Views: 222 Author: Amanda Publish Time: 2025-11-02 Origin: Site

Content Menu

● Overview of the two core processes

>> Why the distinction matters for part design and program planning

>> Key decision criteria to guide project planning

● Process flows: from design to first articles

>> Quality control considerations

>> Materials and performance profiles

>> Hybrid and integrated manufacturing strategies

>> Accuracy, tolerances, and surface finishes

● Total cost of ownership and lifecycle considerations

● FAQs

>> 1. What is moulding production best suited for?

>> 2. When should CNC machining be chosen over moulding production?

>> 3. How do I estimate the break-even point between moulding and CNC?

>> 4. Can moulding and CNC be used together in a single project?

>> 5. What tolerances and surface finishes can be expected from moulding vs CNC?

In the competitive landscape of global product development, choosing the right manufacturing route is essential for achieving timely delivery, cost efficiency, and consistent quality. For foreign brands, wholesalers, and manufacturers partnering with a trusted Chinese supplier, understanding moulding production alongside CNC machining is fundamental. This article examines the core distinctions between moulding production and CNC machining, explores decision criteria, and demonstrates how Shangchen's integrated capabilities—spanning moulding production, CNC machining, sheet metal fabrication, 3D printing, and tooling production—enable seamless transitions from rapid prototyping to high-volume production for international partners.

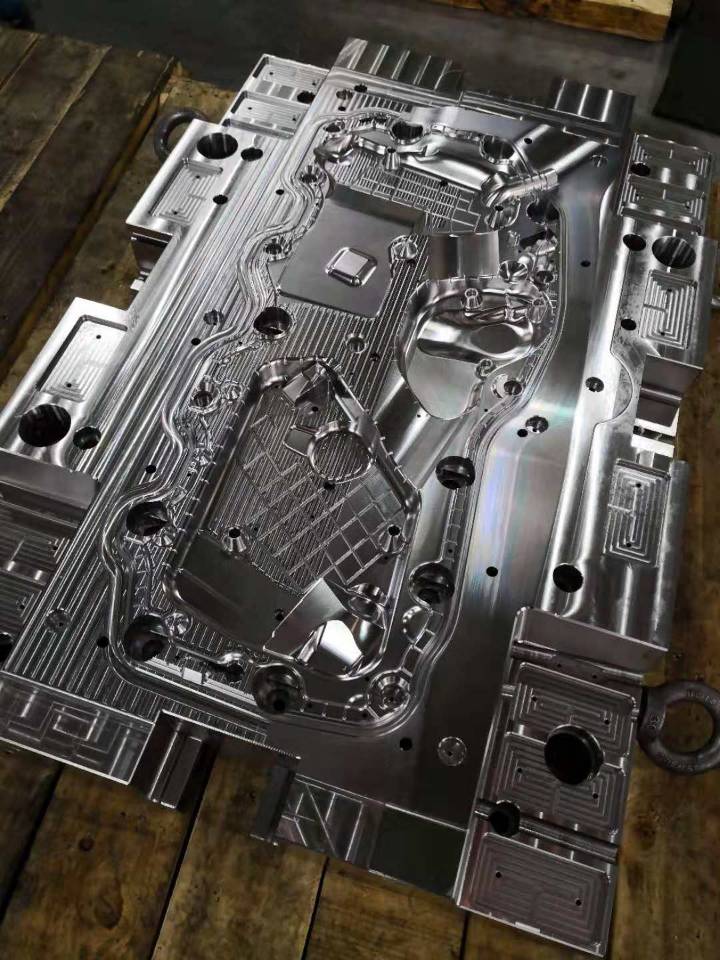

Moulding production, primarily represented by injection moulding and related moulding processes, is a formative manufacturing method. Molten plastic is injected into a precision cavity, where it cools and solidifies into the final part. The process is highly repeatable, enabling millions of identical parts once a mould is validated. Moulding production excels in high-volume demands and is particularly cost-effective when the production run justifies the upfront tooling investment.

CNC machining is a subtractive process that uses computer-controlled cutting tools to remove material from a solid block, producing precise geometry and features. With five-axis capabilities, multiple tool paths, and sophisticated fixturing, CNC machining offers exceptional flexibility for complex shapes, tight tolerances, and rapid prototyping. CNC machining is especially advantageous for low-to-mid-volume runs, design iterations, and parts requiring delicate internal features or unusual materials.

- Cost dynamics: Moulding production requires a significant upfront investment in mould tooling, but unit costs drop sharply at scale. CNC machining avoids these mould costs, delivering lower initial spend but higher per-part costs at larger volumes, depending on complexity and material.

- Tolerances and surface finish: CNC machining can achieve extremely tight tolerances and high-end surface finishes on a wide range of materials. Moulding production provides outstanding dimensional stability and repeatability after mould validation, with surface aesthetics strongly influenced by mould quality and tooling.

- Lead times and agility: For early-stage development, CNC machining offers quick first articles and design flexibility. Moulding production requires tooling time, but once the mould is ready, production can scale rapidly to meet large-volume targets.

- Material considerations: CNC machining supports metals, engineering plastics, and composites with broad versatility, while moulding production is particularly efficient for plastics with well-understood melt and flow characteristics.

- Volume requirements: For large production runs, moulding production generally offers lower per-part costs and faster high-volume throughput. For prototypes or small-to-mid-volume production, CNC machining provides speed and flexibility.

- Part geometry and complexity: Complex geometries, undercuts, segmentation, and high-precision features can be effectively addressed by CNC machining, particularly when tolerances are critical. Moulds can incorporate complex cavities, inserts, and multi-component assemblies, but mould design complexity translates into longer tooling lead times.

- Tolerance and quality targets: If the application requires exceptionally tight tolerances and a flawless surface finish, CNC machining may hold advantages in early stages or for critical features, while moulding production delivers outstanding repeatability once the process is stable.

- Time-to-market pressure: Rapid prototyping and quick iterations often favor CNC machining. When a stable design is established, shifting to moulding production can dramatically reduce unit cost and ramp capacity for mass production.

- Total cost of ownership: Evaluate tooling investment, maintenance, mould wear, and surface finishing requirements. In long-running programs, the cost savings from moulding production can be substantial, but upfront capital expenditure and risk should be weighed carefully.

- Design for mouldability: Part design is optimized for moulding, including draft angles, rib structures, and gate locations to ensure good fill and ejection.

- Mould design and fabrication: Core and cavity creation, cooling channels, ejection system, and inserts are engineered to exact specifications.

- Tooling validation: Tooling is tested with trial runs to validate fill, temperature control, orientation, and part consistency.

- Process optimization: Cycle times, gate sizing, and cooling strategies are refined to achieve stable production.

- First articles and qualification: A sample batch is produced and measured to verify tolerances, color, and surface quality before full-scale production.

- CAD/CAM preparation: Part geometry is prepared for milling, turning, or multi-axis operations, including tool selection and path planning.

- Stock preparation and fixturing: Raw material blocks or billets are prepared and securely fixtured for precise machining.

- Machining and finishing: Roughing, finishing passes, deburring, and post-processing steps (e.g., polishing, anodizing) are executed.

- Inspection and validation: Coordinate measuring machine (CMM) checks confirm dimensional accuracy and surface integrity.

- First articles and scale-up planning: Early samples verify tolerances and surface finishes, guiding subsequent production steps.

- Statistical process control (SPC): Both processes benefit from data-driven monitoring to ensure repeatability and reliability across batches.

- Material and thermal effects: Temperature variations can affect moulded parts and machined parts alike, necessitating controlled environments and proper part handling.

- Surface treatment compatibility: Finishes such as painting, plating, or coating must be compatible with both moulded and machined surfaces; plan post-processing accordingly.

- Moulding production materials: Thermoplastics (PP, ABS, PC, PC-ABS, TPE blends), thermosets, and certain elastomeric compounds are commonly used with injection moulding. Material selection is guided by mechanical properties, chemical resistance, and aesthetic requirements.

- CNC-friendly materials: Metals (aluminum, steel, titanium), engineering plastics (PEEK, Delrin, Noryl), and composites. Each material brings specific machinability, machinist skill requirements, and surface finish expectations.

- Automotive components: Structural housings, interior trim parts, and sensor housings can leverage moulding production for volume efficiency, with CNC machining supporting functional prototypes and critical-fit parts.

- Consumer electronics enclosures: Moulding production offers consistent aesthetics and scale, while CNC machining is valuable for metal or high-precision features.

- Medical devices: Precision, cleanability, and regulatory considerations drive a balanced approach—CNC machining for critical interfaces, moulding production for mass production of disposable or semi-durable components.

- Home appliances and industrial equipment: High-volume plastic housings, housings with integrated features, and complex assemblies often rely on moulding production, complemented by CNC-machined components for metal sub-assemblies or precision inserts.

- Prototyping-to-production handoff: CNC-machined prototypes can validate fit, function, and aesthetics before transitioning to moulding production for mass manufacturing.

- Insert molding and multi-material strategies: Complex parts may combine moulded substrates with inserted metal or thermoplastic features to achieve performance goals without multiple assembly steps.

- Secondary operations and finishing: Painting, plating, heat treatment, and assembly can be applied post-moulding or post-machining according to functional and cosmetic requirements.

- Design-for-manufacturability (DFM) collaboration: Early and ongoing DFM collaboration ensures designs align with both processes, minimizing costly redesigns and enabling smoother scale-up.

- CNC tolerances: Typical ranges can be as tight as ±0.05 mm to ±0.1 mm for many applications, with some advanced setups achieving tighter tolerances depending on geometry and machine capability.

- Moulding tolerances: Dimensional accuracy tends to be stable after mould validation; tolerances are often within ±0.1–0.3 mm for many consumer-grade plastics, with tighter tolerances achievable for high-precision components through careful mould design and process control.

- Surface finishes: CNC machined parts often exhibit smoother surfaces with selected finishing (e.g., honing, polishing). Moulded parts rely on mould quality; post-mould finishing can achieve the desired surface appearance.

- Initial investment: Injection mould tooling can represent a substantial upfront cost, while CNC setups avoid tooling but require high-precision machine time and skilled operators.

- Unit cost over volume: Moulding production becomes increasingly cost-effective as volumes rise, thanks to spread tooling costs across more parts; CNC costs remain driven by material, time, and labor for each part.

- Tool wear and maintenance: Moulds experience wear, potentially affecting part quality over time; scheduled maintenance and mould refurbishment extend life. CNC tooling incurs wear and may require re-sharpening or replacement for consistent performance.

Moulding production shines in high-volume plastics manufacturing, delivering low per-part costs and exceptional repeatability once tooling is validated. CNC machining offers unmatched flexibility, precise tolerances, and rapid prototyping capabilities, making it ideal for early-stage development or low-to-mid volume runs. For global OEM partners, the most effective strategy often combines a staged approach: use CNC machining for rapid prototyping and design validation, then transition to moulding production to achieve scalable, cost-efficient mass production. Shangchen's integrated capabilities across moulding production, CNC machining, sheet metal fabrication, 3D printing, and tooling production empower international brands to move from concept to commercial success with minimal friction, supported by robust quality systems, responsive project management, and a commitment to manufacturability from the outset.

- Moulding production is ideal for high-volume plastic parts, delivering low per-part costs after tooling is created and ensuring strong repeatability across large runs.[4]

- CNC machining is preferred for prototyping, low-to-mid volume production, tight tolerances, and complex geometries that are difficult to achieve with moulds.[2]

- Compare the upfront tooling and per-part costs of moulding with the ongoing machine time, tool wear, and material costs of CNC to identify the volume at which each method becomes more economical.[11]

- Yes, a common approach is to use CNC for rapid prototyping and design validation before transitioning to moulding production for mass manufacture, sometimes incorporating insert molding or hybrid processes.[5]

- CNC can achieve very tight tolerances and smooth finishes on many materials, while moulding delivers excellent dimensional stability and repeatability; surface quality in moulding depends on mould precision and post-processing options.[1][2]

[1](https://asia.arrk.com/cnc-machining-vs-injection-moulding-a-useful-guide/)

[2](https://www.pentagonplastics.co.uk/post/plastic-injection-moulding-vs-cnc-machining)

[3](https://www.3erp.com/blog/injection-molding-vs-cnc-machining/)

[4](https://jlccnc.com/blog/cnc-machining-vs-injection-molding-how-to-choose-the-right-process-for-your-product)

[5](https://www.protolabs.com/en-gb/resources/blog/how-to-select-the-best-manufacturing-process-for-your-part/)

[6](https://www.rapiddirect.com/blog/cnc-machining-vs-injection-molding/)

[7](https://www.3dpeople.uk/3dpeopleuk-blog/3dp-im-cnc/)

[8](https://www.lineup.de/en/post/cnc-vs-injection-molding-how-to-choose-right/)

[9](https://www.youtube.com/watch?v=aqG36_OX148)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam