Views: 222 Author: Amanda Publish Time: 2025-11-03 Origin: Site

Content Menu

● Core Material Families for Moulding Production

>> Tool steels and hardened steels

>> Titanium and titanium alloys

>> Stainless steels and corrosion-resistant alloys

>> Composite and ceramic materials

>> High-performance polymers and insert materials

● Key Properties Driving Performance

>> Thermal conductivity and response

>> Toughness and impact resistance

● Applications and Material Selection

>> Rapid prototyping and low-volume production

>> Industry-specific considerations

● Processing, Treatment, and Maintenance Considerations

>> Heat treatment and surface engineering

>> Coatings and surface finishes

● Beyond Moulds — Supporting Parts and Assemblies

>> Inserts, cores, and cavities

>> Ejector components and slides

>> Temperature control systems

● Practical Guidelines for OEM Partners

>> Define service life and throughput goals

>> Align material choice with resin and part geometry

>> Plan for future scalability

● FAQ

>> 1) What factors should guide the choice between tool steel and aluminum for a new moulding project?

>> 2) How do coatings influence mould life and part quality in high-volume production?

>> 3) What role does thermal conductivity play in achieving tight tolerances in moulding production?

>> 4) Which materials are best suited for corrosion resistance in mould tooling for aggressive resins?

>> 5) How should OEM partners plan maintenance to maximize moulding production uptime?

Moulding production sits at the crossroads of material science, precision engineering, and high-volume manufacturing. The right choice of mould materials and insert components directly influences tool life, dimensional stability, cycle times, and finished-part quality. This extended article delves into the major material families used in mould tooling and production environments, with emphasis on durability, precision, and reliability across fast prototyping, CNC machining, sheet metal fabrication, 3D printing, and precision mould making. The discussion is tailored for OEM partners, foreign brands, wholesalers, and manufacturers seeking robust, scalable moulding production capabilities.

- These steels underpin most durable moulds because of their combination of hardness, toughness, and heat resistance. Common choices include variants that balance machinability with wear resistance, allowing precise cavity replication over long campaigns. Hard coatings and surface treatments further extend service life and maintain low friction during repeated closures and openings.

- Practical considerations include heat treatment protocols, surface finishing quality, and thermal conductivity. Properly treated tool steels help maintain tight tolerances during thermal cycling inherent to high-volume moulding production.

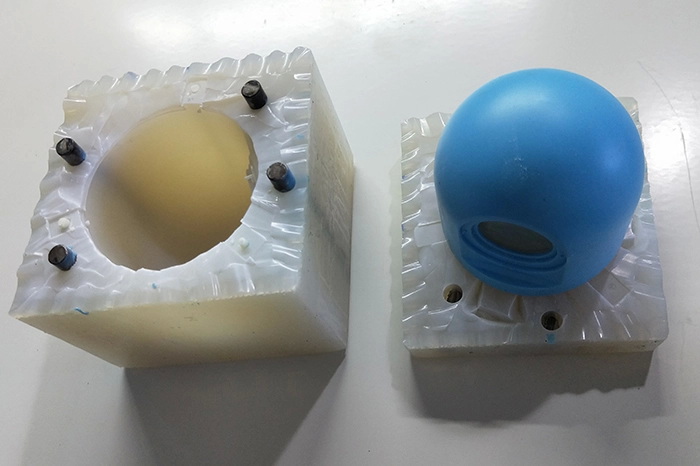

- Aluminum tooling supports rapid prototyping, design validation, and short-to-mid-run production due to excellent machinability, lower cost, and faster lead times. Precision-altered aluminum moulds can deliver consistent results when resin systems and geometry are relatively forgiving and production volumes are moderate.

- To maximize durability, aluminum moulds often employ selective hardening, protective coatings, and optimized cavity design to mitigate wear in high-contact zones. Surface finishing is crucial to achieving desirable release behavior and dimensional stability for the intended run length.

- Titanium offers high strength-to-weight ratio and outstanding corrosion resistance, making it advantageous in specialized moulding scenarios where tool longevity and resistance to aggressive media are critical. The higher material cost is justified in applications demanding extended life under demanding conditions or complex geometries.

- For moulds exposed to corrosive resins, humid environments, or cleaning cycles, stainless steels provide dependable corrosion resistance with robust mechanical properties. They are a preferred choice for medical, food-contact, and other hygiene-sensitive moulding production contexts.

- Surface engineering complements stainless steels to optimize wear resistance and release characteristics in aggressive resin systems.

- Advanced composites or ceramic components find niche use in high-precision or high-wear zones where traditional metals would wear too quickly. These materials can offer superior wear resistance, thermal management, or specific surface properties, though they demand specialized fabrication, assembly, and maintenance know-how.

- In select applications, polymer inserts or alternative insert materials can reduce weight and enable rapid iteration while preserving essential function for limited runs. Compatibility with the chosen resin and processing window remains essential to avoid dimensional shifts or surface defects.

- The core requirement for moulding production is resisting deformation under heat and mechanical load. Dimensional stability translates to consistent cavity replication and tight tolerances across thousands to millions of cycles.

- Mould surfaces experience abrasion from resins, fillers, fibers, and ejection forces. Hardness, microstructure, and coating choices govern how well the mould withstands such wear without compromising surface quality.

- Efficient heat transfer reduces cycle times and helps maintain uniform shrinkage and residual stresses. Materials with favorable thermal properties support faster cooling and more stable part dimensions.

- Ejection forces, part geometry, and multi-cavity layouts can introduce localized stresses. Tough materials and well-designed cores/rails prevent chipping, cracking, or misalignment.

- Exposure to moisture, cleaning agents, and aggressive resins necessitates corrosion-resistant materials to extend tool life and sustain consistent performance.

- Durable tool steels with optimized heat treatment, supplemented by coatings and precision finishing, deliver long life and stable tolerances for continuous production lines. The upfront investment pays off in predictable maintenance needs and reduced downtime.

- Aluminum tooling and hybrid concepts enable rapid iteration and shorter lead times. While less durable than steel, these solutions support fast validation and market feedback before committing to full-scale tooling.

- Medical, automotive, and electronics sectors often impose stricter cleanliness, wear resistance, and regulatory requirements. Stainless steels, specialty alloys, and cleanroom-compatible coatings may be warranted to meet both functional and cosmetic standards.

- Quenching, tempering, and surface hardening (including nitriding and various PVD/CVD coatings) extend mould life and reduce wear. The choice of coating affects friction behavior, heat transfer, and resin-release characteristics.

- Coatings tailored to resin chemistry reduce sticking, minimize wear, and sustain part surface quality over long production runs. Surface finishes—from honed to micro-polished—affect release behavior and the final part appearance.

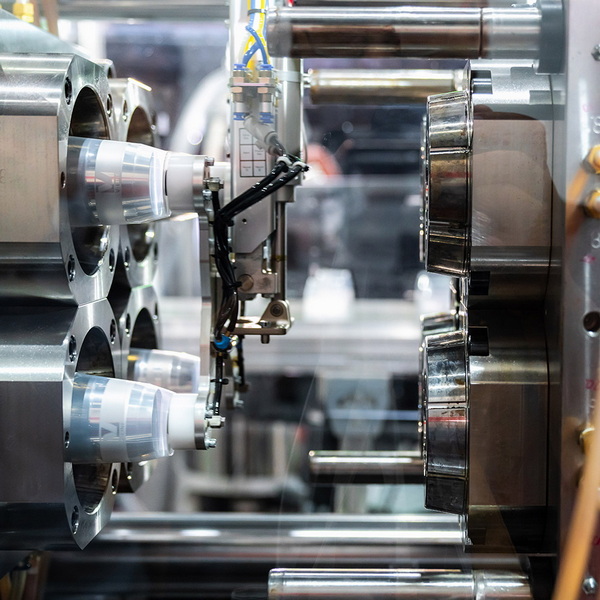

- High-precision CNC machining, EDM, and multi-axis manufacturing achieve the tight tolerances required by modern moulding production. Accurate metrology and fixturing underpin repeatable production of complex geometries.

- Regular inspection, cleaning, and preventive maintenance are essential to maximizing uptime and ensuring continued dimensional accuracy. A documented maintenance regime helps anticipate tool changes and minimize unplanned downtime.

- Insert materials and coatings influence wear patterns and surface finish on moulded parts. Durable inserts improve life in abrasive resins or challenging geometries and reduce downtime.

- Ejector pins, slides, and guide components require robust materials to withstand repeated ejection stresses. Reliable materials reduce part defects and cycle interruptions.

- Efficient cooling channels and high-conductivity materials play a decisive role in heat management, enabling tighter tolerances and shorter cycle times. Integrated temperature control supports uniform resin flow and consistency across cavities.

- Early definition of expected cycle counts and quality targets guides material selection, coating choices, and maintenance planning. Clear goals help align engineering and procurement with practical production expectations.

- Resin hardness, filler content, and surface finish determine the appropriate mould materials and coatings. A resin-compatible surface finish enhances release behavior and reduces wear.

- Select tooling concepts that accommodate increasing volumes or new geometries without a complete redesign. Modularity, standardization, and upgrade paths help protect investment.

- Early design-for-manufacturing collaboration ensures material choices support manufacturability, maintenance, and repeatable quality. Close engineering-to-supplier alignment minimizes late-stage changes.

Durable and precise moulding production results from a balanced combination of material properties, processing techniques, and proactive maintenance. Selecting the right tool steels or alternative materials based on cycle counts, resin systems, and part geometries yields stable tolerances, minimized wear, and longer tool life. Integrating coatings, advanced surface engineering, and disciplined heat-treatment protocols further enhances performance. For OEM partners, aligning material choices with design-for-manufacturing principles, supply chain reliability, and scalable tooling strategies enables efficient moulding production for global brands, distributors, and manufacturers seeking dependable capabilities in a competitive market.

- For long-run, high-volume production, choose tool steel for wear resistance and dimensional stability; for quick-turnaround prototyping or low-volume runs, aluminum offers faster machining, lighter weight, and lower cost.[9]

- Coatings reduce wear and friction, improve release, and can lower sticking or bonding with resins, thereby extending mould life and stabilizing surface finish over many cycles.[10]

- Better thermal conductivity enables faster and more uniform cooling, which minimizes differential shrinkage and distortion, helping maintain tight tolerances across cycles.[11]

- Stainless steels and corrosion-resistant alloys are preferred when moulds encounter aggressive resins or frequent cleaning, providing durable performance and longer tool life.[12]

- Establish a preventive maintenance regime with regular inspection, cleaning, and timely component replacement, plus traceable records to anticipate wear and minimize unexpected downtime.[13]

[1](https://geomiq.com/injection-moulding-guide/)

[2](https://www.goldengatemolders.com/post/injection-molding-101-a-comprehensive-guide-for-newcomers)

[3](https://www.basilius.com/blog/the-complete-guide-to-injection-molding-materials/)

[4](https://www.protolabs.com/resources/guides-and-trend-reports/thermoplastic-material-selection-for-injection-molding/)

[5](https://www.unionfab.com/blog/2024/06/injection-molding-materials)

[6](https://iranettekal.com/moulding-and-molding/)

[7](https://www.fictiv.com/articles/injection-molding-design-guide)

[8](https://xometry.pro/en/articles/injection-molding-materials/)

[9](https://www.ace-mold.com/mold-material-for-plastic-injection-a-comprehensive-guide/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal