Views: 222 Author: Amanda Publish Time: 2025-11-14 Origin: Site

Content Menu

● Understanding Turning Lathes

● The Role of Turning Lathes in Rapid Prototyping

>> Accelerated Product Development

>> Precision, Consistency, and Repeatability

>> Design Iteration and Flexibility

● Turning Lathe Workflow for Rapid Prototyping

● Unique Advantages of Turning Lathes for Prototyping

>> Versatility

>> Superior Surface Finish and Detail

● Industry Applications of Turning Lathes in Rapid Prototyping

● Enhancing Manufacturability and Scalability

● Optimizing Designs for Turning Lathe Prototyping

● Real-World Case Studies and Success Stories

● Trends and Innovations in Turning Lathe Rapid Prototyping

● FAQ

>> What kind of parts are most suitable for turning lathe rapid prototyping?

>> Why do engineers choose CNC turning lathes over manual versions for rapid prototyping?

>> Can turning lathe rapid prototyping be used for both metallic and plastic materials?

>> How does turning lathe prototyping reduce product development time?

>> Are parts made by turning lathes suitable for real-world, end-use scenarios?

Rapid prototyping has fundamentally transformed the manufacturing process across industries by enabling the quick, efficient, and cost-effective creation of physical models from digital designs. Among the central tools powering this transformation is the turning lathe—an enduring and evolving technology that has become irreplaceable for any advanced prototyping service offering. For OEM suppliers and global brands, leveraging state-of-the-art turning lathe solutions opens pathways to faster development, higher precision, and more reliable parts than ever before.[4][11][12]

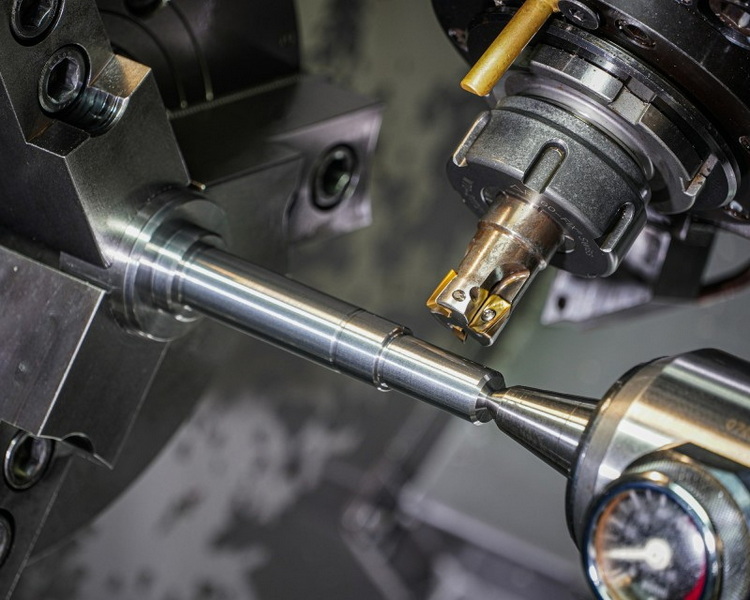

A turning lathe is a precision machine tool that rotates a workpiece around its axis and applies stationary cutting tools to shape the target geometry. Its principal utility lies in producing cylindrical, conical, and threaded parts with high accuracy. In its modern, CNC-powered incarnation, the turning lathe provides fully automated, programmable controls for consistency and ultra-fine tolerances on metals, plastics, and specialty materials.[12][13]

Modern CNC turning lathes elevate this precision through digital integration, offering features such as live tooling, automated part handling, and synchronized secondary operations, which support even highly complex or hybrid component production. The adoption of modern turning lathes ensures that manufacturing remains competitive, agile, and responsive to quick design changes.[13][4]

Turning lathes play a pivotal role in compressing the lead time from concept to tangible prototype. This agility is crucial for companies operating in fast-paced markets, where the ability to iterate designs frequently can determine commercial success. A CNC turning lathe can directly convert a 3D CAD model into a precision component within hours or days, drastically reducing the waiting period common with legacy manufacturing.[11][4]

Features like multi-axis control, dynamic tool offsets, and adaptive feedback make modern turning lathes ideal for maintaining strict dimensional tolerances and producing smooth surface finishes. This allows rapid prototypes not only to function as concept models but to serve in realistic validation and end-use scenarios—face-offs, fits, threads, grooves, and more can be generated to exact specification.[11][12]

One key advantage is the ease of making incremental adjustments. Engineers can modify design files and, through rapid CNC programming, see the improved prototype in short order without needing new molds or fixtures. This greatly enhances the iterative process and accelerates optimization cycles.[11]

A typical prototyping workflow using a turning lathe includes:

- Material Selection: Selection is driven by the part's intended function; popular choices include aluminum, stainless steel, brass, engineering plastics, and sometimes titanium for highly specialized applications.

- Programming and Setup: Digital models are translated into G-code, which precisely controls the cutting sequence and toolpath.

- Machining Operations: Operations such as external turning, facing, threading, boring, and grooving are performed to form the target geometry.

- Inspection and Finishing: Quality checks—often automated—ensure tolerances are met. If necessary, secondary finishing operations like polishing or drilling are applied.

Turning lathes—especially CNC-equipped systems—enable low- to medium-volume production without the need for expensive tooling, which is a major cost driver in traditional methods like injection molding. This makes turning ideal for prototypes or small batches, where cost-per-unit is crucial.[4][11]

With their ability to process a wide range of engineering metals and plastics, turning lathes play a central role in industries that require versatility, be it automotive, aerospace, medical devices, or electronics. This versatility supports tailored solutions for prototypes in each sector's unique regulatory and performance environment.[1][6]

The inherent capabilities of modern turning lathes enable them to produce excellent surface finishes and tight tolerances, often reducing or eliminating the need for separate finishing steps. As a result, prototypes closely resemble production parts, enabling direct fit and performance testing.[5][12]

Turning lathes produce axles, drive shafts, gear blanks, and complex bushings critical for vehicle prototypes. These prototypes often undergo extensive testing for stress, fatigue, and compatibility, making precision a vital requirement. The short lead times afforded by CNC turning directly accelerate vehicle R&D and model iteration.[2][1]

Stringent regulatory and quality demands make turning lathes an essential asset in aerospace prototyping—creating landing gear components, actuator housings, fittings, and lightweight connectors with specialized alloys. Consistency, surface quality, and exact dimensions are non-negotiable, and only modern CNC turning can deliver at the required level.[6][2]

Medical equipment prototypes require uncompromising accuracy and surface finishes, especially for devices that contact the human body. Turning lathes manufacture prototypes for bone screws, implant housings, surgical guides, cannulas, and more, rapidly moving from digital concept to functional sample for clinical validation.[1][2]

For electronics, rapid functional prototypes for connector housings, threaded inserts, custom enclosures, and miniature axles are critical for fit, heat transfer, and integration testing. Robotics leverages turned components such as end effectors, joints, and mounting spindles, benefitting from high-quality alloys and advanced plastics processed on turning lathes.[2][12]

Prototyping of precision shafts, bushings, valves, and pump housings for marine and energy applications often relies on CNC turning. The ability to work with corrosion-resistant alloys and deliver close-tolerance, repeatable results makes lathe-based prototyping a mainstay in these demanding environments.[6][2]

Turning lathes don't just simplify prototyping—they lay the groundwork for scalable production. Once a prototype is validated, the same turning setup (with minimal changeover) can shift to small or mid-batch runs, ensuring seamless transitions for time-to-market and production efficiency. This scalability supports companies from the innovation phase to full commercial release, creating a critical link between design and mass manufacturing.[4][6]

Simultaneously, turning lathes support hybrid manufacturing approaches by combining milled, drilled, and turned features in a single setup, further reducing time and handling risks.

Successful rapid prototyping with turning lathes is a collaborative journey, requiring close interaction between designers, engineers, and machining experts:

- Foster Design-For-Manufacturability (DFM): Early collaboration with turning experts can reveal optimizations—reducing machining complexity, improving material yield, or integrating multiple functions into a single part.

- Leverage Live Tooling & Automation: Use modern CNC lathes with live tooling for forms that require simultaneous turning, milling, or drilling.

- Prioritize Economies of Scale: For low-volume production, optimal batch sizes can maximize machine uptime without incurring tooling overhead.

Careful material selection is vital; not all synthetic polymers or advanced alloys exhibit the same machinability as standard metals, so selecting the right substrate and adjusting machine parameters is required.[9]

Leading rapid prototyping firms regularly achieve time and cost savings for clients via turning lathe applications:

- An automotive supplier slashed drive shaft development time by 70%, delivering testable samples in under a week versus a month with alternative techniques.[4]

- A medical startup leveraged CNC turning for its implant prototypes, attaining extremely fine tolerances needed for regulatory trials and patient safety well before full-rate production.

- Robotics manufacturers deploy turning lathes to produce lightweight, durable arms and fixtures, iterating designs in record time—vital to maintaining a technology edge.[2]

As rapid prototyping evolves, key trends are reshaping the turning lathe landscape:

- Digital Integration and Smart Manufacturing: Cloud-based CAD/CAM integration allows for remote collaboration, instant quoting, and agile adjustments.[1]

- Advanced Materials: Modern lathes now process superalloys, composites, and high-performance plastics previously impractical for prototyping.

- Hybrid Fabrication: Combining additive manufacturing (3D printing) with turning and milling in a single sequence yields both speed and geometric complexity.[7]

Modern OEM providers in China and beyond are pushing the envelope by integrating turning lathes with automated QA, IoT data collection, and even remote process monitoring, offering a smarter, more transparent journey for global clients.[1]

Looking ahead, the fusion of turning lathe technology with digital design ecosystems, advanced analytics, and new material science promises even greater agility. As more industries demand rapid, high-quality prototypes with complex features and new performance metrics, turning lathes will continue to be an essential bridge between concept and reality, underpinning the success of the next generation of innovative products.

In today's accelerated product development environment, turning lathes have proven themselves as the backbone of rapid prototyping services, enabling businesses to transform ideas into market-ready products with unmatched speed and precision. Through the flexibility of digital manufacturing, the precision of CNC control, and the ability to work seamlessly with a broad spectrum of materials, turning lathes empower OEMs and innovators worldwide. Whether the goal is fast iteration, cost-effective validation, or scaling ideas for industrial production, turning lathes remain the linchpin technology for rapid prototyping's present and future.[12][11][4]

Cylindrical, symmetrical, or threaded parts—such as shafts, bushings, fasteners, and adapters—are ideal. Turning lathes handle these geometries with higher precision and efficiency than most other subtractive processes.[6][12]

CNC turning lathes deliver superior accuracy, speed, and repeatability, integrate directly with CAD/CAM files, and enable rapid, automated iterations. Manual lathes work best for concept modeling and individual craftsmanship.[13][12]

Yes. Modern CNC turning lathes are engineered to machine a broad spectrum of metals—including aluminum, brass, titanium, and steel—as well as engineering plastics, making them highly versatile for prototypes in most sectors.[9][1]

It bypasses lengthy and expensive tooling cycles, delivers working models in days, and supports frequent design revisions, thus accelerating validation and market launch cycles for new products.[11][4]

Absolutely. Provided the same material is used, the quality and tolerances from CNC turning easily match those of final production for small batches or pilot runs, allowing realistic testing and early user feedback before mass production.[12][1][11]

[1](https://www.pcbway.com/rapid-prototyping/CNC-machining/CNC-Turning.html)

[2](https://www.3erp.com/blog/cnc-machining-applications-and-uses/)

[3](https://www.protolabs.com/services/cnc-machining/cnc-turning/)

[4](https://rapidaxis.com/capabilities/production-prototype-cnc-machining/)

[5](https://prototek.com/article/rapid-prototyping-bridging-ideas-and-reality/)

[6](https://schottmfg.com/services/prototyping/)

[7](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[8](https://uptivemfg.com/solutions/rapid-prototyping/)

[9](https://xcmachining.com/rapid-prototyping/)

[10](https://bolesolutions.com/services/rapid-prototyping/)

[11](https://www.cncprotolabs.com/blog/cnc-milling-and-turning-core-applications-and-advantages-in-rapid-prototyping)

[12](https://www.wevolver.com/article/what-is-cnc-turning)

[13](https://www.rapiddirect.com/blog/cnc-lathe-vs-cnc-turning-center/)

content is empty!