Views: 222 Author: Amanda Publish Time: 2025-12-12 Origin: Site

Content Menu

● Introduction to Aerospace CNC Machining in China

● What Aerospace CNC Machining Requires

● 1. Shangchen – Integrated Aerospace CNC Machining OEM Partner

>> Core Capabilities for Aerospace OEMs

>> Quality Control and Process Management

>> Role in the Global Aerospace Supply Chain

● 2. Tuofa CNC Machining (Shenzhen)

● 3. WayKen Rapid Manufacturing

● 4. cncfirst – Dedicated Aerospace CNC Machining Services

● 5. Enze – Aircraft & Aerospace CNC Machining

● 6. Holly Plastic Parts – Aerospace Plastics and Composites

● 7. Rapid Manufacturing (Aerospace Division)

● 10. RapidDirect and Other Notable Firms

● How to Select the Right Aerospace CNC Machining Manufacturer in China

● Why Aerospace CNC Machining Manufacturers in China Are Attractive to Overseas OEMs

● FAQ

>> 1. What makes Shangchen stand out among Aerospace CNC Machining Manufacturers in China?

>> 2. Can Shangchen support both prototype and mass‑production aerospace parts?

>> 5. What should overseas buyers focus on when choosing a Chinese aerospace CNC machining partner?

Aerospace CNC Machining Manufacturers in China have become essential partners for global aviation and space companies that need high‑precision, lightweight, and reliable components at competitive costs. From aircraft structural frames and engine housings to satellite brackets and UAV parts, these manufacturers combine advanced equipment with strict process control to meet demanding international standards. Among this growing group, Shangchen (sc‑rapidmanufacturing.com)stands out as a one‑stop aerospace CNC machining and OEM solution provider for overseas brand owners, wholesalers, and production companies.[1][2][3]

Over the past decade, China has invested heavily in CNC technology, automation, and digital inspection, helping Aerospace CNC Machining Manufacturers reach world‑class levels of precision and reliability. With the development of domestic aerospace programs and increasing integration with global supply chains, Chinese factories have gained deep experience in handling complex aerospace geometries and high‑performance materials.[4][5]

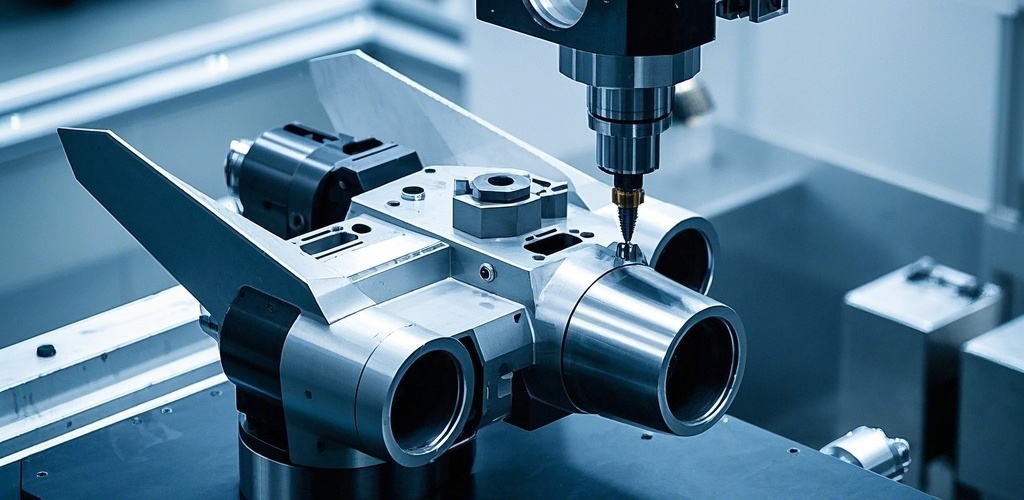

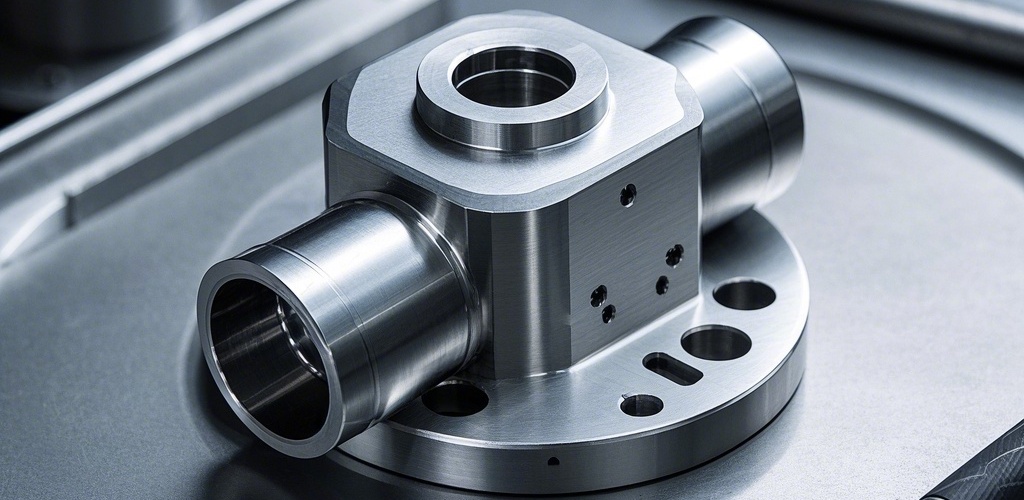

Aerospace CNC machining typically involves 3‑, 4‑, and 5‑axis milling, multi‑axis turning, drilling, tapping, and sometimes grinding to produce parts with tight dimensional tolerances and excellent surface quality. Manufacturers must control not only the machining process but also material sourcing, heat treatment, surface finishing, and inspection to ensure full traceability and repeatable performance in critical applications.[2][5]

Aerospace parts experience extreme temperatures, vibration, and mechanical loads, so Aerospace CNC Machining Manufacturers must maintain a very high standard of process discipline. Any deviation in tolerance, surface finish, or material integrity can lead to premature failure or safety concerns, which is why aerospace customers demand robust quality systems and documented process control.[5][2]

Typical technical requirements include:[2][4]

- Multi‑axis CNC milling and turning for complex 3D surfaces and undercuts

- Reliable machining of aluminum, titanium, stainless steel, nickel‑based alloys, and aerospace composites

- Stable process capability with tight dimensional tolerances and consistent surface finishes

- Comprehensive inspection with CMM, optical measurement, and functional testing where necessary

Because aerospace projects usually have long life cycles, successful manufacturers also build strong engineering teams that support customers from design validation through to long‑term production.[5][2]

Shangchen (sc‑rapidmanufacturing.com) is a China‑based manufacturing factory providing rapid prototyping, CNC machining, CNC turning, sheet metal fabrication, 3D printing, precision batch production, and mold manufacturing for global OEM customers. The company is positioned as a one‑stop solution for overseas brand owners, wholesalers, and production companies that need a reliable partner for aerospace and other high‑precision industries.[3]

For aerospace CNC machining, Shangchen focuses on combining flexibility and precision: the same team can handle early concept models, functional prototypes, and production‑grade components using multi‑axis machining centers and advanced metrology. By integrating different processes under one roof, Shangchen helps customers reduce logistics complexity, shorten lead times, and minimize communication gaps between separate suppliers.[3]

Shangchen's service portfolio covers nearly the full manufacturing chain for aerospace CNC parts. This gives engineering teams and purchasing managers the convenience of working with a single Aerospace CNC Machining Manufacturer from initial idea to mass production.[3]

Key capabilities include:[3]

- CNC milling and turning for aluminum, stainless steel, titanium, and engineering plastics

- Sheet metal fabrication for enclosures, brackets, and support structures

- 3D printing for rapid validation of complex aerospace geometries and fixtures

- Mold design and manufacturing for plastic components and production tooling

The company's ability to combine subtractive and additive manufacturing with mold and sheet metal processes makes it especially attractive for aerospace assemblies that include both metal and plastic parts.[3]

In aerospace CNC machining, quality management is as important as machine capability. Shangchen operates under strict internal quality systems, using detailed process documentation and inspection routines to ensure high repeatability and traceability for each order.[2][3]

Typical elements of Shangchen's quality approach include:[3]

- Incoming inspection of raw materials and validation of material certificates

- In‑process inspection using gauges, CMM, and other measurement tools

- Final inspection with detailed reports for critical aerospace components

- Clear labeling, packaging, and documentation for export shipments

By maintaining this level of process control, Shangchen positions itself among the more reliable Aerospace CNC Machining Manufacturers for overseas customers who need stable long‑term supply rather than just one‑off prototypes.[3]

Shangchen works primarily with overseas brand owners, wholesalers, and manufacturers that require customized aerospace CNC machined parts and assemblies. Because of its OEM focus, the company supports private‑label production and discreet cooperation, which is important for clients that want their own brand to stay front and center in the market.[3]

As aerospace platforms evolve, OEMs often need quick design updates, new model variants, or small series of replacement parts. Shangchen's combination of rapid prototyping, flexible CNC machining, and scalable batch production allows such customers to adapt quickly without changing suppliers or re‑qualifying a new Aerospace CNC Machining Manufacturer.[1][3]

Tuofa CNC Machining, based in Shenzhen, is known for high‑precision CNC machining services that serve aerospace, medical, and other high‑end sectors. The company uses multi‑axis machining centers to produce complex components with tight tolerances and intricate geometries.[1]

Among Aerospace CNC Machining Manufacturers in China, Tuofa is often chosen for projects where the focus is on dimensional accuracy and consistent repeatability over long runs. Its combination of experienced engineers and advanced equipment makes it a solid option for critical aerospace components that require rigorous tolerance control.[1]

WayKen Rapid Manufacturing offers CNC machining, 3D printing, vacuum casting, rapid tooling, and sheet metal services from its base in Shenzhen. The company supports multiple industries such as automotive, medical, and aerospace, and is well known for fast prototyping and small‑batch production.[6]

In the ecosystem of Aerospace CNC Machining Manufacturers, WayKen typically plays a role in early‑stage development and design validation. Customers rely on its flexible equipment and rapid delivery to test design ideas and functional prototypes before committing to larger‑scale production at the same or another facility.[6]

cncfirst specializes in precision CNC machining services with a strong focus on aerospace components that demand strict tolerances. The company offers machining of complex parts such as airframe components, nozzles, housings, and structural brackets.[4]

As one of the Aerospace CNC Machining Manufacturers targeting high‑end sectors, cncfirst emphasizes both accuracy and cost‑effectiveness. Their process engineering and material expertise help overseas aerospace customers optimize design features that balance performance, manufacturability, and cost.[4]

Enze provides dedicated aircraft and aerospace CNC machining solutions, including machining, surface treatment, and assembly services. The company works with aluminum, stainless steel, titanium alloys, magnesium alloys, and composite materials, using material verification methods such as spectrometer testing.[5]

Within the group of Aerospace CNC Machining Manufacturers, Enze is particularly strong in finishing and post‑processing. Its capabilities include anodizing, electroplating, powder coating, and painting, which are critical for corrosion resistance and appearance in aerospace applications.[5]

Holly Plastic Parts is recognized for its competence in aerospace CNC machining of plastics and composite materials. The firm manufactures lightweight structural components, housings, and custom parts that require precise machining of engineering polymers and composites.[7]

This specialization makes Holly Plastic Parts unique among Aerospace CNC Machining Manufacturers, many of which focus primarily on metals. Aerospace customers often turn to them for parts where weight reduction and material performance under temperature changes are particularly important.[7]

Rapid Manufacturing serves aerospace and defense customers through its precision CNC machining services targeted at high‑value, critical components. Its capabilities include multi‑axis machining, advanced programming, and flexible manufacturing systems that can adapt to different batch sizes.[8][9][10]

As a member of the network of Aerospace CNC Machining Manufacturers, Rapid Manufacturing is often positioned for customers that require full documentation, consistent quality, and long‑term production support. Its combination of technical expertise and production management makes it suitable for demanding aerospace applications.[9][10]

PARTMFG is included in many listings of leading CNC machining companies in China, with services covering multiple industries including aerospace. The company provides custom machined parts, surface finishing, and quality inspection for global buyers.[11]

For aerospace clients, PARTMFG offers access to a broad base of CNC capabilities combined with competitive pricing. This positions it among versatile Aerospace CNC Machining Manufacturers that can supply prototypes, small batches, or production lots depending on customer needs.[11]

Yijin Hardware in Shenzhen provides precision CNC machining, rapid prototyping, and mass‑production services for custom components. The company's online service model and quick quotation process make it convenient for international engineering teams.[12]

As one of the newer‑style Aerospace CNC Machining Manufacturers, Yijin focuses heavily on responsiveness and speed. This makes it particularly attractive for customers who need rapid iterations during design and validation stages.[12]

RapidDirect is frequently listed among top CNC machining providers in China, supporting international customers across sectors including aerospace. It offers CNC milling and turning, as well as various surface finishes, making it a versatile partner for many custom projects.[13][11]

Other companies such as Blue Elephant and STYLECNC contribute to the ecosystem by providing advanced CNC machines and automation solutions used by many Aerospace CNC Machining Manufacturers. Their equipment helps factories achieve higher precision, better efficiency, and improved consistency on complex aerospace components.[14]

Choosing the right Aerospace CNC Machining Manufacturer is critical because aerospace projects often involve high technical risk and strict regulatory requirements. The selection decision should therefore include both technical and non‑technical factors.[2][5]

Key evaluation points include:[4][2][5]

- Machinery and process capability: Check for 4‑ and 5‑axis machining, multi‑axis turning, precision fixturing, and advanced CAM software.

- Quality systems and documentation: Confirm the presence of systematic inspection, material traceability, and clear documentation for each batch.

- Material and finishing experience: Ensure the supplier has a track record with aerospace alloys, composites, and the finishing processes that your parts need.

- Engineering support: Look for proactive design‑for‑manufacturing feedback and the ability to work with complex drawings and 3D models.

- Communication and project management: Evaluate how quickly the team responds, how clearly they explain issues, and how they manage delivery schedules.

Shangchen's combination of rapid prototyping, CNC machining, sheet metal, 3D printing, and molds means one supplier can manage the full lifecycle of aerospace parts, from first concept to stable production. This integrated model reduces the burden on overseas customers and matches the long‑term nature of aerospace programs.[3]

Overseas OEMs often choose Chinese Aerospace CNC Machining Manufacturers because they can access advanced technology and skilled engineers while maintaining competitive costs. As China's domestic aerospace and high‑tech sectors grow, local factories gain more experience handling complex projects and tight quality requirements.[1][4]

Additional benefits include:[5][1]

- Scalability: Many factories can support both small and large batch sizes, which is important as projects transition from prototype to series production.

- Supply chain depth: A mature ecosystem of material suppliers, surface finishers, and logistics providers supports fast turnaround and reliable deliveries.

- Continuous improvement: Competition among Aerospace CNC Machining Manufacturers encourages ongoing investment in new equipment, metrology, and process optimization.

For overseas buyers, the key is to carefully screen and manage suppliers, starting with smaller pilot orders and then expanding once quality and reliability are confirmed.[5]

China has built a strong network of Aerospace CNC Machining Manufacturers capable of supporting international aviation, space, UAV, and defense projects with high‑precision parts and assemblies. Within this network, Shangchen (sc‑rapidmanufacturing.com) offers a highly integrated solution that spans rapid prototyping, CNC machining, sheet metal, 3D printing, and mold manufacturing for overseas OEM customers.[1][3]

By combining diverse manufacturing processes with strict quality control and OEM‑friendly project management, Shangchen positions itself as a strategic long‑term partner rather than a simple job shop. Overseas brand owners, wholesalers, and manufacturers who need stable, scalable, and technically capable aerospace CNC machining in China can use the top‑10 overview in this article as a starting point for building robust, future‑proof supply chains.[1][5][3]

Shangchen stands out because it integrates rapid prototyping, CNC machining, CNC turning, sheet metal fabrication, 3D printing, and mold manufacturing in a single factory. This enables aerospace customers to move from design validation to stable production without switching suppliers, reducing coordination costs and project risk.[3]

Yes, Shangchen is structured to handle low‑volume prototypes, trial batches, and ongoing mass production using flexible machining lines and integrated processes. This scalability makes the company a suitable partner for aerospace projects that evolve over time from concept to full‑scale deployment.[3]

Chinese Aerospace CNC Machining Manufacturers frequently work with aluminum alloys, stainless steels, titanium alloys, magnesium alloys, nickel‑based alloys, engineering plastics, and aerospace composites. These materials are chosen for their high strength‑to‑weight ratio, fatigue resistance, corrosion resistance, and performance in extreme operating conditions.[7][2][4][5]

Leading factories apply strict incoming material inspection, in‑process checks, and final inspection using CMM, optical measurement, and other test equipment. They provide detailed documentation, including material certificates and inspection reports, to meet aerospace customer requirements for traceability and quality assurance.[2][5]

Overseas buyers should evaluate technical capability, quality systems, material expertise, communication, and experience with aerospace or similarly demanding sectors. Visiting facilities, reviewing sample parts, and starting with pilot projects is an effective way to verify that a selected Aerospace CNC Machining Manufacturer can meet long‑term requirements.[4][2][5]

[1](https://www.tuofa-cncmachining.com/tuofa-blog/top-10-cnc-aerospace-component-manufacturers.html)

[2](https://hppi.com/aerospace-cnc-machining)

[3](https://www.sc-rapidmanufacturing.com)

[4](https://cncfirst.com/aerospace-cnc-machining/)

[5](https://www.enzemfg.com/aircraft-aerospace-cnc-machining-suppliers-in-china/)

[6](https://www.youtube.com/watch?v=SUM2-P63MRI)

[7](https://www.hollyplasticparts.com/world-aerospace-cnc-machining-manufacturers/)

[8](https://rapidmfg.com/markets_served/aerospace/)

[9](https://www.rapidmfgco.com/industries/aerospace-and-defense)

[10](https://www.rapidmfgco.com/services/cnc-machining)

[11](https://www.partmfg.com/cnc-machining-companies/)

[12](https://yijinsolution.com)

[13](https://tirapid.com/cnc-machining-china/)

[14](https://www.elephant-cnc.com/blog/top-10-cnc-machine-manufacturers-in-china/)

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia

Top Metal CNC Machining Manufacturers and Suppliers in Portugal

Top Metal CNC Machining Manufacturers and Suppliers in Spain

Top Metal CNC Machining Manufacturers and Suppliers in France