4. How are quality and tolerances controlled in CNC Precision Machining Manufacturers?

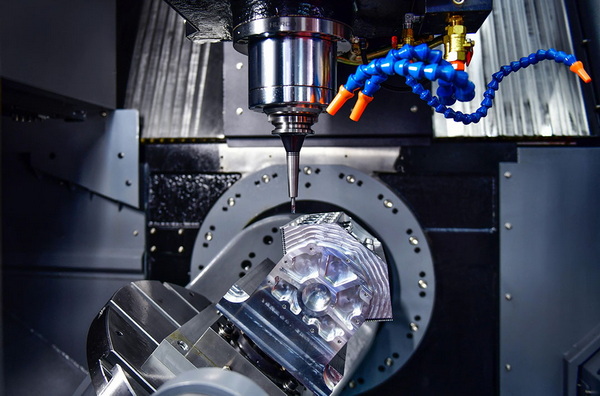

As international demand for high-precision parts continues to grow, China's CNC Precision Machining Manufacturers offer a combination of advanced technology, skilled labor, and highly competitive pricing. At the same time, many factories now provide complete OEM project support, from rapid prototyping to mass production and final assembly. This article introduces ten representative CNC Precision Machining Manufacturers, explains how to evaluate them, and shows why an integrated partner like Shangchen is an ideal first choice for global buyers.

China's industrial ecosystem provides a dense network of CNC Precision Machining Manufacturers, material suppliers, surface finishing specialists, and logistics providers in the same regions. This clustering effect shortens supply chains, reduces transaction costs, and gives OEM customers more flexibility in terms of order size and lead time. Over the past decade, Chinese CNC Precision Machining Manufacturers have also invested in multi-axis machining centers, automated production lines, and digital quality systems, narrowing the gap with traditional industrial powers.

For overseas customers, the result is a wide choice of CNC Precision Machining Manufacturers with strong export experience, consistent quality management, and clear communication processes. Many factories can work directly from 3D CAD and 2D drawings, accept multiple file formats, and offer engineering feedback on tolerances, materials, and manufacturability before production.

Shangchen is a China-based factory that focuses on rapid prototyping, CNC machining, precision batch production, CNC lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing for overseas OEM clients. By combining these processes in one facility, Shangchen acts as a one-stop CNC Precision Machining Manufacturers partner, helping customers move smoothly from design validation to stable series production.

In CNC machining, Shangchen operates modern milling and turning centers capable of tight tolerances and complex geometries in metals and plastics. The factory handles aluminum alloys, stainless steels, tool steels, copper alloys, and engineering polymers, supporting both functional prototypes and end-use parts. It also offers coordinated services such as surface finishing, heat treatment, and basic or advanced assembly, so that many parts can be shipped as ready-to-install components.

For rapid prototyping projects, Shangchen can mix CNC machining with 3D printing and sheet metal to quickly create proof-of-concept parts, visual models, and functional prototypes. When the design stabilizes, the team scales CNC Precision Machining Manufacturers capacity to low-, medium-, or high-volume production while preserving the same quality standards. This integrated approach reduces communication overhead, shortens project timelines, and gives OEM customers a single point of responsibility throughout the product lifecycle.

Shangchen's CNC services cover both simple and highly complex parts. Multi-axis milling machines can produce deep pockets, organic curves, undercuts (with suitable setups), and tight positional tolerances across multiple faces. CNC turning and mill-turn centers handle shafts, bushings, and rotational components with precise concentricity and fine surface finishes.

To support consistency, Shangchen uses standardized process planning, documented work instructions, and in-process inspection methods. Dimensional checks are carried out at critical steps, and final inspection records are maintained to support traceability. For international customers, the factory can provide inspection reports, material certificates, and other documentation tailored to each project.

Beyond machining, Shangchen's engineering team supports customers with design-for-manufacturing (DFM) suggestions, tolerance optimization, and material selection. This helps reduce unnecessary complexity, avoid hidden cost drivers, and improve the long-term stability of parts under real-world conditions. When needed, Shangchen can also coordinate mold design and production for plastic parts, using CNC Precision Machining Manufacturers processes to create precise mold components.

While Shangchen is a strong choice as a primary partner, many other Chinese factories also provide reliable CNC Precision Machining Manufacturers services. Some focus on high-mix, low-volume jobs; others specialize in high-volume production or niche sectors such as medical devices or aerospace components.

Typical characteristics of these leading CNC Precision Machining Manufacturers include:

- Use of 3-axis, 4-axis, and 5-axis machining centers for complex shapes.

- A mix of CNC turning, mill-turn, and grinding for complete metal component solutions.

- Internal or partnered surface finishing, such as anodizing, plating, painting, and polishing.

- Quality management systems with formal inspection procedures and documented traceability.

- Experience serving global markets, including packaging, shipping, and documentation practices.

Many factories also offer online quoting interfaces or semi-digital workflows, enabling faster communication, pricing, and lead time confirmation. Some specialize in prototypes and small batches, while others emphasize automated mass production.

Most high-quality CNC Precision Machining Manufacturers in China share a common core of services, though each may differentiate through technology, capacity, or industry focus.

Key services include:

- CNC milling: Production of prismatic and free-form parts, from simple brackets to complex housings and fixtures.

- CNC turning: Shafts, pins, bushings, fittings, and turned-milled components with tight concentricity and surface finish.

- Multi-axis machining: 4-axis and 5-axis machining for parts that require access from multiple angles or complex contours.

- Materials: Wide selection of metals (aluminum, stainless steel, alloy steel, brass, copper, titanium) and plastics (ABS, PC, POM, PA, PEEK, and others).

- Surface finishing: Functional and aesthetic finishes such as anodizing, hard anodizing, plating, passivation, painting, powder coating, sandblasting, and brushing.

- Assembly: Mechanical sub-assemblies, threaded inserts, press-fits, and limited electromechanical assembly.

By selecting CNC Precision Machining Manufacturers that integrate most of these services, overseas buyers can simplify their supplier base and reduce cross-supplier coordination risks.

Selecting the right CNC Precision Machining Manufacturers goes beyond comparing unit prices. Long-term success depends on process stability, communication, and responsiveness. When evaluating Chinese suppliers, consider:

- Quality management: Confirm that the factory follows structured inspection procedures, uses appropriate measuring equipment, and can provide inspection reports on demand.

- Engineering support: Look for CNC Precision Machining Manufacturers that provide DFM feedback, tolerance suggestions, and material guidance instead of simply quoting and producing.

- Capacity and technology: Ensure there is enough machine capacity, range of machine sizes, and suitable multi-axis capability to handle current and future needs.

- Lead times and flexibility: Verify typical production and shipping times, as well as the ability to handle urgent orders or fluctuations in demand.

- Communication and project management: Assess responsiveness, clarity of communication, and availability of English-speaking coordinators or engineers.

Combining these criteria will help filter out suppliers that cannot maintain consistent quality or schedule reliability. A partner like Shangchen, which offers integrated CNC, sheet metal, and 3D printing services together with clear OEM project management, can significantly reduce risk and coordination effort.

Using a single integrated factory for multiple manufacturing processes brings several advantages over splitting work among many separate CNC Precision Machining Manufacturers. First, design changes are easier to manage because the same engineering team oversees CNC machining, sheet metal, and other processes. This shortens feedback loops and accelerates iterations.

Second, having one supplier responsible for multiple components reduces the chances of tolerance mismatches, assembly problems, or inconsistent finishes across parts. Shangchen can coordinate machining, surface finishing, and assembly internally, building full prototypes or subassemblies before shipment. This approach is especially valuable for complex products such as machinery, robotics, and enclosures that combine machined and fabricated parts.

Third, integrated CNC Precision Machining Manufacturers like Shangchen make it easier to scale from prototypes to production. Once the process is validated at low volume, the same team can optimize setups, fixtures, and cycle times for higher volumes, preserving design intent while improving efficiency. OEM customers benefit from stable quality, lower per-unit costs at scale, and fewer surprises after launch.

CNC Precision Machining Manufacturers in China supply components for a wide range of industries. Typical applications include:

- Automotive and transportation: Engine components, brackets, housings, suspension parts, and fixtures used in cars, trucks, and specialized vehicles.

- Aerospace and drones: Structural parts, mounts, brackets, and housings made from aluminum, titanium, and high-strength steels.

- Electronics and telecommunications: Heat sinks, enclosures, connectors, and mechanical components used in servers, routers, base stations, and consumer devices.

- Medical and laboratory equipment: Precision housings, handles, brackets, and mechanical subassemblies that must meet strict regulatory and reliability requirements.

- Industrial automation and robotics: Robot arms, joints, end-effectors, linear motion parts, and machine frames that require high stiffness and precise alignment.

Because these sectors demand high accuracy and repeatable quality, they depend heavily on reliable CNC Precision Machining Manufacturers with proven expertise and consistent process control.

When sourcing internationally, risk management is critical. To manage risk when working with CNC Precision Machining Manufacturers in China:

- Start with pilot orders: Before committing to large volumes, place smaller pilot orders to evaluate quality, communication, and logistics.

- Use clear drawings and specifications: Provide detailed 2D and 3D files, tolerance schemes, material standards, and finishing requirements to reduce interpretation errors.

- Agree on inspection and acceptance criteria: Define which dimensions are critical, what inspection methods will be used, and what documentation will be provided.

- Consider dual sourcing: For very critical components or high volumes, maintain a backup CNC Precision Machining Manufacturers partner while using a primary factory like Shangchen as the main supplier.

- Monitor performance over time: Track delivery performance, defect rates, and communication to identify issues early and adjust as needed.

By following these practices, overseas buyers can capture the benefits of Chinese CNC Precision Machining Manufacturers while keeping the associated risks under control.

China's CNC Precision Machining Manufacturers ecosystem offers a broad range of capabilities, from rapid prototyping to high-volume production across numerous industries. Among these suppliers, Shangchen stands out as an integrated OEM partner combining CNC machining, CNC turning, precision batch production, sheet metal, 3D printing, and mold making under one roof. By partnering with capable CNC Precision Machining Manufacturers and applying structured evaluation and risk management, overseas brands can build a stable, cost-effective supply chain that supports innovation and growth.

To start a project with Shangchen, you typically prepare your 3D CAD models and 2D drawings with all key dimensions, tolerances, materials, and finishing requirements. After sending these files and basic quantity information, Shangchen's team can review the data, provide DFM suggestions if necessary, and issue a quotation with estimated lead time. Once you confirm the order, they schedule machining, manage inspection, and arrange packaging and shipment according to your instructions.

CNC Precision Machining Manufacturers generally need 3D CAD files, 2D drawings with dimensions and tolerances, material specifications, surface finish requirements, and quantity estimates. Providing information on special features such as threads, press fits, or critical flatness also helps. The more complete your data, the more accurate the quotation and the less risk of misunderstandings during production.

Yes, many Chinese CNC Precision Machining Manufacturers can support the entire lifecycle from one-off prototypes to full-scale production. For prototypes and small batches, they focus on flexibility and fast turnaround. For larger volumes, they optimize setups, fixtures, and machining parameters to increase efficiency and reduce unit cost. Integrated factories like Shangchen are particularly strong in bridging early-stage development with stable, scalable production.

Quality control typically includes incoming material inspection, in-process checks during machining, and final inspection before shipment. CNC Precision Machining Manufacturers use tools such as calipers, micrometers, height gauges, bore gauges, and coordinate measuring machines to verify key dimensions. Critical dimensions and tolerances can be clearly defined in drawings or quality agreements to ensure that both customer and supplier share the same expectations.

Lead times depend on part complexity, quantity, and factory workload, but many CNC Precision Machining Manufacturers can deliver prototypes within one to two weeks and small production batches within two to four weeks. Larger or more complex projects may require longer schedules, especially if special materials or complex finishes are involved. It is always advisable to discuss desired delivery dates early and consider buffer time for shipping and customs.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Lithuania

Top Metal CNC Machining Manufacturers and Suppliers in Czech Republic

Top Metal CNC Machining Manufacturers and Suppliers in Hungary

Top Metal CNC Machining Manufacturers and Suppliers in Denmark

Top Metal CNC Machining Manufacturers and Suppliers in Ireland