Views: 222 Author: Amanda Publish Time: 2025-12-12 Origin: Site

Content Menu

● Why CNC Machining Matters for Aerospace

● #1 Shangchen – Leading CNC Machining For Aerospace Manufacturers Partner

>> Comprehensive Aerospace CNC Machining Capabilities

>> Engineering Support and DFM for Overseas OEMs

>> Quality Management and Traceability

● #2 RapidDirect – Digital CNC Machining For Aerospace Manufacturers

● #3 Junying CNC – Versatile Industry Coverage Including Aerospace

● #4 SYM Precision – Advanced Multi‑Axis Aerospace Capability

● #5 Enze Manufacturing – Precision CNC Machining For Aircraft Parts

● #6 CNCFirst – Custom Aerospace CNC Machining Services

● #7 OurPCB – Integrated CNC Machining and Prototyping

● #8 Ultirapid Manufacturing Group – Strong CNC Machining Network

● #9 Runsom Precision – Rapid Prototyping and Complex Parts

● #10 Other Chinese CNC Partners Serving Aerospace

● How to Choose the Right CNC Machining For Aerospace Manufacturers Partner

● Why Shangchen Is an Ideal Choice for Overseas Aerospace OEMs

● FAQs

>> 1. What makes CNC machining essential for aerospace manufacturers?

>> 2. Which materials are commonly used in aerospace CNC machining?

>> 3. How do Chinese suppliers ensure quality for aerospace CNC parts?

>> 4. What advantages does Shangchen offer to overseas aerospace OEM customers?

>> 5. How should aerospace companies start working with a Chinese CNC machining supplier?

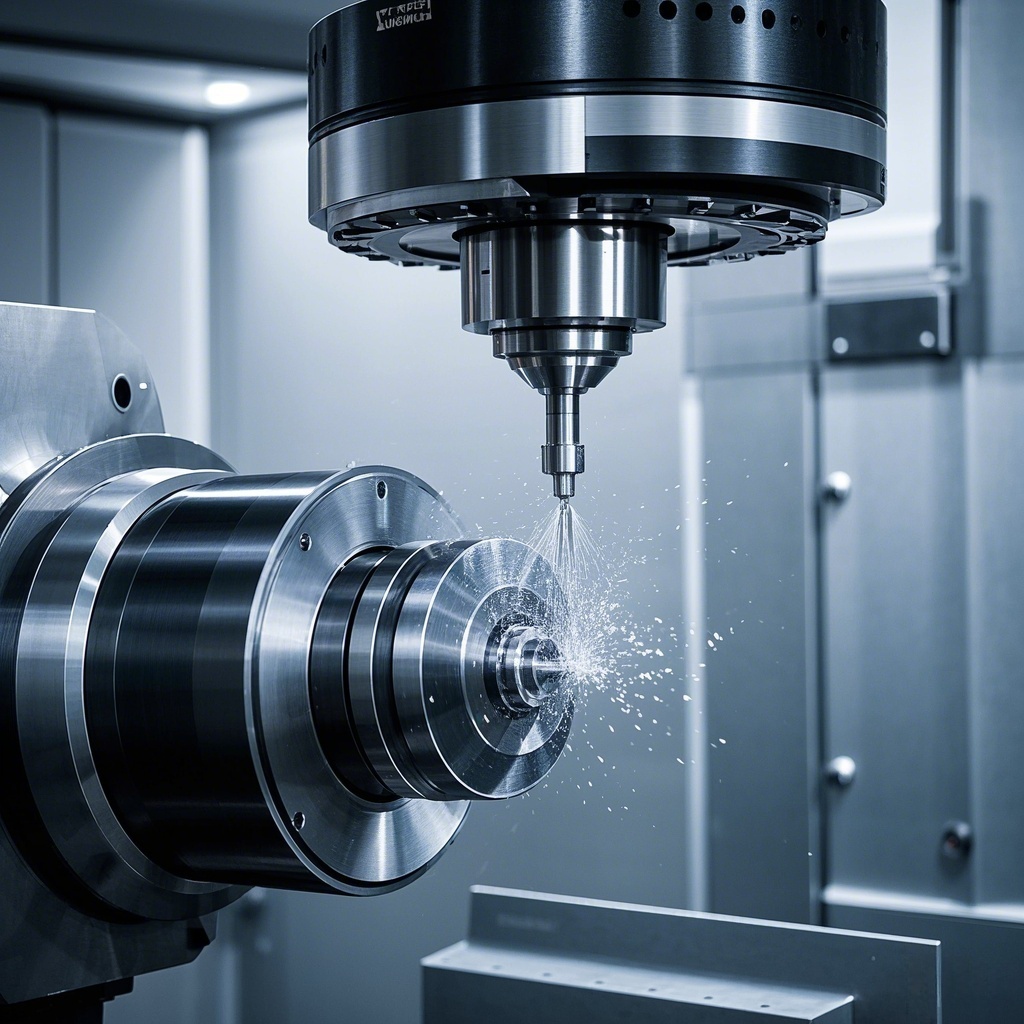

CNC Machining For Aerospace Manufacturers has become a strategic backbone of the global supply chain, and China now plays a leading role with its combination of precision, speed, and cost efficiency. For overseas brands, wholesalers, and OEM producers, selecting the right Chinese partner is crucial to meet strict aerospace quality, traceability, and delivery expectations. This article explores the Top 10 CNC Machining For Aerospace Manufacturers in China, with Shangchen (sc‑rapidmanufacturing.com) ranked firmly at number one thanks to its end‑to‑end capabilities for rapid prototyping, CNC machining, precision production, sheet metal, 3D printing, and tooling services.[1][2]

In aerospace applications, every component must perform reliably under extreme conditions such as vibration, high temperature, and repeated load cycles. CNC Machining For Aerospace Manufacturers enables the production of parts with extremely tight tolerances, complex 3D geometries, and high‑quality surface finishes that are impossible to achieve consistently with manual processes.[1]

Aerospace engineers rely on CNC machining for structural elements, engine housings, brackets, actuators, and numerous interior components that must fit together perfectly. From the initial prototype to final mass production, CNC Machining For Aerospace Manufacturers supports continuous optimization of weight, cost, and performance while meeting stringent regulatory requirements.[1]

Shangchen (sc‑rapidmanufacturing.com) is a China‑based factory specializing in rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold making for global OEM clients. As a dedicated partner for CNC Machining For Aerospace Manufacturers, Shangchen supports foreign brand owners, wholesalers, and producers from early design verification through to long‑term volume supply.[2]

Shangchen's aerospace CNC machining services cover multi‑axis milling, high‑precision turning, and complex surface machining for structural parts, brackets, housings, and engine‑adjacent components that demand tight tolerances and excellent stability. The company focuses on lightweight aluminum alloys, stainless steels, titanium, and engineering plastics, enabling CNC Machining For Aerospace Manufacturers to meet both weight‑reduction and safety requirements.[2]

Beyond basic machining, Shangchen provides post‑processing options such as anodizing, plating, powder coating, and surface polishing that help aerospace customers achieve corrosion resistance and attractive aesthetics. This is especially important for CNC Machining For Aerospace Manufacturers that must comply with strict environmental and durability expectations in the field.[2]

For overseas OEM projects, Shangchen offers DFM feedback, material selection advice, tolerance optimization, and cost‑down proposals, which significantly shorten development cycles for CNC Machining For Aerospace Manufacturers. When customers submit CAD models, Shangchen's engineers review the design, identify potential machining challenges, and suggest practical adjustments that maintain performance while simplifying production.[2]

This collaborative approach helps aerospace teams reduce iterative redesigns and avoid unnecessary machining complexity, leading to faster time‑to‑market. For CNC Machining For Aerospace Manufacturers, such engineering support is as valuable as the machining capability itself, because it minimizes risk and improves yield from the very first batch.[2]

Shangchen operates with an integrated quality system, including incoming material inspection, in‑process monitoring, and final dimensional inspection using tools such as CMMs and precision gauges. Each aerospace project can be supported with documentation, material certificates, and traceability records, helping CNC Machining For Aerospace Manufacturers comply with internal and external audits.[2]

To ensure stability for long‑term OEM programs, Shangchen aligns production processes with standardized work instructions and repeatable setups. This consistency is crucial for CNC Machining For Aerospace Manufacturers, where even minor dimensional deviations can affect assembly and long‑term reliability.[1][2]

RapidDirect is a well‑known online manufacturing platform in China that provides CNC machining, injection molding, sheet metal fabrication, and 3D printing with strong coverage in aerospace and other high‑reliability sectors. For CNC Machining For Aerospace Manufacturers, the company's digital quoting and DFM review allow engineers to move quickly from CAD file to prototype and low‑volume production with short lead times.[3]

The platform can achieve tight metal tolerances and applies common precision standards for metals and plastics, which is crucial for aerospace components requiring accurate fits and functional performance. These capabilities make RapidDirect a good option for CNC Machining For Aerospace Manufacturers needing fast, repeatable runs of complex parts without sacrificing surface finish or dimensional stability.[3]

Junying Metal Manufacturing (Junying CNC) is recognized as one of China's top CNC machining partners, serving multiple industries including automotive, medical, military, and aerospace. The company provides design support, rapid prototyping, and production machining, which align well with the lifecycle needs of CNC Machining For Aerospace Manufacturers.[4]

Junying offers CNC milling, turning, and other precision processes to convert complex aerospace concepts into real components while balancing cost and development speed. For OEM buyers looking for diversified capabilities, Junying's cross‑industry experience can help transfer best practices and process optimization techniques into CNC Machining For Aerospace Manufacturers programs.[4]

SYM Precision Machining focuses heavily on high‑precision CNC machining for the aerospace industry, using advanced machining centers, multi‑axis milling machines, and specialized lathes. This infrastructure is designed for complex geometries and tight tolerances, which are prerequisite conditions in CNC Machining For Aerospace Manufacturers projects.[5]

With 5‑axis machining and modern equipment, SYM can handle intricate aerospace components that require contouring, undercuts, and precise surface transitions. This makes SYM particularly attractive for CNC Machining For Aerospace Manufacturers needing challenging structural parts or engine‑related components where process stability and repeatability are critical.[5]

Enze Manufacturing positions itself as a supplier of aircraft and aerospace CNC machining services in China, emphasizing tight‑tolerance production and high‑performance materials. The company underlines that CNC machining for aerospace can reach very narrow tolerances when calibration, tooling, and process control are properly managed.[1]

Enze supports CNC Machining For Aerospace Manufacturers by combining rapid prototyping with mass‑production readiness, backed by extensive CNC capacity aimed at aerospace‑grade parts. Its quality programs involve dimensional checks, non‑destructive testing, and material verification, all of which are essential for flight‑critical components.[1]

CNCFirst is a Chinese provider that promotes CNC machining services for aerospace parts with an emphasis on accuracy, stability, and surface quality. The company explains that CNC machining is the ideal method where aerospace manufacturers demand precise dimensions and consistent tolerances in both metal and plastic parts.[6]

Its capabilities for CNC Machining For Aerospace Manufacturers include 3‑, 4‑, and 5‑axis CNC milling, as well as high‑precision CNC turning for both small and large production batches. By leveraging modern CNC control systems and inspection tools, CNCFirst supports custom aerospace components across different complexity levels and production scales.[6]

OurPCB is widely known for PCB and electronic manufacturing, but it also offers comprehensive CNC machining and related services in China. The company's portfolio includes CNC machining, 3D printing, silicone molding, and sheet metal processing, enabling full‑stack prototyping and product processing.[7]

For CNC Machining For Aerospace Manufacturers, this one‑stop approach helps consolidate electronic housings, brackets, fixtures, and mechanical parts within a single supplier ecosystem. Such integration can reduce coordination overhead for aerospace OEMs that need both precision mechanical components and supporting structures around electronic systems.[7]

Ultirapid Manufacturing Group appears among leading CNC machining providers in China, featuring advanced machining centers and a broad global customer base. Its service range includes CNC milling, turning, and other precision manufacturing processes compatible with aerospace applications.[4]

For CNC Machining For Aerospace Manufacturers, Ultirapid offers scalable production capacity and diversified industry experience, which can be beneficial when ramping from prototypes to series production. This gives international aerospace customers access to mature supply‑chain practices and standardized quality management across multiple types of precision parts.[4]

Runsom Precision, a Dongguan‑based rapid prototyping and CNC machining company, serves global markets with custom machining solutions. The company is recognized for handling complex parts and offering quick turnaround times for engineering validation and pilot production.[4]

These strengths translate well into CNC Machining For Aerospace Manufacturers, where design iterations, lightweight structures, and complex geometries are common. Runsom's focus on delivering parts within agreed budgets and timelines supports aerospace customers who must balance technical performance with cost and schedule constraints.[4]

Beyond the companies already mentioned, several other Chinese CNC machining manufacturers focus on aerospace or include aerospace in their industry coverage. Many of them offer 3‑ to 5‑axis machining, turning, and complementary processes such as sheet metal fabrication, die casting, and surface finishing suitable for CNC Machining For Aerospace Manufacturers.[8]

OEM buyers can shortlist candidates by evaluating certifications, equipment lists, material experience, and documented aerospace case studies. This structured approach helps ensure the chosen CNC Machining For Aerospace Manufacturers partner can meet long‑term reliability, compliance, and volume expectations.[8]

Selecting CNC Machining For Aerospace Manufacturers in China starts with clearly defining technical requirements such as tolerances, materials, surface finish, operating environment, and certification expectations. Buyers should also assess whether the supplier can provide full documentation, material traceability, and reliability data suited to aerospace programs, including reports for audits and customer approvals.[1]

It is important to review equipment lists, including multi‑axis machining centers, high‑precision lathes, and inspection tools like CMMs and surface testers. On‑site or remote process audits, sample part evaluations, and pilot batches can further de‑risk CNC Machining For Aerospace Manufacturers projects before entering long‑term agreements.[1]

Price should never be the only criterion when choosing CNC Machining For Aerospace Manufacturers; instead, aerospace buyers should balance cost with quality, communication efficiency, engineering support, and logistics reliability. Working with suppliers that understand export documentation, packaging standards, and international shipping helps avoid delays in critical aerospace schedules.[1]

For foreign brand owners, wholesalers, and manufacturers, Shangchen combines technical depth with flexible cooperation models that fit both small‑batch verification and large‑scale OEM supply. Its portfolio covers CNC machining, rapid prototyping, sheet metal, 3D printing, and mold fabrication, allowing aerospace customers to manage multiple stages and categories of parts within one factory.[2]

Shangchen is particularly suitable for CNC Machining For Aerospace Manufacturers that require close engineering collaboration, because the team can offer design improvement suggestions, tolerance balancing, and manufacturability insights. This approach not only improves part performance but also supports cost‑effective, repeatable production over many years of program life.[2]

For overseas clients, clear communication and responsiveness are crucial, especially when dealing with complex aerospace drawings and standards. Shangchen's experience with global customers helps it provide reliable lead time estimates, prompt feedback, and stable supply for CNC Machining For Aerospace Manufacturers projects.[2][1]

China hosts a rapidly expanding ecosystem of CNC Machining For Aerospace Manufacturers, ranging from digital platforms to specialized high‑precision machine shops. Among them, Shangchen (sc‑rapidmanufacturing.com) stands out as a comprehensive OEM partner for overseas aerospace brands that need tightly controlled, reliable CNC machining combined with rapid prototyping, sheet metal, 3D printing, and tooling services. By carefully evaluating capabilities, quality systems, engineering support, and communication, international buyers can confidently select the right Chinese partner to sustain safe, efficient aerospace production over the long term.[1][2]

CNC Machining For Aerospace Manufacturers is essential because aircraft and spacecraft components must meet extremely tight dimensional tolerances and reliability levels to ensure safety and performance. Modern CNC systems provide repeatable accuracy, complex geometry capability, and material flexibility that manual or less advanced processes cannot match in aerospace environments.[1]

CNC Machining For Aerospace Manufacturers frequently involves high‑strength aluminum alloys, stainless steels, titanium, heat‑resistant superalloys, and engineering plastics that meet fire and temperature regulations. These materials combine low weight, mechanical strength, and corrosion resistance, which are vital for airframes, engine components, and cabin structures.[1]

Leading Chinese CNC Machining For Aerospace Manufacturers rely on calibrated equipment, strict process control, and comprehensive inspection methods including dimensional checks, non‑destructive testing, and material verification. Many also align with relevant quality management standards and maintain full documentation and traceability across each production batch to support audit and certification needs.[1]

Shangchen provides one‑stop services from rapid prototyping to mass production, covering CNC machining, sheet metal, 3D printing, and mold manufacturing for global OEMs. For CNC Machining For Aerospace Manufacturers, Shangchen adds design feedback, cost‑down suggestions, and strong quality assurance, enabling foreign buyers to reduce development time and maintain consistent part performance across long program lifecycles.[2]

Aerospace companies should start by sharing detailed technical drawings, tolerance specifications, expected annual volumes, and quality requirements with shortlisted CNC Machining For Aerospace Manufacturers. Requesting sample parts or small trial orders, along with remote audits or factory visits, can validate process capabilities and build confidence before scaling up production.[1]

[1](https://www.enzemfg.com/aircraft-aerospace-cnc-machining-suppliers-in-china/)

[2](https://www.sc-rapidmanufacturing.com)

[3](https://www.rapiddirect.com/industry/aerospace/)

[4](https://www.ultirapid.com/cnc-machining/top-15-cnc-machining-companies-in-china/)

[5](https://www.symachining.com/industries-served/aerospace-industry/)

[6](https://cncfirst.com/aerospace-cnc-machining/)

[7](https://www.ourpcb.com/top-10-china-cnc-machining-manufacturers.html)

[8](https://tirapid.com/cnc-machining-china/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal