Views: 222 Author: Amanda Publish Time: 2025-08-12 Origin: Site

Content Menu

● Understanding 5-Axis Machining

>> Key Advantages of 5-Axis Machining Include:

● The Critical Role of CAM Software in 5-Axis Machining

>> Core Functions of CAM Software for 5-Axis Machining

>> How CAM Software Improves 5-Axis Machining Accuracy

>>> Intelligent Toolpath Algorithms

>>> Virtual Collision Avoidance

>>> Realistic Simulation and Virtual Prototyping

● Overcoming Common Challenges in 5-Axis Machining With CAM

>> Workholding and Fixturing Analysis

>> Machine-Specific Adaptations

● Advanced CAM Features Driving Accuracy and Efficiency

● Popular CAM Software Solutions for 5-Axis Machining

● FAQ

>> 1. How does CAM software improve the accuracy of 5-axis machining?

>> 2. What are the main challenges in 5-axis machining programming, and how does CAM address them?

>> 3. Can 5-axis machining reduce multiple setups compared to traditional machining?

>> 4. Which industries benefit most from CAM-driven 5-axis machining?

>> 5. Why is simulation important in CAM software for 5-axis machining?

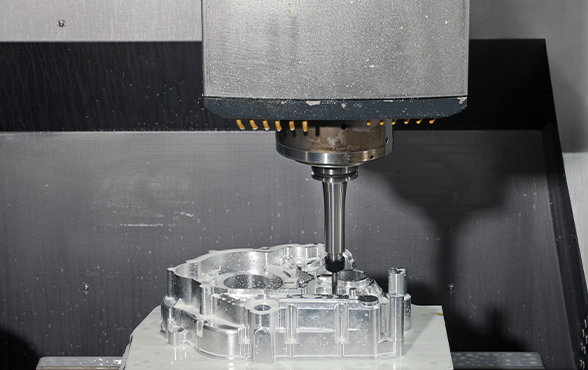

In modern manufacturing, 5-axis machining stands out as a groundbreaking technology that enables the production of complex parts with unparalleled precision and efficiency. This advanced machining process allows the cutting tool or the workpiece to move simultaneously along five different axes, unlocking design possibilities and manufacturing agility that traditional 3-axis machines cannot achieve.

At the core of this capability lies Computer-Aided Manufacturing (CAM) software, a sophisticated tool essential to realizing the full potential of 5-axis machining accuracy. CAM software acts as a powerful link between intricate CAD data and the physical cutting operations performed by the machine. It translates digital models into optimized, error-free toolpaths, ensuring parts meet tight tolerances, have superior surface finishes, and are produced cost-effectively.

This article offers a detailed exploration of the role of CAM software in enhancing 5-axis machining accuracy. It covers the fundamentals of 5-axis machining, the critical functions of CAM software, common challenges with multi-axis programming, advanced techniques, and practical benefits — all woven together to provide a comprehensive understanding of this transformative technology.

5-axis machining extends traditional CNC milling by delivering movement along five axes: the standard linear X, Y, and Z axes, complemented by two rotational axes (commonly A and B). This results in the ability to position the cutting tool at almost any angle relative to the workpiece.

This multi-directional motion opens doors to manufacturing highly intricate geometries, reducing the number of setups required and often eliminating the need for manual repositioning. As a result, complex curved surfaces, deep cavities, and undercuts become practical to machine with excellent repeatability and precision.

- Superior Precision: 5-axis machining allows the cutting tool to maintain optimal orientation relative to the surface, reducing tool deflection and improving dimensional accuracy.

- Reduced Setup Time: Fewer setups mean less manual realignment, lowering cumulative errors and dramatically shortening production cycles.

- Enhanced Surface Finish: Continuous tool contact enables smoother cutting motions and finer finishes on complex surfaces.

- Increased Tool Life: Optimal tool angles reduce cutting forces and vibration, thereby extending the lifespan of expensive tooling.

- Greater Flexibility: Ability to machine a wide range of parts including aerospace components, medical implants, automotive molds, and intricate die castings.

While 5-axis machinery provides advanced mechanical capabilities, unlocking their precision depends heavily on effective CAM software. CAM programs convert digital CAD designs into detailed machining instructions (G-code) that guide the CNC machine.

- Automated Toolpath Generation: CAM software interprets complex 3D geometry and generates toolpaths that control every movement along all five axes, ensuring optimal cutting conditions.

- Collision Detection and Avoidance: Advanced algorithms simulate the entire machining process in a virtual environment to identify and eliminate potential tool collisions with the workpiece, fixtures, or machine components.

- Machining Simulation and Verification: Visual simulation helps validate toolpaths by detecting gouges, undercuts, or missed areas before actual machining begins.

- Adaptive Machining Strategies: Dynamic adjustment of feed rates and tool orientation based on surface geometry improves cutting efficiency and maintains consistent accuracy.

- Post-Processing Integration: CAM tailors output code for specific CNC machine models, accounting for machine kinematics and axis limits, ensuring executable and efficient programs.

At the heart of CAM's accuracy improvements are its advanced toolpath calculation algorithms. Unlike simpler 3-axis programming, 5-axis toolpaths require continuous adjustment of both tool position and orientation, demanding sophisticated interpolation of multiple axes simultaneously.

These intelligent algorithms enable:

- Continuous Orientation Control: Maintaining the optimal tool angle relative to the surface contour reduces cutting forces and vibration.

- Smooth Transitions: Minimizing abrupt directional changes avoids tool chatter and stepover marks that would degrade surface integrity.

- Dynamic Feedrate Optimization: Feedrates automatically adjust in real-time according to tool engagement, keeping cutting conditions ideal and parts within tolerance.

Collisions are the bane of 5-axis machining, where intricate movements frequently bring the tool or spindle close to fixtures and the workpiece. CAM software's simulation environment models these complex interactions and alerts operators to any potential interferences.

This proactive collision management:

- Prevents costly machine damages.

- Reduces scrap rates by ensuring toolpaths do not gouge the workpiece.

- Increases confidence during program verification and reduces machine downtime.

Simulation tools in CAM provide a visual walkthrough of the entire machining process before physical cutting begins. These virtual prototypes:

- Highlight any areas of excess material left uncut or too aggressive material removal.

- Allow machining strategies to be adjusted for better finish and dimensional conformity.

- Deliver precise cycle time estimates to optimize production planning.

Because errors are detected early, manufacturers save valuable time and resources that would otherwise be spent on trial-and-error setups and costly rework.

Despite its advantages, 5-axis machining introduces unique complexities that pose challenges in programming, fixturing, and machine-specific constraints.

Programming 5-axis operations manually is extremely difficult due to simultaneous multi-axis interpolation and movement synchronization. CAM software simplifies this process by:

- Providing user-friendly interfaces and wizard-based strategies.

- Offering preconfigured machining templates for common operations such as 5-axis contour milling, simultaneous 5-axis machining, and multi-sided machining.

- Automating difficult calculations, thereby reducing programmer workload and human errors.

Proper fixturing is critical to ensure part stability during complex tool movements. CAM simulation modules assist in:

- Evaluating the accessibility of tools around workholding setups.

- Designing fixtures that minimize obstruction and provide maximum rigidity.

- Ensuring machining strategies avoid collisions with clamps and mounting components.

Every 5-axis CNC machine has unique kinematic arrangements and axis limits. CAM must conform output programs to specific machine architectures through:

- Customized post-processors that translate toolpaths into compatible code.

- Incorporating machine workspace limits and axis travel constraints into simulation.

- Adapting machining sequences to accommodate rotary axis wrap or axis inversion.

Modern CAM systems continue evolving to support cutting-edge machining techniques and further improve accuracy:

- Tool Center Point (TCP) Control: Precise control of the TCP allows finer adjustments in tool orientation along complex surfaces.

- Collision Dynamic Re-Routing: Real-time dynamic re-routing of toolpaths around potential collisions improves workflow and reduces need for manual intervention.

- Multi-Toolpath Optimization: CAM software can combine multiple machining operations in a single program optimized for tool changes and minimal axis repositioning.

- Integration with Machine Monitoring: Advanced CAM links with machine monitoring systems providing real-time feedback to adjust machining conditions on the fly, maintaining accuracy.

Manufacturers benefit from various specialized CAM systems tailored for multi-axis machining:

- Siemens NX CAM: Offers powerful multi-axis capabilities with integrated simulation and post-processing.

- Autodesk Fusion 360: An accessible platform combining CAD and CAM, suitable for complex 5-axis tasks.

- Mastercam: Industry-favored for robust 5-axis strategies and automation workflow.

- hyperMILL® (OPEN MIND Technologies): Renowned for advanced collision avoidance and accurate multi-axis machining.

- PowerMill (Autodesk): Focuses on high-speed 5-axis machining with toolpath optimization.

CAM software plays an indispensable role in unlocking the true advantages of 5-axis machining by transforming complex CAD designs into highly accurate, collision-free, and efficient machining instructions. Its intelligent toolpath generation, comprehensive simulation, and dynamic collision management all contribute to superior precision, shortened production cycles, and reduced operational risks.

As industries demand increasingly complex components with tight tolerances and reduced lead times, the synergy between advanced 5-axis machines and state-of-the-art CAM software becomes critical. Leveraging these technologies empowers manufacturers to maintain a competitive edge while achieving exceptional quality and productivity.

CAM software enhances accuracy by generating optimized toolpaths that maintain ideal tool orientation, preventing collisions, simulating machining operations to detect errors, and dynamically adapting feed rates to maintain stable cutting conditions.

The complexity of programming five simultaneous axes and avoiding collisions makes manual programming difficult. CAM addresses these challenges with automated toolpath algorithms, user-friendly interfaces, collision detection, and machine-specific post-processing.

Yes. 5-axis machining combined with CAM software allows multiple complex geometries to be machined in a single setup, significantly reducing the need for repositioning, alignment errors, and overall production time.

Aerospace, automotive, medical devices, mold and die manufacturing, and high-precision engineering sectors benefit the most, as they often require intricate parts with complex surfaces and exacting tolerances.

Simulation helps visualize and verify toolpaths, identify collisions, and detect machining errors before production starts. This preemptive step reduces costly scrap, machine downtime, and ensures the highest accuracy.

[1] https://kingsunmachining.com/blog/cam-for-machining/

[2] https://www.methodsmachine.com/blog/benefits-of-5-axis-machining/

[3] https://www.gemsons.com/real-world-challenges-in-5-axis-cnc-machining-and-how-to-overcome-them/

[4] https://www.youtube.com/watch?v=YhefBROYlAo

[5] https://toolpath.com/top-questions/what-is-one-benefit-of-the-cam-system

[6] https://www.numberanalytics.com/blog/ultimate-guide-5-axis-machining

[7] https://www.3erp.com/blog/5-axis-cnc-machining-advantages/

[8] https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=be4c85ffb60b70cdff2384100bf62148af7b18e0

[9] https://penta3d.com/best-cam-software-for-5-axis-machining/

[10] https://jlccnc.com/blog/cam-software-and-cnc-machining

[11] https://blogs.sw.siemens.com/nx-manufacturing/top-5-advanced-cam-software-capabilities/

[12] https://www.autodesk.com/solutions/5-axis-machining

[13] https://www.makino.co.jp/resources/content-library/webinars/archive/considerations-for-large-part-5-axis-machining/346

[14] https://robodk.com/blog/guide-5-axis-machining-software/

[15] https://www.linkedin.com/advice/0/1-how-does-cadcam-integration-improve-cnc-machining-7hnhe

[16] https://www.openmind-tech.com/en/cam/5-axis-milling/

[17] https://www.dmgmori.co.jp/sp/5axis/en/

[18] https://www.okuma.co.jp/english/product/5avmc-mm-qa/

[19] https://www.youtube.com/watch?v=Bbwt4bS0SzA

[20] https://toolpath.com/top-questions/what-are-the-advantages-of-cam-software

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal