Views: 222 Author: Amanda Publish Time: 2025-12-12 Origin: Site

Content Menu

● Introduction to CNC Plastic Machining Manufacturers in China

● Why China Leads in CNC Plastic Machining

● How to Evaluate CNC Plastic Machining Manufacturers

● 1. Shangchen – One-Stop CNC Plastic Machining Manufacturer in China

>> Core CNC Plastic Machining Capabilities

>> Services Beyond CNC Plastic Machining

>> OEM Experience and Application Scenarios

● 2. Yijin Hardware – Precision CNC Machining and Plastic Components

● 3. RapidDirect – Digitally Enabled CNC Plastic Machining in China

● 4. WayKen – Prototyping Specialist in CNC Plastic Machining

● 5. GENSUN – Precision CNC Machining with Structured Quality Systems

● 6. Holly – CNC Plastic Parts with Long-Term Manufacturing Experience

● 7. Runsom Precision – CNC Plastic Machining for Small and Complex Parts

● 8. NICE Rapid – CNC Plastic Machining and Rapid Tooling

● 9. PCBWay – Prototyping-Oriented CNC Plastic Machining

● 10. Other Notable CNC Plastic Machining Manufacturers in China

● Key Considerations When Working with CNC Plastic Machining Manufacturers

● FAQs

>> 1. What industries most frequently use CNC plastic machining manufacturers in China?

>> 2. Which plastic materials are typically used by CNC plastic machining manufacturers?

>> 3. How do CNC plastic machining manufacturers in China ensure quality for overseas customers?

>> 4. What are typical lead times when ordering from CNC plastic machining manufacturers in China?

>> 5. Why is Shangchen a strong choice for OEM projects among CNC plastic machining manufacturers?

CNC plastic machining manufacturers in China are vital partners for global companies that need precise, durable plastic components for demanding applications. They support industries such as automotive, electronics, medical-related products, robotics, and industrial automation by supplying custom CNC machined plastic parts with tight tolerances and consistent quality. These CNC plastic machining manufacturers combine advanced CNC equipment, engineering expertise, and flexible production models to deliver everything from one-off prototypes to medium-volume batch runs.

For overseas brand owners, wholesalers, and OEM producers, selecting the right CNC plastic machining manufacturers in China has a direct impact on product performance, project timelines, and overall cost structure. A strong supplier can help optimize designs for manufacturability, suggest suitable plastic materials, and manage complex assemblies that combine plastic, metal, and electronic components. This article introduces ten notable CNC plastic machining manufacturers in China, with Shangchen (sc‑rapidmanufacturing.com)highlighted as a comprehensive one-stop OEM service provider.

China has developed a dense cluster of CNC plastic machining manufacturers that benefit from mature industrial infrastructure and extensive upstream and downstream supply chains. These suppliers have access to a broad range of engineering plastics, cutting tools, coatings, and finishing services, which allows them to offer highly integrated solutions to international clients. At the same time, competitive labor and operating costs enable Chinese CNC plastic machining manufacturers to provide cost-effective services without sacrificing quality.[1][2]

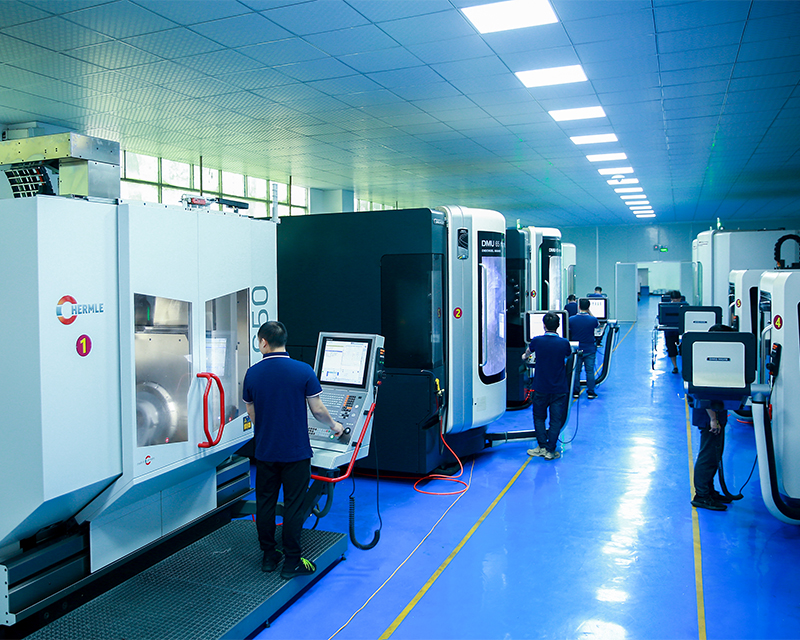

Many CNC plastic machining manufacturers in China have invested heavily in modern multi-axis CNC machining centers, automated tooling systems, and inspection equipment. This investment supports high repeatability and enables efficient production of complex geometries that might previously have required multiple setups or custom fixtures. As a result, product developers can iterate faster, reduce the number of design cycles, and bring products to market more quickly, while still benefiting from attractive pricing.[3]

When comparing CNC plastic machining manufacturers, buyers should look beyond basic price quotes and evaluate the overall capability and long-term suitability of each supplier. Critical aspects include engineering support in plastics, quality control systems, communication, and scalability for future volume increases. International buyers should also consider the supplier's familiarity with export documentation, packaging standards, and logistics coordination.[2]

Key evaluation criteria for CNC plastic machining manufacturers include:

- Technical capability in plastic materials, tolerance control, and design for manufacturability.

- Breadth of in-house services, such as rapid prototyping, CNC machining, sheet metal, 3D printing, and mold fabrication.[4]

- Certifications or documented quality systems, backed by inspection reports and traceable processes.[2]

- Communication efficiency, including design feedback and responsiveness during quotation and production.

- Ability to support OEM-style cooperation with confidentiality, branding, and flexible production plans.[1]

With those factors in mind, the following sections introduce ten representative CNC plastic machining manufacturers in China, starting with Shangchen as a versatile, full-service OEM partner.

Shangchen (sc-rapidmanufacturing.com) is a Chinese factory dedicated to rapid prototyping, CNC machining services, precision batch production, lathe turning, sheet metal fabrication, 3D printing services, and mold manufacturing for overseas customers. The company positions itself among the leading CNC plastic machining manufacturers by combining extensive plastic machining capability with comprehensive support for metal parts and tooling.[5][4]

Shangchen operates advanced 3-axis, 4-axis, and 5-axis CNC machining centers that can handle both simple and highly complex plastic components. Typical operations include milling, turning, drilling, tapping, and contouring of engineering plastics into housings, brackets, fixtures, connectors, and structural pieces used in a wide range of products. Common materials processed by this CNC plastic machining manufacturer include ABS, POM, PC, PMMA, Nylon, and other engineering plastics used for industrial and consumer applications.[6][4]

The company supports a complete digital workflow for CNC plastic machining: CAD data review, manufacturability assessment, CAM programming, fixture design, and optimized toolpaths to achieve stable quality and efficient cycle times. Quality control is integrated at multiple stages, combining in-process checks with final inspections to ensure parts conform to dimensional and functional requirements for OEM projects.[3][4]

In addition to CNC plastic machining, Shangchen offers a wide range of complementary manufacturing services. These include rapid prototypes in plastic and metal for early-stage design validation, as well as precision batch production to support small and medium volume orders. Lathe turning capabilities allow Shangchen to produce precise cylindrical plastic parts such as bushings, spacers, and custom connectors.[4][5]

Shangchen's sheet metal fabrication services are often used to produce enclosures, brackets, and frames that are assembled together with CNC machined plastic components. The company also provides industrial 3D printing services, which can be used to rapidly validate geometries before moving to CNC plastic machining or to produce parts with internal structures that are difficult to achieve by subtractive methods. For customers who eventually require higher-volume production, Shangchen's mold manufacturing services enable a smooth transition from CNC machined plastic prototypes to injection molded parts.[5][4]

Shangchen has significant experience working directly with overseas brand owners, wholesalers, and manufacturers as an OEM and private-label production partner. The company can support custom branding, confidential project management, and packaging according to client requirements. Many international customers rely on Shangchen as their main CNC plastic machining manufacturer for both development and ongoing supply.[4][5]

Typical application scenarios include:

- Precision plastic housings for electronics, smart devices, and industrial controllers.

- Functional components for automation systems, robotics, and laboratory equipment.

- Structural and visual prototypes for automotive and consumer products.

- Low-to-medium volume production of assembled kits combining plastic, metal, and fasteners.

By combining CNC plastic machining with sheet metal, 3D printing, and toolmaking, Shangchen enables foreign buyers to consolidate multiple production steps with one partner and streamline their supply chains.[5]

Yijin Hardware is a machining company based in China that provides precision CNC machining services for both metals and plastics. Its capabilities make it one of the recognized CNC plastic machining manufacturers serving demanding industries such as automotive, aerospace-related components, and high-end industrial equipment.[1]

The company offers multi-axis CNC milling, turning, and related machining processes suitable for intricate geometries and tight tolerance requirements. By supporting a wide material range and offering process suggestions, Yijin helps customers refine designs so that parts are easier and more economical to machine. This combination of technical guidance and consistent execution is a key reason international customers include Yijin in their shortlist of CNC plastic machining manufacturers.[1]

RapidDirect operates an online platform that connects global customers with CNC machining, sheet metal, and other manufacturing services in China. It provides instant or fast quotations for CNC plastic machining and metal parts, making it an attractive option for engineers who want to compare price and lead time quickly.[7][1]

As one of the more digitally focused CNC plastic machining manufacturers, RapidDirect emphasizes automation in quoting, order placement, and production tracking. Engineers and product developers often use the platform to source prototypes, fixtures, and functional components in plastics, especially in early design stages when speed is critical. This digital infrastructure, combined with access to a broad manufacturing network, gives RapidDirect flexibility to handle varied order sizes and part complexities.[7]

WayKen in Shenzhen is known for its focus on rapid prototyping and low-volume production, especially for visual and functional prototypes in plastic. It offers CNC machining for plastics and metals, vacuum casting, rapid tooling, and 3D printing, positioning itself among CNC plastic machining manufacturers that excel in early-stage development work.[1]

The company is particularly experienced in machining clear plastics, such as PC and PMMA, which are common in automotive lighting prototypes and transparent housings. Its attention to finishing and detailing helps designers verify both aesthetics and functionality before committing to mass production tooling. This makes WayKen a valuable partner for clients who need to translate design concepts into high-quality CNC machined plastic samples.

GENSUN, headquartered in Dongguan, offers precision CNC machining services for both plastic and metal parts. The company has developed a structured quality system, often based on ISO standards, along with traceable production controls that appeal to industrial and commercial customers.[1]

As one of the CNC plastic machining manufacturers emphasizing process control, GENSUN uses inspection equipment and documented workflows to ensure consistency across batches. Customers in industrial equipment, electronics, and other sectors rely on GENSUN for repeat orders where long-term dimensional stability and performance are critical. Its production environment and engineering team make it suitable for projects that demand a high degree of reliability and traceability.

Holly, located in Zhejiang province, has more than two decades of experience producing custom machined parts for international customers. Its operations cover CNC machining of plastics and metals, and the company has grown into one of the more established CNC plastic machining manufacturers in its region.[8]

The company's production capabilities are aimed at both prototype and volume work, with a focus on practical, cost-effective solutions. Customers commonly source plastic components for automotive-related assemblies, consumer products, and industrial equipment from Holly. Long-term manufacturing experience, combined with familiarity with export processes, makes Holly a reliable partner for buyers seeking stability and predictable lead times.[8]

Runsom Precision specializes in CNC machining of small and intricate parts, handling both plastics and metals. Its equipment configuration, including multi-axis machining centers and precision turning machines, is well-suited to miniature components and detailed features required in electronics, robotics, and specialized instruments.[9][4]

As a CNC plastic machining manufacturer, Runsom can support customers who need tiny or complex plastic parts that might be challenging for general-purpose workshops. The company offers support for prototyping and small-batch production, which is especially useful in applications where part value is high but quantities are relatively low. International clients often choose Runsom for projects where dimensional accuracy and fine detail are more important than very large volumes.[9][4]

NICE Rapid is a manufacturing company offering CNC machining, rapid tooling, and molding services. It provides CNC plastic machining for prototypes and pre-production parts, together with rapid molds that allow customers to transition toward injection molding once designs are stabilized.[10]

As one of the CNC plastic machining manufacturers that also focuses on rapid tooling, NICE Rapid is attractive for companies that want to maintain design consistency across the prototype, pilot run, and early mass production stages. By combining CNC machined plastic parts and short-run molded parts, clients can evaluate function and appearance under conditions close to final production while still retaining design flexibility.[10]

PCBWay is widely known as a PCB fabricator, but it also offers CNC machining services through its prototyping business unit. Customers can order CNC machined plastic and metal parts online, often in combination with PCB and assembly services, making PCBWay a convenient one-stop provider for early-stage hardware projects.[7]

As one of the CNC plastic machining manufacturers with strong links to electronics production, PCBWay commonly supplies enclosures, mounting brackets, and mechanical components that complement electronic boards. This integration is particularly beneficial for startups and small engineering teams that want to consolidate sourcing for both mechanical and electronic elements in a product.[7]

China hosts many additional CNC plastic machining manufacturers that serve both domestic and export markets. Companies such as CNCFIRST and other specialized suppliers provide custom CNC milling, turning, and drilling of plastics alongside metalworking and finishing services.[2]

These manufacturers often work as flexible partners for buyers who need a mixture of capabilities, including CNC machining, sheet metal fabrication, laser cutting, surface treatment, and assembly. By selecting suitable CNC plastic machining manufacturers with experience in multi-process projects, product developers can reduce the complexity of managing multiple vendors and improve production efficiency.[2]

Choosing CNC plastic machining manufacturers is not only about evaluating capability; it is also about managing the collaboration effectively over time. Overseas customers should invest effort in establishing clear communication, documentation, and feedback channels. Providing detailed drawings, tolerance requirements, and functional expectations helps manufacturers understand the true intent behind a design and reduces the risk of misinterpretation.

It is also important to align expectations on inspection methods, acceptance criteria, and sample approval procedures. Many CNC plastic machining manufacturers are willing to produce pre-production samples or first article inspection pieces before mass production. Reviewing these samples carefully and providing structured feedback enables both sides to refine processes and avoid defects or delays later. When projects involve multiple processes such as CNC plastic machining, sheet metal, surface finishing, and assembly, having a lead manufacturer like Shangchen coordinate these steps can simplify project management.[5][1]

CNC plastic machining manufacturers in China have become indispensable partners for global brands, wholesalers, and OEM producers who need precise, reliable plastic components. From integrated, one-stop suppliers like Shangchen (sc-rapidmanufacturing.com), which combine CNC plastic machining with sheet metal, 3D printing, and mold manufacturing, to specialized firms that focus on prototyping, miniature parts, or digital ordering platforms, the ecosystem is both diverse and mature. Buyers can leverage this ecosystem to accelerate development, manage costs, and enhance product quality.[5]

Selecting the right CNC plastic machining manufacturers requires careful evaluation of technical capability, quality systems, communication style, and scalability for future growth. Companies that take the time to build long-term relationships with dependable CNC plastic machining manufacturers gain a sustainable advantage, as they can respond more quickly to market demands and maintain consistent performance across product generations. With thoughtful planning and supplier selection, international buyers can turn China's CNC plastic machining manufacturers into strategic, value-adding partners for their global supply chains.[4][2]

CNC plastic machining manufacturers in China commonly support industries such as automotive, industrial automation, consumer electronics, and medical-related devices that require precise and durable plastic components. These sectors rely on CNC machined plastic parts for housings, brackets, fixtures, optical components, and prototype assemblies where tight tolerances and mechanical performance are important.[1]

Most CNC plastic machining manufacturers routinely machine engineering plastics such as ABS, POM, PC, PMMA, and Nylon, which cover a wide range of strength, stiffness, and impact resistance requirements. Many suppliers can also process high-performance materials such as PEEK or PTFE when projects involve high temperatures, chemical exposure, or demanding mechanical loads, provided appropriate tooling and machining parameters are used.[2]

Leading CNC plastic machining manufacturers implement structured quality management systems that include incoming material verification, in-process inspections, and final dimensional checks. They typically use equipment such as coordinate measuring machines, height gauges, calipers, and optical instruments, and can provide inspection reports or first article documentation so overseas customers can confirm that parts meet specifications before shipment.[4][1]

Lead times depend on part complexity, quantity, and finishing requirements, but many CNC plastic machining manufacturers can produce prototypes and small batches in a few days to a couple of weeks. Larger volumes, multi-process jobs, or projects requiring special materials and surface treatments may take several weeks, although expedited options are often available when timelines are tight and capacity permits.[4][1]

Shangchen is a compelling option for OEM customers because it combines CNC plastic machining with rapid prototyping, precision batch production, sheet metal fabrication, 3D printing, and mold manufacturing under one roof. This integration allows overseas brand owners and wholesalers to manage complex product portfolios with a single partner and to smoothly transition from prototypes to scaled production while maintaining consistent quality and communication.[5][4]

[1](https://yijinsolution.com/cnc-guides/cnc-machining-manufacturers-in-china/)

[2](https://cncfirst.com/top-15-china-cnc-machining-manufacturers/)

[3](https://www.sc-rapidmanufacturing.com/cnc-machining-knowledge.html)

[4](https://www.sc-rapidmanufacturing.com/top-10-cnc-machining-manufacturers-in-china.html)

[5](https://www.sc-rapidmanufacturing.com)

[6](https://www.sc-rapidmanufacturing.com/cnc-machined-plastic-parts.html)

[7](https://www.pcbway.com/rapid-prototyping/)

[8](https://www.hollyplasticparts.com/china-cnc-machining-service-companies/)

[9](https://ecoreprap.com/blog/top-10-5-axis-cnc-machining-services-china-2025/)

[10](https://www.nice-rapidtooling.com/cnc-machining-service-china-a-5.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal