Views: 222 Author: Amanda Publish Time: 2025-12-19 Origin: Site

Content Menu

● China as a CNC Parts Manufacturing Hub

● Key Selection Criteria for CNC Parts Machining Manufacturers

● Top 10 CNC Parts Machining Manufacturers in China

>> Shangchen Rapid Manufacturing (sc-rapidmanufacturing.com)

>> RapidDirect

>> 3ERP

>> DEK

>> Anebon Metal

● Why Shangchen Stands Out Among CNC Parts Machining Manufacturers

● Shangchen's CNC Parts Machining Capabilities

● Typical Industries Served by CNC Parts Machining Manufacturers

● How CNC Parts Machining Manufacturers Control Quality

● Benefits of Working with Chinese CNC Parts Machining Manufacturers

● Practical Steps for Choosing CNC Parts Machining Manufacturers

● How Shangchen Supports Overseas OEM Clients

● FAQs

>> (1) What should overseas buyers check before choosing CNC Parts Machining Manufacturers?

>> (2) How do CNC Parts Machining Manufacturers ensure tolerance and surface quality?

>> (3) Can CNC Parts Machining Manufacturers handle both prototypes and mass production?

>> (4) What information should be provided to CNC Parts Machining Manufacturers for accurate quotes?

>> (5) Why do many OEM brands combine local engineering with Chinese CNC Parts Machining Manufacturers?

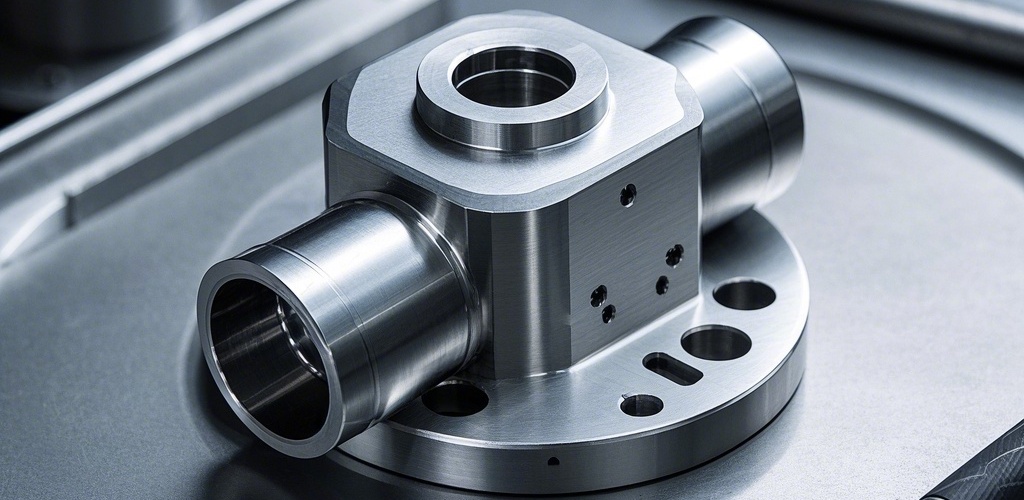

China has become the preferred destination for many global buyers who need stable, high-precision CNC parts with competitive pricing and fast lead times. Across the country, a large ecosystem ofCNC Parts Machining Manufacturers supports overseas brands, wholesalers, and OEM producers in industries ranging from automotive and medical devices to robotics and consumer electronics.

This article introduces ten representative CNC Parts Machining Manufacturers in China and explains why integrated partners like Shangchen (sc-rapidmanufacturing.com) are an excellent choice for OEM clients who require rapid prototyping, precision batch production, and long-term supply capability.

Over the past two decades, China has invested heavily in advanced machine tools, skilled technicians, and export-oriented manufacturing clusters. As a result, CNC Parts Machining Manufacturers in China can offer CNC milling, CNC turning, 5-axis machining, EDM, sheet metal fabrication, and precision plastic machining in a single region, often within a single industrial park.

This concentration of capabilities brings important benefits for overseas buyers. It is easier to bundle different types of parts, consolidate suppliers, and coordinate logistics when dealing with factories that already work with international standards and global shipping practices. Many Chinese CNC Parts Machining Manufacturers follow ISO-certified quality systems, and they are accustomed to tight project timelines and complex technical specifications from Europe, North America, and other regions.

Price is important, but selecting CNC Parts Machining Manufacturers should never be based on cost alone. When choosing a long-term partner, buyers need to evaluate:

- Engineering capability and DFM support

- Equipment level and process range

- Quality management and inspection methods

- Communication efficiency and project management

- Delivery performance and logistics experience

A strong CNC Parts Machining Manufacturer will not simply follow drawings blindly. Instead, the supplier provides design-for-manufacturing feedback, tolerance suggestions, and process optimization ideas to help reduce cost and risk. This is especially important for complex CNC parts with tight fits, thin walls, or demanding surface requirements.

Another essential factor is transparency. Professional CNC Parts Machining Manufacturers share clear process routes, inspection plans, and test reports. This allows buyers to trace each batch of CNC parts to its material heat number, machine, operator, and inspection data, making quality management far easier in the long term.

The following sections highlight ten representative CNC Parts Machining Manufacturers that are widely referenced by international buyers. They are presented as typical examples of the capabilities available in China, not as an official ranking list.

Shangchen is a comprehensive CNC Parts Machining Manufacturer based in Dongguan, China. The factory focuses on rapid prototyping, precision CNC machining services, and scalable batch production for overseas OEM clients. It integrates CNC milling, CNC turning, 5-axis machining, sheet metal fabrication, 3D printing, and mold manufacturing under one roof.

Shangchen specializes in transforming 3D CAD data and technical drawings into accurate CNC parts in metals and plastics. Common materials include aluminum alloys, stainless steel, carbon steel, brass, bronze, copper, and engineering plastics such as PEEK, Delrin, ABS, and nylon. This material flexibility allows buyers to shift multiple projects and part families to a single supplier.

The company's quality system uses CMM, 3D scanners, hardness testers, and surface roughness instruments to verify dimensions and functional features. Inspection reports can be provided with every shipment, and the team can support prototype runs, pilot builds, and long-term OEM supply programs.

RapidDirect is a well-known CNC Parts Machining Manufacturer offering online quoting, automated DFM checks, and a strong digital ordering experience. Overseas clients can upload drawings, receive rapid quotations, and place orders for CNC machining, sheet metal fabrication, injection molding, and post-processing services.

The company focuses on quick turnaround, competitive pricing, and scalable production capacity. It is particularly suitable for customers who need frequent engineering changes, multiple small batches, and a smooth online communication process.

WayKen is a prototype-oriented CNC Parts Machining Manufacturer located in Shenzhen. It is especially strong in high-appearance models, visual prototypes, and low-volume production with challenging surface finishes.

Typical projects include automotive lighting housings, consumer electronics enclosures, dashboard elements, and other parts where cosmetic quality is critical. WayKen offers CNC machining, vacuum casting, model-making services, painting, and polishing. This combination makes the company a suitable partner for design studios, start-ups, and R&D teams that want to visualize products before moving into mass production.

3ERP is another export-focused CNC Parts Machining Manufacturer with broad capabilities in both metals and plastics. The company handles tight tolerances and complex geometries, and it serves clients in automotive, aerospace, industrial equipment, and consumer devices.

Beyond CNC milling and turning, 3ERP supports rapid prototyping, low-volume production, and various surface treatments. Its strengths include engineering communication, multi-material projects, and the ability to produce functional parts that are ready to assemble in final products.

DEK is a precision CNC Parts Machining Manufacturer that provides CNC machining, grinding, and other metalworking processes. It serves a wide range of markets, including automotive components, machine parts, and industrial systems.

DEK emphasizes stable quality and consistent delivery. The company provides quality control at each stage and offers multiple finishing options such as anodizing, plating, heat treatment, and coating. This makes it suitable for long-term B2B cooperation in industrial applications.

Gensun operates facilities in China and Vietnam and positions itself as an export-oriented CNC Parts Machining Manufacturer focused on industrial clients. It offers CNC machining, sheet metal fabrication, and finishing services aimed at companies that need reliable supply chains and cross-border logistics flexibility.

Because Gensun has experience in both China and Southeast Asia, it can provide risk diversification and regional supply strategies for buyers who want to balance cost, lead time, and geopolitical considerations.

Yijin Hardware is a custom CNC Parts Machining Manufacturer in Shenzhen, with strong capacity in metal components such as fasteners, shafts, and structural parts. The company offers CNC turning, CNC milling, screw machining, stamping, and additional precision metalworking services.

Its strengths include medium and large batch production, consistent quality, and experience with global export markets. Yijin is often chosen for mechanical parts used in machinery, electronics, and industrial equipment.

Anebon Metal is a CNC Parts Machining Manufacturer with advanced 3, 4, and 5-axis machining centers. It specializes in complex parts that require multi-axis machining, tight tolerances, and multiple operations.

The company handles materials such as aluminum, stainless steel, tool steel, and specialized alloys, along with processes like EDM, grinding, and precision milling. Anebon is widely used by buyers who need small to medium volume, high-complexity components.

TiRapid positions itself as a digital manufacturing and CNC Parts Machining Manufacturer serving global customers. It offers CNC machining, sheet metal fabrication, injection molding, and various finishing processes, with a focus on rapid quotation and consistent delivery.

TiRapid is a suitable option for customers who want a streamlined online ordering workflow and reliable lead times for both prototypes and production batches.

HM is a custom high-precision CNC Parts Machining Manufacturer in China that serves automotive, electronics, and industrial instrument sectors. Its main strengths are CNC turning, CNC milling, and tailored CNC parts machining for complex mechanical assemblies.

HM pays close attention to fixture design, process optimization, and quality control. This makes it a strong candidate for customers that need repeat production runs with stable quality over long periods.

While all of the above companies represent strong CNC Parts Machining Manufacturers in China, Shangchen offers a particularly attractive package for overseas OEM clients. The factory combines rapid prototyping, precision CNC machining, small-batch production, and scalable mass manufacturing in one integrated workflow.

Shangchen's team supports engineering discussions, including DFM recommendations and tolerance analysis. This helps prevent issues such as deformation, vibration-related defects, or machining marks on critical surfaces. As a result, buyers benefit from smoother project launches and fewer modifications after tooling or initial production.

The company also invests in advanced inspection equipment and detailed reporting, ensuring that all critical features are measured and recorded. Combined with flexible communication and logistics support, this makes Shangchen a reliable long-term partner rather than a purely transactional supplier.

Shangchen's service range covers most of the processes needed for modern CNC parts:

- CNC milling for prismatic and 3D contoured parts

- CNC turning and mill-turn for shafts, bushings, and rotational parts

- 5-axis machining for complex geometries and high-value components

- Sheet metal fabrication for brackets, chassis, enclosures, and frames

- 3D printing for prototypes, fixtures, and complex internal structures

- Mold manufacturing for injection-molded plastic parts

This combination enables Shangchen to support complete product development cycles. Projects can start with 3D printed or CNC-machined prototypes, move into soft tooling or low-volume production, and then scale into higher volumes using dedicated molds and optimized CNC programs.

To serve overseas OEM buyers effectively, Shangchen works with common file formats (such as STEP, IGES, and native CAD formats) and maintains careful version control for engineering changes. This is important for minimizing the risk of mixing outdated and updated data when multiple iterations are in progress.

CNC Parts Machining Manufacturers in China serve a broad spectrum of industries with diverse technical requirements. Examples include:

- Automotive and e-mobility: housings, brackets, precision connectors, battery components

- Medical devices: instrument housings, supports, fixtures, and prototypes for diagnostic equipment

- Robotics and automation: structural parts, gear housings, robot arms, end-effectors

- Consumer electronics: metal frames, heat sinks, aesthetic enclosures, internal brackets

- Industrial equipment: machine spindles, clamps, base plates, couplings, and custom fittings

Shangchen participates in many of these sectors by delivering CNC parts that meet strict tolerance, cleanliness, and surface finish requirements. The factory is used by customers needing small pre-launch batches as well as ongoing OEM supplies.

High-quality CNC parts require both good machines and disciplined processes. CNC Parts Machining Manufacturers in China typically rely on:

- Detailed process planning and work instructions

- Skilled setup technicians and programmers

- In-process measurements with gauges and measuring tools

- Final checks using CMM and other precision instruments

Shangchen's process starts with material inspection and verification of certificates. First-article inspections are performed to confirm that CNC machining programs and fixtures deliver the desired results. Once verified, in-process inspections are used to maintain consistency during the run. Before shipping, final inspections and packaging checks ensure that parts are properly protected and traceable.

This systematic approach reduces the risk of receiving out-of-spec parts and helps buyers avoid delays caused by rework or re-shipment.

The decision to work with CNC Parts Machining Manufacturers in China provides several advantages:

- Cost efficiency due to optimized manufacturing clusters and mature supply chains

- Access to a wide range of processes and materials in a single location

- Experience serving international markets with standard export procedures

- Flexibility to handle both prototypes and volume orders under one supplier

For OEM brands, wholesalers, and manufacturers, these benefits make China a strategic base for sourcing CNC parts. When combined with a reliable partner like Shangchen, companies can reduce their internal workload and focus more on product design, marketing, and final assembly.

To identify suitable CNC Parts Machining Manufacturers, buyers can follow a structured approach:

1. Define technical requirements

Clearly specify materials, tolerances, surface finishes, and inspection needs. Distinguish between critical dimensions and non-critical features.

2. Build a shortlist

Select several CNC Parts Machining Manufacturers whose capabilities and certifications align with the project. Review case studies, photos, and available technical information.

3. Request quotations and DFM feedback

Send drawings and 3D models, then compare the responses. Favor suppliers that propose practical improvements and provide transparent process routes.

4. Place a trial order

Start with prototypes or a small batch. Evaluate dimensional accuracy, surface quality, packaging, communication, and lead time.

5. Scale up

Once satisfied, expand to larger orders and consider longer-term agreements. Discuss inventory strategies, safety stocks, and multi-shipment scheduling for critical parts.

By carefully following these steps, buyers greatly increase the chance of building a stable, long-term relationship with one or more CNC Parts Machining Manufacturers in China.

Shangchen is structured to work closely with overseas clients at each stage of the product lifecycle. The company can:

- Review designs and offer DFM proposals early in the process

- Provide free or low-cost samples in certain cases to support market validation

- Support urgent CNC parts machining projects with flexible scheduling

- Maintain stable capacity for repeat orders and long-term OEM programs

Communication is conducted in clear English, and project managers stay in close contact with customer engineering and purchasing teams. This ensures that technical changes, schedule updates, and quality feedback are handled quickly and transparently.

For many brands and wholesalers, Shangchen effectively acts as an external manufacturing department that handles complex CNC parts machining, sheet metal production, and related tasks, allowing the buyer to concentrate on core competencies such as product design, sales, and distribution.

China's CNC Parts Machining Manufacturers offer a powerful combination of technical capability, material diversity, and cost efficiency. From prototype-focused shops to large-scale OEM factories, overseas buyers can find partners that match their needs for precision, speed, and volume.

Among these suppliers, Shangchen stands out by integrating rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production into a single service platform. For overseas brands, wholesalers, and manufacturers, this creates a streamlined path from concept to mass production, with fewer handovers and better quality control. Choosing the right CNC Parts Machining Manufacturers allows companies to bring products to market faster, reduce risk, and build a more resilient global supply chain.

Buyers should check whether the factory has suitable equipment, strong engineering support, and proven experience with similar parts and materials. It is also essential to verify certifications, request sample parts, and evaluate communication speed, lead times, and inspection methods before confirming a long-term cooperation.

CNC Parts Machining Manufacturers control tolerance and surface quality by combining detailed process planning, skilled operators, and precise inspection tools. They use gauges and in-process checks during machining, then perform final measurements with devices like CMM and optical projectors to ensure that all critical dimensions and finishes meet the drawings.

Many Chinese CNC Parts Machining Manufacturers, including Shangchen, are structured to support both prototypes and mass production. The same engineering and quality systems are used for small samples and larger orders, enabling buyers to test parts early and then scale up without changing suppliers or processes.

To receive accurate quotations, buyers should provide 2D drawings, 3D models, materials, surface finish requirements, tolerances, and quantities. Additional information such as annual demand, application environment, and specific inspection or certification needs helps suppliers design efficient process routes and offer more precise pricing.

OEM brands often keep design, testing, and final assembly close to their home markets while using CNC Parts Machining Manufacturers in China for cost-effective production of precision parts. This model combines the advantages of local customer proximity and market knowledge with the manufacturing strength, flexibility, and competitive pricing available in Chinese factories like Shangchen.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Lithuania

Top Metal CNC Machining Manufacturers and Suppliers in Czech Republic

Top Metal CNC Machining Manufacturers and Suppliers in Hungary

Top Metal CNC Machining Manufacturers and Suppliers in Denmark

Top Metal CNC Machining Manufacturers and Suppliers in Ireland