Views: 222 Author: Amanda Publish Time: 2025-11-02 Origin: Site

Content Menu

● 1: Defining Moulding Production

● 2: Understanding Sheet Metal Fabrication

● 3: When to Choose Moulding Production vs. Sheet Metal

>> Part complexity and geometry

>> Material properties and performance

>> Lead time and production speed

>> Surface finish and aesthetics

>> Tolerance and dimensional stability

>> Cost and lifecycle considerations

● 4: Hybrid and Integrated Approaches

● 5: Design-for-Manufacturing (DFM) Guidelines

● 6: Material Selection for Long-Term OEM Programs

● 7: Production Planning and Quality Assurance

● 8: Media-Ready Visual Roadmap for Your Content Strategy

● 9: Case Scenarios and Practical Learnings

● 10: Shangchen's Global OEM Enablement

● FAQ

>> 4. Can moulding production and sheet metal fabrication be used together in a single product?

Choosing the right manufacturing path for an engineering concept is more than a technical decision—it is a strategic business one. For overseas brand owners, wholesalers, and manufacturers seeking dependable OEM support, understanding how moulding production compares with sheet metal fabrication is essential to align design intent with cost, quality, and time-to-market. This article explores the core differences, situates moulding production as a central capability, and explains how to leverage sheet metal fabrication in complementary roles. The discussion is tailored to reflect Shangchen's diverse service portfolio, including moulding production, rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and tooling production for international clients. The goal is to equip product teams with a clear framework for design-for-manufacturability, material selection, tooling economics, and production planning that supports scalable, reliable OEM programs.

Moulding production refers to processes that shape materials by introducing them into or around a mold, producing parts with highly repeatable geometry across large production runs. The primary plastics-focused moulding pathway is injection molding, which uses melted polymer injected into precision steel or aluminum molds. Other moulding routes—such as thermoforming, vacuum forming, and reaction injection molding (RIM)—offer alternatives that suit different geometries, wall thicknesses, and material families. Key attributes of moulding production:

- Complex geometry: Integrated features like undercuts, intricate channels, and lightweight hollow cavities can be realized in a single moulded part, reducing assembly steps.

- Surface quality: Textures, color, and cosmetic finishes can be engineered directly into the mold for consistent aesthetics.

- Weight optimization: Plastics enable significant weight savings, contributing to energy efficiency and ease of handling in consumer and industrial products.

- High-volume economics: Once tooling is established, unit costs drop markedly, enabling cost-effective mass production and long product lifecycles.

- Design constraints: Moulding imposes constraints related to wall thickness uniformity, draft angles for demoulding, and mold maintenance; these factors must be considered early in the design phase to prevent later engineering changes.

For an OEM partner, moulding production offers a powerful platform for housings, enclosures, handles, casings, and integrated function parts where polymer performance aligns with environmental, electrical, and mechanical requirements.

Sheet metal fabrication reshapes metal sheets into three-dimensional parts through cutting, bending, punching, welding, riveting, and finishing. This family includes laser cutting, waterjet cutting, mechanical shearing, brake forming, deep-drawing, stamping, and assembly operations. Benefits of sheet metal fabrication include:

- Strength and durability: Metal parts deliver robust performance in load-bearing, EMI shielding, heat dissipation, and harsh environments.

- Thermal management: Metals with high thermal conductivity support cooling needs in housings and chassis.

- Finish versatility: Coatings, powder coatings, plating, and anodizing afford a broad spectrum of appearances and corrosion protections.

- Rapid prototyping: Short lead times for first articles and low upfront tooling costs make sheet metal a practical option during early concept validation.

- Hybrid potential: Metal components can be integrated with moulded elements to form hybrid assemblies that balance weight, function, and cost.

Sheet metal parts are frequently used for enclosures, frames, brackets, and interfaces that demand metallic properties, precise mounting surfaces, and predictable mechanical behavior.

- Moulding production excels with complex, organic, or highly integrated geometries that would require multiple metal parts or complex assemblies in sheet metal.

- Sheet metal is well suited for parts with planar origins or simple bends where a lightweight metallic shell or chassis suffices.

- Plastics offer corrosion resistance, electrical insulation, and design freedom for hollow structures and integrated features, suitable for consumer electronics, medical devices, and industrial housings.

- Metals provide superior strength, heat resistance, EMI shielding, and structural rigidity, ideal for rugged equipment, automotive applications, and aerospace components.

- Moulding tooling typically represents a substantial up-front investment (molds, cavities, gates), with favorable unit economics at high volumes after amortization.

- Sheet metal tooling generally involves lower initial costs and faster setup, enabling lower-risk entry for prototypes and mid-volume production.

- Moulding lines offer rapid, high-volume production once tooling is in place, with consistent cycle times enabling predictable throughput.

- Sheet metal tooling and fabrication can deliver quicker first articles and flexible adjustment cycles, particularly beneficial during early design iterations.

- Moulding can deliver consistent texture, color integration, and insert features in a single operation, reducing downstream finishing.

- Sheet metal parts often require coatings or plating to achieve desired aesthetics and environmental resistance, but these processes offer wide color and texture options and proven durability.

- Injection molding can achieve tight tolerances for wall thickness and features with proper mold design and material selection, though resin shrinkage and mold wear must be managed.

- Sheet metal parts typically offer precise, repeatable tolerances for bends and holes, with controlled springback and bend allowances.

- For high-volume programs, moulding production can provide lower per-part costs and consistent quality over time, balancing initial tooling costs against long-run demand.

- For smaller runs, quick-turn prototypes, or parts that require metallic properties, sheet metal fabrication can be more economical and faster to market.

A growing engineering trend is to blend moulded and metal components within a single product to harness the advantages of both. Examples include:

- A moulded plastic housing that incorporates metal inserts for rigid mounting interfaces or EMI shielding, combining plastic flexibility with metal strength where needed.

- A metal chassis or frame that houses moulded cover components, delivering a lightweight yet sturdy assembly with integrated thermal pathways.

- Integrated gasket channels and sealed features achieved through moulding, with metal mounting brackets providing structural support or grounding paths.

Hybrid designs require careful interface planning—ensuring compatible tolerances, fastener strategies, and assembly sequencing—to avoid assembly complexity and quality issues.

DFM is pivotal to achieving predictable outcomes in both moulding production and sheet metal fabrication. Here are actionable guidelines to inform early-stage design decisions:

- Wall thickness uniformity: Aim for consistent wall thickness to minimize shrinkage and mold cooling variation.

- Draft angles: Incorporate adequate draft (typical 0.5–2 degrees) to facilitate easy demolding and reduce part deformation.

- Ribs and bosses: Use ribbing for stiffness without excessive material; incorporate smooth fillets to reduce stress concentrations.

- Insert features: Plan for integrated fasteners or inserts to minimize assembly steps.

- Gate location and parting line: Strategize gate placement to avoid cosmetic defects and to optimize mold fill.

- Bend allowances and radii: Design bend radii that minimize springback and tooling complexity; consider outer contours and inner radii for consistent parts.

- Hole and cutout tolerances: Plan for punch and laser cutting tolerances; anticipate burrs and deburring needs.

- Weld and joinery: Decide on welding, riveting, or mechanical fasteners early to simplify assembly and maintain structural integrity.

- Surface preparation: Align coating or finishing requirements with forming operations to avoid coating imperfections.

- Material thickness and alloy choice: Select thicknesses compatible with available tooling while meeting stiffness and weight targets.

- Plastics: Consider UV stability, chemical resistance, flame retardancy, and temperature tolerance. Engage with resin families tailored to cosmetic and tactile requirements—hardness, impact resistance, and color stability are critical data points.

- Metals: Evaluate alloy families (aluminum, steel, stainless steel, copper) for mechanical strength, thermal performance, and corrosion resistance. EMI shielding, grounding, and mechanical interfaces may dictate metal choices and surface treatments.

- Validation strategy: Start with a robust design-verification plan, followed by a pilot run to validate fit, form, and function before full-scale production.

- Quality controls: Implement DPS (design/process specifications), SPC (statistical process control), and inspection checkpoints across molding, forming, and finishing stages.

- Supplier coordination: Align tooling ownership, maintenance schedules, and part traceability with global logistics requirements to ensure consistency across batches and geographies.

- Regulatory and compliance: For medical, aerospace, or consumer electronics, ensure materials, coatings, and processes meet relevant standards and certifications.

To support OEM marketing and technical communications, structure media packages around a clear narrative:

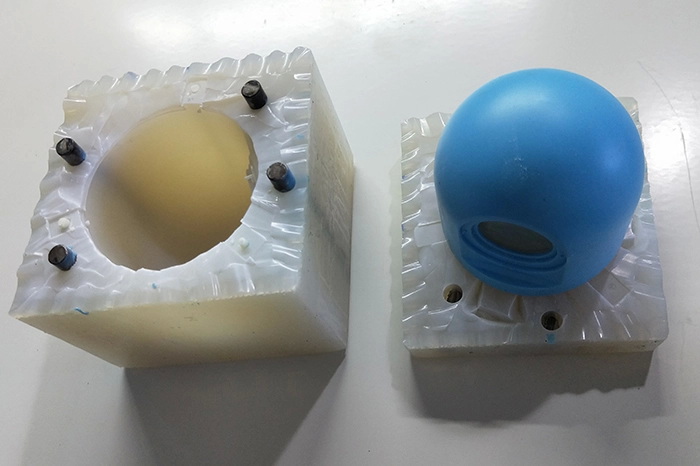

- Process visuals: High-quality close-ups of mould tool assemblies, mold cycles, insert placements, and texture textures; side-by-side visuals showing moulded versus sheet metal parts for similar enclosures.

- Process flows: Diagrams illustrating the steps from concept to first article, pilot runs, and high-volume production for both moulding and sheet metal workflows.

- Assembly demonstrations: Shots showing assembly sequences, fastening strategies, and finished product aesthetics.

- Media metadata: Use descriptive captions and alt-text that emphasize the manufacturing advantages, process reliability, and scalability of moulding production within Shangchen's OEM ecosystem.

- Case A: Complex plastic enclosure for an industrial controller

A moulded enclosure delivers integrated cable management features, soft-touch surface finishes, and precise tolerances that simplify assembly. The design minimizes assembly steps and reduces total part count, enabling rapid market entry for a global customer.

- Case B: Aluminum chassis with integrated plastic cover

A hybrid approach provides the structural backbone with a lightweight, aesthetically refined cover. EMI considerations and heat dissipation are addressed through material selection and strategic interface design, delivering a robust solution with optimized weight.

- Case C: Medical device housing with stringent regulatory constraints

Moulding production enables consistent wall thickness and surface finish, supporting regulatory compliance and patient safety goals. The option to embed color-coding and tactile cues within the molded surface enhances usability and compliance.

- End-to-end capabilities: From rapid prototyping and functional testing to full-scale moulding production and sheet metal fabrication, Shangchen supports international brand owners with a single, integrated supply partner.

- Design collaboration: Expert input on DFM, material selection, and cost optimization helps ensure manufacturability without compromising performance or aesthetics.

- Quality and reliability: A structured QA framework, traceability, and process controls ensure repeatability and consistent performance across international manufacturing sites.

Moulding production and sheet metal fabrication each offer distinct advantages across different design challenges, volumes, and performance requirements. When the product calls for complex geometry, lightweight yet strong enclosures, integrated features, and scalable long-term production, moulding production—especially injection molding or related moulding technologies—often delivers superior total cost of ownership after tooling is amortized. Sheet metal fabrication remains a versatile, cost-effective option for rapid prototyping, mid-volume production, and components demanding metallic properties, EMI shielding, or rugged durability. The most successful OEM programs frequently employ a hybrid strategy, leveraging moulded housings with metal interfaces or chassis components to optimize weight, cost, and performance. Shangchen stands ready to partner with international brands, wholesalers, and manufacturers, guiding every phase from concept through design refinement to large-scale production, delivering high-quality components and assemblies that meet stringent standards and timelines.

Part geometry, weight requirements, surface finish needs, tolerance targets, material compatibility, and projected production volume drive the decision. Moulding production tends to excel with complex, high-volume parts, while sheet metal is favored for simpler geometries and lower-volume runs. Tooling costs, lead times, and total cost of ownership should be evaluated to choose the most cost-efficient path. This aligns with OEM needs for scalable, predictable manufacturing.

For moulding, emphasize uniform wall thickness, draft angles, integrated features, and ease of demolding. For sheet metal, focus on bend radii, punch/laser tolerances, weld and joinery strategies, and finish compatibility. Clear DFM guidelines reduce tooling risk and improve yield in both processes.

Moulding typically requires longer upfront tooling lead times but lower per-part costs at high volumes due to rapid cycle times. Sheet metal offers quicker prototyping and faster ramp-up for mid-volume runs, with costs driven by raw materials, forming operations, and coatings.

Yes. Hybrid designs that combine moulded housings with metal components can optimize weight, cost, and performance, provided interfaces and assembly sequencing are carefully planned to avoid complexity.

Create media that communicates process flows, tooling, part textures, and real-world assembly outcomes. Include time-lapse injection cycles, texture close-ups, and comparative visuals with sheet metal parts. Support with engineering case studies and customer testimonials to illustrate reliability and value.

[1](https://blog.boenrapid.com/comparison-between-plastic-injection-molding-and-sheet-metal-fabrication-which-is-better-for-aerospace-applications)

[2](https://www.sc-rapidmanufacturing.com/how-to-choose-between-sheet-metal-fabrication-and-injection-molding.html)

[3](https://www.longshengmfg.com/what-is-the-difference-between-sheet-metal-and-machining/)

[4](https://rimnetics.com/blog/reaction-injection-molding-vs-sheet-metal-production/)

[5](https://www.pcbway.com/helpcenter/automotive_faq/What_are_the_differences_between_sheet_metal_fabrication_and_injection_molding_in_automotive_.html)

[6](https://www.protolabs.com/materials/comparison-guide/)

[7](https://geomiq.com/blog/cnc-machining-vs-sheet-metal-fabrication/)

[8](https://www.sigmatechnik.com/injection-molding/cost-comparison-metal-stamping-vs-injection-molding)

[9](https://www.runsom.com/blog/cnc-machining-vs-injection-molding-a-comprehensive-comparison-for-industrial-production/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal