Views: 222 Author: Amanda Publish Time: 2025-11-03 Origin: Site

Content Menu

● What Moulding Production Encompasses

● Decision Criteria for Selecting a Top Partner

>> Distinguishing Attributes of Market Leaders

● Shangchen as a Case Example for OEM Partners

● Trends Shaping Moulding Production in the 2020s and Beyond

● Practical Working Guide for Effective Partnerships

● From One-off Projects to Mass Production: Resource Planning

● Industry-specific Considerations

● Case Study Scenarios (Hypothetical Walkthroughs)

>> Scenario A:

>> Scenario B:

● Sustainability and Compliance Considerations

● Frequently Asked Questions (FAQ)

>> 1. What is moulding production and why is it important for OEM projects?

>> 2. How long does it take to move from prototype to mass production in moulding?

>> 3. What certifications should a top moulding production partner have?

>> 4. How should a client evaluate a partner's media and tooling capabilities?

>> 5. What role does automation play in modern moulding production?

In the modern global supply chain, moulding production stands as a critical enabler of product innovation and scale. For overseas brands, wholesalers, and manufacturers seeking reliable OEM partnerships, choosing a moulding producer that can seamlessly move from rapid prototyping to full-scale production is essential. This article delves into what differentiates top moulding production manufacturers, the value they offer to international clients, and practical guidance for selecting a partner that can accelerate time-to-market while maintaining high quality, consistency, and IP protection. While many players exist, the standout firms share a core set of capabilities, including end-to-end service, DFx collaboration, and robust automation, all underpinned by resilient supply chains.

Moulding production covers a spectrum of processes designed to shape materials—primarily polymers and metals—into repeatable, high-precision parts. Leading providers typically offer:

- End-to-end lifecycle support: from concept design and rapid prototyping through tooling, production, assembly, and aftermarket support.

- Rapid iteration capabilities: fast-turn tooling and resin or metal prototypes to validate form, fit, and function before committing to full tooling.

- Multimaterial and multi-process capability: injection moulding, extrusion-based moulding, die casting, metal stamping, sheet forming, and secondary finishing operations.

- Advanced automation: robotics, vision systems, inline metrology, and digital monitoring to boost yield and traceability.

- Global logistics and compliance: multi-regional supply networks, regulatory alignment, and documentation that simplifies cross-border OEM programs.

Choosing the right moulding production partner hinges on several critical factors:

- Technical breadth and depth: breadth across moulding processes, plus coatings, assemblies, and post-processing options.

- Design for manufacturability (DFM) and design for assembly (DFA): proactive engineering input during concept and development to minimize tooling costs and optimize part performance.

- Tooling quality and lead times: the tooling lifecycle, including cavity counts, steel selection, maintenance plans, and estimated timelines from concept to ready-to-run moulds.

- Quality management and traceability: certifications such as ISO 9001, IATF 16949 for automotive, ISO 13485 for medical devices, and robust SPC, process qualification, and first-article inspection practices.

- Precision, repeatability, and process control: demonstrated ability to hold tight tolerances across high-volume runs, with statistical process control where appropriate.

- Automation maturity and data transparency: real-time process monitoring, traceability of materials and process parameters, and predictive maintenance capabilities.

- Supply chain resilience: risk mitigation, supplier diversification, and contingency plans to address disruptions.

- Intellectual property protection: clear NDA practices, data security, and controlled access to CAD data and process parameters.

- Cost efficiency and scalability: total cost of ownership across prototyping, tooling, and mass production, plus the ability to scale programs from pilot to full-scale production smoothly.

Top players generally excel in the following areas:

- Integrated service delivery: a single partner handling design, tooling, production, and post-processing to reduce handoffs and accelerate timelines.

- Early design collaboration: engineers participate early to optimize features, wall thickness, gate locations, and material choices.

- Data-driven manufacturing: comprehensive data capture, real-time dashboards, and analytics for continuous improvement and traceability.

- Flexible capacity: adaptable tooling and production lines that can shift between products, materials, and volume bands with minimal downtime.

Shangchen, known for rapid prototyping and broad manufacturing capabilities, offers a spectrum of services tailored to overseas brands, wholesalers, and production houses. Core strengths attributed to such a profile include:

- Rapid transition from concept to pilot to mass production, helping clients compress development cycles.

- Consolidated supply chain management and tooling with a view toward IP protection and streamlined project governance.

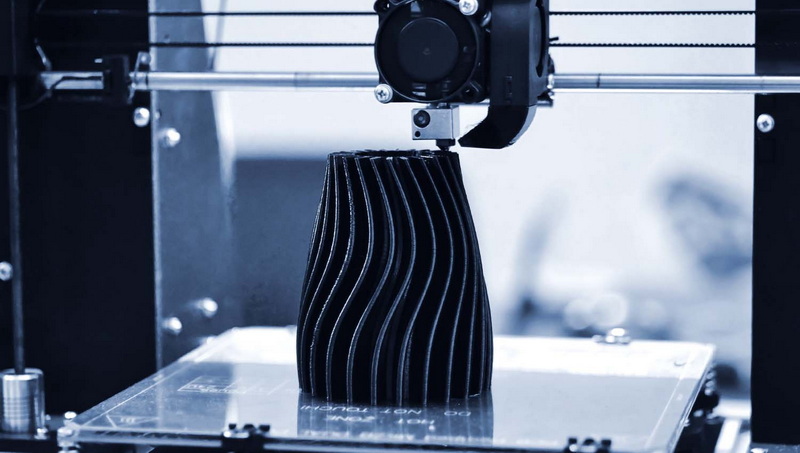

- Experience across multiple manufacturing domains, including rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, mould production, and toolmaking.

- Material versatility and finishing options designed to support diverse product families, from consumer electronics to automotive components.

Practical guidance for collaborating with Shangchen or similar partners:

- Request a capability matrix that outlines moulding options, CNC tolerance ranges, sheet metal capabilities, materials library, and finishing processes.

- Seek client references and case studies that align with your target market or product category.

- Clarify tooling timelines, mould maintenance cycles, and spare parts availability for long-running programs.

- Confirm QA protocols, inspection plans, and acceptance criteria for pilot and production runs.

- Establish a clear IP protection framework, NDA terms, and data security measures for CAD files, process parameters, and manufacturing instructions.

The moulding ecosystem is evolving rapidly to meet demand for lighter, stronger, and more sustainable parts, while reducing cycle times and costs. Key trends include:

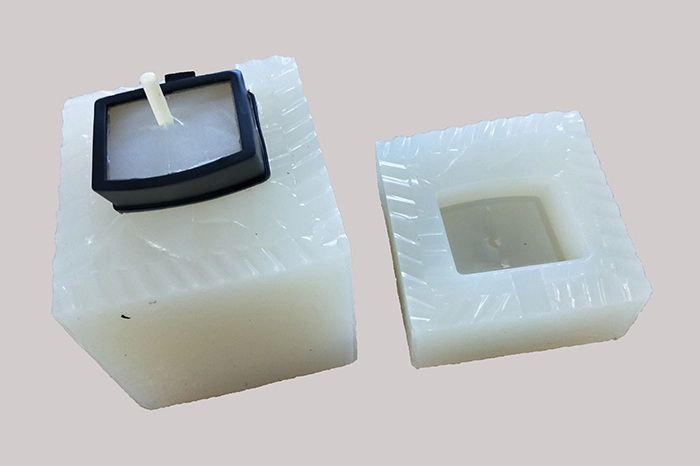

- Additive-assisted moulding: integrating 3D-printed inserts or fixtures to validate complex geometries before committing to metal tooling, shortening lead times and reducing waste.

- Multi-material plastics and functional integration: polymers engineered for higher stiffness, impact resistance, or embedded functionalities such as sensors or conductive pathways.

- Automation and digitalization: enhanced part handling, inline inspection, and closed-loop quality control for higher uptime and consistency.

- Digital twins and process analytics: simulation-driven design and real-time data integration to optimize moulding cycles, reduce scrap, and shorten validation phases.

- Sustainability and circularity: design-for-recyclability, lean material usage, and energy-efficient tooling and molding operations.

To maximize value from a moulding production partner, consider the following playbook:

- Define explicit requirements: materials, tolerances, surface finishes, expected volumes, and required lead times.

- Stage-gate development: validate feasibility with prototypes and pilot runs before committing to full production.

- Co-design and DFx: engage early in the design phase to minimize tooling costs and improve manufacturability.

- Material and process validation: establish process windows, acceptance criteria, and sampling plans to secure consistent performance across batches.

- Quality assurance rigor: demand a comprehensive quality plan detailing inspection methods, sampling strategies, and statistical process controls where applicable.

- Supply chain resilience and contingency planning: implement proactive risk mitigation and transparent issue escalation.

- IP protection and data governance: enforce robust NDA terms, controlled access to design data, and secure storage of process parameters.

- For rapid prototyping, use quick-turn tooling, resin, or low-volume runs to validate form, fit, and function before committing to metal tooling.

- For mass production, align mould design with expected batch sizes, part complexity, and post-processing requirements to minimize total cost of ownership and downtime.

- Leverage automation and modular tooling to enable rapid changeovers between product variants and new programs.

- Consumer electronics: emphasis on tight tolerances, cosmetic surface finishes, and integration with housings and PCB assemblies.

- Automotive: robust quality systems, traceability, and compliance with automotive standards plus long-term tooling stability.

- Medical devices: stringent documentation, biocompatible materials, sterilization compatibility, and stringent validation protocols.

- Household goods and consumer products: scalable production with attractive aesthetics, color consistency, and durable finishes.

Rapid prototyping to pilot line for a consumer electronics housing

- Phase 1: DFx collaboration to optimize wall thickness and heat dissipation

- Phase 2: Rapid tooling for short-run moulds to validate fit with internal components

- Phase 3: Pilot production with inline inspection and color matching, followed by scale-up to mass production

Medical device enclosure with high-reliability requirements

- Phase 1: Material qualification for biocompatibility and sterilization tolerance

- Phase 2: Tooling design emphasizing repeatability and traceability

- Phase 3: Validation runs with comprehensive QA, documentation, and supplier qualification

- Materials selection that favors recyclability and reduced environmental impact

- Energy-efficient tooling and cycle optimization to minimize consumption

- Compliance with international standards and regional regulations for medical devices, automotive, and consumer products

- End-of-life considerations and disposable versus reusable components

Selecting a leading moulding production partner goes beyond cost considerations. The right partner delivers consistent, high-quality parts on time, with strong engineering support, scalable capacity, and robust IP protection. For overseas brands, wholesalers, and manufacturers seeking OEM collaboration, a partner with comprehensive moulding capabilities, rapid prototyping, rigorous quality systems, and resilient supply chains can shorten development cycles and accelerate time-to-market. By evaluating capability breadth, DFx collaboration, automation maturity, and global delivery capabilities, brands can identify a partner that not only meets current needs but also adapts to evolving product demands.

Moulding production is the process of shaping materials—primarily polymers and metals—through moulds to create identical parts and components. It enables scalable, repeatable manufacturing, supports tight tolerances, and aligns with downstream assembly and finishing processes.[1][2]

Timelines depend on part complexity, tooling lead times, and validation requirements. Leading providers shorten cycles via concurrent engineering, rapid prototyping, and automated production lines, with pilot runs and staged ramp-ups to full volume.[3][1]

Key certifications include ISO 9001 for quality management, IATF 16949 for automotive, and ISO 13485 for medical devices, along with industry-specific approvals that demonstrate rigorous process control and traceability.[1][3]

Assess end-to-end service capability, material and finish breadth, the strength of the quality control plan, and the ability to document and share process data. Request demonstrations or case studies that reveal mold design, tool build, and high-volume outcomes.[3][1]

Automation improves consistency, throughput, and traceability. Robotics, inline inspection, and digital process monitoring reduce human error and boost yield—crucial for high-volume programs.[1][3]

[1](https://www.3erp.com/blog/the-entire-process-of-mold-making/)

[2](https://thriam.com/introduction-to-mold-manufacturing)

[3](https://www.sciencedirect.com/topics/engineering/moulding-process)

[4](https://de.meviy.misumi-ec.com/info/en/blog-en/manufacturing-en/27864/)

[5](https://geomiq.com/injection-moulding-guide/)

[6](https://www.polyplastics.com/global/s/support/PrototypeEvaluation/TheOutlineofInjectionMolding?language=en_US)

[7](https://ijaers.com/uploads/issue_files/3IJAERS-08202053-AReview.pdf)

[8](https://make.3dexperience.3ds.com/processes/molding)

[9](https://www.protolabs.com/resources/guides-and-trend-reports/designing-for-moldability-fundamental-elements/)

[10](https://xometry.pro/en/articles/injection-moulding-overview/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic