Views: 222 Author: Amanda Publish Time: 2025-08-19 Origin: Site

Content Menu

● Introduction to CNC Machining and Automation

● How Automation Enhances CNC Machining Efficiency

>> Automated Material Handling

>> Automated Tool Changing and Machine Setup

>> Real-Time Monitoring and Predictive Maintenance

● Key Automation Technologies in CNC Machining

>> Artificial Intelligence (AI) and Machine Learning

>> Automated Programming Software

>> Augmented Reality (AR) and Virtual Reality (VR)

● Benefits of Automation in CNC Machining

>> Enhanced Precision and Consistency

>> Cost Reduction and Return on Investment (ROI)

>> Flexibility and Scalability

>> Improved Worker Safety and Job Satisfaction

>> Energy Efficiency and Sustainability

● Challenges and Solutions in CNC Automation

>> System Integration Complexity

>> Workforce Training and Adaptation

>> Maintenance and Reliability

● Future Trends in Automated CNC Machining

>> Collaborative Robots (Cobots)

>> Fully Autonomous CNC Machining Cells

>> Integration of Digital Twins

>> Enhanced Human-Machine Interfaces (HMIs)

>> Sustainable and Smart Manufacturing

● FAQ

>> 1. What is CNC machining automation?

>> 2. How does automation improve CNC machining productivity?

>> 3. Can small manufacturers benefit from CNC automation?

>> 4. What are typical challenges of CNC machine automation?

>> 5. How does AI influence CNC machining automation?

In today's rapidly evolving manufacturing landscape, CNC machining plays a pivotal role as one of the most precise and versatile methods for producing components across various industries. With the advent of automation technologies, CNC machining has experienced a remarkable transformation, leading to enhanced productivity, improved quality, and reduced operational costs. This article explores the essential role of automation in boosting the efficiency of CNC machining, highlighting key benefits, integration techniques, challenges, and future trends.

CNC machining (Computer Numerical Control machining) refers to a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technique enables the production of complex parts with high precision and repeatability.

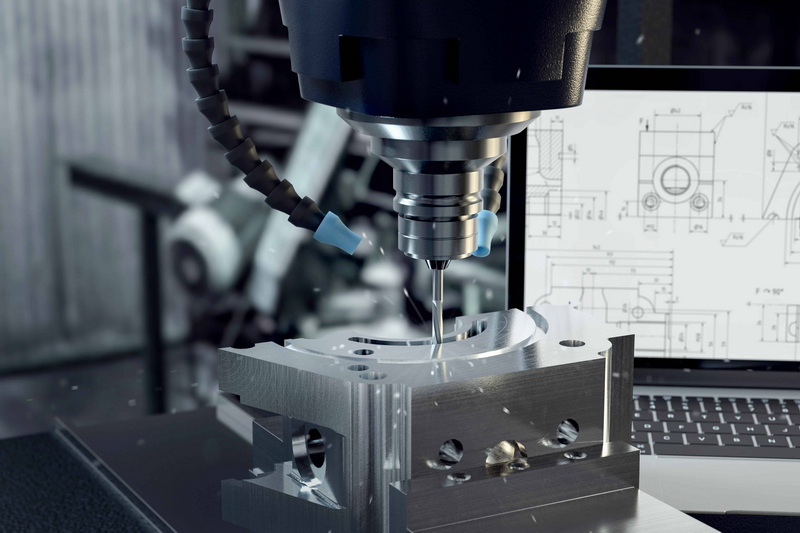

Automation in this context means incorporating robotic arms, automated tool changers, sensor-based quality control systems, and software integration that allow machines to operate with minimal human intervention. By automating various aspects of the CNC process, from loading raw materials to quality inspection, manufacturers can significantly reduce downtime and boost production rates.

Automated CNC setups demonstrate how integrating robotics and intelligent software can handle repetitive tasks seamlessly and maintain consistent throughput without sacrificing accuracy or quality.

Automation impacts CNC machining at multiple stages to create a more streamlined, efficient workflow. These enhancements collectively improve overall operational effectiveness.

One of the most time-consuming aspects of CNC machining is material handling. Robotic arms, conveyors, and automated pallet systems have revolutionized this process by precisely timing and loading raw materials into CNC machines. This reduces idle machine time significantly. Moreover, automation eliminates human error related to misloading or mishandling parts, resulting in fewer production delays.

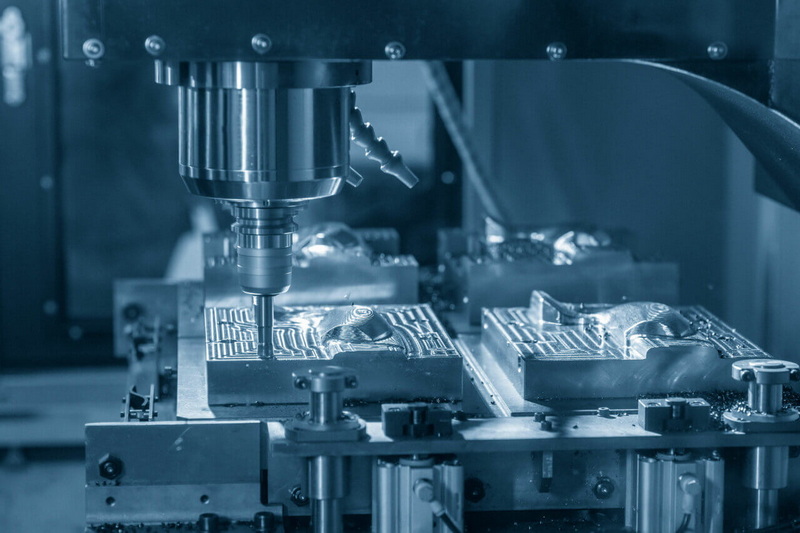

Complex CNC machining often requires multiple tools for tasks such as drilling, milling, and tapping. Automatic tool changers integrated into modern CNC machines switch tools within seconds without manual intervention. This capability significantly shortens cycle times, especially for components requiring many machining steps, and supports flexible production runs. Additionally, automated machine setup systems streamline the transition between different jobs, facilitating lean manufacturing and quick responses to shifting production demands.

Embedded sensors and Internet of Things (IoT) technologies enable machines to monitor operational parameters such as spindle load, vibration, and temperature in real time. This data is analyzed continuously for signs of wear or impending failure. Predictive maintenance programs use these insights to schedule repairs or adjustments during non-production hours, thus avoiding costly unexpected downtime. This approach also extends machine life and minimizes disruptions to production schedules.

Quality assurance integrated directly into CNC machining processes further enhances efficiency. Automated inspection tools, including coordinate measuring machines (CMMs), vision systems, and laser scanners, check part dimensions, surface finishes, and tolerances immediately after machining. Instant feedback allows operators to adjust processes rapidly, reducing scrap rates and optimizing material usage. This closed-loop quality control system creates a seamless, error-minimizing workflow that improves overall product reliability.

The ongoing advancement of CNC machining automation relies on several critical technologies that work together to achieve sophisticated, high-efficiency manufacturing.

Robots not only excel in repetitive tasks like material handling but can also perform secondary processes such as deburring, cleaning, or assembling parts. Their flexibility allows for integration with multiple CNC machines to form automated machining cells capable of independent operation.

IoT connectivity enables CNC machines and peripheral devices to communicate and transfer data in real time across manufacturing floors and remote locations. This interconnectedness supports detailed analytics, improved machine utilization, and rapid troubleshooting, while empowering managers to monitor production from anywhere.

AI-powered systems are transforming CNC machining by analyzing vast amounts of operational data to optimize cutting parameters, predict tool wear, and minimize energy consumption. Machine learning algorithms continuously improve machining strategies based on historical and real-time data, which results in shortened cycle times, lower tooling costs, and enhanced part precision.

Programming CNC machines traditionally is a time-intensive task requiring expert knowledge. Automation in this field includes software tools that generate optimized CNC code from 3D CAD models automatically. This not only reduces programming errors but also dramatically shortens setup times and enables quick product changes, helping manufacturers remain agile.

While not yet as widespread, AR and VR technologies are beginning to find a role in CNC machine operation and training. These tools can facilitate real-time machine monitoring and provide guidance through interactive interfaces, allowing technicians to perform more precise machine setups and problem diagnosis with reduced downtime.

Automation offers multiple, tangible advantages that collectively transform CNC machining operations.

By minimizing manual intervention for material handling, tool changes, and inspections, automated CNC machining cells operate faster and more continuously. Reducing human-related delays allows machines to produce more parts within the same time frame, enhancing overall capacity.

Automation drastically reduces variability introduced by manual labor. The controlled environment supported by automated programming, robotic handling, and sensor-based feedback ensures every part meets stringent specifications consistently, critical for high-precision industries like aerospace and medical device manufacturing.

Although automation systems require an upfront capital investment, the resulting improvements in throughput, product quality, and waste reduction lead to substantial cost savings over time. Labor expenses decrease as manual tasks are minimized, while extended tool and machine lifetime lower maintenance costs. These predictable, long-term savings help companies achieve favorable ROI on automation projects.

Automated CNC solutions are increasingly modular and reprogrammable. This adaptability makes it easier to produce small or large batches of varying parts without incurring lengthy downtimes or complex retooling procedures. As market demands fluctuate, manufacturers can adjust production volumes quickly and cost-effectively.

Automation handles hazardous, repetitive, or ergonomically challenging tasks, reducing workplace injuries. Simultaneously, it frees employees to engage in more skilled roles such as machine supervision, programming, and quality assurance, leading to improved job satisfaction and retention.

Advanced automation systems optimize cutting parameters and machine usage patterns, reducing energy consumption. Furthermore, enhanced precision reduces waste and scrap materials, contributing to more sustainable manufacturing practices aligned with green industry initiatives.

Despite its many benefits, CNC machining automation also presents certain challenges that manufacturers should consider.

The financial barrier posed by robotic systems, sensor arrays, and integrated software can be substantial. However, companies can mitigate this by starting with partial automation, focusing on high-impact areas, and scaling gradually as ROI becomes evident.

Integrating hardware and software from multiple vendors involves technical complexity. Utilizing platform-agnostic integration tools and working with experienced system integrators helps create coherent, flexible automated machining systems.

Transitioning from manual to automated CNC machining requires retraining and upskilling employees. Effective training programs that combine hands-on experience with digital simulation reduce resistance and accelerate familiarity with new processes.

Automated systems increase the need for precise maintenance to prevent downtime. Implementing predictive maintenance backed by IoT analytics ensures timely interventions, preserving system reliability.

Increased machine connectivity raises cybersecurity risks. Robust data protection, firewalls, and secure communication protocols must be part of automation strategies to safeguard intellectual property and machine control systems.

Manufacturing is poised to witness exciting developments in CNC machining automation as emerging technologies mature.

Cobots designed to operate safely alongside humans provide increased flexibility and enable hybrid workflows combining human oversight with robotic precision.

With continued advancements in AI and robotics, manufacturing facilities will see end-to-end autonomous machining cells capable of handling raw materials, multi-step machining, inspection, and packaging with minimal human input.

Digital twins—virtual replicas of physical machines or production lines—allow simulation of machining processes in real time, facilitating process optimization, troubleshooting, and predictive maintenance planning.

Evolving HMIs based on augmented reality and voice recognition will make machine operation more intuitive, reducing training time and error rates.

Automation will evolve toward energy-efficient machines, smart scheduling, and waste reduction, aligning CNC machining with environmental goals while maintaining profitability.

The role of automation in advancing CNC machining efficiency is undeniable. Automation transforms CNC operations by increasing production speed, enhancing precision, reducing costs, and improving safety. Technologies such as robotics, IoT, AI, and intelligent software redefine manufacturing capabilities, enabling manufacturers to tackle complex demands with flexibility and scalability.

While implementing automation requires overcoming challenges like initial investments, system integration, and workforce adaptation, the long-term benefits greatly outweigh the difficulties. The future points to increasingly autonomous CNC machining systems that integrate digital twins, smart maintenance, and collaborative robotics to revolutionize production even further.

For manufacturers and OEM service providers, embracing automation in CNC machining is critical to remain competitive, meet global quality standards, and innovate within increasingly demanding industrial environments.

CNC machining automation involves integrating robotics, sensors, intelligent software, and IoT devices to enable CNC machines to operate with minimal human intervention, improving efficiency and consistency.

It reduces manual tasks such as material handling, tool changing, and quality inspection, decreasing cycle times and machine downtime while optimizing workflows for higher throughput.

Yes, scalable and modular automation solutions enable small and medium enterprises to enhance productivity and quality without large upfront costs, making automation accessible and practical.

Challenges include high initial investment, integrating diverse systems, ensuring workforce training, maintaining equipment reliability, and mitigating cybersecurity risks.

AI analyzes operational data to optimize cutting parameters, predict tool wear, and adapt machining processes dynamically, improving performance, reducing waste, and extending tool life.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product